Are you curious about the cost of manufacturing a foam mattress? Look no further, as we break down the top 10 factors that contribute to the overall cost of producing a foam mattress.Foam Mattress Manufacturing Cost:

The production cost of a foam mattress can vary depending on several factors. These include the type of foam used, the size and density of the mattress, and the manufacturing process. Keep reading to learn more about the specific elements that impact the production cost of a foam mattress.Foam Mattress Production Cost:

Before looking at the cost of manufacturing a foam mattress, it is important to consider the expenses associated with running a foam mattress factory. These costs include the price of equipment, materials, labor, and other overhead expenses. All of these factors can influence the final cost of a foam mattress.Foam Mattress Factory Cost:

The expenses involved in manufacturing a foam mattress can be broken down into several categories. These include the cost of raw materials, labor, and packaging. Each of these factors plays a significant role in determining the overall cost of producing a foam mattress.Foam Mattress Manufacturing Expenses:

Similarly, the production expenses of a foam mattress can be divided into different categories. These include the cost of foam, fabric, and other materials, as well as the cost of labor and machinery used in the production process.Foam Mattress Production Expenses:

In addition to the cost of producing a foam mattress, there are also other expenses associated with running a foam mattress factory. These can include rent, utilities, maintenance, and other overhead costs. These expenses can add up and contribute to the overall cost of a foam mattress.Foam Mattress Factory Expenses:

When planning to manufacture a foam mattress, it is important to have a budget in place. This budget should take into consideration all of the expenses mentioned above, as well as any other costs that may be unique to your specific manufacturing process. By setting a budget, you can ensure that your production costs stay within a manageable range.Foam Mattress Manufacturing Budget:

Similar to the manufacturing budget, the production budget for a foam mattress should take into account all of the expenses involved in the production process. This can help manufacturers stay on track and make necessary adjustments to stay within budget.Foam Mattress Production Budget:

In addition to the manufacturing and production budgets, it is important for foam mattress factories to have an overall budget. This budget should cover all of the expenses associated with running the factory, from employee salaries to equipment maintenance. By carefully managing this budget, factories can ensure that their overall costs do not exceed their allotted budget.Foam Mattress Factory Budget:

In order to keep production costs in check, it is important for manufacturers to regularly analyze the cost of producing a foam mattress. This can involve looking at the cost of materials, labor, and other expenses, and making adjustments as needed. By consistently analyzing production costs, manufacturers can identify areas where they can cut costs and improve efficiency. In conclusion, the cost of manufacturing a foam mattress can vary depending on a variety of factors. By understanding these factors and carefully managing expenses, manufacturers can produce high-quality foam mattresses at a reasonable cost. By regularly analyzing production costs and setting realistic budgets, foam mattress factories can ensure continued success in the industry.Foam Mattress Manufacturing Cost Analysis:

The Cost of Manufacturing Foam Mattresses

Understanding the Process

When it comes to

foam mattress manufacturing

, there are several factors that contribute to the overall cost. The process of creating a foam mattress involves several steps, including designing, cutting, shaping, and assembling the various layers of foam. Each of these steps requires specialized equipment and skilled labor, which can add to the overall cost of production.

When it comes to

foam mattress manufacturing

, there are several factors that contribute to the overall cost. The process of creating a foam mattress involves several steps, including designing, cutting, shaping, and assembling the various layers of foam. Each of these steps requires specialized equipment and skilled labor, which can add to the overall cost of production.

