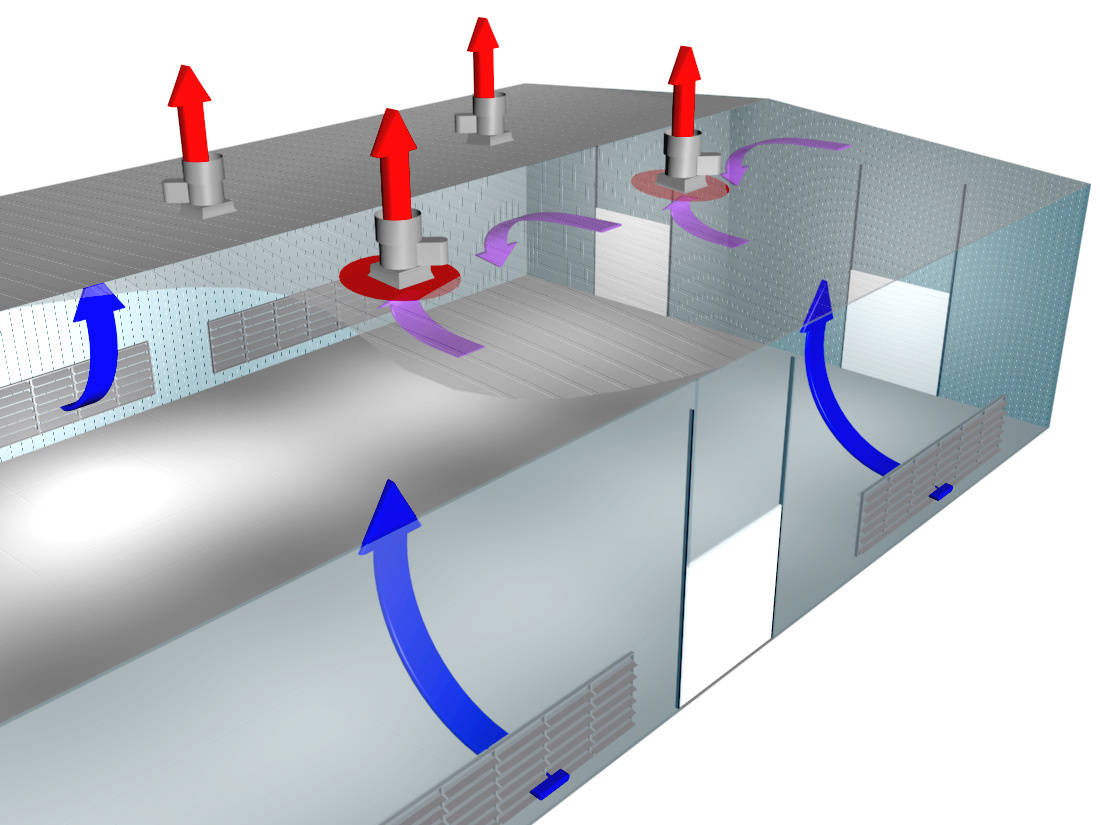

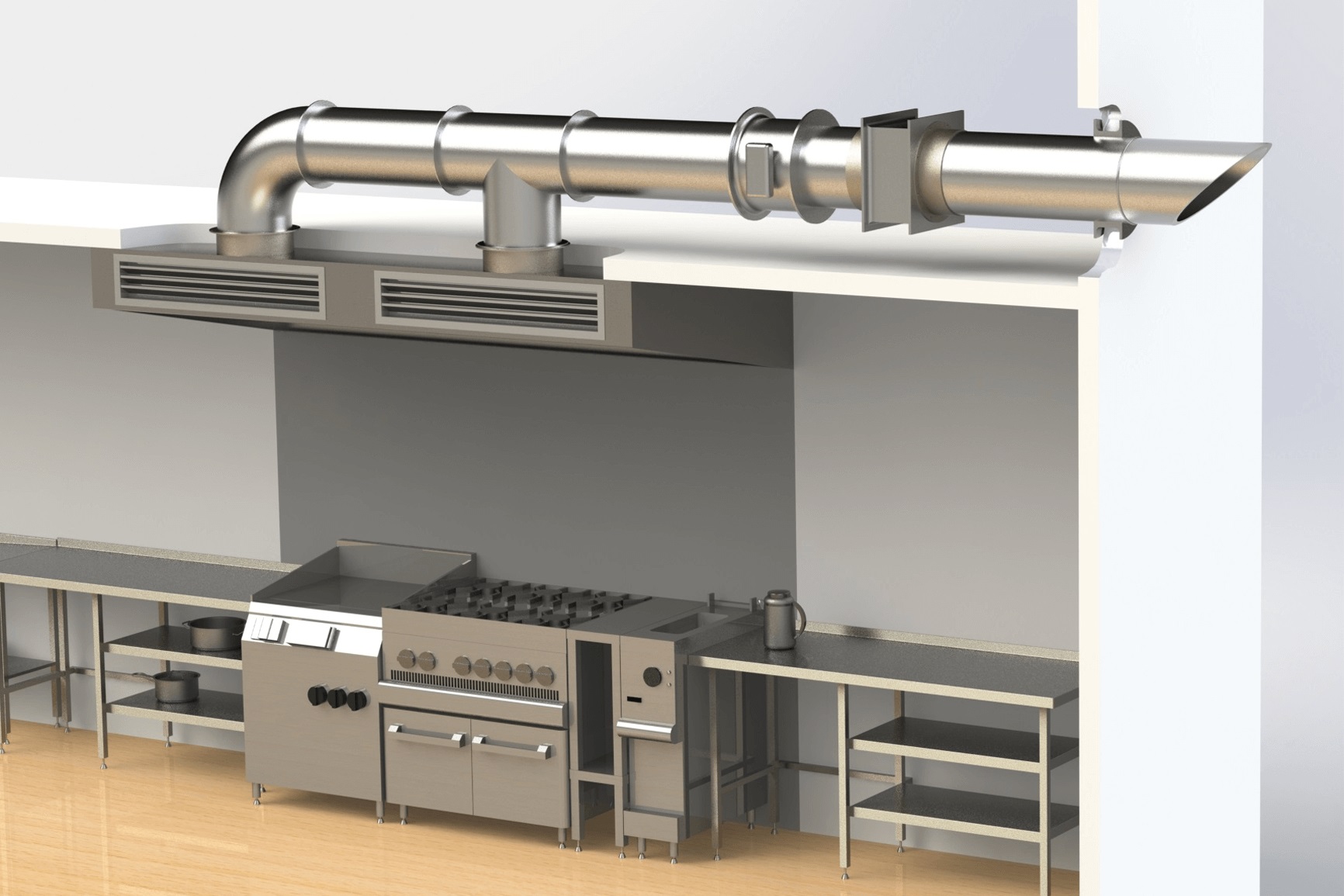

Industrial kitchens are known for their high heat and steam production, making proper ventilation a crucial aspect of their design. Without adequate ventilation, these kitchens can become uncomfortable and unsafe for workers, and can also lead to food contamination. Therefore, it is essential to incorporate effective ventilation systems into the design of industrial kitchens. The first step in ventilation design for industrial kitchens is understanding the layout and size of the space. This will help determine the type and size of ventilation system needed to effectively remove heat, smoke, and grease from the kitchen. It is also important to consider the type of cooking equipment and the volume of food being prepared, as these factors can affect the ventilation requirements.1. Ventilation Design for Industrial Kitchens

