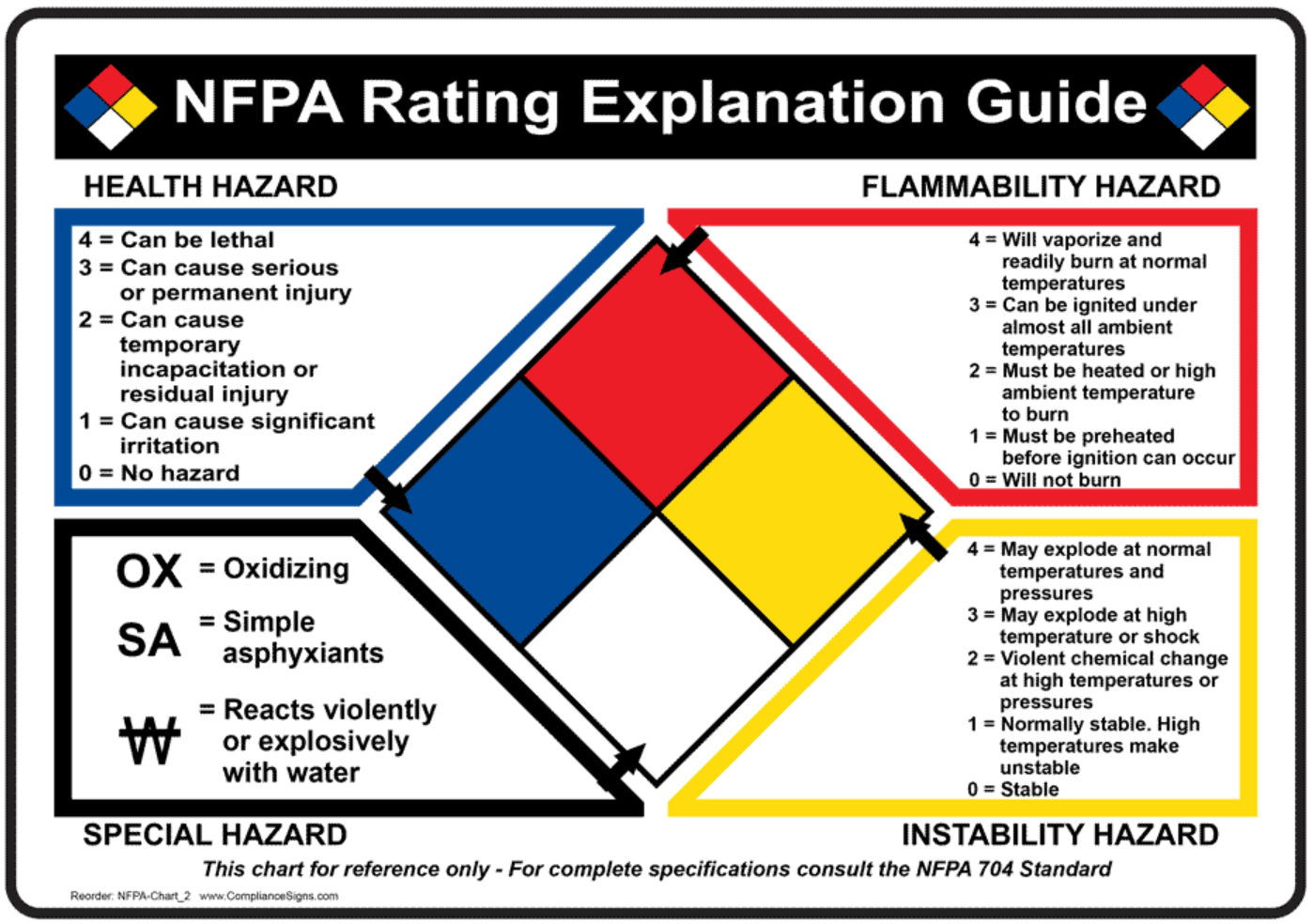

The National Fire Protection Association (NFPA) 96 is a set of standards that specifically addresses the design and installation of ventilation systems in commercial kitchens. These standards aim to minimize the risk of fire hazards and ensure the safety of workers and customers in the kitchen area. Compliance with NFPA 96 is crucial for any industrial kitchen design, as it sets the foundation for a safe and functional workspace. Some key requirements from NFPA 96 include proper ventilation for cooking equipment, adequate clearance between appliances and combustible materials, and regular maintenance of ventilation systems. Failure to comply with these standards can result in serious consequences, including fires and health hazards.1. National Fire Protection Association (NFPA) 96

