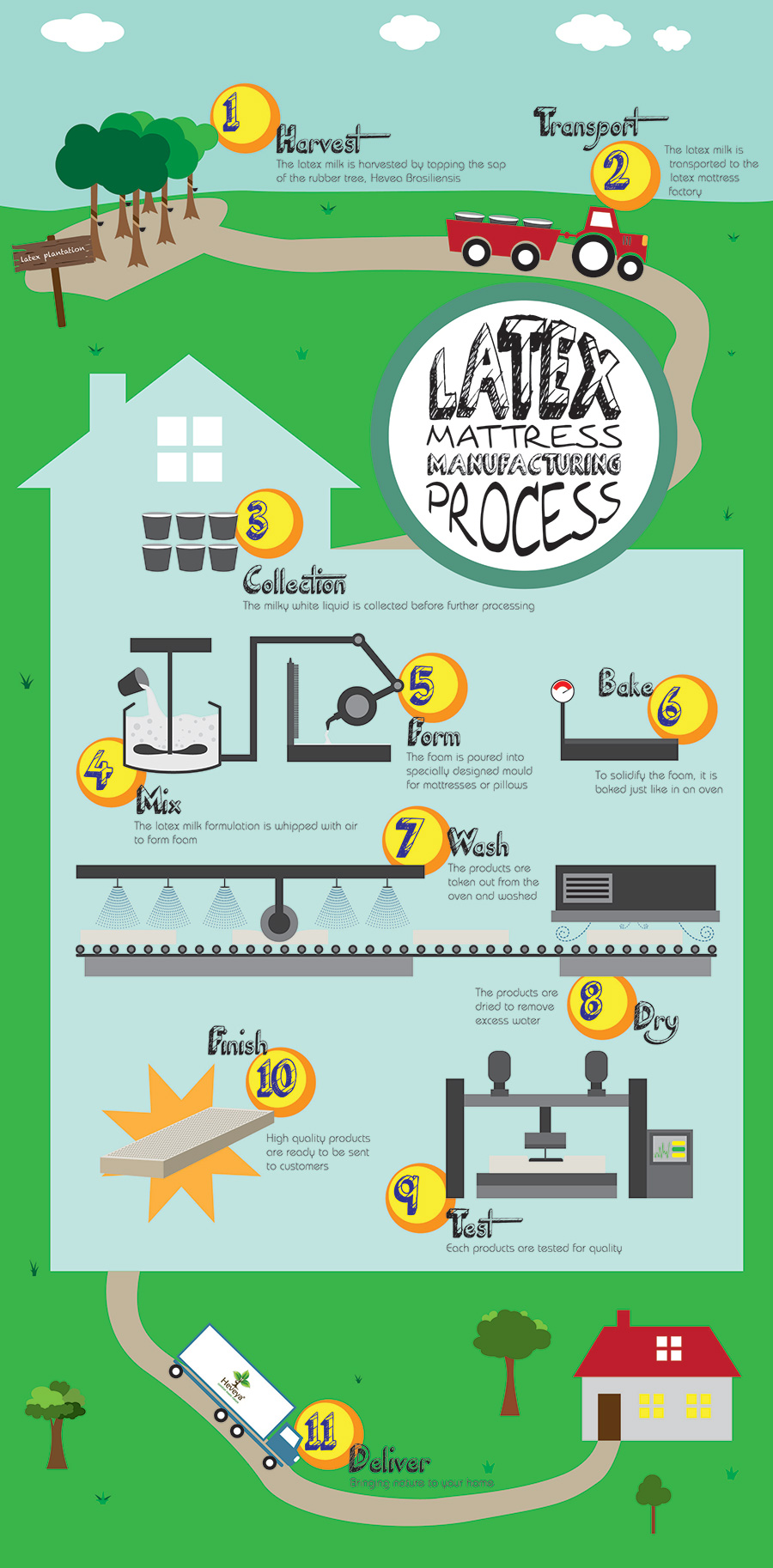

The process of manufacturing a mattress may seem simple at first, but there are actually many steps involved in creating the perfect sleeping surface. From selecting the right materials to assembling the final product, there is a lot that goes into the process. Let's take a closer look at how a mattress is made. First, the raw materials are carefully chosen to ensure the highest quality and comfort. This includes materials such as foam, cotton, and springs. Each material plays a crucial role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This is where the real magic happens. The different layers of foam, cotton, and springs are strategically placed and bonded together to create the perfect balance of comfort and support. After the materials are assembled, the mattress is then sewn and stitched together. This is done with precision and care to ensure that the mattress will last for years to come. The stitching also adds to the overall durability and stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall aesthetics. The mattress is then inspected for any imperfections and packaged for shipping. As you can see, the mattress manufacturing process is a complex and intricate one. Every step is carefully thought out and executed to create the perfect sleeping surface. So the next time you lay down on your mattress, you can appreciate all the hard work and craftsmanship that went into creating it.1. Mattress Manufacturing Process: How a Mattress is Made

