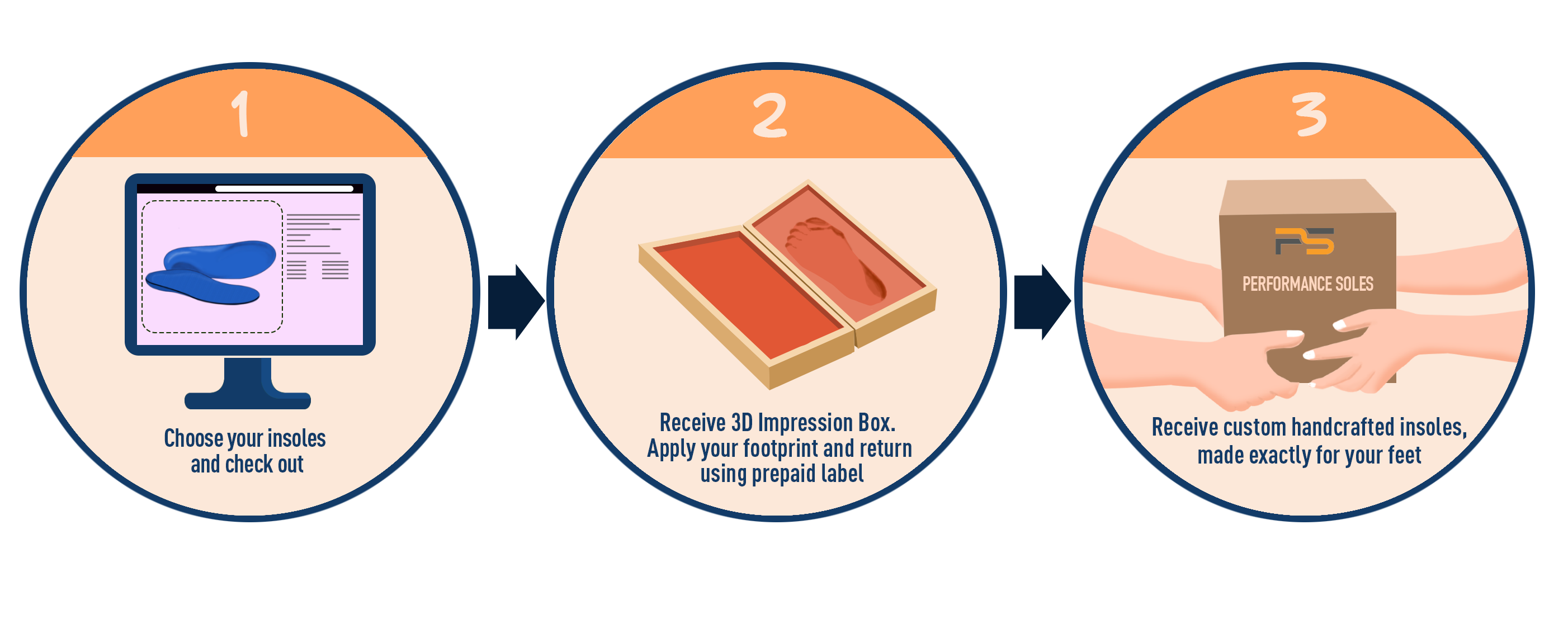

Spring mattresses have been a popular choice for many years, providing comfort and support for a good night's sleep. But have you ever wondered how these mattresses are made? The process of manufacturing a spring mattress is a complex and intricate one, involving careful design, quality materials, and advanced technology. In this article, we will take a closer look at the top 10 steps involved in the spring mattress manufacturing process.1. Spring Mattress Manufacturing Process: A Comprehensive Guide

The first step in the manufacturing process is designing the mattress. This involves choosing the type and arrangement of springs, as well as the size and shape of the mattress. The design is crucial as it will determine the overall comfort and support of the mattress.2. How Spring Mattresses are Made