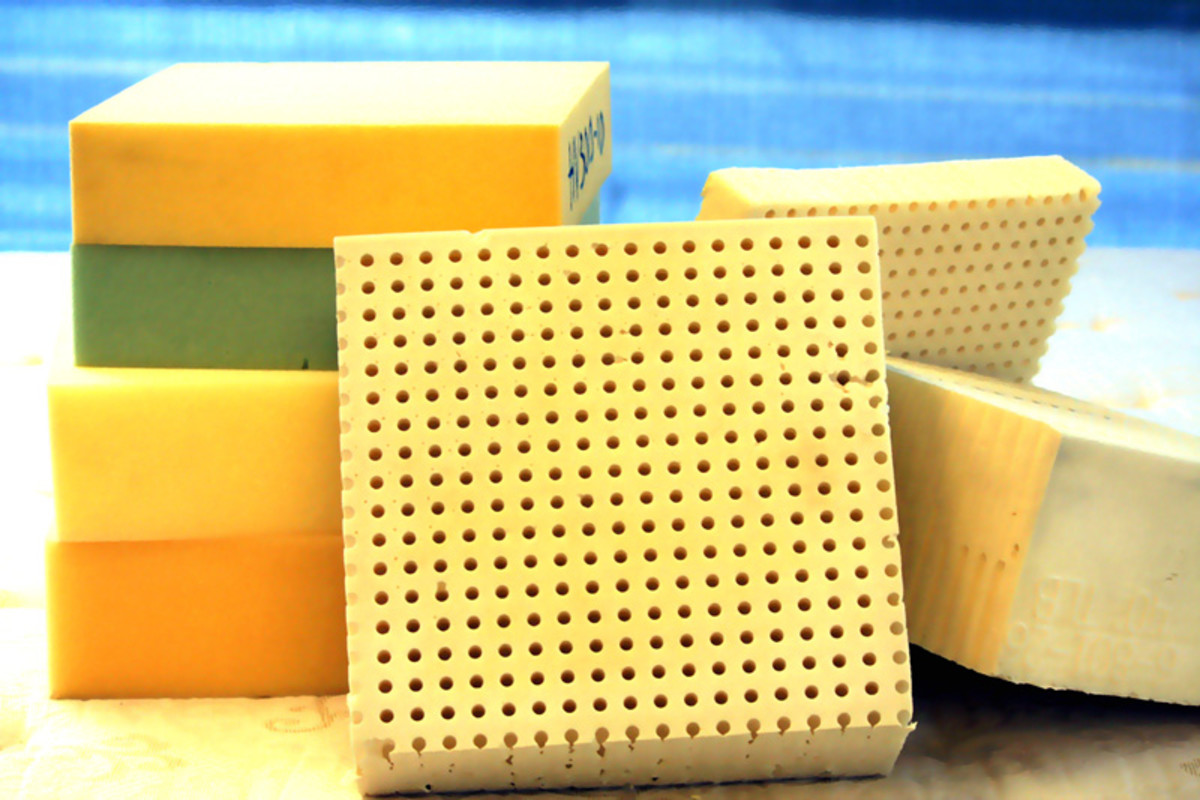

Raw Materials

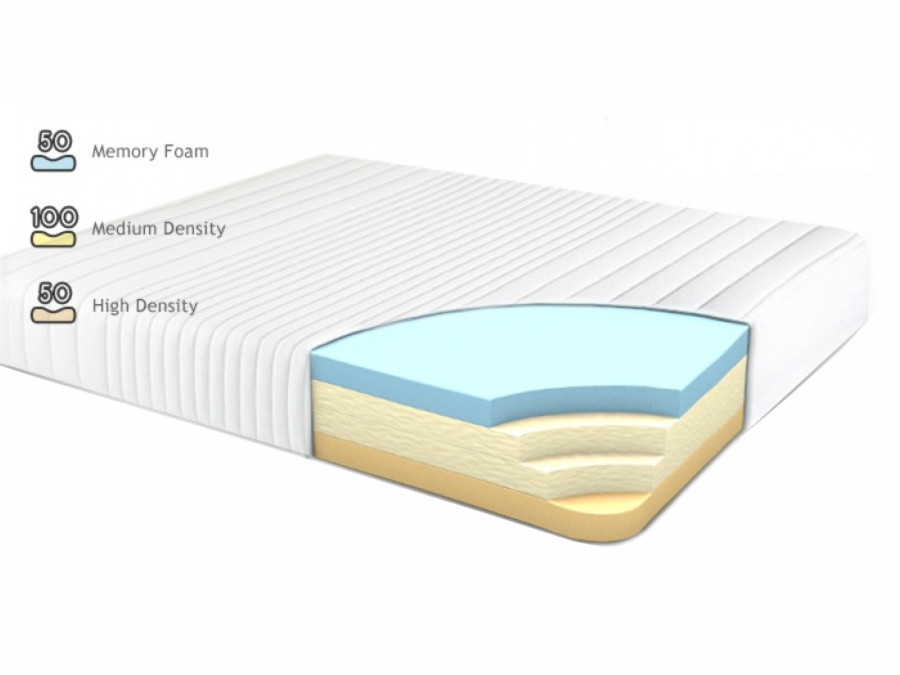

One of the main components of foam mattresses is, of course, foam. This foam is typically made from

polyurethane

, a versatile material that is known for its durability and support. However, the cost of polyurethane can vary greatly depending on the quality and type of foam used. Higher density foams, which are typically used in top-of-the-line mattresses, can be more expensive than lower density foams. Thus, the type of foam used can significantly impact the cost of manufacturing a foam mattress.

