Foam mattresses have become increasingly popular in recent years due to their comfort, support, and durability. However, have you ever wondered how they are made? In this article, we will take a closer look at the top 10 main steps in the foam mattress manufacturing process. From the production to the shipping, we will explore each step in detail. So, let's dive in! Introduction

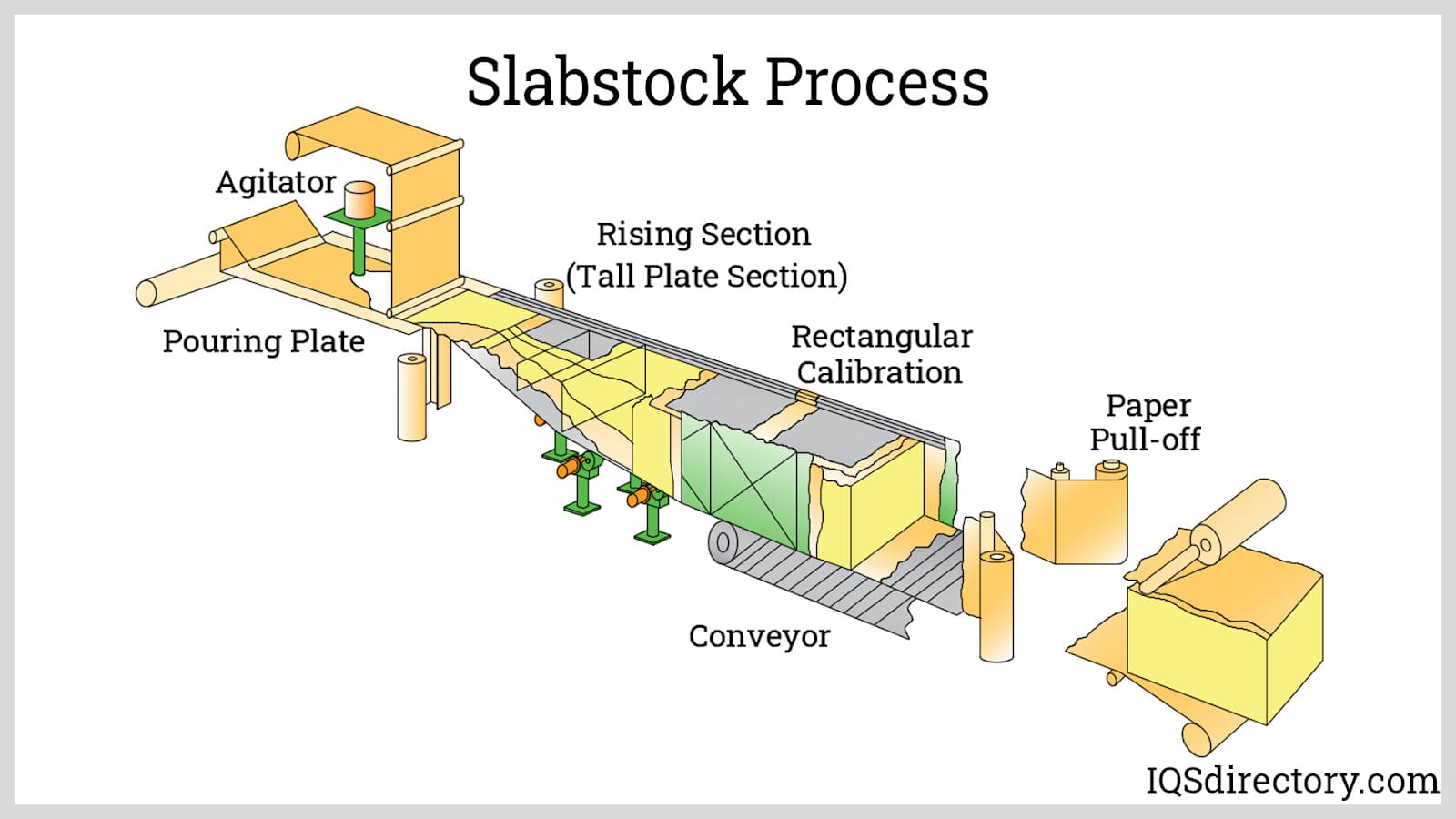

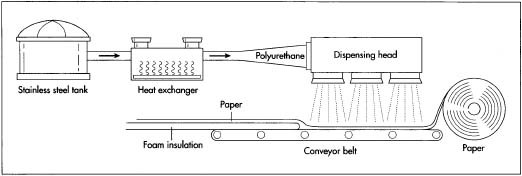

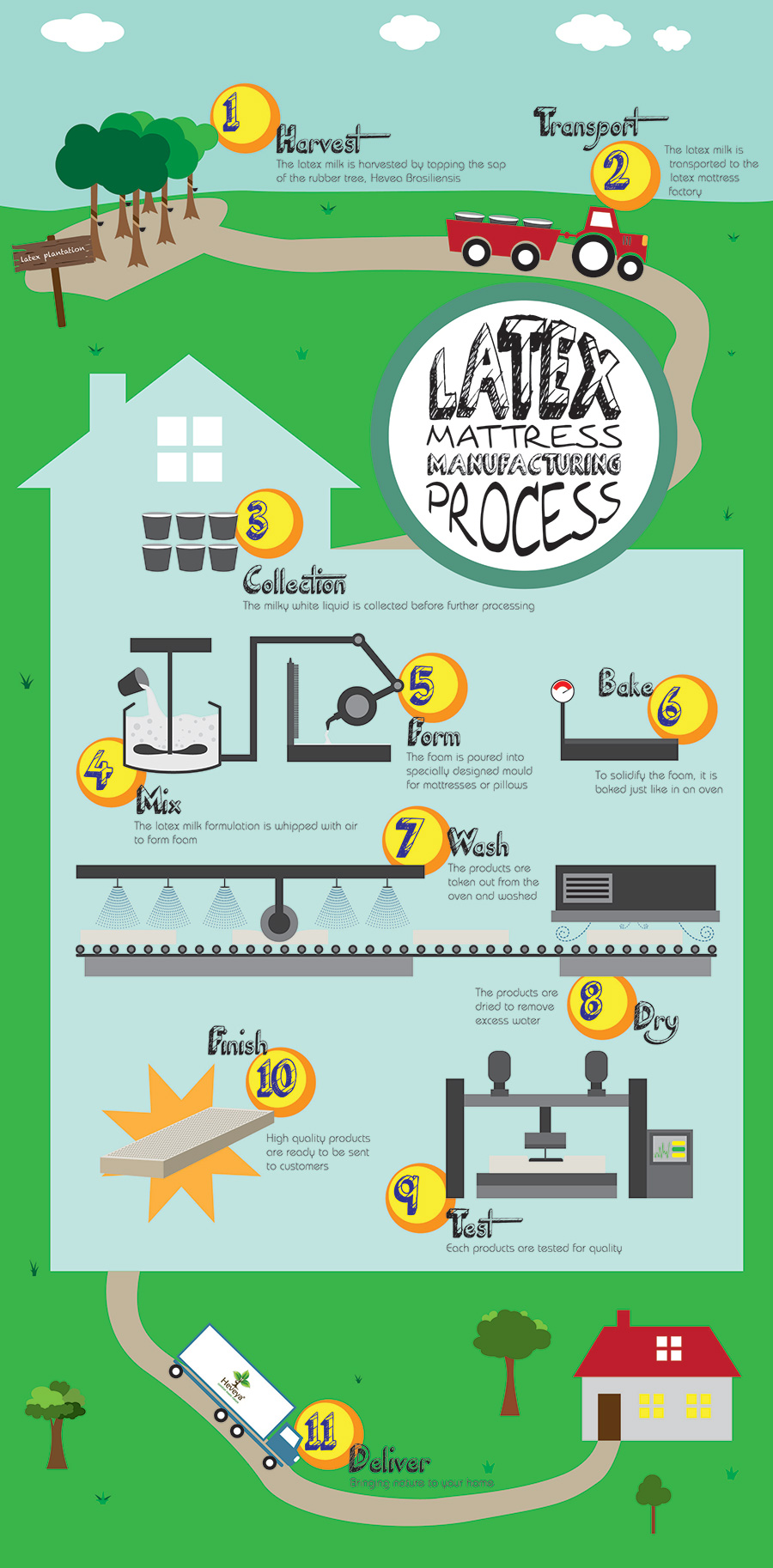

The first step in the foam mattress manufacturing process is the production of the foam itself. High-quality foam is crucial for a comfortable and supportive mattress. The foam is made from various materials, such as polyurethane, memory foam, or latex, depending on the type of mattress being produced. The foam is mixed with water and other chemicals to create a liquid, which is then poured into molds to form the desired shape and size of the mattress. Foam Mattress Manufacturing Process