The process of manufacturing a mattress involves several stages, each crucial in creating a comfortable and supportive sleeping surface. Let's take a closer look at each step of the process. The first step is selecting the right materials. This includes choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a vital role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. In conclusion, the manufacturing process of a mattress requires careful selection of materials, precise cutting and assembly, and attention to detail in the finishing stages. This results in a high-quality and comfortable mattress that will provide you with a good night's sleep for years to come.2. The Manufacturing Process of a Mattress

Have you ever wondered how a mattress is made? The process may seem simple, but there are actually many steps involved in creating the perfect sleeping surface. Here is a step-by-step guide to mattress manufacturing. The first step is selecting the right materials. This includes choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a vital role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. By following these steps, the result is a high-quality and comfortable mattress that is ready to provide you with a good night's sleep.3. Step-by-Step Guide to Mattress Manufacturing

The process of manufacturing a bed mattress involves multiple stages, each crucial in creating a comfortable and supportive sleeping surface. Let's take a closer look at the different stages of the bed mattress manufacturing process. The first stage is selecting the right materials. This includes choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a vital role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. Understanding the bed mattress manufacturing process can help you appreciate the amount of thought and craftsmanship that goes into creating a high-quality and comfortable mattress.4. Understanding the Bed Mattress Manufacturing Process

The process of manufacturing a mattress may seem simple, but there are actually many intricate steps involved. Let's take a closer look at the ins and outs of mattress manufacturing. The first step is selecting the right materials. This involves carefully choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a crucial role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. The ins and outs of mattress manufacturing involve attention to detail and precision to create a high-quality and comfortable sleeping surface.5. The Ins and Outs of Mattress Manufacturing

Have you ever wondered how a mattress is made? It's a complex process that involves transforming raw materials into a comfortable and supportive sleeping surface. Let's take a closer look at the mattress manufacturing process. The first step is selecting the right materials. This involves carefully choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a crucial role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. The mattress manufacturing process involves transforming raw materials into a comfortable and supportive sleeping surface, and it's a true testament to the art and science of crafting a high-quality mattress.6. From Raw Materials to Finished Product: The Mattress Manufacturing Process

The process of manufacturing a mattress involves a combination of art and science. While the design and engineering of a mattress require creativity and skill, there is also a science behind the process. Let's take a closer look at the science behind mattress manufacturing. The first step is selecting the right materials. This involves carefully choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a crucial role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the science comes into play. The materials are precisely measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. The science behind mattress manufacturing ensures that the final product is not only comfortable but also supportive and durable.7. The Science Behind Mattress Manufacturing

The process of manufacturing a mattress involves several stages, each crucial in creating a comfortable and supportive sleeping surface. Let's take a closer look at the different stages of mattress manufacturing. The first stage is selecting the right materials. This includes choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a vital role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support. Once the materials are cut, they are then assembled together. This involves layering the different materials in a specific order to create the ideal balance of comfort and support. The materials are bonded together to ensure they stay in place and provide a consistent sleeping surface. After the materials are assembled, the mattress is then stitched and sewn together. This is done with precision and care to create a strong and durable final product. The stitching also adds to the overall stability of the mattress. Finally, the finishing touches are added. This includes adding the cover, which not only protects the mattress but also adds to the overall appearance. The mattress is then inspected for any defects and packaged for shipping. Exploring the different stages of mattress manufacturing allows us to appreciate the amount of effort and attention to detail that goes into creating a high-quality and comfortable mattress.8. Exploring the Different Stages of Mattress Manufacturing

Creating a quality mattress is both an art and a science. It takes creativity, skill, and precision to craft a comfortable and supportive sleeping surface. Let's take a closer look at the art of crafting a quality mattress through the manufacturing process. The first step is selecting the right materials. This involves carefully choosing the type of foam, cotton, and springs that will be used in the mattress. Each material has its own unique properties and plays a crucial role in the overall construction of the mattress. Next, the materials are cut and shaped to the desired size and shape. This is where the design and engineering of the mattress come into play. The materials are carefully measured and cut to ensure a perfect fit and maximum support.9. The Art of Crafting a Quality Mattress: The Manufacturing Process

The Importance of a High-Quality Mattress in House Design

Why the Right Mattress Matters

When designing a house, many people may focus on the aesthetics and functionality of the furniture and decor, but one crucial element that is often overlooked is the mattress. However, the mattress is the foundation of a good night's sleep and plays a significant role in our overall health and well-being. Therefore, choosing the right mattress is a vital part of the house design process.