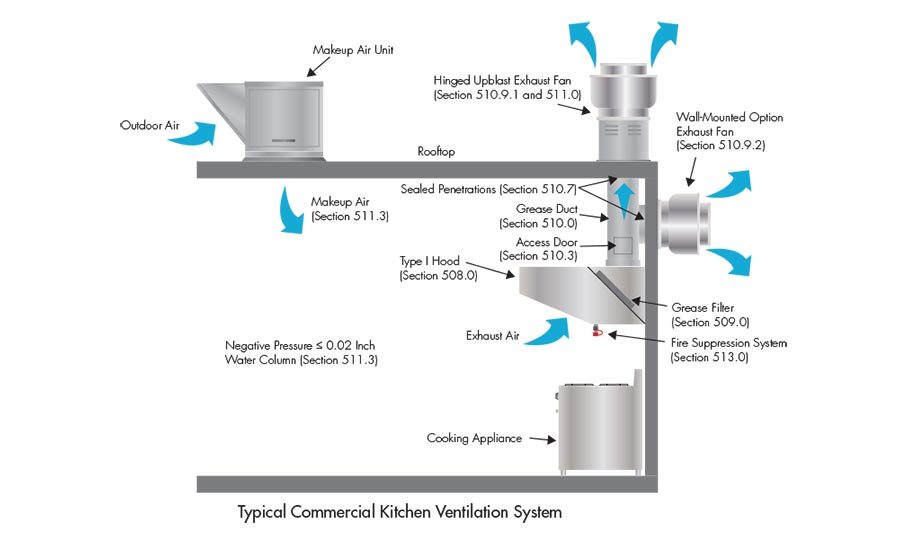

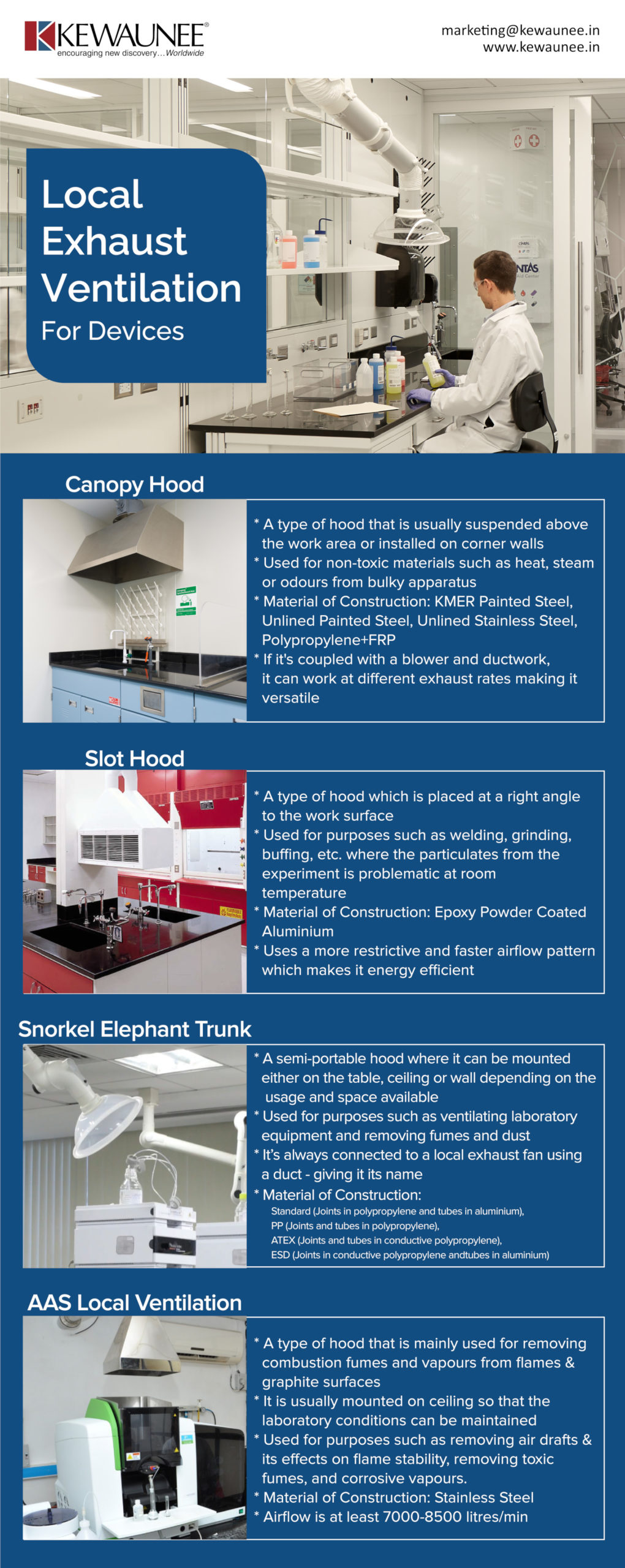

There are various types of ventilation systems that can be used in industrial kitchens, each with its own benefits and drawbacks. The most common type is a ventilation hood, which is typically installed above cooking equipment to remove heat, smoke, and grease from the air. Other options include exhaust fans, make-up air units, and air purification systems. It is important to choose a ventilation system that is properly sized for the kitchen and meets local building codes and regulations. It is also recommended to consult with a professional ventilation designer to ensure the system is designed and installed correctly for maximum efficiency and safety.2. Industrial Kitchen Ventilation Systems

When designing a ventilation system for an industrial kitchen, there are some best practices that should be followed to ensure optimal performance. One of the most important factors is proper placement of the ventilation hood. It should be located directly above the cooking equipment and extend at least 6 inches beyond the edges to effectively capture and remove smoke and grease. Additionally, regular maintenance and cleaning of the ventilation system is crucial to prevent buildup of grease and other contaminants, which can decrease its efficiency and increase fire hazards. It is also recommended to install fire suppression systems in the kitchen as an added safety measure.3. Best Practices for Industrial Kitchen Ventilation