Once the foam is poured into the molds, it is left to cure for a specific amount of time. This process allows the foam to expand and take on its final shape. The time needed for curing varies depending on the type and density of the foam, but it usually takes a few hours. After the curing process is complete, the foam is removed from the molds and ready for the next steps. Foam Mattress Production

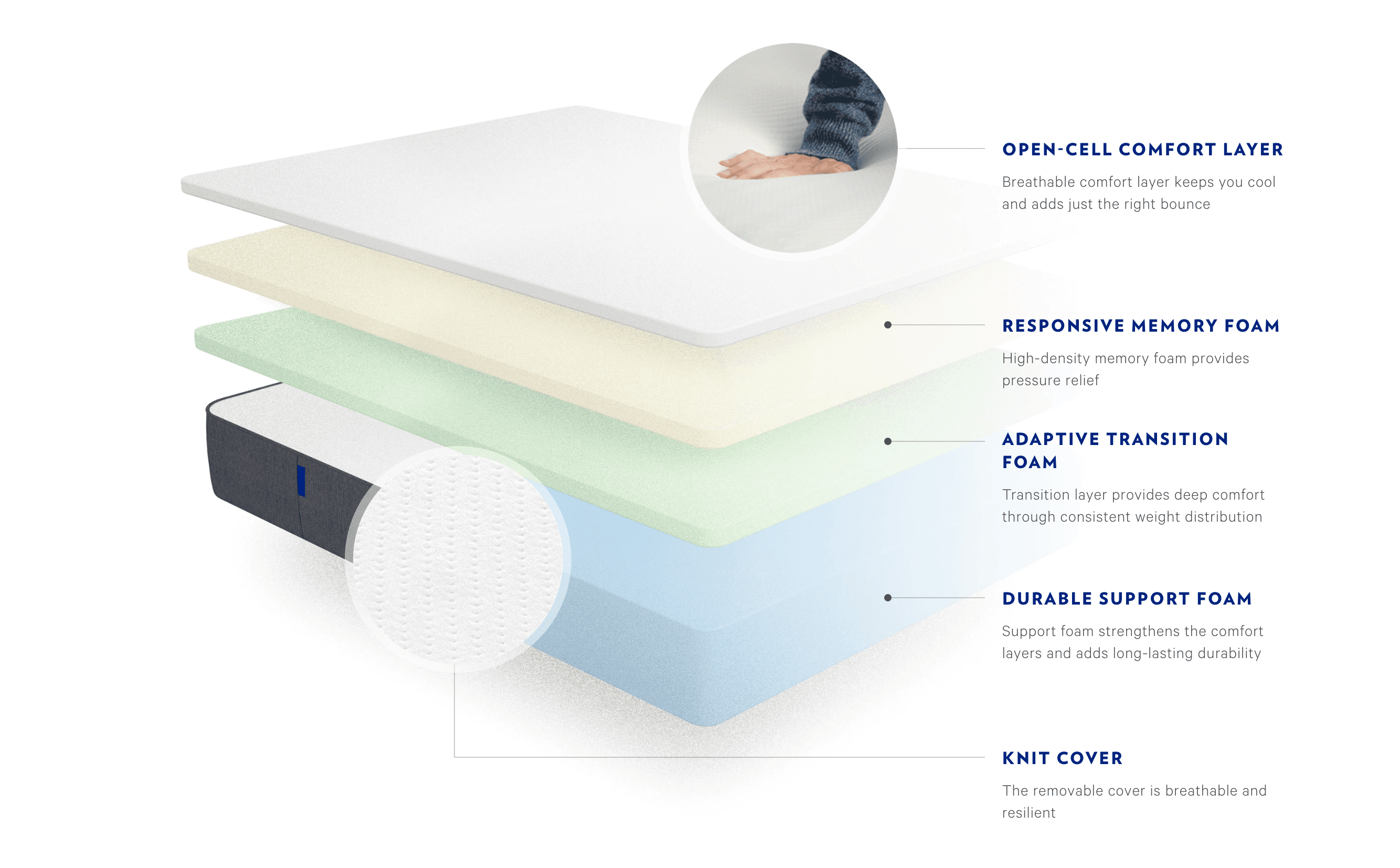

After the production of the foam, the next step is to assemble the mattress. This involves layering different types of foam, such as memory foam, gel foam, and support foam, to create the desired level of comfort and support. The layers are carefully placed on top of each other and then glued together to ensure they stay in place. Foam Mattress Assembly