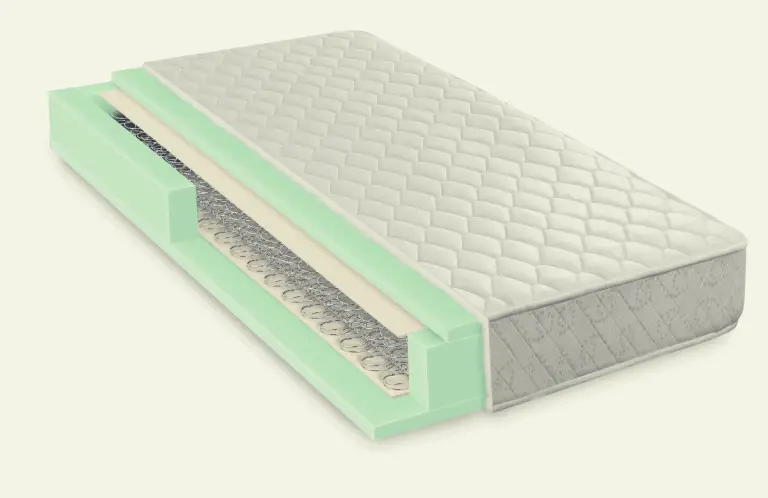

Once the design is finalized, the manufacturing process begins. The first step is to create the frame of the mattress using a combination of steel and wood. This frame will provide the structure and support for the remainder of the manufacturing process.3. The Step-by-Step Process of Manufacturing a Spring Mattress

