1. Automated Mattress Pad Production Machines

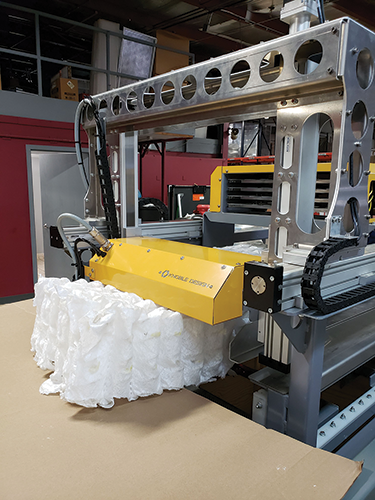

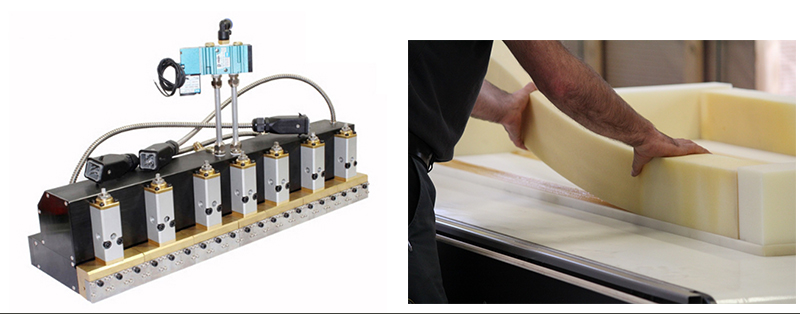

With the increasing demand for high-quality and comfortable mattresses, the production of mattress pads has become a crucial aspect of the bedding industry. To keep up with the growing market, manufacturers are turning to automated mattress pad production machines that can produce a large number of pads in a short amount of time. These advanced machines are equipped with cutting-edge technology and can efficiently handle the entire production process, from cutting and sewing to filling and packaging. The use of automated machines not only speeds up the production process but also ensures consistency and precision in every mattress pad produced.

2. High-Speed Mattress Pad Production Line

Time is of the essence in the manufacturing industry, and when it comes to producing mattress pads, it's no different. That's why the top manufacturers invest in high-speed production lines that can produce a large volume of pads per hour. These production lines are designed to optimize efficiency and reduce production time, resulting in cost savings for the company. With the use of high-speed mattress pad production lines, manufacturers can meet the ever-increasing demand for quality bedding products while maintaining a competitive edge in the market.

3. Customizable Mattress Pad Manufacturing Equipment

Every customer has different preferences when it comes to mattress pads, and manufacturers need to cater to these diverse needs. That's where customizable mattress pad manufacturing equipment comes into play. These machines can be adjusted to produce different sizes, materials, and designs of mattress pads according to the customer's requirements. The ability to customize production not only allows manufacturers to offer a variety of options to their customers but also helps to reduce wastage and increase efficiency in the production process.

4. Efficient Mattress Pad Production Solutions

In the highly competitive bedding industry, efficiency is key to staying ahead of the competition. That's why manufacturers are constantly searching for efficient production solutions that can streamline their processes and reduce costs. From automated cutting and sewing machines to high-speed filling and packaging equipment, efficient mattress pad production solutions are essential for meeting the market demand and maintaining profitability. These solutions also help to minimize errors and improve the overall quality of the final product, ensuring customer satisfaction.

5. Multi-Functional Mattress Pad Production Machinery

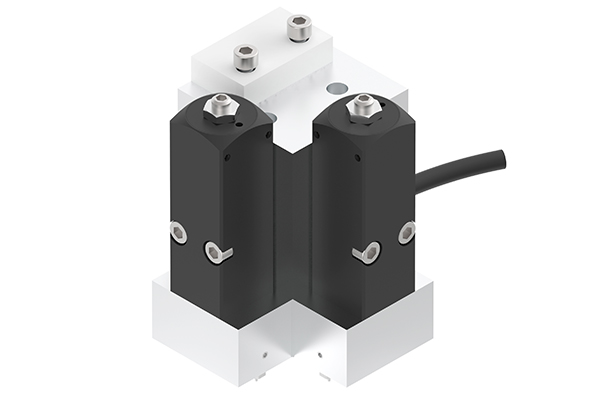

The versatility of multi-functional mattress pad production machinery is a significant advantage for manufacturers. These machines can perform multiple tasks, such as cutting, sewing, quilting, and filling, in one production line. This not only saves space in the factory but also increases productivity and reduces the need for additional equipment. With their ability to handle various processes, multi-functional machines are a cost-effective solution for producing high-quality mattress pads.