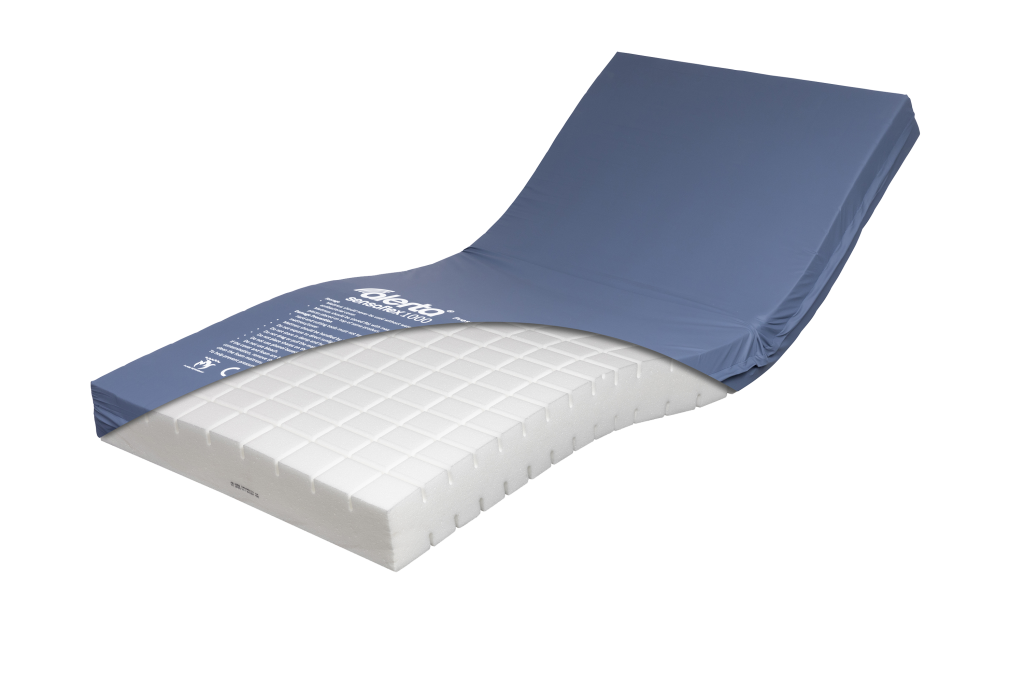

In addition to foam, there are other materials used in the manufacturing of foam mattresses. These materials include fabric, thread, zippers, and labels. The fabric is used to cover the foam and create the outer layer of the mattress. The thread is used to stitch the fabric together, while the zippers allow for easy removal and washing of the cover. Labels are also attached to provide important information, such as the size and type of mattress. Foam Mattress Materials

Once the foam layers are assembled, the mattress is ready to be cut to its final shape and size. This is done using specialized cutting machines that ensure precision and accuracy. The foam is cut according to the dimensions of the mattress, and any excess foam is trimmed off. This step is crucial in creating a perfectly fitting mattress. Foam Mattress Cutting

After the foam is cut, the next step is to glue the layers together. This is done using a special adhesive that is safe and non-toxic. The glue is applied to the edges of the foam layers and then pressed together to create a strong bond. This process ensures that the layers stay in place and do not shift or bunch up over time. Foam Mattress Gluing

