Memory Foam: The Key Ingredient in Comfortable Mattresses

When it comes to getting a good night's sleep, having a comfortable mattress is crucial. One of the main factors in creating a comfortable and supportive mattress is the use of memory foam. This innovative material has revolutionized the mattress industry and has become a mainstay in the production process of high-quality mattresses.

The Production Process of Memory Foam

The creation of memory foam involves a complex and meticulous production process. It starts with the combination of various chemicals, including polyurethane, water, and other substances. The mixture is then heated and allowed to expand to create a foam-like substance.

Next, the foam is poured into molds and baked to set its shape. This is followed by a cooling process, during which the foam hardens and solidifies. The final step in the production process is cutting the foam into the desired size and shape to be used in mattresses.

Mattress Manufacturing: Incorporating Memory Foam

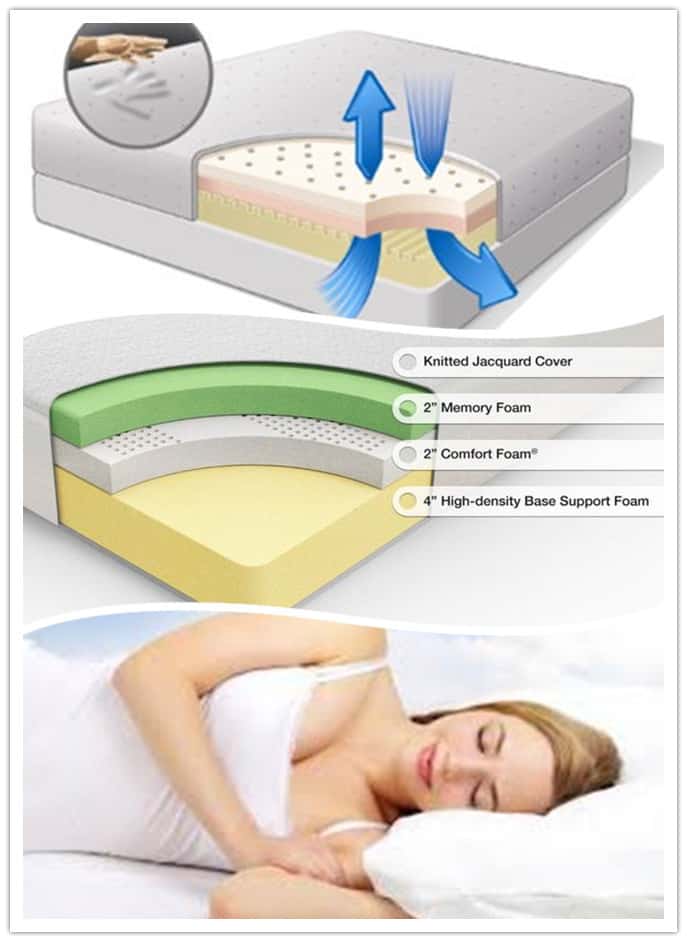

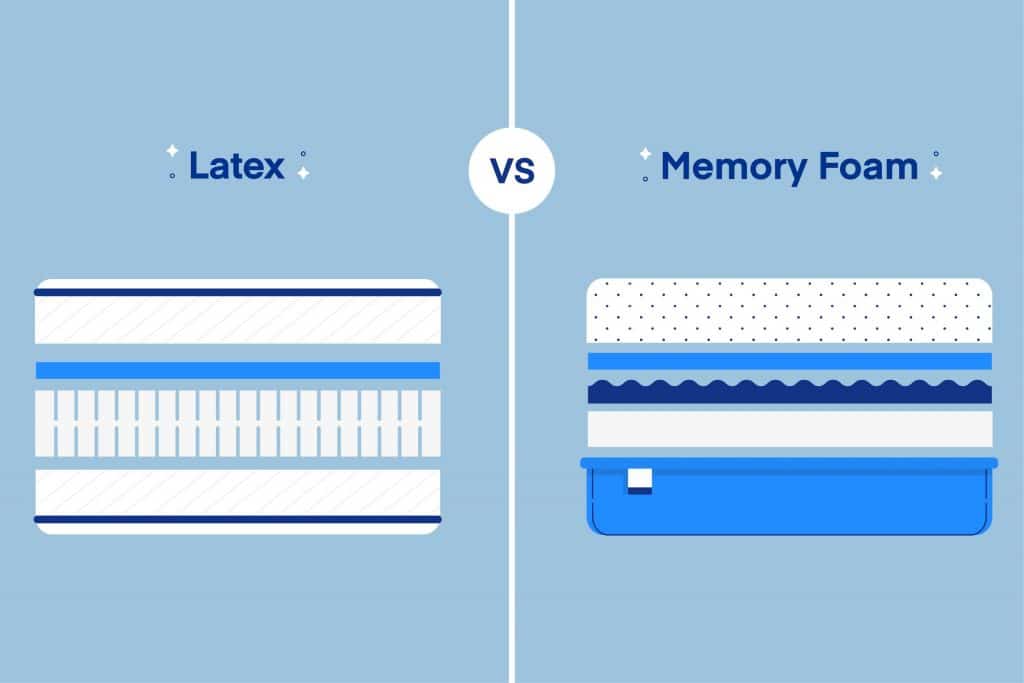

Once the memory foam is produced, it is ready to be incorporated into mattresses. This is where the expertise of mattress manufacturers comes into play. They carefully layer the memory foam with other materials, such as springs and support foam, to create a comfortable and supportive mattress.

The placement and combination of these materials require precision and skill to ensure the final product is both comfortable and durable. The use of memory foam in the production process allows for the creation of mattresses that conform to the body's shape, providing optimal support and pressure relief.

The Ins and Outs of Memory Foam Production

To understand the production process of memory foam, it's important to know how this material is made. The key to memory foam's unique properties lies in its open-cell structure. This allows the foam to respond to heat and pressure, molding to the body's shape and evenly distributing weight.

Additionally, memory foam is known for its ability to bounce back to its original shape once pressure is removed. This makes it a durable and long-lasting material, perfect for use in mattresses. These qualities make memory foam production a highly sought-after process in the mattress industry.