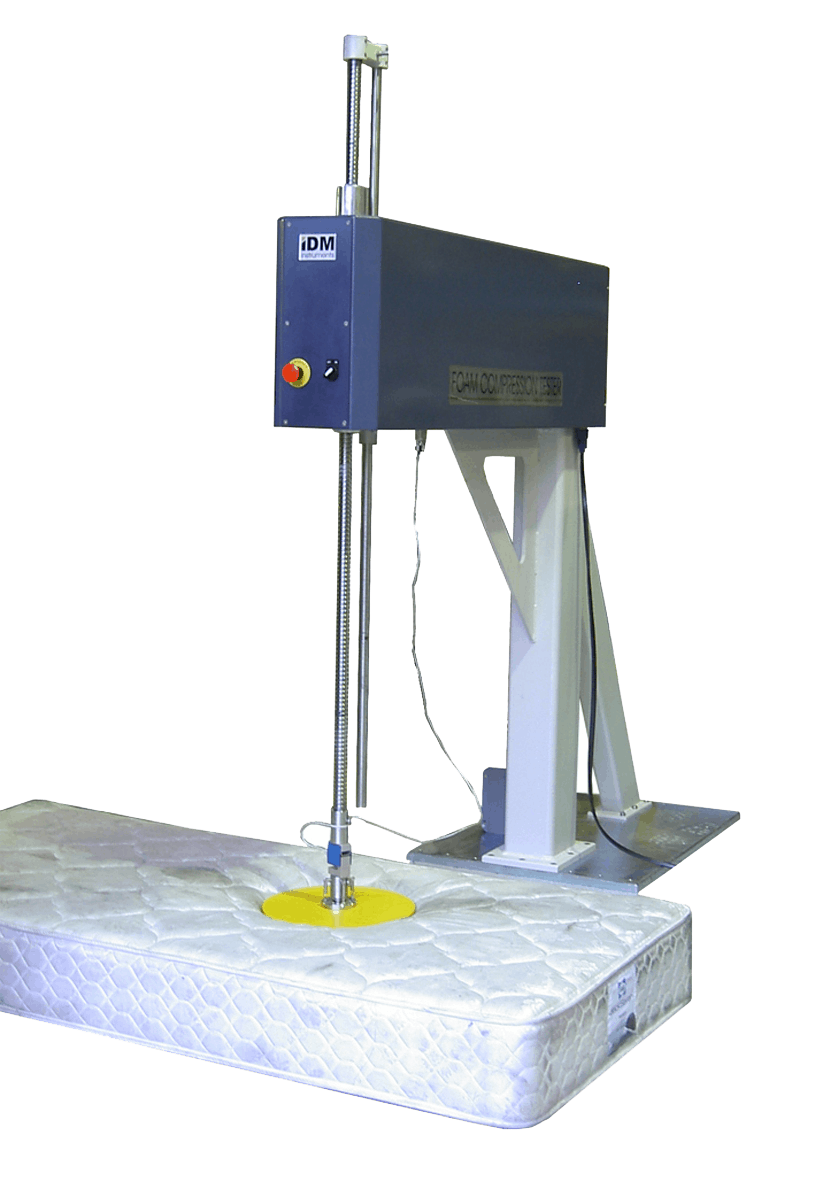

6. Advanced Mattress Pad Production Technology

The use of advanced technology in mattress pad production has revolutionized the industry. With the incorporation of computerized systems and digital controls, manufacturers can monitor and adjust the production process in real-time, resulting in more precise and consistent products. Additionally, advanced technology has also improved the overall quality of mattress pads by allowing for more intricate designs and better control over the material used. This has led to a significant increase in customer satisfaction and brand loyalty for manufacturers.

7. Industrial Mattress Pad Production Systems

To keep up with the growing demand for mattress pads, manufacturers need to have an industrial-grade production system in place. These systems are designed to handle large volumes of production and can operate continuously, ensuring a constant supply of mattress pads to the market. They also have a higher level of precision and efficiency, resulting in fewer errors and wastage. With an industrial production system, manufacturers can meet the demands of their customers and maintain a competitive edge in the market.

8. Automated Quilting and Filling Machines for Mattress Pads

The quilting and filling process is a crucial step in mattress pad production that requires precision and accuracy. That's why manufacturers invest in automated quilting and filling machines that can handle this process efficiently. These machines are equipped with advanced technology and can accurately fill and quilt the pads, resulting in a more comfortable and durable final product. With the use of automated quilting and filling machines, manufacturers can produce high-quality mattress pads that meet the expectations of their customers.