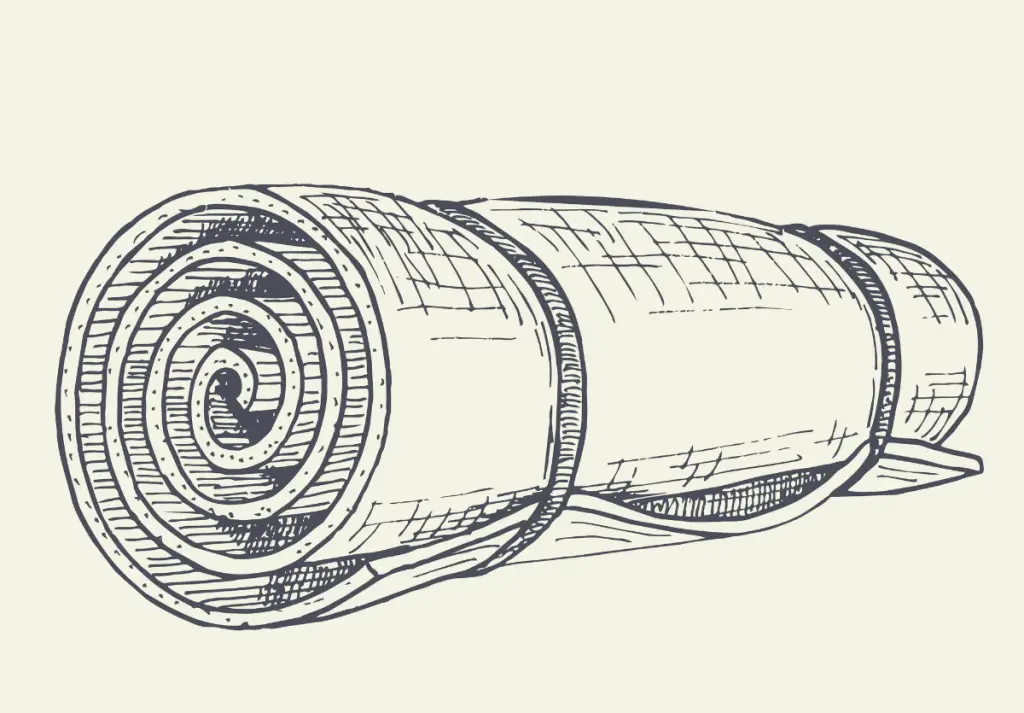

Once the foam layers are glued together, the mattress is compressed to reduce its size for shipping and storage purposes. This is done using a machine that compresses the mattress to a fraction of its original size. The compressed mattress is then rolled up and tightly wrapped in plastic for protection. This step is crucial in reducing shipping costs and making it easier to transport the mattresses. Foam Mattress Compression

After the compression process is complete, the mattress is ready to be packaged for shipping. The rolled-up mattress is placed in a box or plastic bag and sealed for protection. Labels are attached to the packaging, providing important information, such as the size, type, and brand of the mattress. The packaging is also designed to protect the mattress during transportation and storage. Foam Mattress Packaging

Before the mattresses are shipped out, they undergo a thorough quality control process. This involves checking for any defects or imperfections in the foam, stitching, and packaging. Any issues found are addressed and corrected before the mattresses are approved for shipping. This step ensures that customers receive a high-quality product that meets their expectations. Foam Mattress Quality Control