The International Building Code (IBC) is a comprehensive set of regulations that govern the construction of buildings, including commercial kitchens. It sets standards for the design, construction, and maintenance of structures to ensure safety and accessibility for all occupants. Compliance with the IBC is mandatory for all new construction and renovations in many jurisdictions. For industrial kitchen design, the IBC covers important aspects such as building layout, plumbing and electrical systems, and fire safety measures. It also includes requirements for accessibility and egress, ensuring that the kitchen is safe and easy to navigate for all individuals.2. International Code Council (ICC) IBC

The ANSI Z83.11 standard specifically addresses the design and installation of gas-fired appliances in commercial kitchens. It covers a wide range of equipment, including ovens, fryers, and grills, and sets safety standards for their operation and maintenance. One key requirement from ANSI Z83.11 is the use of proper ventilation systems for gas-fired appliances. This helps to prevent the build-up of dangerous fumes and ensures the safety of workers and customers. It also sets standards for the installation and use of gas equipment, such as proper clearance from combustible materials and regular maintenance.3. American National Standards Institute (ANSI) Z83.11

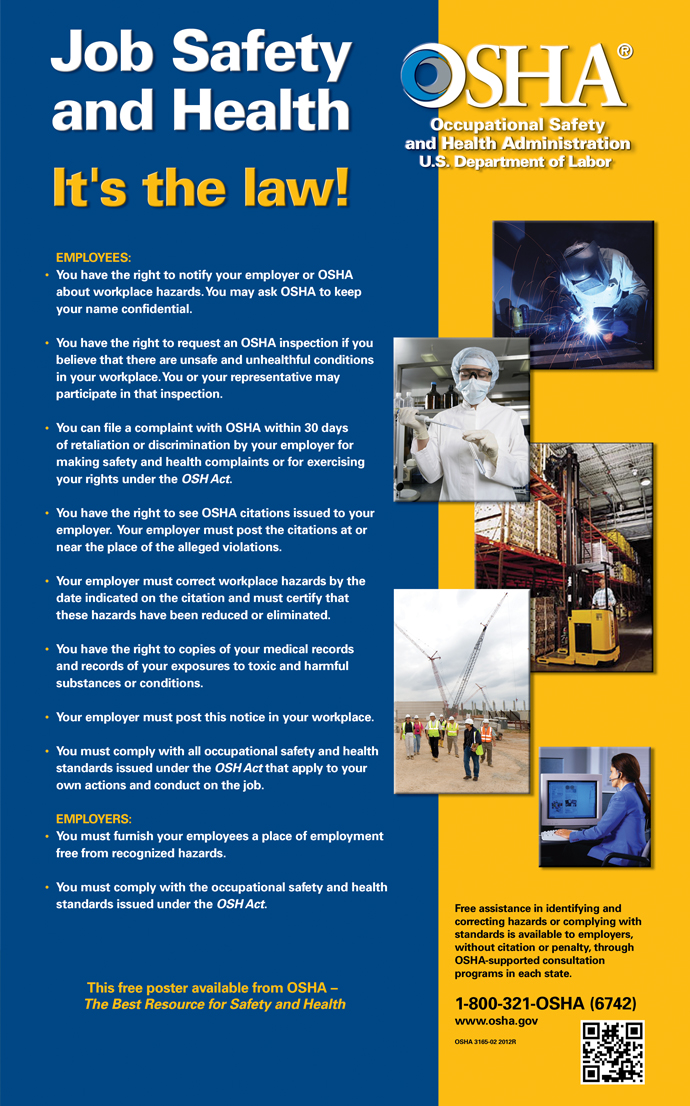

The Occupational Safety and Health Administration (OSHA) is a federal agency that sets and enforces workplace safety standards. OSHA 1910.147 specifically addresses the control of hazardous energy, also known as lockout/tagout procedures. These procedures are crucial for the safe operation and maintenance of equipment in industrial kitchens. According to OSHA 1910.147, all energy sources, including electrical, mechanical, and thermal, must be properly controlled during maintenance or repair work to prevent accidents and injuries. This standard also requires the use of lockout/tagout devices to isolate and secure energy sources during these activities.4. Occupational Safety and Health Administration (OSHA) 1910.147

The FDA Food Code is a set of guidelines that covers food safety and sanitation in commercial kitchens. These guidelines are designed to prevent foodborne illnesses and ensure the safety of consumers. Compliance with the FDA Food Code is mandatory for all food establishments, including industrial kitchens. Some key requirements from the FDA Food Code include proper food storage, handling, and temperature control. It also sets standards for cleaning and sanitizing equipment and surfaces, as well as personal hygiene practices for food handlers. By following these guidelines, industrial kitchens can maintain a safe and sanitary environment for food preparation.5. Food and Drug Administration (FDA) Food Code

The ASHRAE Standard 62.1 sets ventilation standards for commercial buildings, including industrial kitchens. These standards aim to provide a healthy and comfortable indoor environment for occupants by regulating the quality and quantity of air circulation. For industrial kitchen design, ASHRAE Standard 62.1 sets requirements for the design and operation of ventilation systems, including the use of proper filtration and exhaust systems. It also specifies the amount of outside air that needs to be introduced into the kitchen space to maintain air quality and prevent the build-up of cooking odors and fumes.6. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 62.1