The Memory Foam Production Line

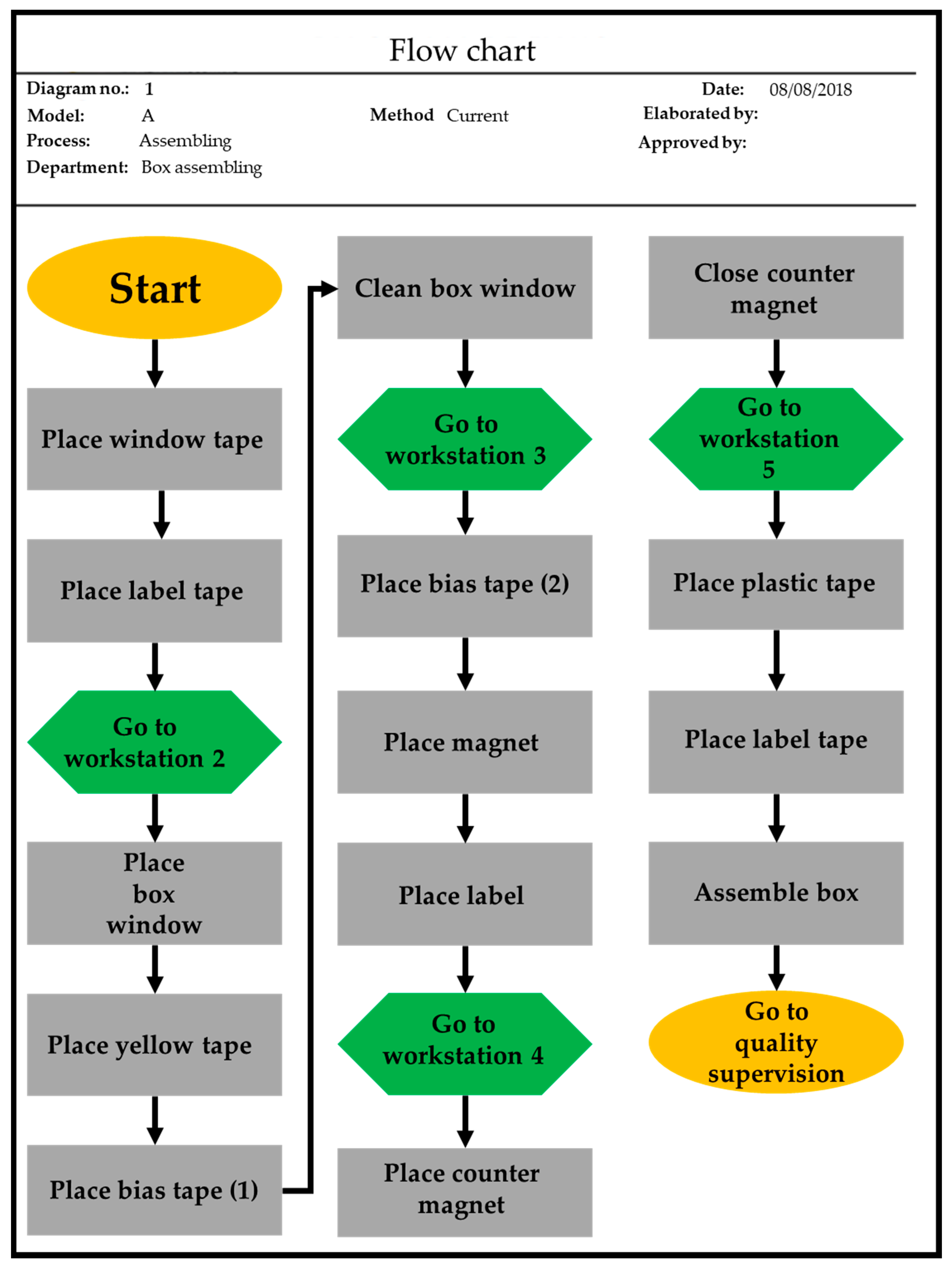

The production of memory foam involves the use of specialized equipment and machinery. The memory foam production line consists of several stages, including mixing, heating, molding, cooling, and cutting. Each stage is crucial in creating high-quality memory foam that meets industry standards and provides the desired level of comfort and support.

Additionally, the use of advanced technology and machinery in the production line ensures consistency and efficiency in the production process, resulting in top-of-the-line memory foam mattresses.

Putting It All Together: Memory Foam Mattress Assembly

After the memory foam is produced and cut to the appropriate size, it's time to assemble the mattress. This involves layering the memory foam with other materials, such as springs and support foam, to create a comfortable and supportive sleep surface.

Assembly also includes adding a cover, which often consists of a soft and breathable material that helps regulate body temperature during sleep. The memory foam mattress is then stitched and sewn together, creating a finished product ready to be shipped to customers.

The Role of Advanced Equipment in Memory Foam Mattress Production

The use of advanced equipment and machinery is crucial in the production of memory foam mattresses. These machines are designed to mix, heat, mold, and cut the foam with precision and consistency, resulting in a high-quality product every time.