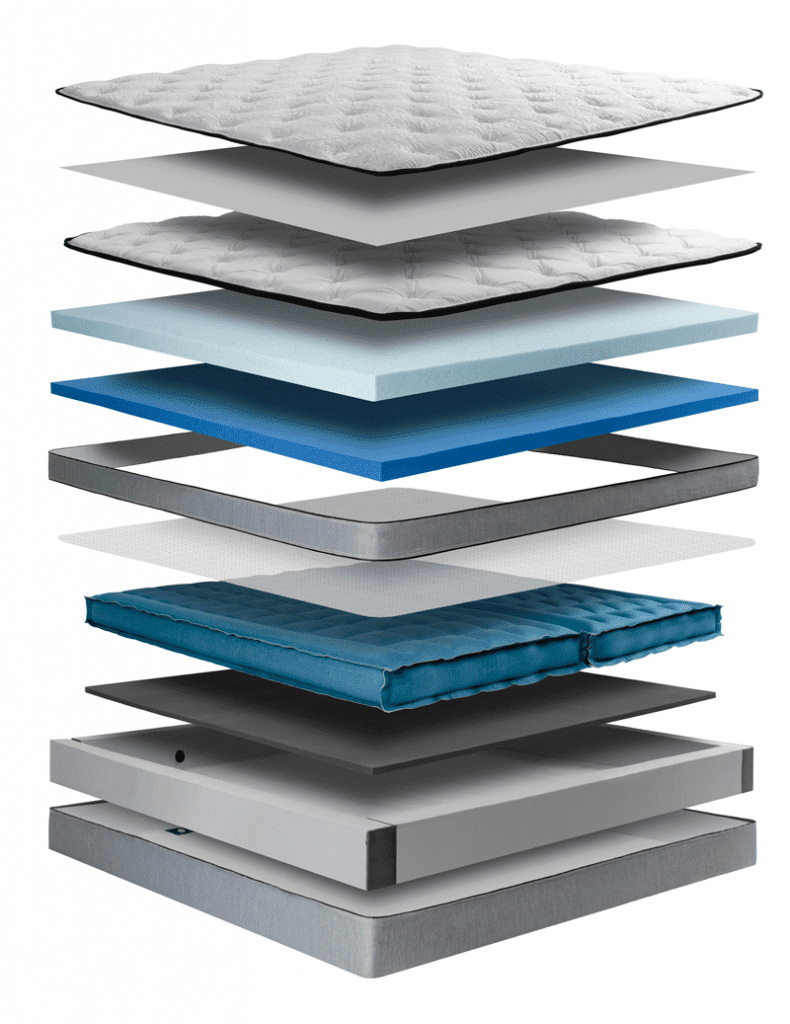

9. High-Quality Materials for Mattress Pad Production

The quality of materials used in mattress pad production plays a significant role in the overall comfort and durability of the product. That's why top manufacturers source high-quality materials for their production processes. From soft and breathable fabrics to high-density filling materials, using top-notch materials ensures that the end product meets the expectations of customers. With the use of high-quality materials, manufacturers can also build a reputation for producing superior and long-lasting mattress pads.

10. Cost-Effective Mattress Pad Production Equipment

The cost of production is a crucial factor for any business, and the bedding industry is no exception. That's why manufacturers are constantly looking for cost-effective production equipment that can help reduce expenses without compromising on quality. From automated machines that increase efficiency to multi-functional equipment that minimizes the need for additional machines, cost-effective production equipment is essential for the long-term success of manufacturers. By keeping production costs low, manufacturers can offer competitive prices to their customers and maintain profitability in the market.

The Importance of Quality Mattress Pads Production Machines in House Design

Maximizing Comfort and Functionality

In the world of house design, every detail matters. From the layout to the furniture, homeowners strive to create a space that is both comfortable and functional. One crucial element that often gets overlooked is the

mattress pad

. Mattress pads not only provide an extra layer of comfort and support, but they also protect the mattress from wear and tear. Therefore, it is essential to invest in high-quality

mattress pads production machines

to ensure that your home's sleeping spaces are designed to perfection.

In the world of house design, every detail matters. From the layout to the furniture, homeowners strive to create a space that is both comfortable and functional. One crucial element that often gets overlooked is the

mattress pad

. Mattress pads not only provide an extra layer of comfort and support, but they also protect the mattress from wear and tear. Therefore, it is essential to invest in high-quality

mattress pads production machines

to ensure that your home's sleeping spaces are designed to perfection.