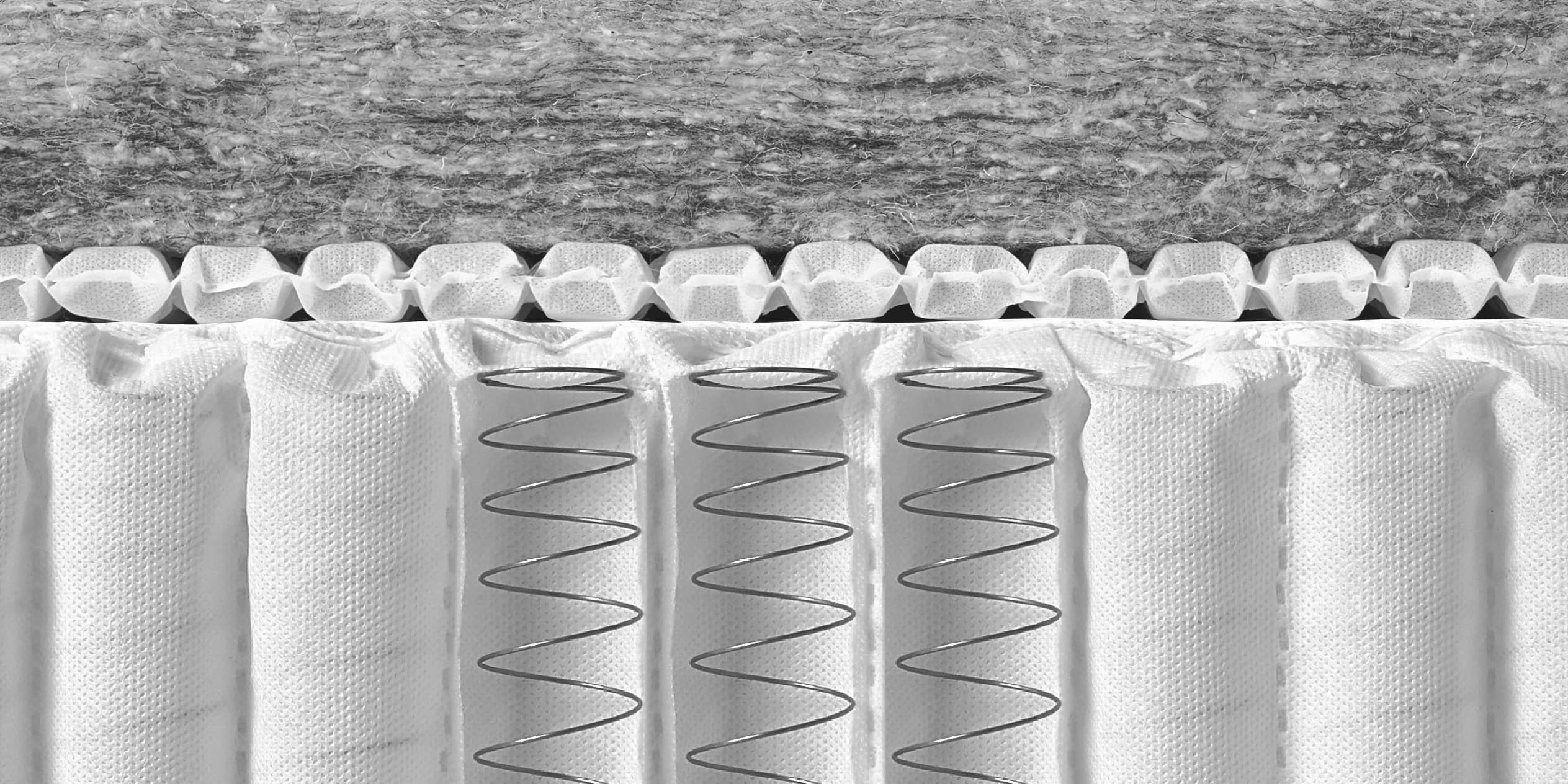

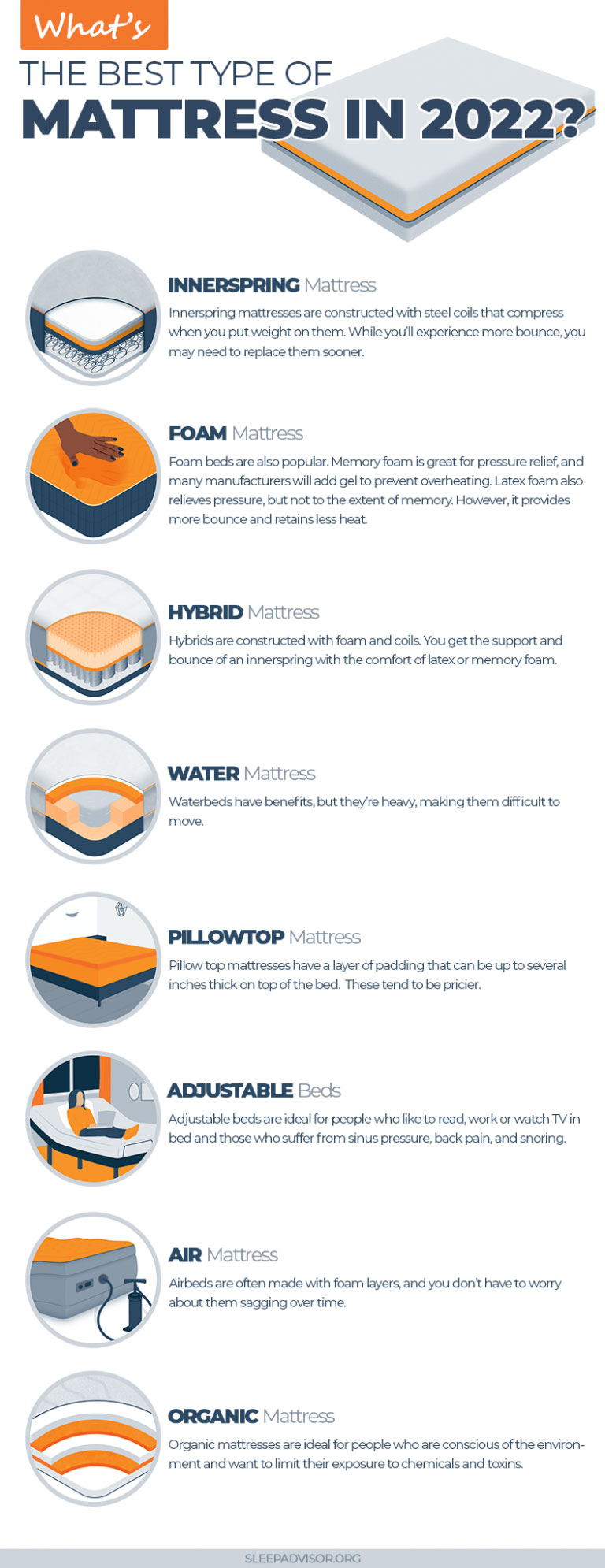

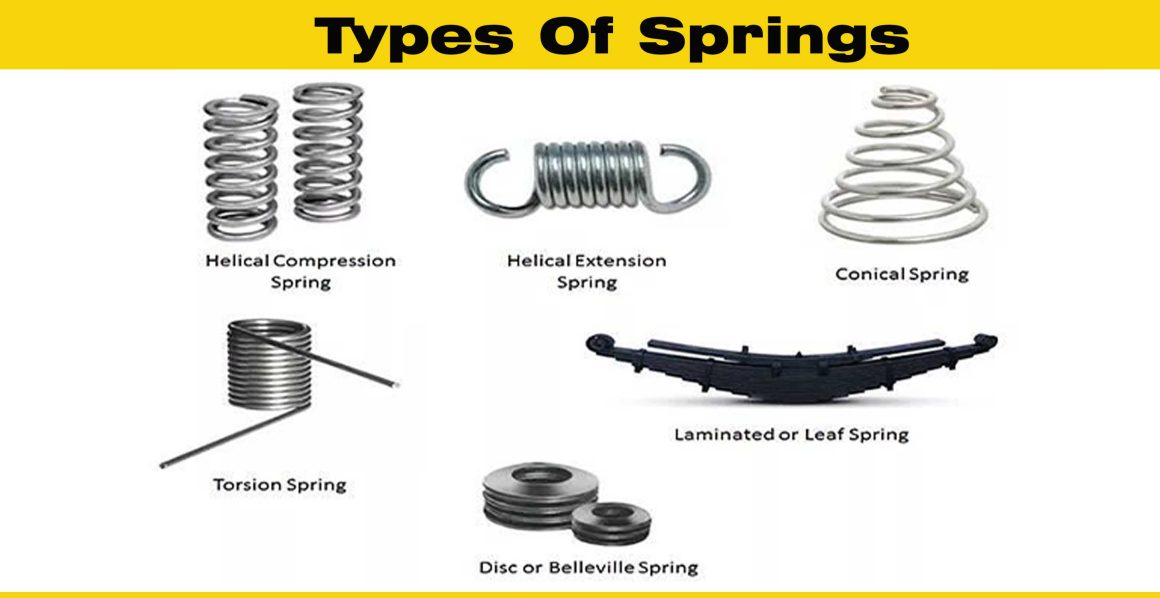

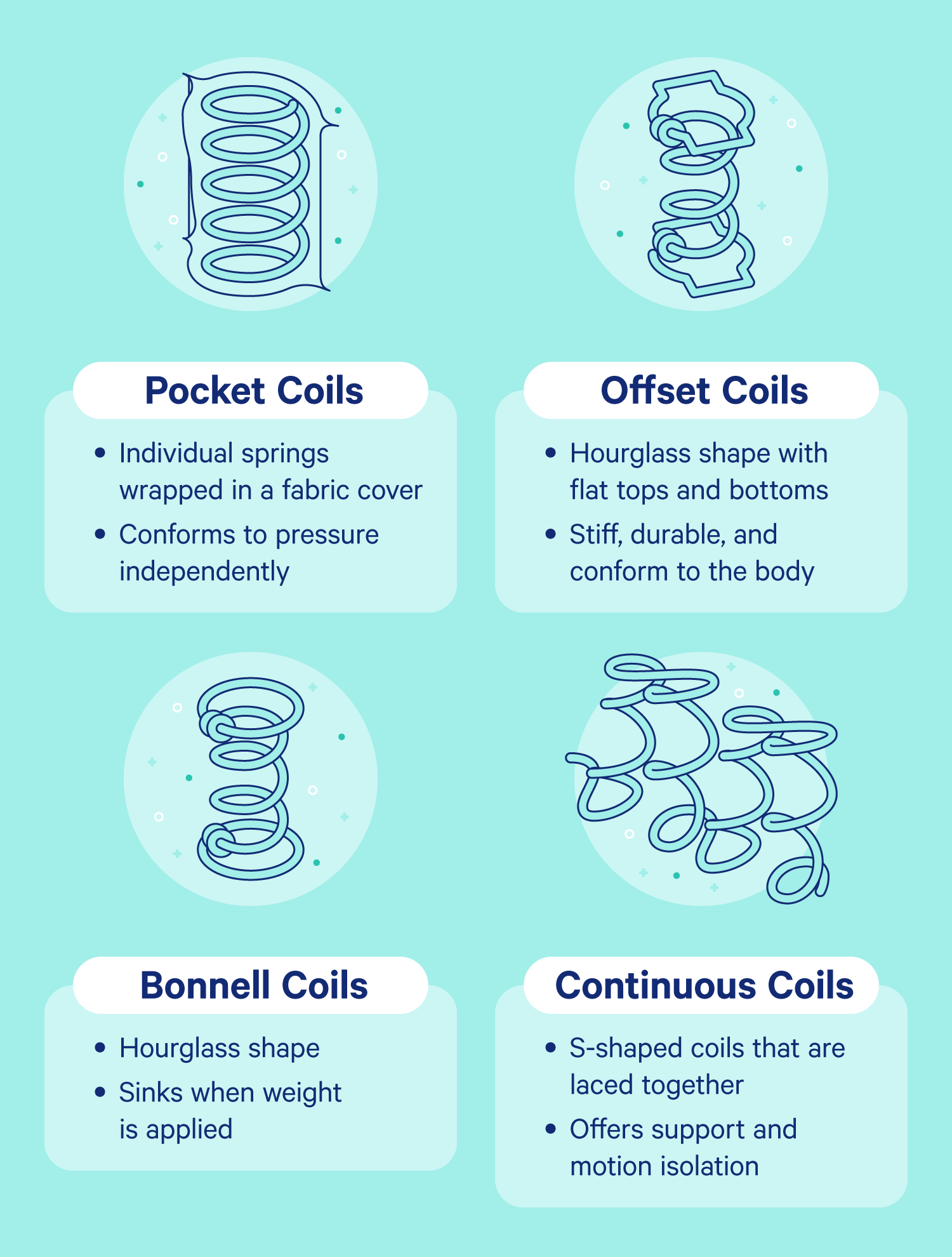

The next step is to insert the springs into the frame. There are various types of springs used in mattresses, including Bonnell, pocket, and continuous coil. The type of spring used will depend on the design and desired level of support.4. Understanding the Inner Workings of a Spring Mattress

