Foam mattresses have become increasingly popular in recent years due to their comfort and affordability. The manufacturing process for these mattresses involves various steps and the use of specialized equipment to ensure a high-quality product. Let's take a closer look at the top 10 main steps involved in the foam mattress manufacturing process. Foam Mattress Manufacturing Process

Polyurethane (PU) foam is the most commonly used material in foam mattresses. It is a type of plastic foam that is known for its durability and ability to provide support and comfort for the sleeper. The manufacturing process for PU foam mattresses involves the use of various chemicals and processes to create the final product. Polyurethane Foam Mattress Manufacturing Process

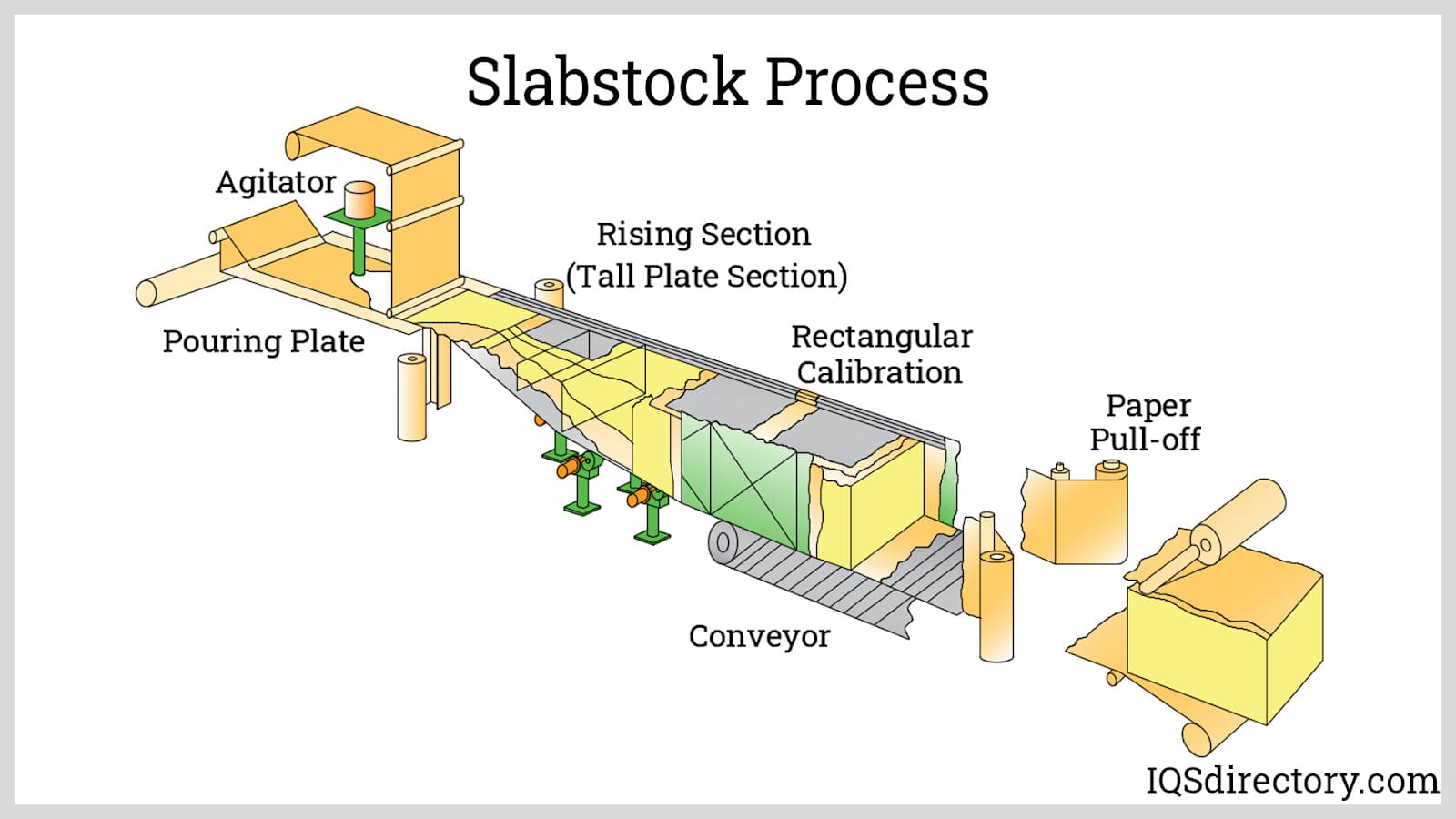

The production of PU foam mattresses starts with the creation of the foam itself. This involves blending different chemicals together to create a liquid foam that is then poured into molds. The molds are then heated to trigger a reaction that causes the foam to expand and fill the mold. Once cooled, the foam is removed from the molds and cut into the desired size and shape for the mattress. PU Foam Mattress Production