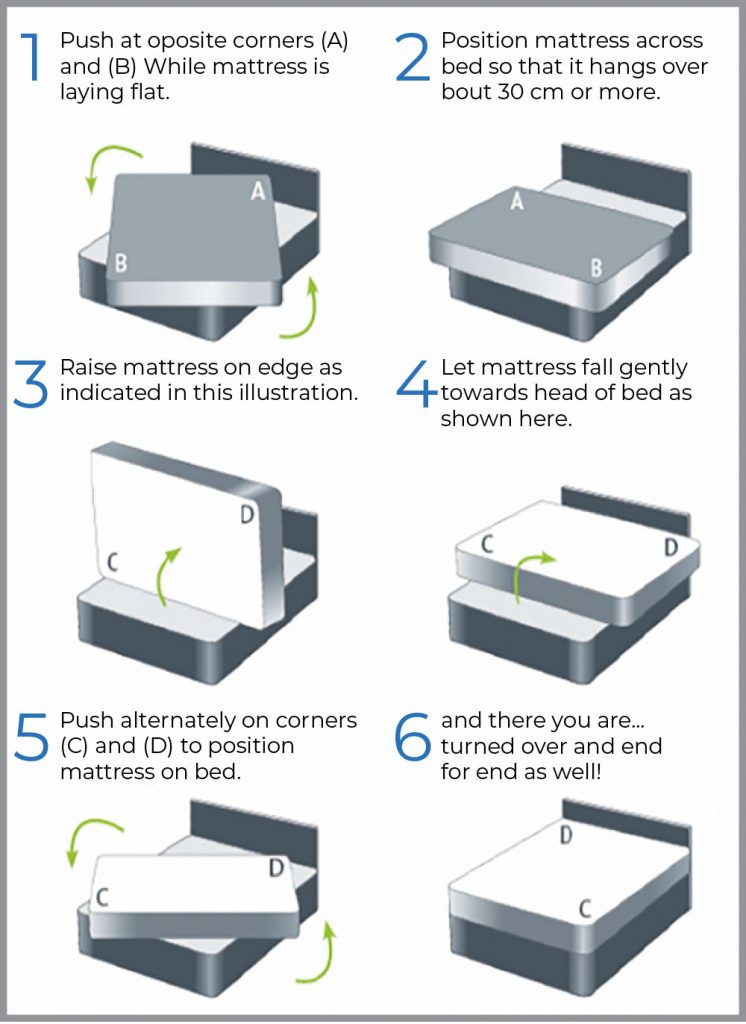

Efficiency and Precision

When it comes to manufacturing mattress pads, having the right production machines is crucial. These machines are specifically designed to produce

mattress pads

with precision and efficiency, resulting in a high-quality end product. With the advancement of technology, modern

mattress pads production machines

are equipped with state-of-the-art features such as automated cutting and stitching, ensuring that every mattress pad is made to the exact specifications.

When it comes to manufacturing mattress pads, having the right production machines is crucial. These machines are specifically designed to produce

mattress pads

with precision and efficiency, resulting in a high-quality end product. With the advancement of technology, modern

mattress pads production machines

are equipped with state-of-the-art features such as automated cutting and stitching, ensuring that every mattress pad is made to the exact specifications.

Cost-Effective Solution

Investing in

mattress pads production machines

may seem like a significant expense, but it is a cost-effective solution in the long run. By producing your own mattress pads, you eliminate the need to outsource this essential element of house design. This not only saves you money but also allows you to have complete control over the quality and design of your mattress pads.

Investing in

mattress pads production machines

may seem like a significant expense, but it is a cost-effective solution in the long run. By producing your own mattress pads, you eliminate the need to outsource this essential element of house design. This not only saves you money but also allows you to have complete control over the quality and design of your mattress pads.

Customization and Personalization

One of the major advantages of using

mattress pads production machines

is the ability to customize and personalize your mattress pads. With the option to choose from a variety of materials, patterns, and designs, you can create unique and personalized mattress pads that complement your house design perfectly. This level of customization is not possible when purchasing pre-made mattress pads from a store.

One of the major advantages of using

mattress pads production machines

is the ability to customize and personalize your mattress pads. With the option to choose from a variety of materials, patterns, and designs, you can create unique and personalized mattress pads that complement your house design perfectly. This level of customization is not possible when purchasing pre-made mattress pads from a store.

Conclusion

In conclusion,

mattress pads production machines

play a crucial role in house design. They not only provide comfort and protection for your mattresses but also offer a cost-effective and customizable solution. By investing in high-quality production machines, you can ensure that your home's sleeping spaces are designed to perfection, leaving you with a restful and comfortable night's sleep. So, when planning your next house design project, don't forget to consider the importance of quality

mattress pads production machines

.

In conclusion,

mattress pads production machines

play a crucial role in house design. They not only provide comfort and protection for your mattresses but also offer a cost-effective and customizable solution. By investing in high-quality production machines, you can ensure that your home's sleeping spaces are designed to perfection, leaving you with a restful and comfortable night's sleep. So, when planning your next house design project, don't forget to consider the importance of quality

mattress pads production machines

.