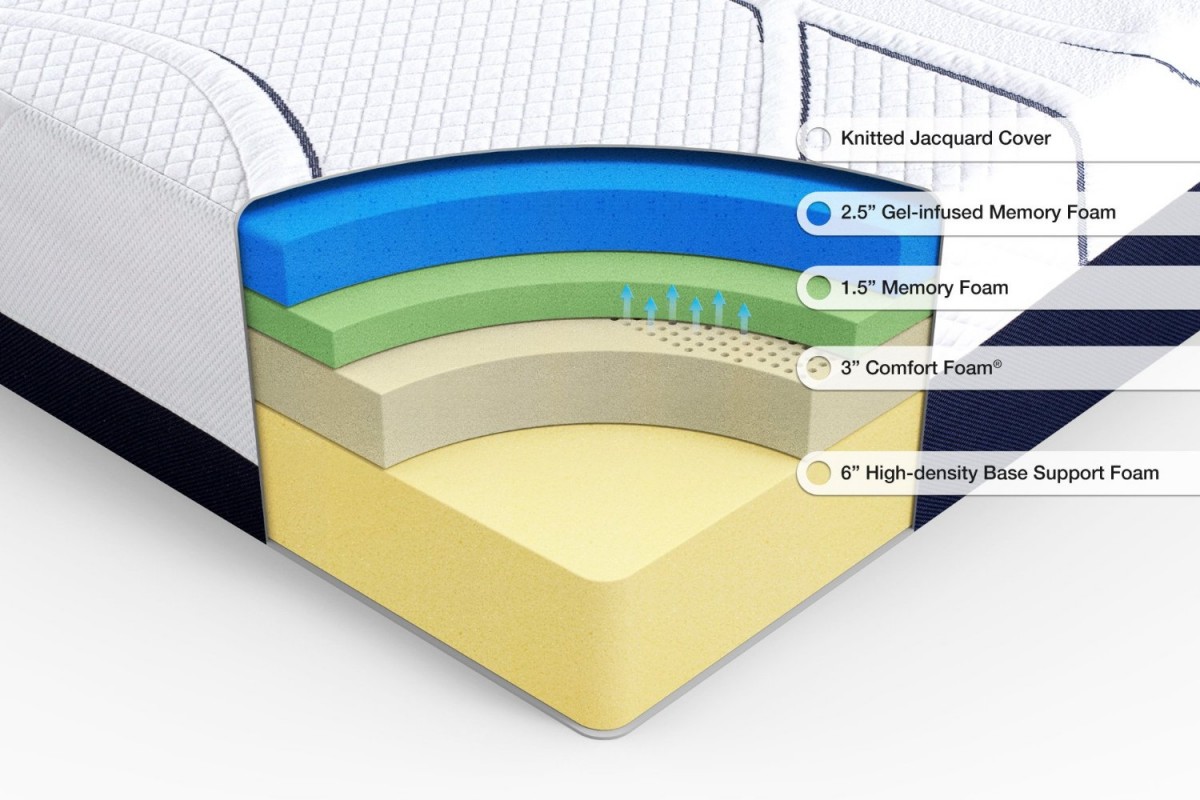

The quality of the materials used in the manufacturing process is crucial to the overall comfort and durability of the mattress. This includes the type of foam used for cushioning and the fabric used for the outer cover.5. The Importance of Quality Materials in Spring Mattress Manufacturing

As mentioned earlier, there are various types of springs used in mattresses. Each type has its own unique benefits and functions. For example, Bonnell springs are known for their durability and support, while pocket springs provide individualized support for different parts of the body.6. Exploring Different Types of Springs Used in Mattresses