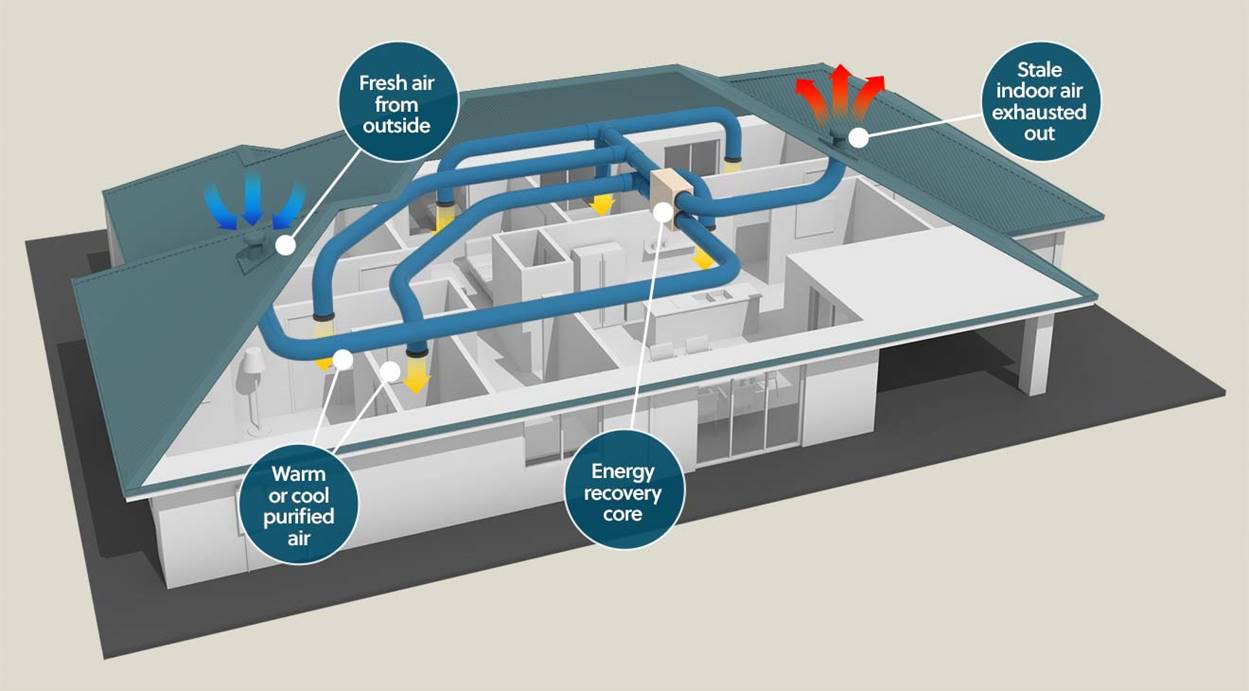

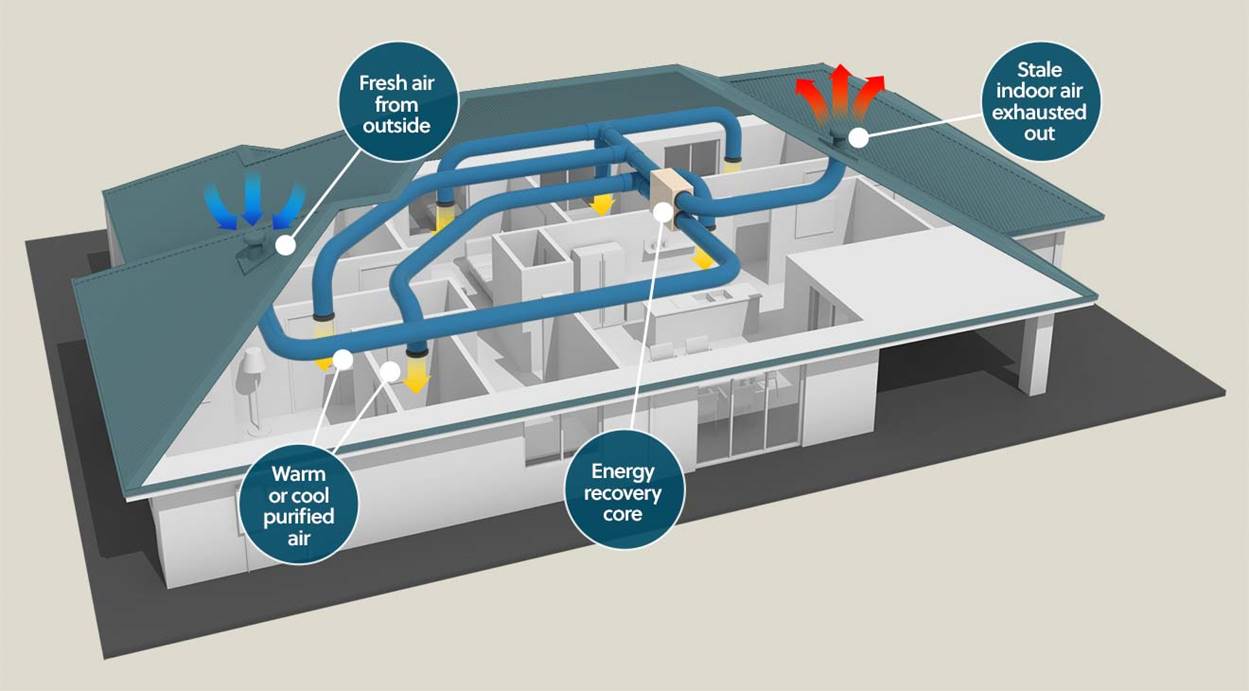

An efficient ventilation system is not only important for the comfort and safety of workers, but it can also save energy and reduce operating costs. One way to increase efficiency is by incorporating variable speed controls for the ventilation system. This allows for adjusting the fan speed based on the cooking load, rather than running at full speed constantly. Another way to improve efficiency is by using energy-efficient equipment, such as LED lights and low-flow water fixtures, which can reduce the heat load in the kitchen and decrease the ventilation requirements. Proper insulation and sealing of the kitchen space can also help reduce the workload on the ventilation system.4. Designing an Efficient Industrial Kitchen Ventilation System

Proper ventilation is crucial for the health and safety of workers in industrial kitchens. Without proper ventilation, workers can be exposed to high levels of heat, fumes, and grease, which can lead to heat exhaustion, respiratory issues, and other health problems. It can also create an uncomfortable and unpleasant working environment, affecting morale and productivity. Moreover, proper ventilation is essential for food safety. Without adequate removal of smoke and grease, these contaminants can settle on food, causing contamination and potential health hazards for consumers. This can also lead to costly recalls and damage to the reputation of the kitchen.5. Importance of Proper Ventilation in Industrial Kitchens

When designing a ventilation system for an industrial kitchen, there are several factors that should be taken into consideration. These include the type and volume of cooking being done, the layout and size of the kitchen, local building codes and regulations, and the budget for the project. It is also important to consider the noise level of the ventilation system, as it can affect the comfort and productivity of workers. Choosing a system with low noise levels can help create a more pleasant working environment.6. Factors to Consider in Industrial Kitchen Ventilation Design