The UL 710 standard covers the construction and performance of commercial kitchen exhaust hoods. It sets safety standards for ventilation systems and ensures that they are properly designed and installed to prevent fires and other hazards. According to UL 710, exhaust hoods must be constructed of non-combustible materials and must be tested and certified to meet specific performance requirements. Compliance with this standard is important for the safety and functionality of industrial kitchen ventilation systems.7. Underwriters Laboratories (UL) 710

The NSF Standard 2 covers the design and construction of food equipment, including appliances and surfaces, to ensure that they are safe for use in commercial kitchens. This standard sets requirements for materials, construction, and performance to prevent contamination and maintain food safety. Industrial kitchens must comply with NSF Standard 2 to ensure that all equipment and surfaces are safe for food preparation and handling. This standard also requires regular maintenance and cleaning to prevent the build-up of bacteria and other contaminants.8. National Sanitation Foundation (NSF) Standard 2

The ASME A17.1 standard sets safety requirements for elevators and escalators, including those used in commercial buildings. For industrial kitchens, this standard applies to service elevators and dumbwaiters used to transport food and supplies between floors. ASME A17.1 specifies the design, installation, and maintenance standards for these types of elevators to ensure the safety of users and prevent accidents. Compliance with this standard is crucial for industrial kitchens that have multiple levels and require the use of elevators to transport goods.9. American Society of Mechanical Engineers (ASME) A17.1

The NKBA Kitchen Planning Guidelines are a set of recommendations and best practices for designing functional and efficient kitchens. These guidelines cover a wide range of aspects, including layout, storage, and safety, to create a well-designed and user-friendly kitchen space. Industrial kitchens can benefit from following these guidelines, which include suggestions for the placement of appliances, counters, and work areas, as well as proper lighting and ventilation. By incorporating these recommendations into their design, industrial kitchens can create a space that is both functional and visually appealing. Incorporating these 10 main industrial kitchen design standards into the planning and construction of a commercial kitchen is essential for ensuring the safety and functionality of the space. Compliance with these standards not only helps to prevent accidents and hazards but also contributes to creating a professional and efficient workspace for food preparation. By following these guidelines, industrial kitchens can maintain a high level of safety and hygiene, which is crucial for the success and reputation of any food establishment.10. National Kitchen and Bath Association (NKBA) Kitchen Planning Guidelines

Designing an Efficient Industrial Kitchen for Your Business

Maximizing Space and Functionality

When it comes to designing an industrial kitchen, one of the biggest challenges is maximizing space and functionality. This is especially important for businesses that rely heavily on their kitchen operations, such as restaurants or catering companies. In order to meet the demands of a busy kitchen, it is essential to have a layout that is efficient and organized.