The Importance of a Quality Foam Mattress in House Design

The Role of a Foam Mattress in Promoting Good Sleep and Health

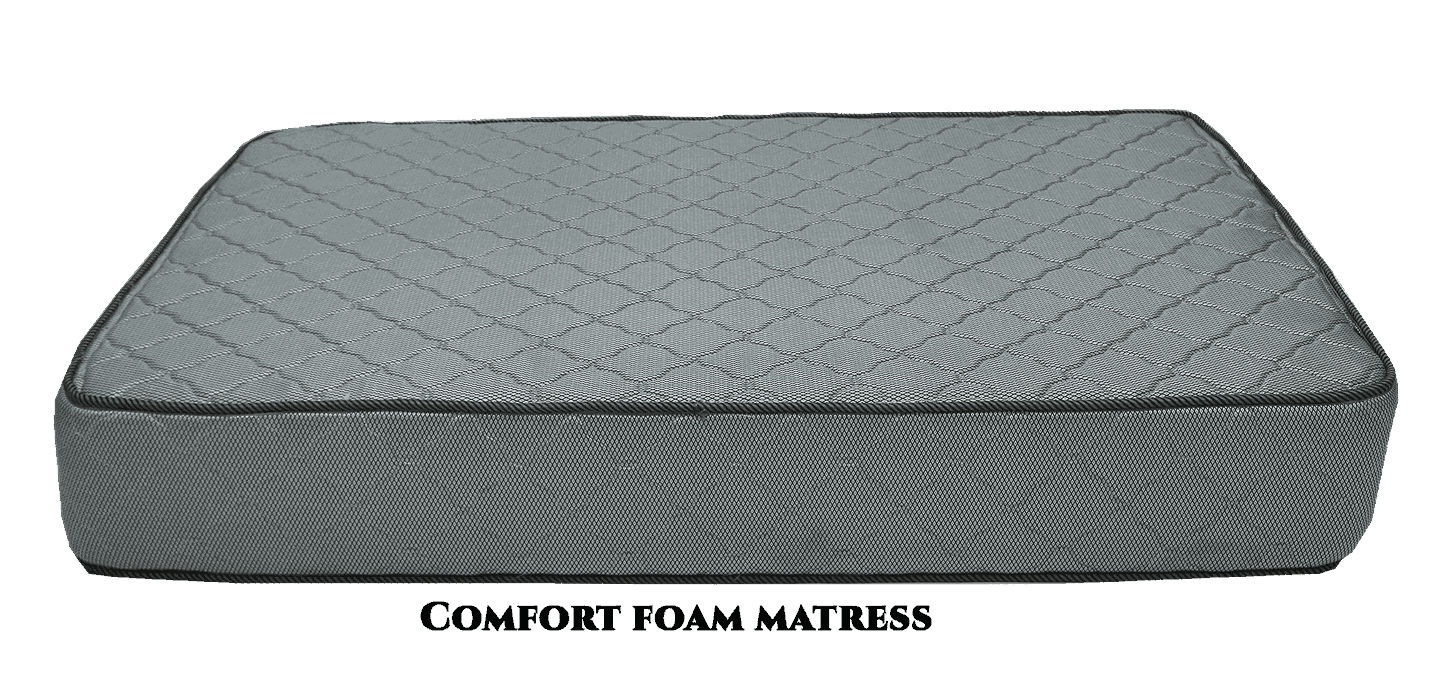

When it comes to designing a house, one of the most important aspects that should not be overlooked is the choice of mattress. After all, a good night's sleep is crucial for maintaining good health and overall well-being. This is where a high-quality

foam mattress

comes into play. Not only does it provide support and comfort for the body, but it also plays a crucial role in ensuring a restful and rejuvenating sleep.

When it comes to designing a house, one of the most important aspects that should not be overlooked is the choice of mattress. After all, a good night's sleep is crucial for maintaining good health and overall well-being. This is where a high-quality

foam mattress

comes into play. Not only does it provide support and comfort for the body, but it also plays a crucial role in ensuring a restful and rejuvenating sleep.

The Manufacturing Process of Foam Mattresses

Foam mattresses are made using a process called

polyurethane foam

molding. It starts with a liquid foam mixture being poured into a mold that is the desired shape and size of the mattress. The foam is then left to expand and set in the mold, creating a solid and supportive base. This process allows for the customization of various foam layers, each with different densities and thicknesses, to provide the perfect balance of comfort and support.

Foam mattresses are made using a process called

polyurethane foam

molding. It starts with a liquid foam mixture being poured into a mold that is the desired shape and size of the mattress. The foam is then left to expand and set in the mold, creating a solid and supportive base. This process allows for the customization of various foam layers, each with different densities and thicknesses, to provide the perfect balance of comfort and support.

The Benefits of a Foam Mattress in House Design

Aside from promoting better sleep and overall health, a foam mattress also has many benefits when it comes to house design.

Memory foam mattresses

, for example, are known for their ability to conform to the body's shape, providing personalized support and pressure relief. This is especially beneficial for individuals with back or joint pain, as the foam helps to alleviate pressure points and promote proper spinal alignment.

Moreover, foam mattresses are also a popular choice for house design due to their durability. High-quality foam mattresses are designed to last for many years, making them a cost-effective investment for homeowners. They are also hypoallergenic, making them a great option for those with allergies or sensitivities.

Aside from promoting better sleep and overall health, a foam mattress also has many benefits when it comes to house design.

Memory foam mattresses

, for example, are known for their ability to conform to the body's shape, providing personalized support and pressure relief. This is especially beneficial for individuals with back or joint pain, as the foam helps to alleviate pressure points and promote proper spinal alignment.

Moreover, foam mattresses are also a popular choice for house design due to their durability. High-quality foam mattresses are designed to last for many years, making them a cost-effective investment for homeowners. They are also hypoallergenic, making them a great option for those with allergies or sensitivities.

In Conclusion

In conclusion, when it comes to house design, a

foam mattress

is a crucial element that should not be overlooked. Not only does it play a vital role in promoting good sleep and overall health, but it also has numerous benefits that make it a top choice for homeowners. So when designing your dream house, be sure to choose a high-quality foam mattress for the ultimate comfort and support.

In conclusion, when it comes to house design, a

foam mattress

is a crucial element that should not be overlooked. Not only does it play a vital role in promoting good sleep and overall health, but it also has numerous benefits that make it a top choice for homeowners. So when designing your dream house, be sure to choose a high-quality foam mattress for the ultimate comfort and support.

.jpg?fit=fill&bg=0FFF&w=1500&h=1000&auto=format,compress)