As mentioned earlier, there are various types of ventilation systems that can be used in industrial kitchens. The most common type is a ventilation hood, which can be classified as either a canopy hood or an extractor hood. Canopy hoods are typically used for low-volume cooking and are mounted above the cooking equipment, while extractor hoods are typically used for high-volume cooking and are mounted above the cookline. Other types of ventilation systems include exhaust fans, which can be wall-mounted or roof-mounted, and make-up air units, which are used to replace the air being removed by the exhaust system. Air purification systems, such as UV-C light systems, can also be used to remove contaminants from the air.7. Types of Ventilation Systems for Industrial Kitchens

Energy efficiency is a top priority for many businesses, and industrial kitchens are no exception. With the high energy consumption of cooking equipment and ventilation systems, finding energy-efficient solutions is crucial to reduce operating costs and environmental impact. One solution is to use demand-controlled ventilation (DCV) systems, which adjust the ventilation rate based on the cooking load. This can significantly reduce energy consumption and improve the overall efficiency of the system. Energy-efficient lighting and water fixtures can also be incorporated into the design to further reduce the heat load in the kitchen.8. Energy-Efficient Solutions for Industrial Kitchen Ventilation Design

Even with the best intentions, mistakes can happen in the design and installation of industrial kitchen ventilation systems. One common mistake is improper sizing of the ventilation system, which can result in inadequate removal of heat and contaminants from the kitchen. Another mistake is not considering the placement of the ventilation hood in relation to the cooking equipment, which can result in poor capture and removal of smoke and grease. It is also important to regularly maintain and clean the ventilation system to prevent buildup of grease and other contaminants.9. Common Mistakes in Industrial Kitchen Ventilation Design

