1. Casting

The first step in the kitchen sink manufacturing process is casting. This is where molten metal, usually stainless steel, is poured into a mold to create the basic shape of the sink. The mold is made from a special type of sand that can withstand high temperatures and pressure. Once the metal has cooled and solidified, the mold is broken and the rough sink is removed. This is the starting point for all kitchen sinks and forms the foundation for the rest of the manufacturing process.

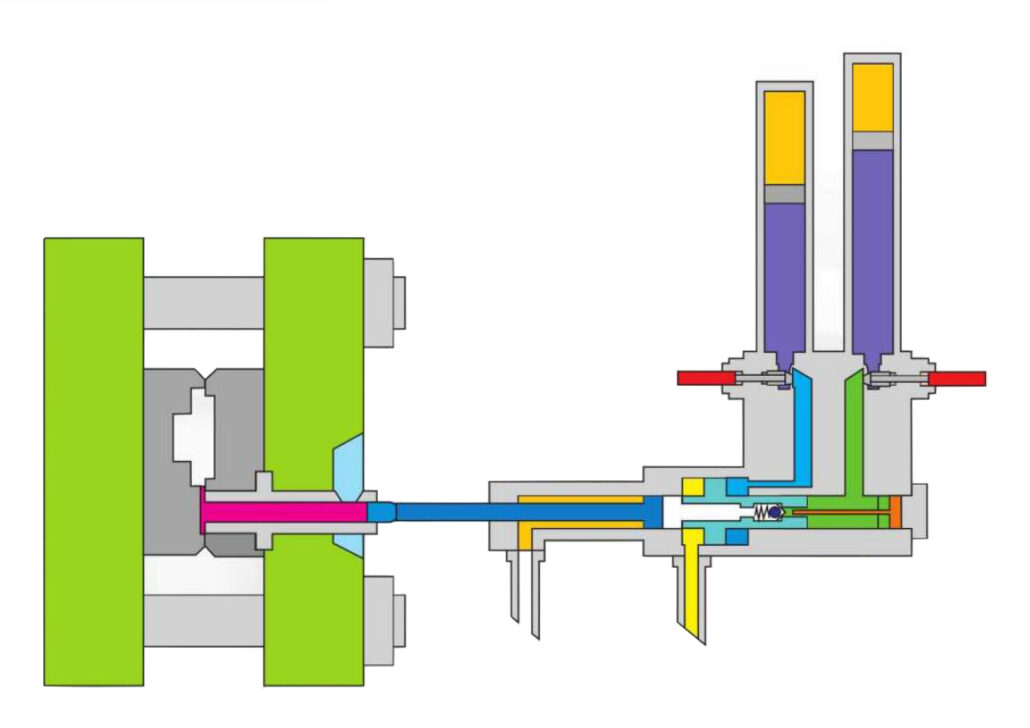

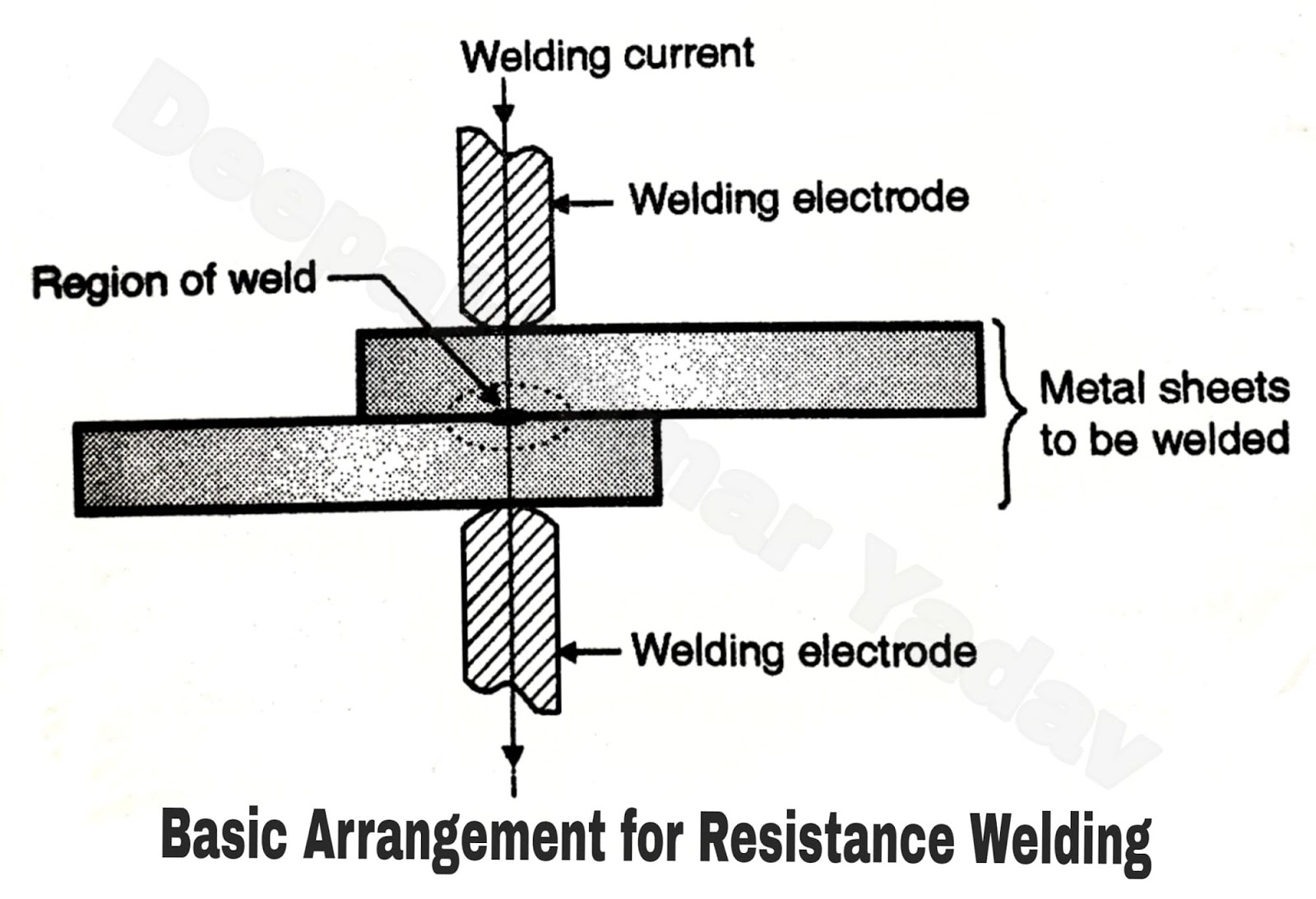