Industrial kitchen design standards

require careful consideration of the workflow and the equipment needed for different tasks. The

main keyword

for any industrial kitchen is "efficiency". The goal is to have a layout that allows for a smooth flow of work, minimizing the time and effort required to prepare and serve food. This not only saves time and money, but also ensures that the food is of high quality and consistency.

When it comes to designing an industrial kitchen, one of the biggest challenges is maximizing space and functionality. This is especially important for businesses that rely heavily on their kitchen operations, such as restaurants or catering companies. In order to meet the demands of a busy kitchen, it is essential to have a layout that is efficient and organized.

Industrial kitchen design standards

require careful consideration of the workflow and the equipment needed for different tasks. The

main keyword

for any industrial kitchen is "efficiency". The goal is to have a layout that allows for a smooth flow of work, minimizing the time and effort required to prepare and serve food. This not only saves time and money, but also ensures that the food is of high quality and consistency.

The Work Triangle

The work triangle is a fundamental concept in kitchen design. It refers to the three main areas of the kitchen: the cooking area, the preparation area, and the storage area. These areas should be positioned in a way that creates an efficient workflow, with minimal movement between them.

Professional kitchen designers

use this concept to create a functional and ergonomic layout for industrial kitchens.

The work triangle is a fundamental concept in kitchen design. It refers to the three main areas of the kitchen: the cooking area, the preparation area, and the storage area. These areas should be positioned in a way that creates an efficient workflow, with minimal movement between them.

Professional kitchen designers

use this concept to create a functional and ergonomic layout for industrial kitchens.

Keeping it Clean and Sanitary

Another important aspect of industrial kitchen design is maintaining cleanliness and sanitation. This is crucial for food safety and preventing cross-contamination. To meet

health and safety standards

, the kitchen design should include easy-to-clean surfaces, proper drainage systems, and designated areas for food storage, preparation, and waste disposal.

Another important aspect of industrial kitchen design is maintaining cleanliness and sanitation. This is crucial for food safety and preventing cross-contamination. To meet

health and safety standards

, the kitchen design should include easy-to-clean surfaces, proper drainage systems, and designated areas for food storage, preparation, and waste disposal.

The Right Equipment

An industrial kitchen is only as efficient as the equipment it contains. It is essential to choose equipment that is suitable for the type and volume of food being prepared. This includes

commercial-grade appliances

, such as ovens, refrigerators, and dishwashers, as well as specialized equipment for specific tasks. Having the right equipment not only increases efficiency but also ensures that the kitchen can handle the demands of a busy business.

In conclusion, designing an industrial kitchen requires careful planning and consideration of

industrial kitchen design standards

. By focusing on efficiency, utilizing the work triangle, maintaining cleanliness, and choosing the right equipment, businesses can create a functional and productive kitchen that meets the demands of their operations.

An industrial kitchen is only as efficient as the equipment it contains. It is essential to choose equipment that is suitable for the type and volume of food being prepared. This includes

commercial-grade appliances

, such as ovens, refrigerators, and dishwashers, as well as specialized equipment for specific tasks. Having the right equipment not only increases efficiency but also ensures that the kitchen can handle the demands of a busy business.

In conclusion, designing an industrial kitchen requires careful planning and consideration of

industrial kitchen design standards

. By focusing on efficiency, utilizing the work triangle, maintaining cleanliness, and choosing the right equipment, businesses can create a functional and productive kitchen that meets the demands of their operations.

:max_bytes(150000):strip_icc()/GettyImages-1188568920-056f66c163fc46a19d817eef55d14933.jpg)