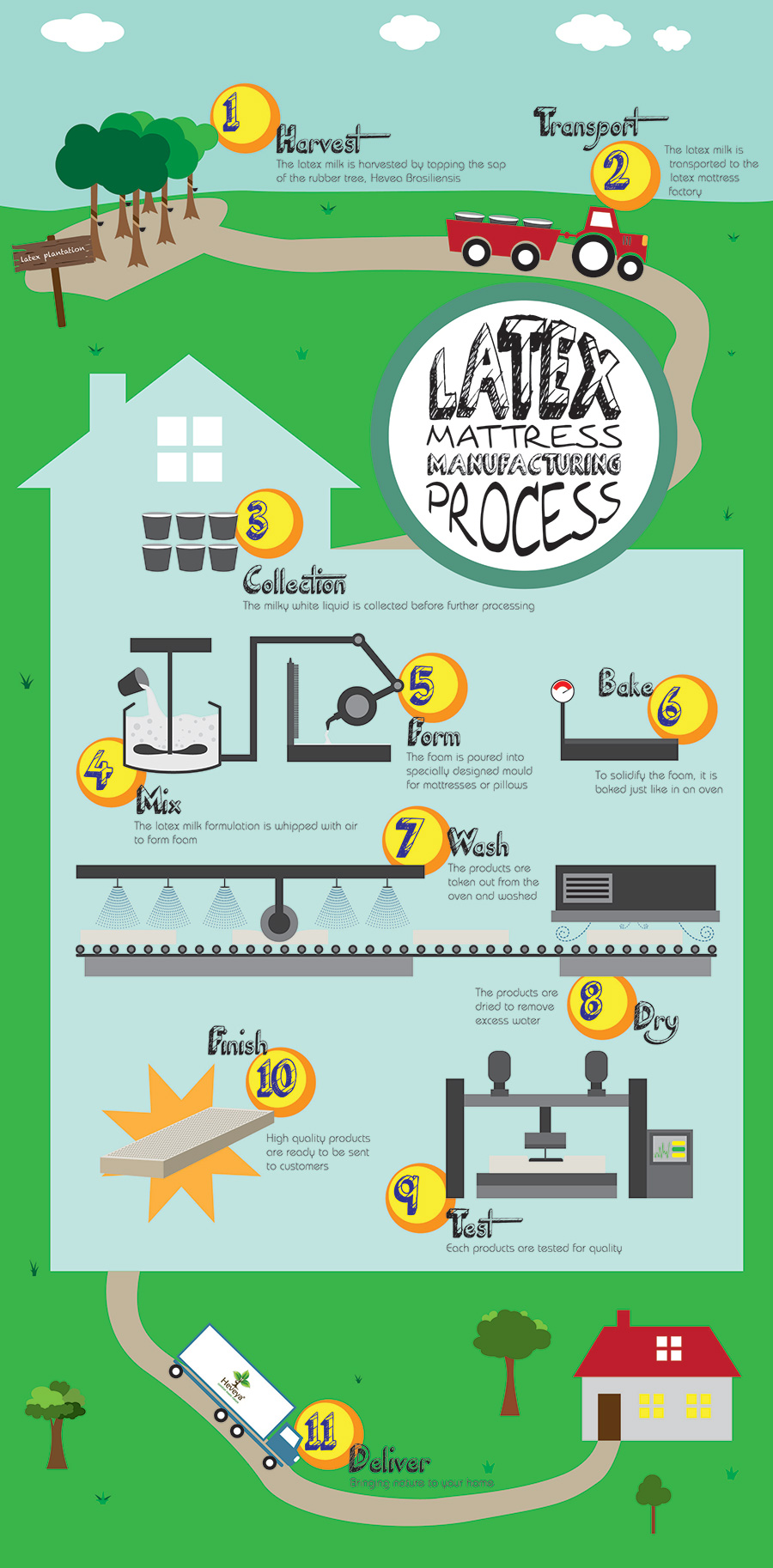

The manufacturing process for foam mattresses involves several steps that must be carefully followed to ensure a high-quality product. These steps include mixing the foam ingredients, pouring the foam into molds, heating and cooling the foam, cutting and shaping the foam, and finally assembling the mattress with other components such as a cover and base. Foam Mattress Manufacturing Steps

To make a PU foam mattress, manufacturers follow a specific set of steps to ensure the foam is of the highest quality. These steps include mixing the chemicals, pouring the foam into molds, curing the foam, and trimming and shaping the foam to the desired size and shape. The foam is then assembled with other components to create the final product. How to Make a PU Foam Mattress

The making process for PU foam mattresses involves a combination of chemical reactions and specialized equipment. The chemicals used must be carefully measured and mixed to create the desired type of foam. The molds used to pour the foam must also be of high quality and able to withstand the heating process. Once the foam is cured and trimmed, it is then assembled with other components to create the finished mattress. PU Foam Mattress Making Process