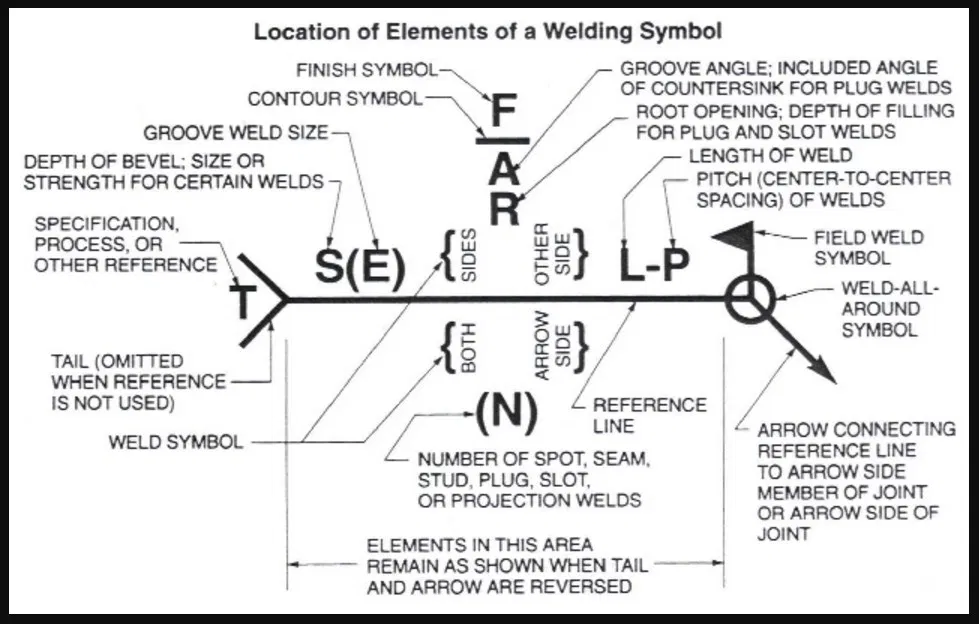

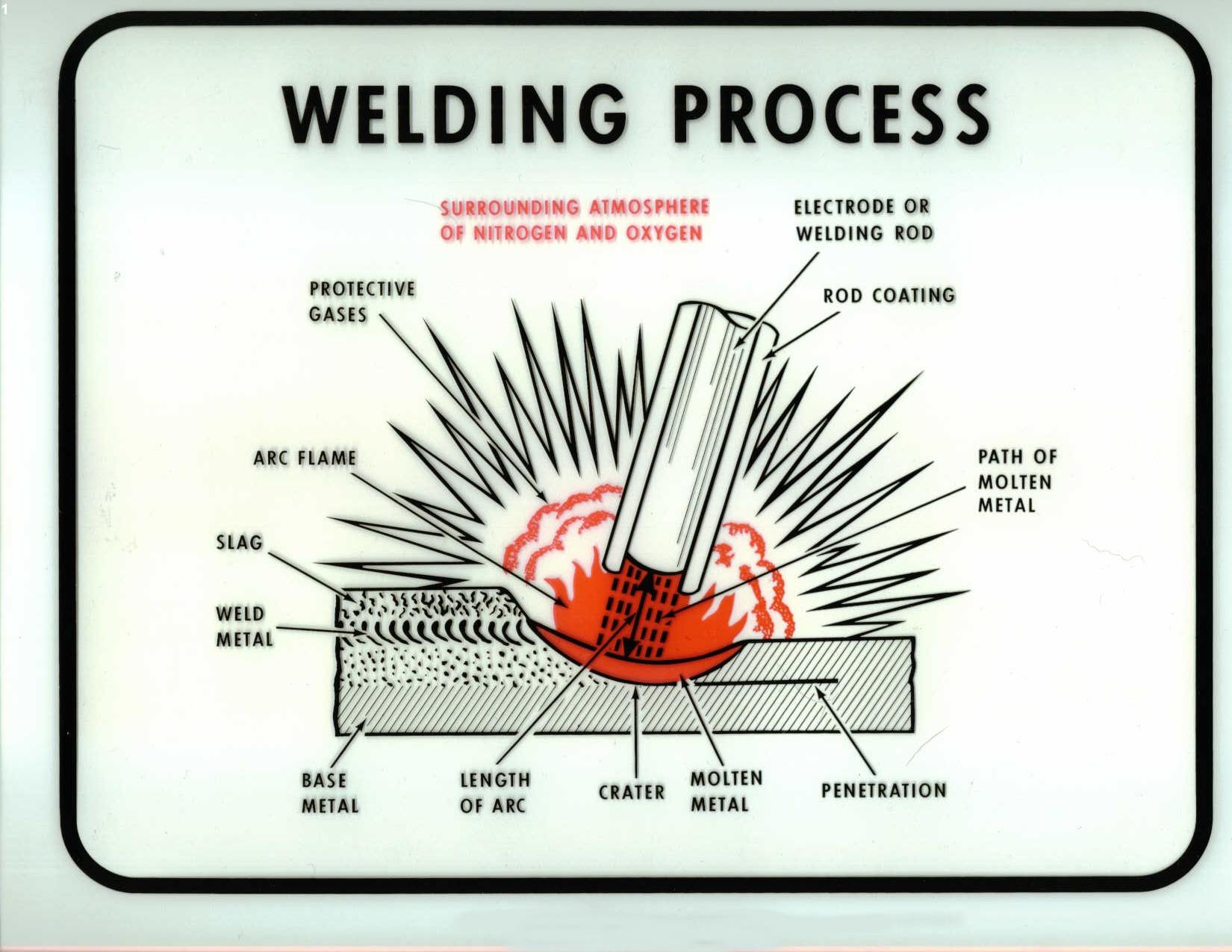

2. Welding

After the rough sink has been cast, it is then sent to the welding department. Here, the different parts of the sink, such as the bowl, drain, and faucet holes, are welded together. This requires highly skilled welders to ensure that the sink is strong and durable. The welding process also helps to smooth out any rough edges and create a seamless appearance.

3. Stamping

Once the sink has been welded together, it is then sent to the stamping department. This is where the sink is given its final shape and design. Using large machines, the sink is stamped into its desired shape and any additional features, such as grooves or ridges, are added. This step is crucial in creating a unique and aesthetically pleasing sink.

4. Forming

After the sink has been stamped, it is then sent to the forming department. Here, the sink is placed in a press and any necessary bends or curves are added to the sink. This step is important in ensuring that the sink fits perfectly into a countertop and allows for proper drainage. It also helps to strengthen the sink and prevent it from denting or warping.