When designing a house, many people may focus on the aesthetics and functionality of the furniture and decor, but one crucial element that is often overlooked is the mattress. However, the mattress is the foundation of a good night's sleep and plays a significant role in our overall health and well-being. Therefore, choosing the right mattress is a vital part of the house design process.

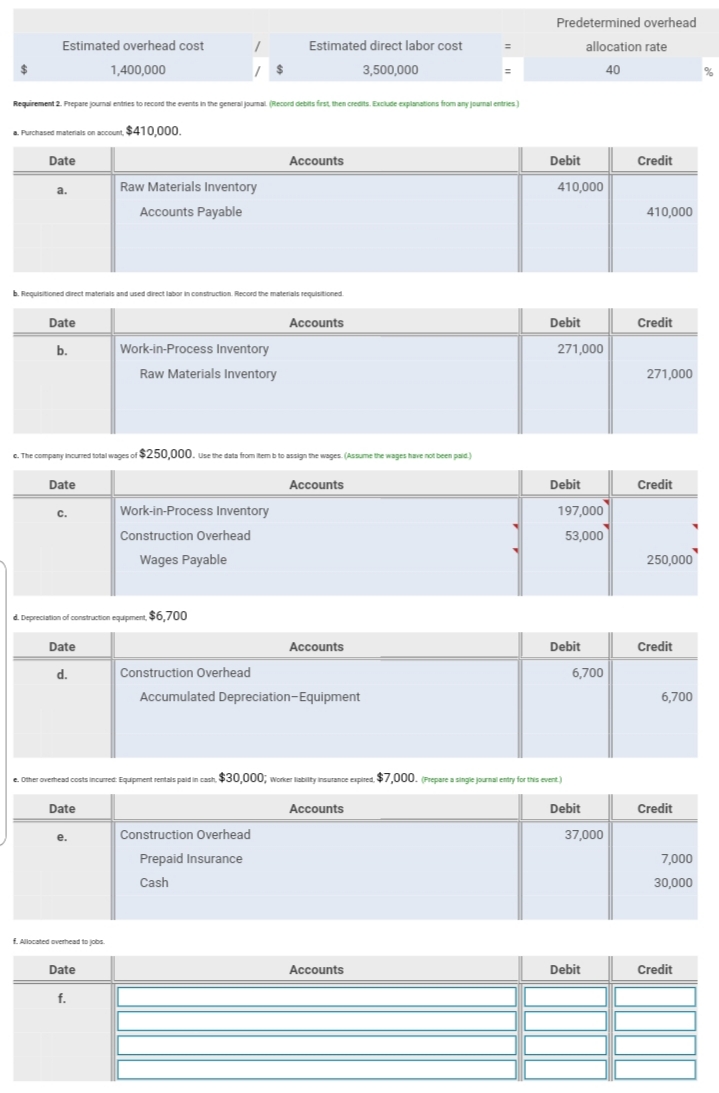

The Manufacturing Process

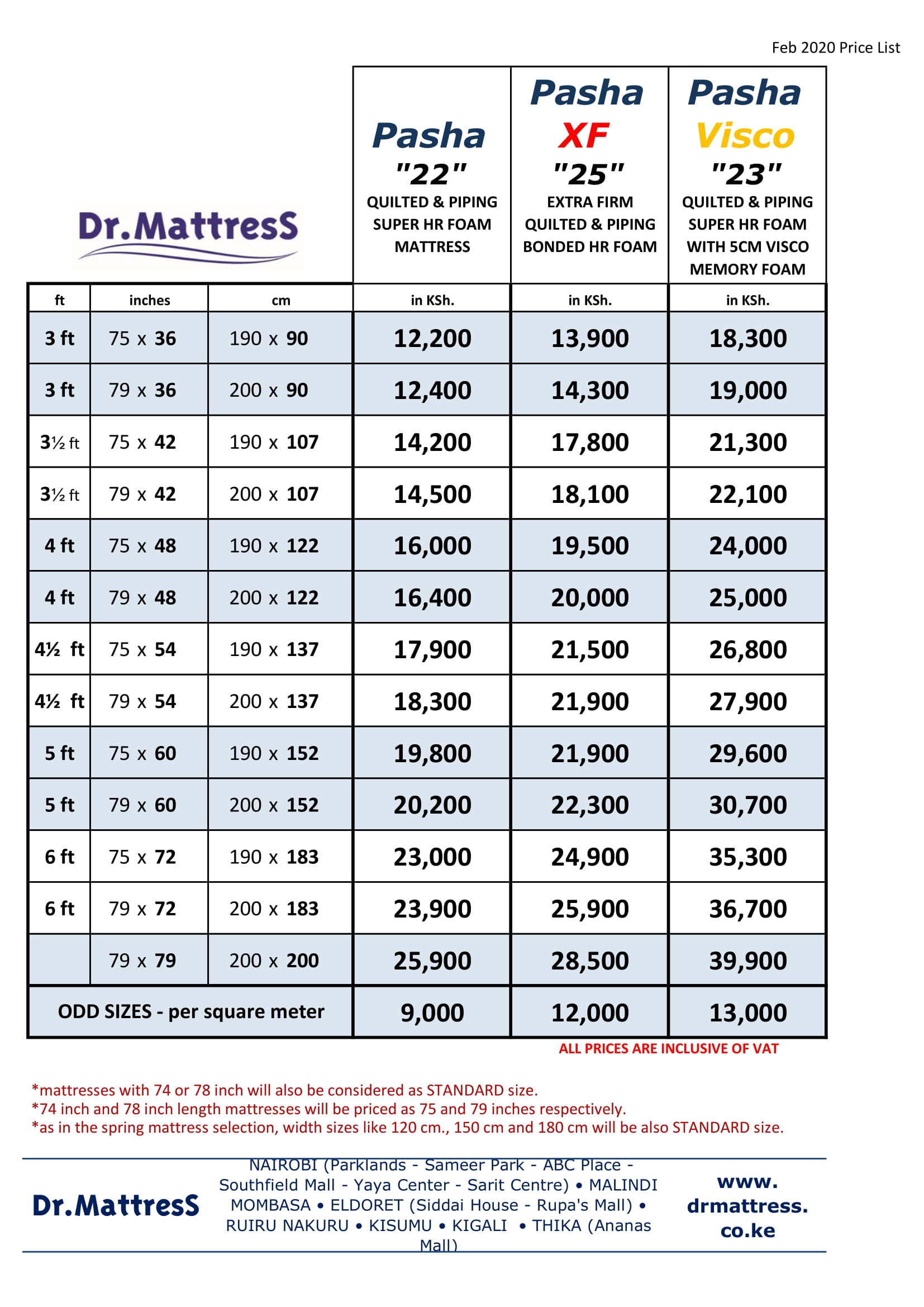

The manufacturing process of a mattress is a complex and intricate one, involving several steps and techniques to ensure the final product is of the highest quality. It starts with selecting the right materials, such as high-density foam, springs, and natural fibers, to provide comfort, support, and durability. These materials are then cut and shaped according to the desired size and shape of the mattress.

Next, the materials are assembled and stitched together using advanced techniques to create different layers for optimum support and comfort.

Additional layers may be added, such as gel-infused memory foam for temperature regulation, or antimicrobial fabrics to prevent the growth of bacteria and allergens.

The manufacturing process of a mattress is a complex and intricate one, involving several steps and techniques to ensure the final product is of the highest quality. It starts with selecting the right materials, such as high-density foam, springs, and natural fibers, to provide comfort, support, and durability. These materials are then cut and shaped according to the desired size and shape of the mattress.

Next, the materials are assembled and stitched together using advanced techniques to create different layers for optimum support and comfort.

Additional layers may be added, such as gel-infused memory foam for temperature regulation, or antimicrobial fabrics to prevent the growth of bacteria and allergens.

The Role of Technology

With advancements in technology, the mattress manufacturing process has become more efficient and precise.

Computerized machinery is used to measure and cut the materials to meet specific dimensions and ensure consistency in the final product.