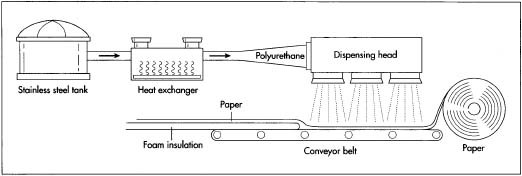

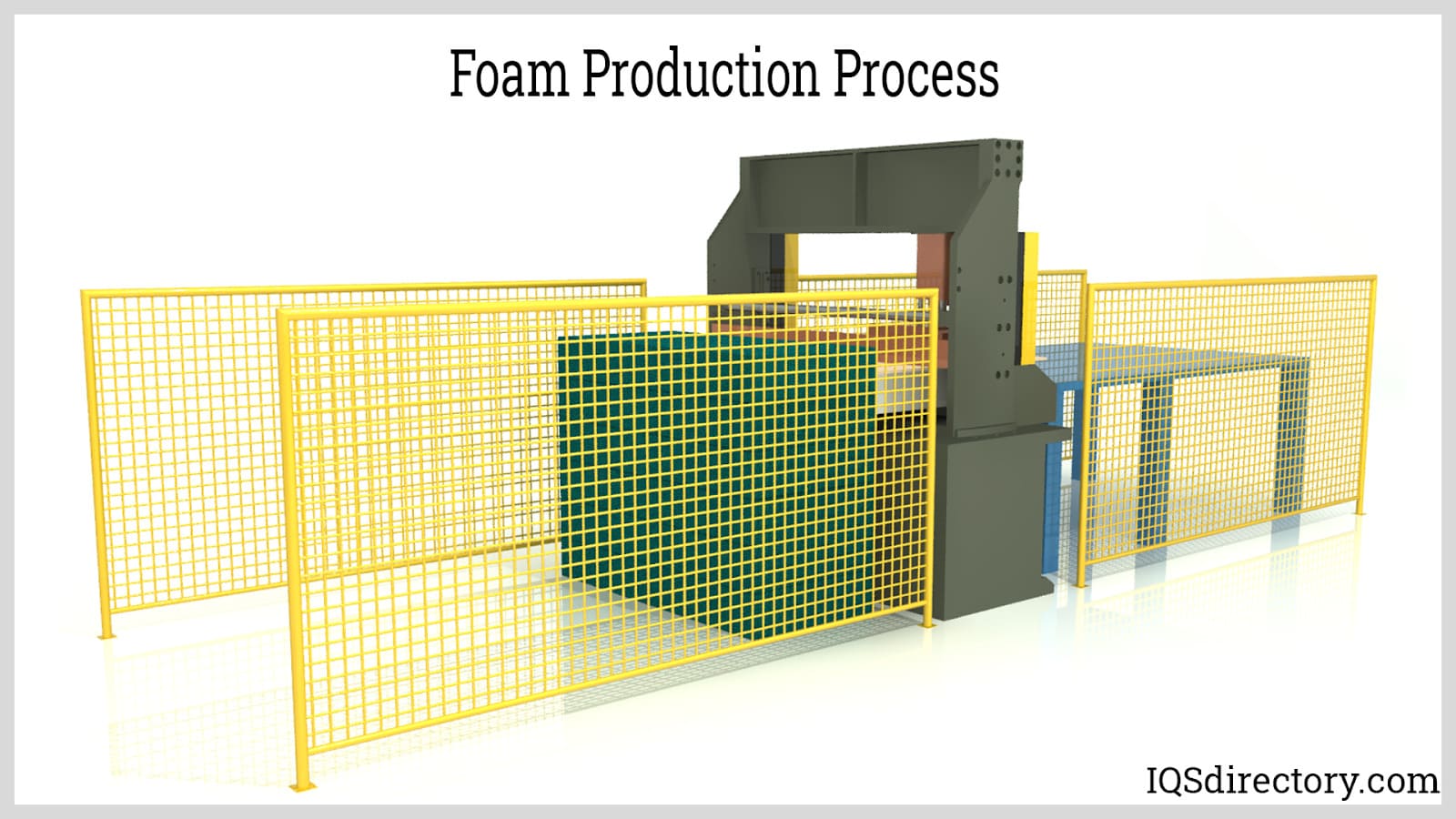

The equipment used in the manufacturing of foam mattresses is specialized and designed specifically for this purpose. It includes mixing machines, molds, heating and cooling equipment, and cutting and shaping machinery. These machines must be maintained and calibrated regularly to ensure the foam produced is of the highest quality. Foam Mattress Manufacturing Equipment

The production line for PU foam mattresses typically consists of several stages, each with its own set of equipment and processes. The first stage involves mixing the chemicals to create the foam, followed by the pouring and molding stage, the heating and cooling stage, and finally the cutting and assembly stage. Each stage must be carefully monitored to ensure the final product meets quality standards. PU Foam Mattress Production Line

The machinery used in the manufacturing of foam mattresses is highly specialized and requires skilled operators to ensure the process runs smoothly. This machinery includes mixing machines that blend the chemicals, molds for shaping the foam, heating and cooling equipment, and cutting and trimming machinery. The use of advanced machinery has greatly improved the efficiency and quality of foam mattress production. Foam Mattress Manufacturing Machinery

The cost of manufacturing PU foam mattresses can vary depending on factors such as the type and quality of foam used, the equipment and machinery used, and labor costs. However, advancements in technology have made the production process more efficient, resulting in lower costs and making foam mattresses more affordable for consumers. PU Foam Mattress Manufacturing Cost