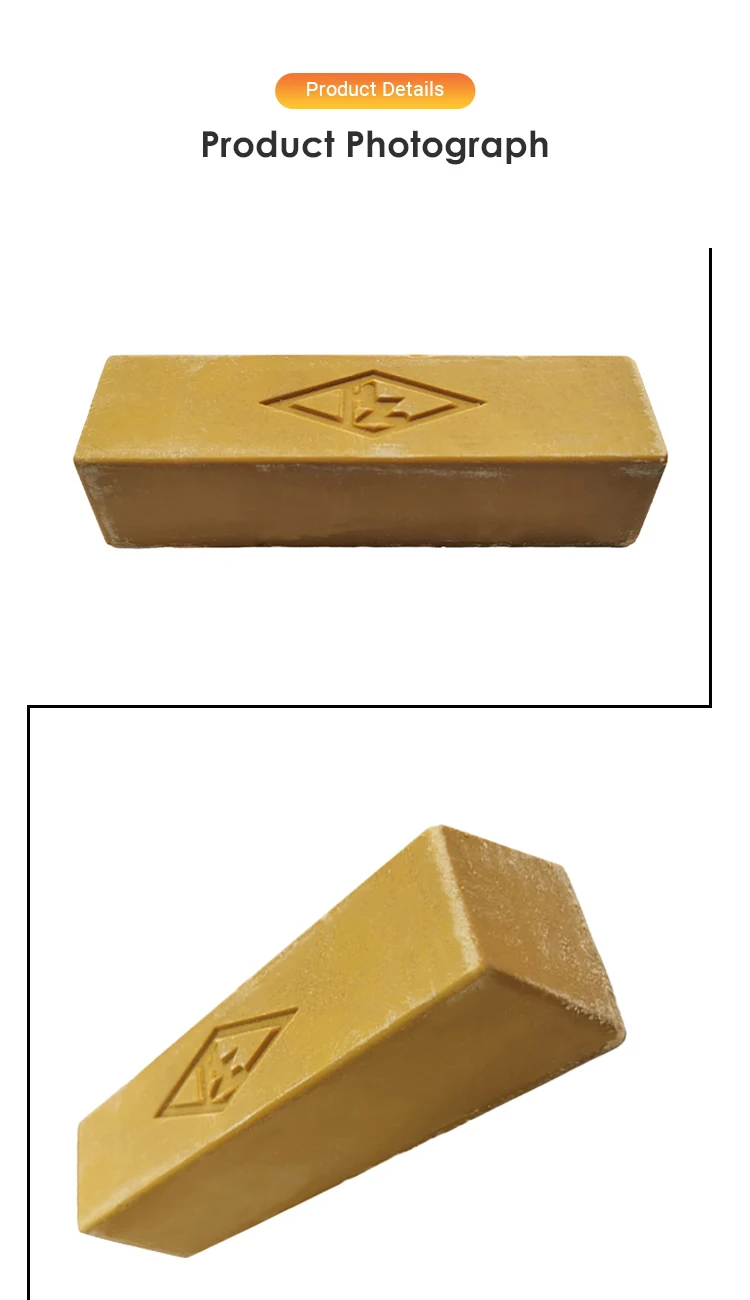

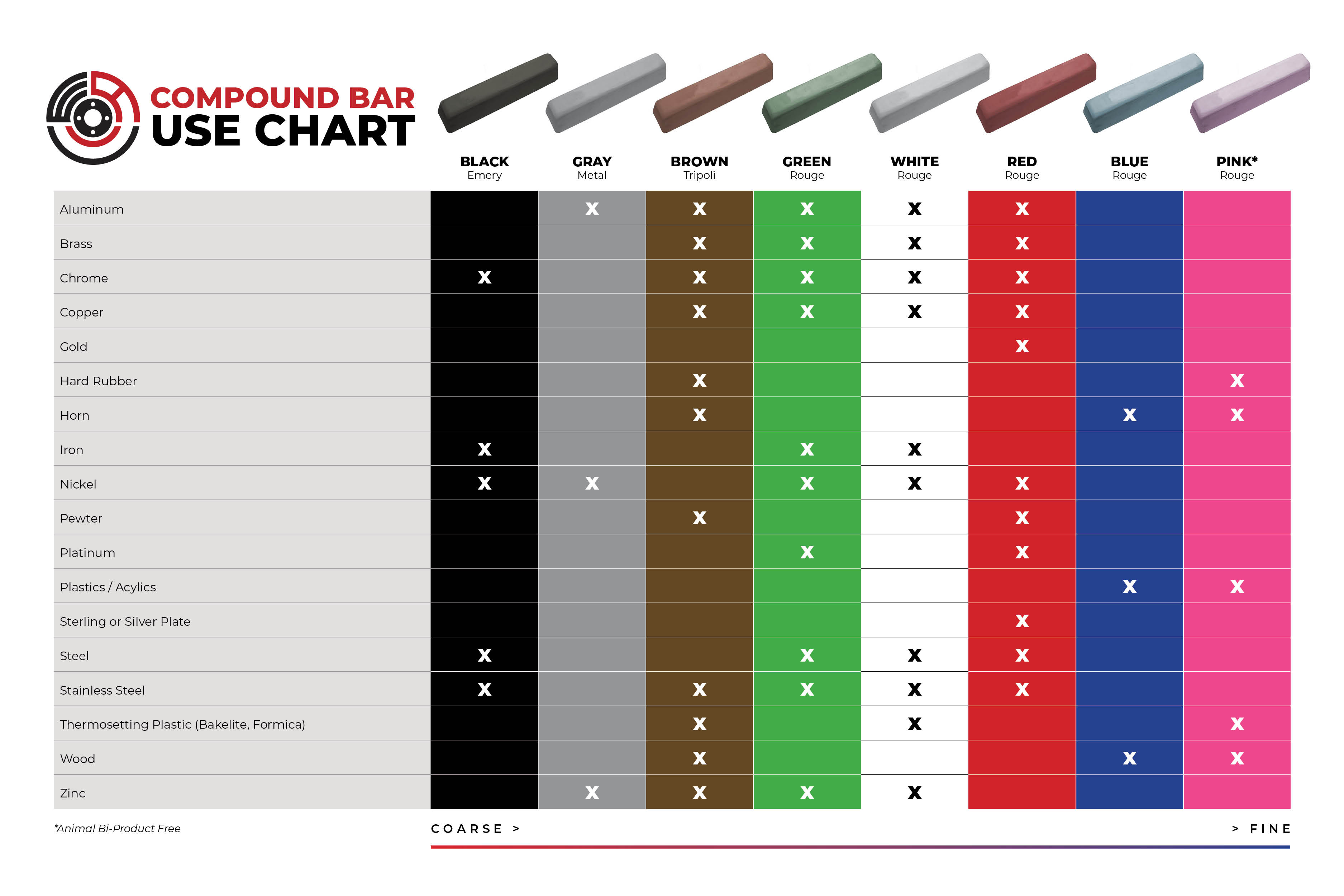

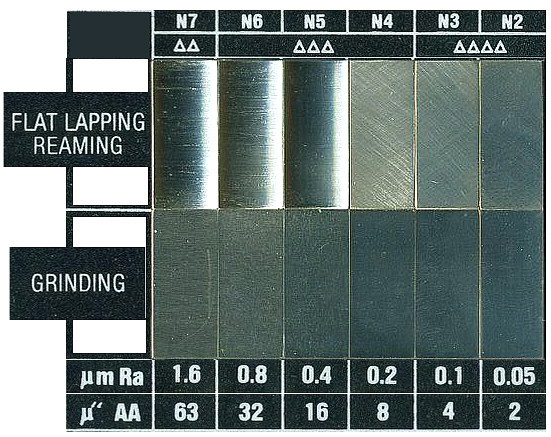

5. Polishing

Once the sink has been formed, it is then sent to the polishing department. This is where the sink is given its smooth and shiny finish. The sink is placed in a large machine that uses different types of abrasives to buff and polish the surface. This step not only gives the sink a beautiful appearance, but it also helps to remove any imperfections or scratches from the previous steps.

6. Finishing

After the sink has been polished, it is then sent to the finishing department. Here, any additional features, such as sprayers or soap dispensers, are added to the sink. This step also involves adding any necessary coatings or treatments to the sink's surface to protect it from scratches and stains. The sink is now almost complete and ready for assembly.