This technology also allows for customization, where customers can choose different levels of firmness or personalized features to suit their individual needs.

With advancements in technology, the mattress manufacturing process has become more efficient and precise.

Computerized machinery is used to measure and cut the materials to meet specific dimensions and ensure consistency in the final product.

This technology also allows for customization, where customers can choose different levels of firmness or personalized features to suit their individual needs.

The Impact on House Design

The quality of the mattress can greatly impact the overall design and atmosphere of a house.

A poorly made mattress can lead to discomfort and disrupted sleep, causing a negative impact on our health and daily lives.

On the other hand, a high-quality mattress can provide the necessary support and comfort for a good night's rest, leading to improved energy levels and productivity during the day.

In conclusion, a high-quality mattress is an essential element in house design, as it directly affects our health and well-being. Therefore, investing in a well-made mattress should be a priority when designing a house. With a thorough understanding of the mattress manufacturing process, individuals can make informed decisions and choose the right mattress to create a comfortable and healthy living space.

The quality of the mattress can greatly impact the overall design and atmosphere of a house.

A poorly made mattress can lead to discomfort and disrupted sleep, causing a negative impact on our health and daily lives.

On the other hand, a high-quality mattress can provide the necessary support and comfort for a good night's rest, leading to improved energy levels and productivity during the day.

In conclusion, a high-quality mattress is an essential element in house design, as it directly affects our health and well-being. Therefore, investing in a well-made mattress should be a priority when designing a house. With a thorough understanding of the mattress manufacturing process, individuals can make informed decisions and choose the right mattress to create a comfortable and healthy living space.