Industrial kitchen ventilation design must comply with local building codes and regulations, which can vary depending on the location. These codes and regulations are in place to ensure the safety and well-being of workers and consumers, and to prevent fire hazards in the kitchen. It is important to consult with a professional ventilation designer who is knowledgeable about these codes and regulations to ensure the system is designed and installed correctly. Failure to comply with these regulations can result in costly fines and potentially dangerous situations in the kitchen.10. Regulations and Codes for Industrial Kitchen Ventilation Design

The Importance of Proper Industrial Kitchen Ventilation Design

Ensuring the Safety of Your Kitchen and Employees

When it comes to industrial kitchen design, ensuring proper ventilation is crucial for the safety of your kitchen and employees. Industrial kitchens are known for producing large amounts of heat, smoke, and grease, which can all be hazardous if not properly ventilated. Without proper ventilation, these elements can build up and create a dangerous environment for both your kitchen equipment and employees.

Proper Ventilation Protects Your Equipment

One of the main reasons for having a well-designed ventilation system in your industrial kitchen is to protect your equipment. The high temperatures and humidity levels in a kitchen can cause damage to your appliances, leading to costly repairs or replacements. By having proper ventilation, you can prevent excess heat and moisture from building up, keeping your equipment in good working condition.

Preventing the Build-Up of Grease and Smoke

In a busy industrial kitchen, grease and smoke are inevitable byproducts of cooking. Without proper ventilation, these elements can build up on your walls, ceilings, and kitchen equipment, creating a fire hazard. The accumulation of grease can also lead to unpleasant odors and potentially harmful bacteria. By having a well-designed ventilation system, you can effectively remove grease and smoke from your kitchen, reducing the risk of fire and ensuring a cleaner and safer environment for your employees.

Complying with Health and Safety Regulations

In addition to protecting your equipment and employees, having proper ventilation in your industrial kitchen is necessary to comply with health and safety regulations. These regulations require commercial kitchens to have a ventilation system that meets specific standards to ensure the health and safety of everyone in the kitchen. Failure to comply with these regulations can result in fines, closure of your kitchen, and even legal action.

When it comes to industrial kitchen design, ensuring proper ventilation is crucial for the safety of your kitchen and employees. Industrial kitchens are known for producing large amounts of heat, smoke, and grease, which can all be hazardous if not properly ventilated. Without proper ventilation, these elements can build up and create a dangerous environment for both your kitchen equipment and employees.

Proper Ventilation Protects Your Equipment

One of the main reasons for having a well-designed ventilation system in your industrial kitchen is to protect your equipment. The high temperatures and humidity levels in a kitchen can cause damage to your appliances, leading to costly repairs or replacements. By having proper ventilation, you can prevent excess heat and moisture from building up, keeping your equipment in good working condition.

Preventing the Build-Up of Grease and Smoke

In a busy industrial kitchen, grease and smoke are inevitable byproducts of cooking. Without proper ventilation, these elements can build up on your walls, ceilings, and kitchen equipment, creating a fire hazard. The accumulation of grease can also lead to unpleasant odors and potentially harmful bacteria. By having a well-designed ventilation system, you can effectively remove grease and smoke from your kitchen, reducing the risk of fire and ensuring a cleaner and safer environment for your employees.

Complying with Health and Safety Regulations

In addition to protecting your equipment and employees, having proper ventilation in your industrial kitchen is necessary to comply with health and safety regulations. These regulations require commercial kitchens to have a ventilation system that meets specific standards to ensure the health and safety of everyone in the kitchen. Failure to comply with these regulations can result in fines, closure of your kitchen, and even legal action.

Final Thoughts

In conclusion, proper ventilation design is a crucial aspect of industrial kitchen design. It not only protects your equipment and employees but also ensures compliance with health and safety regulations. If you're in the process of designing or renovating your industrial kitchen, be sure to prioritize a well-designed ventilation system to create a safe and healthy environment for your kitchen and employees.

In conclusion, proper ventilation design is a crucial aspect of industrial kitchen design. It not only protects your equipment and employees but also ensures compliance with health and safety regulations. If you're in the process of designing or renovating your industrial kitchen, be sure to prioritize a well-designed ventilation system to create a safe and healthy environment for your kitchen and employees.