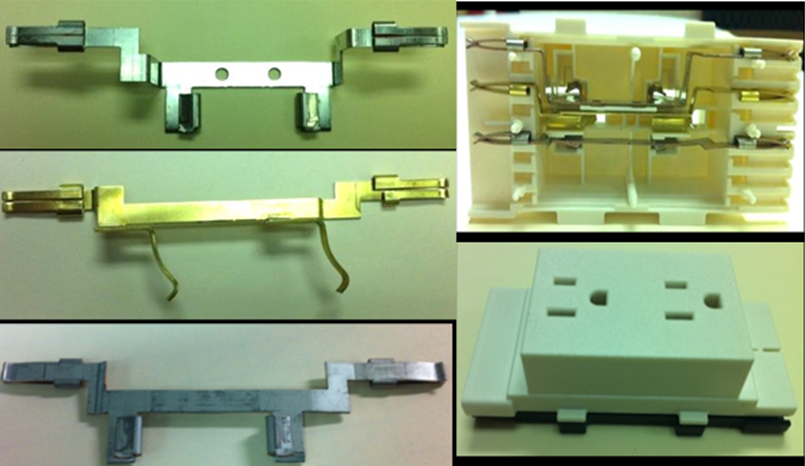

7. Assembly

In the assembly department, all the different parts of the sink are put together to create the final product. This involves attaching the faucet, drain, and any other accessories to the sink. The sink is also inspected at this stage to ensure that all the parts are functioning correctly and that the sink meets quality standards.