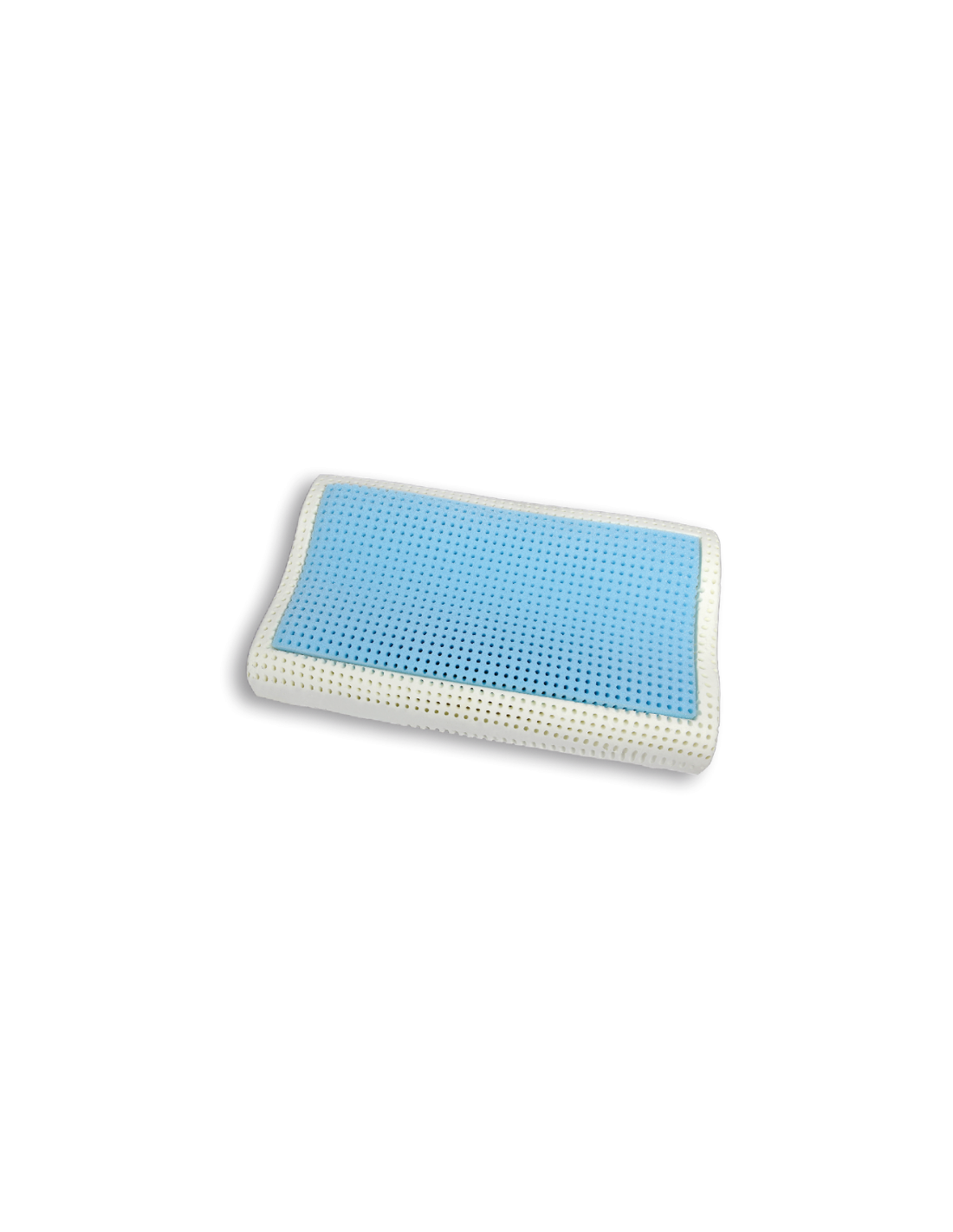

Moreover, the use of advanced equipment has allowed for the development of new production techniques, such as gel-infused memory foam, which provides additional cooling properties and enhances the overall sleeping experience.

The Step-by-Step Process: Memory Foam Mattress Production Steps

The production of memory foam mattresses involves several steps, each of which is essential in creating a comfortable and supportive sleep surface. These steps include mixing, heating, molding, cooling, cutting, layering, and assembly.

Each step requires specialized equipment and techniques to ensure the foam is of the highest quality and meets industry standards. The end result is a mattress that provides optimal comfort and support, allowing for a restful night's sleep.

Innovative Techniques for Memory Foam Mattress Production

The production of memory foam mattresses has evolved over the years, resulting in the development of innovative techniques. These techniques involve the use of different materials and methods to enhance the properties of memory foam and create a more comfortable and supportive sleep surface.