One of the main components of foam mattresses is, of course, foam. This foam is typically made from

polyurethane

, a versatile material that is known for its durability and support. However, the cost of polyurethane can vary greatly depending on the quality and type of foam used. Higher density foams, which are typically used in top-of-the-line mattresses, can be more expensive than lower density foams. Thus, the type of foam used can significantly impact the cost of manufacturing a foam mattress.

Production Efficiency

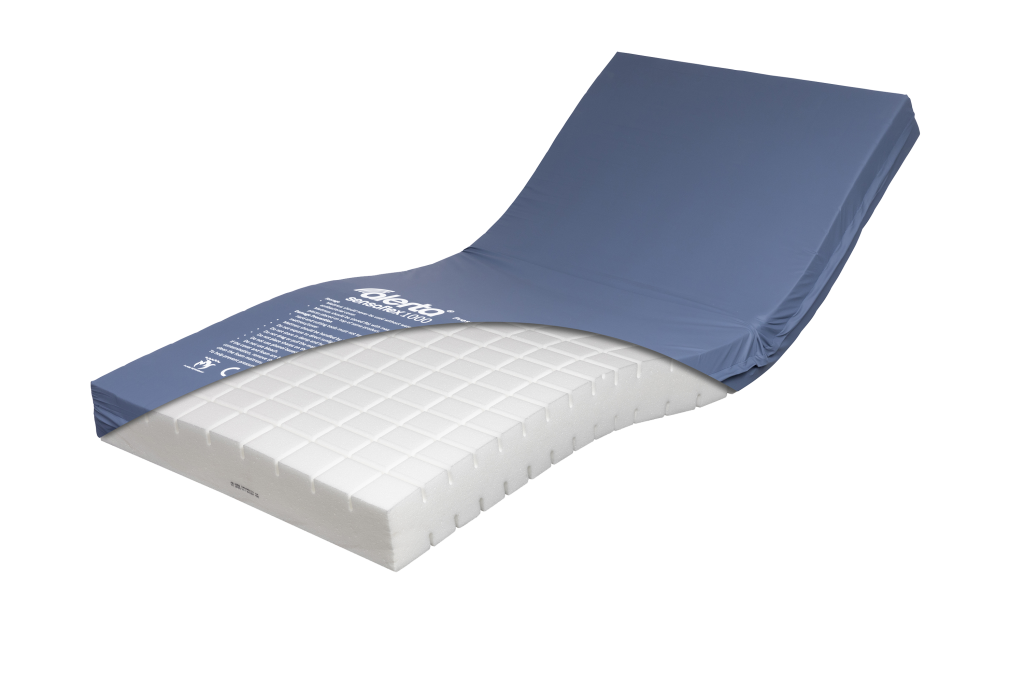

The efficiency of the production process also plays a significant role in the cost of manufacturing foam mattresses. The more efficient the process, the lower the cost of production. This can be achieved through advanced machinery and automation, which can help reduce labor costs and increase productivity. Additionally, using high-quality foam and materials can also improve the overall efficiency of the production process, reducing the likelihood of errors and waste.

The efficiency of the production process also plays a significant role in the cost of manufacturing foam mattresses. The more efficient the process, the lower the cost of production. This can be achieved through advanced machinery and automation, which can help reduce labor costs and increase productivity. Additionally, using high-quality foam and materials can also improve the overall efficiency of the production process, reducing the likelihood of errors and waste.

Quality Control

Another crucial aspect of foam mattress manufacturing cost is quality control. To ensure that each mattress meets high-quality standards, manufacturers must invest in quality control measures. This involves rigorous testing and inspections throughout the production process to identify any defects or flaws. These measures can add to the overall cost, but they are essential in delivering a high-quality product to consumers.

Another crucial aspect of foam mattress manufacturing cost is quality control. To ensure that each mattress meets high-quality standards, manufacturers must invest in quality control measures. This involves rigorous testing and inspections throughout the production process to identify any defects or flaws. These measures can add to the overall cost, but they are essential in delivering a high-quality product to consumers.

Final Thoughts

As you can see, the cost of manufacturing foam mattresses is influenced by various factors, including the production process, raw materials, and quality control measures. It is essential to strike a balance between efficiency and quality to keep costs at a reasonable level while delivering a top-notch product to consumers. By understanding the process and the various factors that impact production costs, manufacturers can continue to produce high-quality foam mattresses at a competitive price point.

As you can see, the cost of manufacturing foam mattresses is influenced by various factors, including the production process, raw materials, and quality control measures. It is essential to strike a balance between efficiency and quality to keep costs at a reasonable level while delivering a top-notch product to consumers. By understanding the process and the various factors that impact production costs, manufacturers can continue to produce high-quality foam mattresses at a competitive price point.