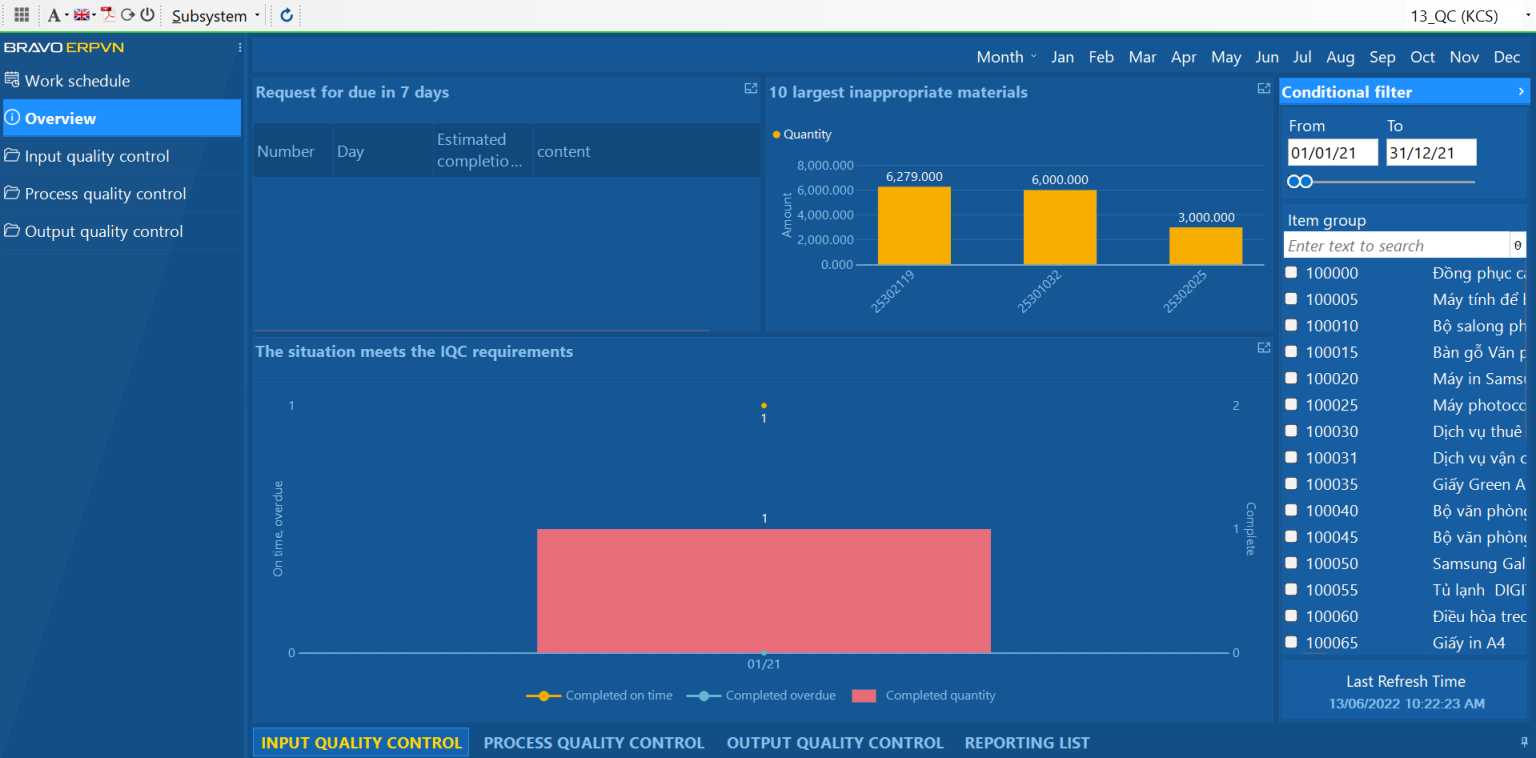

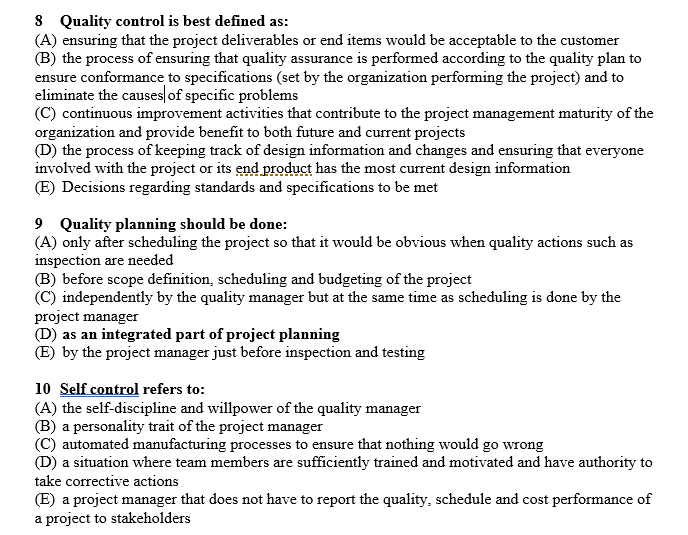

8. Quality Control

Quality control is a crucial step in the kitchen sink manufacturing process. Before the sink is packaged and shipped, it goes through a series of rigorous tests to ensure that it is of the highest quality. These tests include checking for leaks, measuring the sink's dimensions, and testing the finish for durability. Only sinks that pass all the tests are approved for packaging.