The Benefits of Using PU Foam Mattresses in House Design

Comfort and Support

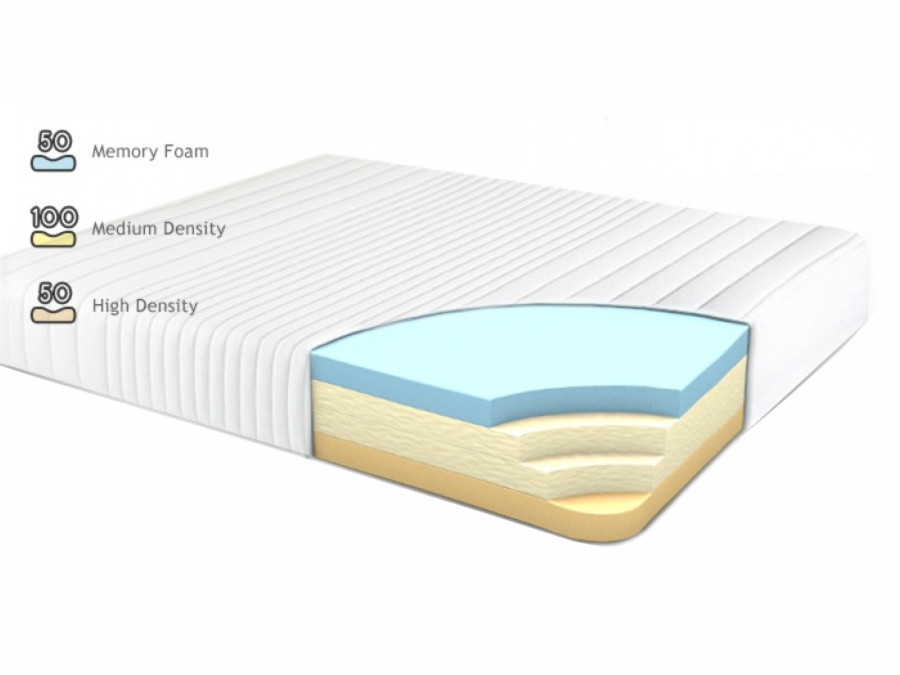

PU foam mattresses have become increasingly popular in house design due to their superior comfort and support. The manufacturing process of these mattresses involves using a combination of polyurethane foam and other materials to create a dense and supportive base. This allows for even distribution of body weight, relieving pressure points and promoting proper spinal alignment. The result is a comfortable and restful sleep, which is essential for overall health and well-being.

PU foam mattresses have become increasingly popular in house design due to their superior comfort and support. The manufacturing process of these mattresses involves using a combination of polyurethane foam and other materials to create a dense and supportive base. This allows for even distribution of body weight, relieving pressure points and promoting proper spinal alignment. The result is a comfortable and restful sleep, which is essential for overall health and well-being.

Durability

Another advantage of using PU foam mattresses in house design is their durability. The manufacturing process involves treating the foam with special chemicals that make it resistant to wear and tear. This means that the mattress can withstand daily use and retain its shape and support for many years. Additionally, the foam is also resistant to dust mites and other allergens, making it a great choice for those with allergies.

Another advantage of using PU foam mattresses in house design is their durability. The manufacturing process involves treating the foam with special chemicals that make it resistant to wear and tear. This means that the mattress can withstand daily use and retain its shape and support for many years. Additionally, the foam is also resistant to dust mites and other allergens, making it a great choice for those with allergies.

Customization

PU foam mattresses can also be customized to meet individual preferences and needs. The manufacturing process allows for different levels of firmness to be achieved, catering to the varying comfort needs of different individuals. This means that you can choose a mattress that is tailored to your specific body type, sleeping position, and comfort preferences.

PU foam mattresses can also be customized to meet individual preferences and needs. The manufacturing process allows for different levels of firmness to be achieved, catering to the varying comfort needs of different individuals. This means that you can choose a mattress that is tailored to your specific body type, sleeping position, and comfort preferences.

Cost-Effective

PU foam mattresses are also a cost-effective option for house design. Due to the efficiency of the manufacturing process, these mattresses are relatively inexpensive compared to other types of mattresses. They also have a longer lifespan, reducing the need for frequent replacements and saving you money in the long run.

PU foam mattresses are also a cost-effective option for house design. Due to the efficiency of the manufacturing process, these mattresses are relatively inexpensive compared to other types of mattresses. They also have a longer lifespan, reducing the need for frequent replacements and saving you money in the long run.

Conclusion

In conclusion, the manufacturing process of PU foam mattresses makes them a top choice for house design. They provide unmatched comfort and support, are highly durable, customizable, and cost-effective. So, if you're looking for a quality mattress that will enhance your sleep and overall well-being, consider investing in a PU foam mattress for your house design.

In conclusion, the manufacturing process of PU foam mattresses makes them a top choice for house design. They provide unmatched comfort and support, are highly durable, customizable, and cost-effective. So, if you're looking for a quality mattress that will enhance your sleep and overall well-being, consider investing in a PU foam mattress for your house design.