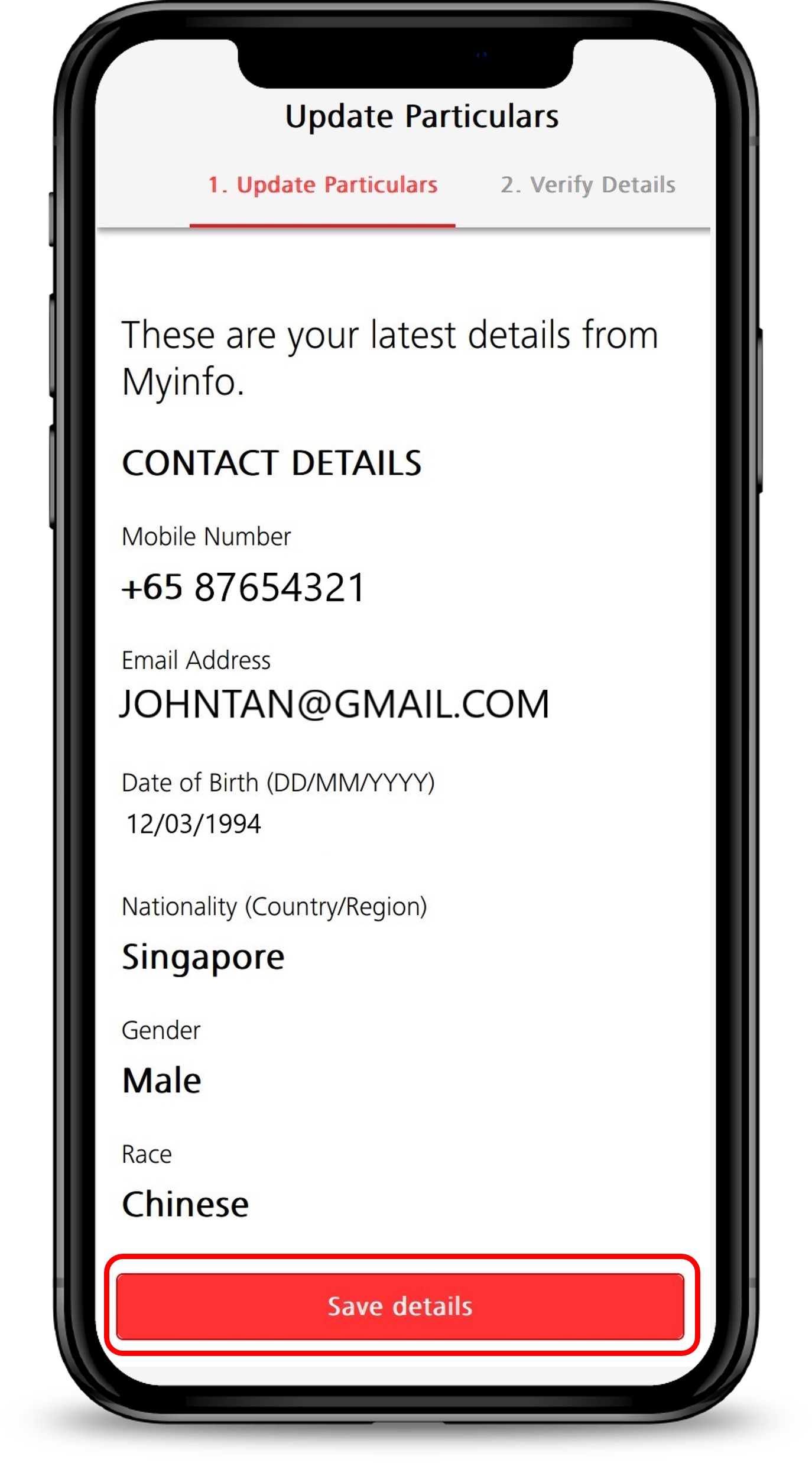

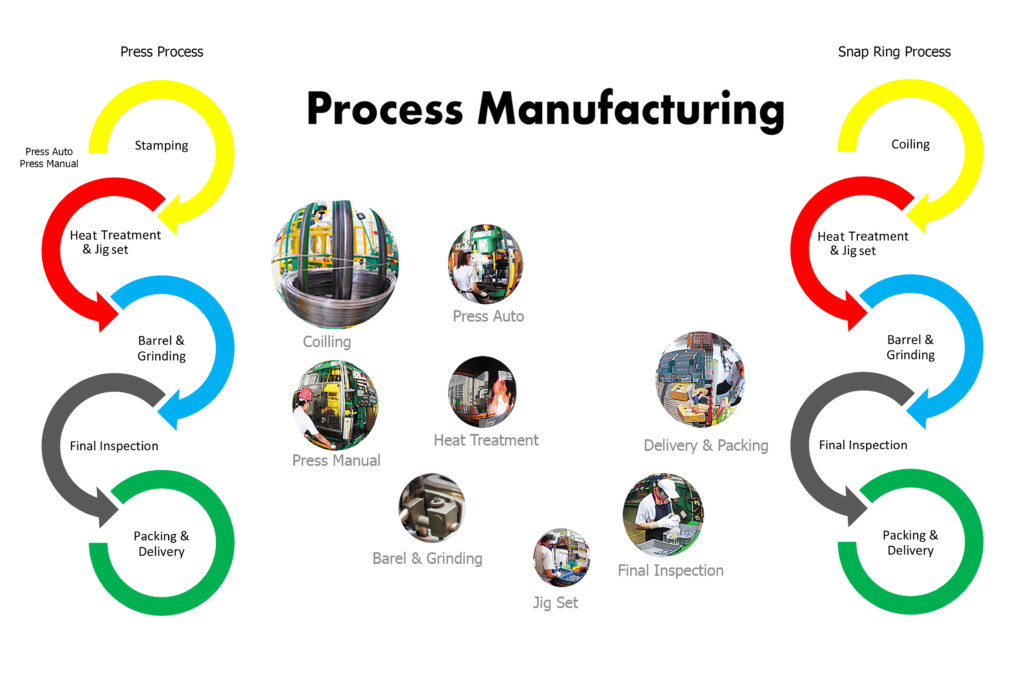

In recent years, technology has played a significant role in the manufacturing of spring mattresses. Advanced machinery and equipment are used to ensure precision and efficiency in the production process. This has also led to the development of new and innovative mattress designs.7. The Role of Technology in Modern Spring Mattress Manufacturing