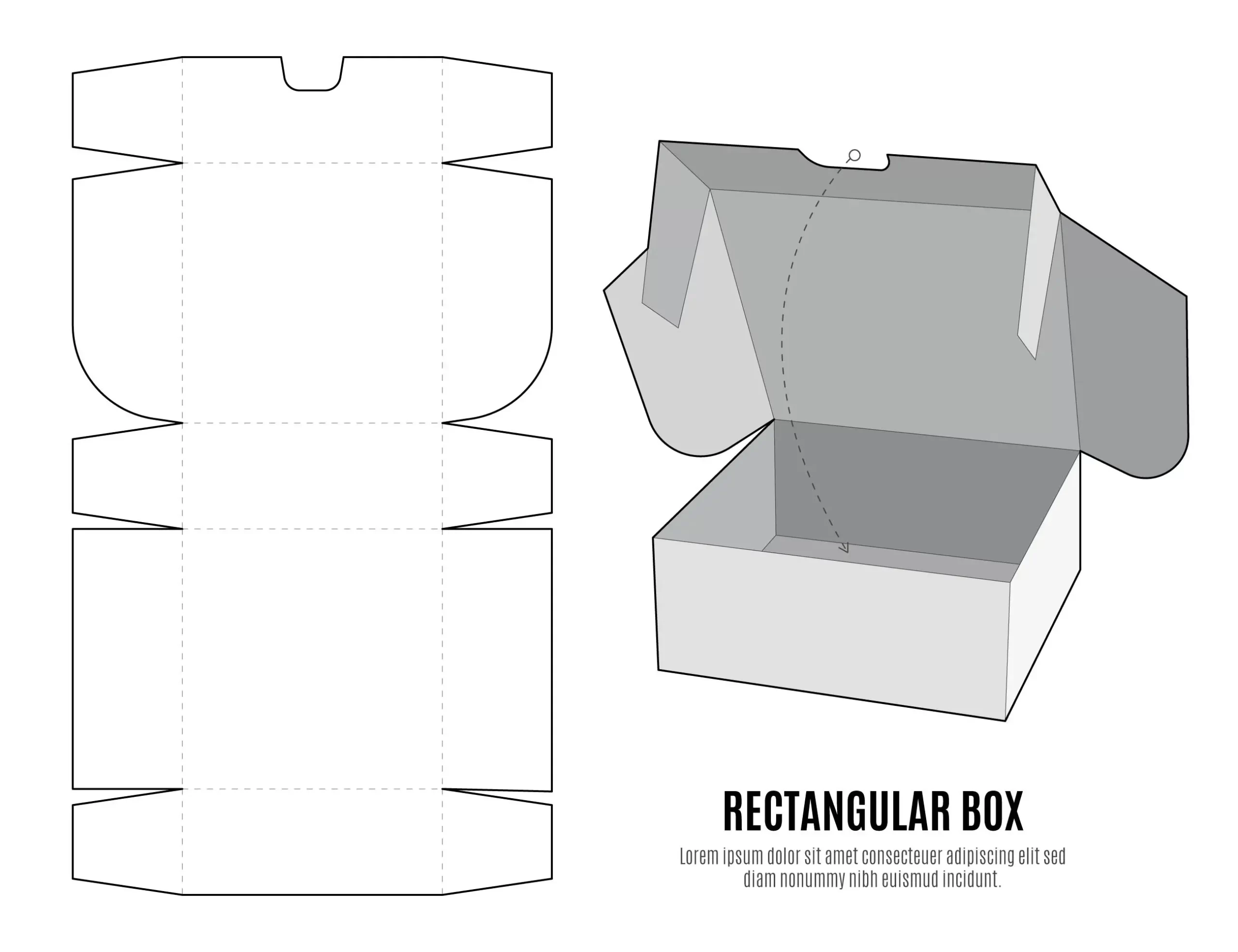

9. Packaging

Once the sink has passed quality control, it is then carefully packaged to prevent any damage during transportation. Most manufacturers use special packaging materials to protect the sink from scratches and dents. The sink is also wrapped in plastic to prevent any moisture from getting in and causing rust. Packaging is an important step in ensuring that the sink arrives at its destination in perfect condition.

10. Shipping

The final step in the kitchen sink manufacturing process is shipping. Once the sink has been packaged, it is loaded onto a truck or container and shipped to its final destination. This can be a local distributor or directly to a customer's home. Manufacturers take great care in shipping their sinks to ensure that they arrive safely and on time.

The process of manufacturing a kitchen sink involves a combination of precision, skill, and attention to detail. Each step is crucial in creating a high-quality and durable sink that will last for years to come. From casting to shipping, every aspect of the process is carefully monitored to ensure that the end product meets the highest standards of quality and craftsmanship.

The Importance of Quality Materials in Kitchen Sink Manufacturing Process

Kitchen sinks are an essential part of any household, serving as a functional and aesthetic centerpiece of the kitchen. While they may seem like a simple fixture, sink manufacturing is a complex process that requires high-quality materials and skilled craftsmanship. This is why it is crucial for homeowners to understand the significance of using quality materials in the kitchen sink manufacturing process.

The first step in the kitchen sink manufacturing process is selecting the right material. The most commonly used materials for kitchen sinks include stainless steel , porcelain , and granite composite . Each of these materials has its own unique properties and benefits, but one thing they all have in common is their durability. A high-quality sink material is essential as it will determine the longevity and functionality of your sink.

Another important aspect of the kitchen sink manufacturing process is the design and construction of the sink. A well-constructed sink will not only enhance the overall look of your kitchen but also ensure its functionality and ease of use. This is where the expertise of skilled craftsmen comes into play. They are responsible for creating the perfect balance between aesthetics and functionality, ensuring that the sink can withstand daily use and remain in top condition for years to come.

One of the main benefits of using quality materials in the kitchen sink manufacturing process is their resistance to corrosion and stains. A high-quality sink will not only maintain its shine and appearance but also be able to withstand harsh chemicals and hot water without getting damaged. This makes cleaning and maintaining the sink a breeze, allowing you to focus on other tasks in the kitchen.

Moreover, using quality materials in the kitchen sink manufacturing process also leads to a more sustainable and eco-friendly product. High-quality materials are less likely to be damaged or need replacement, reducing the amount of waste and resources needed for manufacturing. This not only benefits the environment but also saves homeowners money in the long run by avoiding frequent replacements.

In conclusion, the kitchen sink manufacturing process is a crucial aspect of house design that should not be overlooked. Using high-quality materials and skilled craftsmanship not only ensures a visually appealing sink but also guarantees its functionality and longevity. So, when considering a kitchen sink for your home, remember the importance of quality materials in creating a truly exceptional and durable product.