For example, the use of infused memory foam, such as copper or graphite, can provide additional cooling properties, making it ideal for those who tend to sleep hot. These techniques have allowed for the creation of memory foam mattresses that cater to a wide range of sleep preferences and needs.

In Conclusion

The production process of memory foam mattresses is a complex and intricate one, involving a combination of chemicals, specialized equipment, and skilled labor. However, the end result is a comfortable and supportive mattress that provides a restful night's sleep.

With advancements in technology and production techniques, memory foam mattresses continue to be a popular choice for those looking for a comfortable and durable sleep surface. So the next time you lay down on your memory foam mattress, you can appreciate the meticulous production process that went into creating it.

Benefits of Memory Foam Mattresses

Superior Comfort and Support

A memory foam mattress is designed to conform to your body's unique shape, providing superior comfort and support. The foam evenly distributes your body weight, reducing pressure points and allowing your spine to align in its natural position. This not only ensures a more comfortable sleep, but also helps to alleviate pain and discomfort in the body.

A memory foam mattress is designed to conform to your body's unique shape, providing superior comfort and support. The foam evenly distributes your body weight, reducing pressure points and allowing your spine to align in its natural position. This not only ensures a more comfortable sleep, but also helps to alleviate pain and discomfort in the body.

Durability and Longevity

Memory foam mattresses are known for their durability and longevity. The production process involves using high-quality materials that are designed to withstand the test of time. The foam is also resistant to sagging, ensuring that your mattress maintains its shape and support for years to come.

Memory foam mattresses are known for their durability and longevity. The production process involves using high-quality materials that are designed to withstand the test of time. The foam is also resistant to sagging, ensuring that your mattress maintains its shape and support for years to come.

Hypoallergenic and Dust Mite Resistant

One of the key benefits of memory foam mattresses is their hypoallergenic and dust mite resistant properties. The production process involves using materials that are naturally resistant to allergens and dust mites, making it a great choice for those with allergies or respiratory issues. This helps to create a cleaner and healthier sleep environment.

One of the key benefits of memory foam mattresses is their hypoallergenic and dust mite resistant properties. The production process involves using materials that are naturally resistant to allergens and dust mites, making it a great choice for those with allergies or respiratory issues. This helps to create a cleaner and healthier sleep environment.

Reduces Motion Transfer

Memory foam mattresses are also known for their ability to reduce motion transfer. This means that when one person moves or gets out of bed, the other person is less likely to feel the movement. This is especially beneficial for couples who may have different sleep schedules or movements during the night.

Memory foam mattresses are also known for their ability to reduce motion transfer. This means that when one person moves or gets out of bed, the other person is less likely to feel the movement. This is especially beneficial for couples who may have different sleep schedules or movements during the night.

Customizable Firmness

Another advantage of memory foam mattresses is their customizable firmness. With traditional mattresses, you are limited to a set level of firmness. However, memory foam mattresses come in various levels of firmness, allowing you to choose the one that best suits your comfort and support needs.

Another advantage of memory foam mattresses is their customizable firmness. With traditional mattresses, you are limited to a set level of firmness. However, memory foam mattresses come in various levels of firmness, allowing you to choose the one that best suits your comfort and support needs.

Conclusion

In conclusion, the production process of memory foam mattresses involves using high-quality materials and advanced technology to create a product that offers superior comfort, durability, and support. Its hypoallergenic and dust mite resistant properties, as well as its ability to reduce motion transfer and customizable firmness, make it a popular choice among consumers. Consider investing in a memory foam mattress for a better night's sleep and improved overall health and well-being.

In conclusion, the production process of memory foam mattresses involves using high-quality materials and advanced technology to create a product that offers superior comfort, durability, and support. Its hypoallergenic and dust mite resistant properties, as well as its ability to reduce motion transfer and customizable firmness, make it a popular choice among consumers. Consider investing in a memory foam mattress for a better night's sleep and improved overall health and well-being.