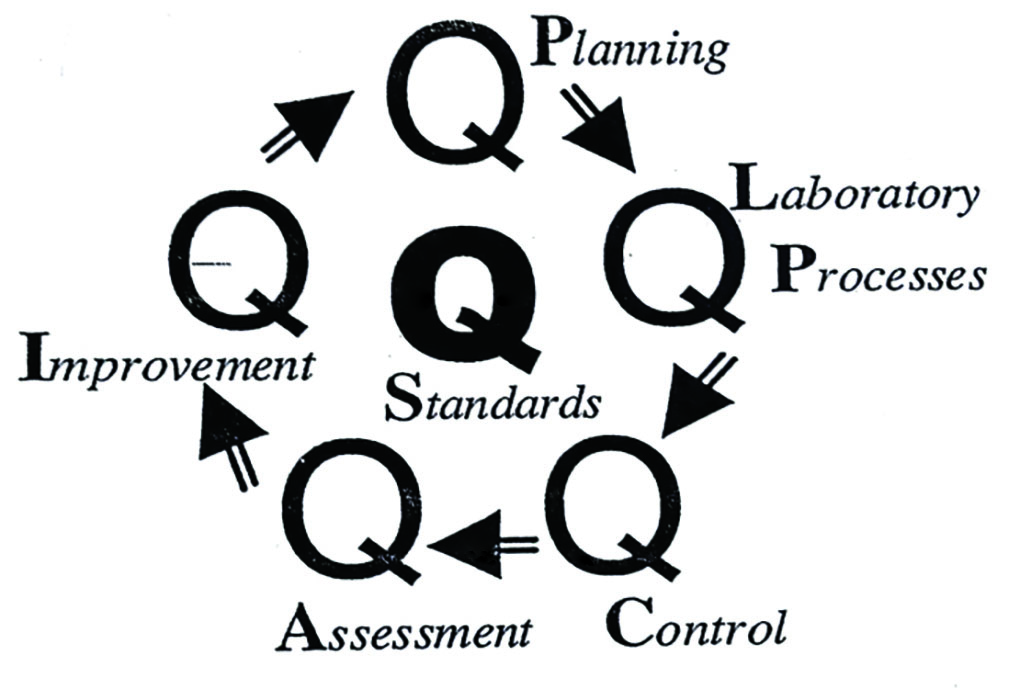

Quality control is a crucial step in the manufacturing process. This involves carefully inspecting the mattress at various stages to ensure that it meets the required standards. Any defects or flaws are identified and corrected before the mattress is sent for packaging and distribution.8. Quality Control in Spring Mattress Production: Ensuring a Perfect Product

With the increasing focus on sustainability and eco-friendliness, mattress manufacturers have also started to consider the environmental impact of their production processes. Many companies are now using eco-friendly materials and implementing sustainable practices in their manufacturing processes.9. The Environmental Impact of Spring Mattress Manufacturing

As technology continues to advance, we can expect to see more innovations in the manufacturing of spring mattresses. This could include the use of smart materials, advanced design techniques, and even 3D printing. The goal is to continuously improve the comfort, support, and durability of spring mattresses for a better sleep experience. In conclusion, the process of manufacturing a spring mattress is a complex and intricate one, involving careful design, quality materials, and advanced technology. By understanding the steps involved, you can have a better appreciation for the comfort and support provided by your mattress. So the next time you lay down for a good night's sleep, remember the effort that goes into making your spring mattress. 10. Innovations in Spring Mattress Manufacturing: What's Next?

The Importance of Spring Mattresses in House Design

Enhanced Comfort and Support

Spring mattresses have been a popular choice for many people when it comes to house design. This is because they offer enhanced comfort and support, making for a more restful sleep. The main component of a spring mattress is the

coil system

, which provides a supportive base for the body. The coils are strategically placed to

support the body's natural curves

and provide a comfortable sleeping surface. This is especially beneficial for those who suffer from back pain or other body aches, as the spring mattress helps to alleviate pressure points and keep the spine properly aligned.

Spring mattresses have been a popular choice for many people when it comes to house design. This is because they offer enhanced comfort and support, making for a more restful sleep. The main component of a spring mattress is the

coil system

, which provides a supportive base for the body. The coils are strategically placed to

support the body's natural curves

and provide a comfortable sleeping surface. This is especially beneficial for those who suffer from back pain or other body aches, as the spring mattress helps to alleviate pressure points and keep the spine properly aligned.

Durability and Longevity

Another key benefit of spring mattresses in house design is their durability and longevity. The coil system in these mattresses is designed to withstand weight and pressure, making them a long-lasting investment. With proper care and maintenance, a spring mattress can last for many years without losing its shape or support. This is especially important for those who are looking to furnish their homes with quality, long-lasting pieces.

Another key benefit of spring mattresses in house design is their durability and longevity. The coil system in these mattresses is designed to withstand weight and pressure, making them a long-lasting investment. With proper care and maintenance, a spring mattress can last for many years without losing its shape or support. This is especially important for those who are looking to furnish their homes with quality, long-lasting pieces.

Variety of Options

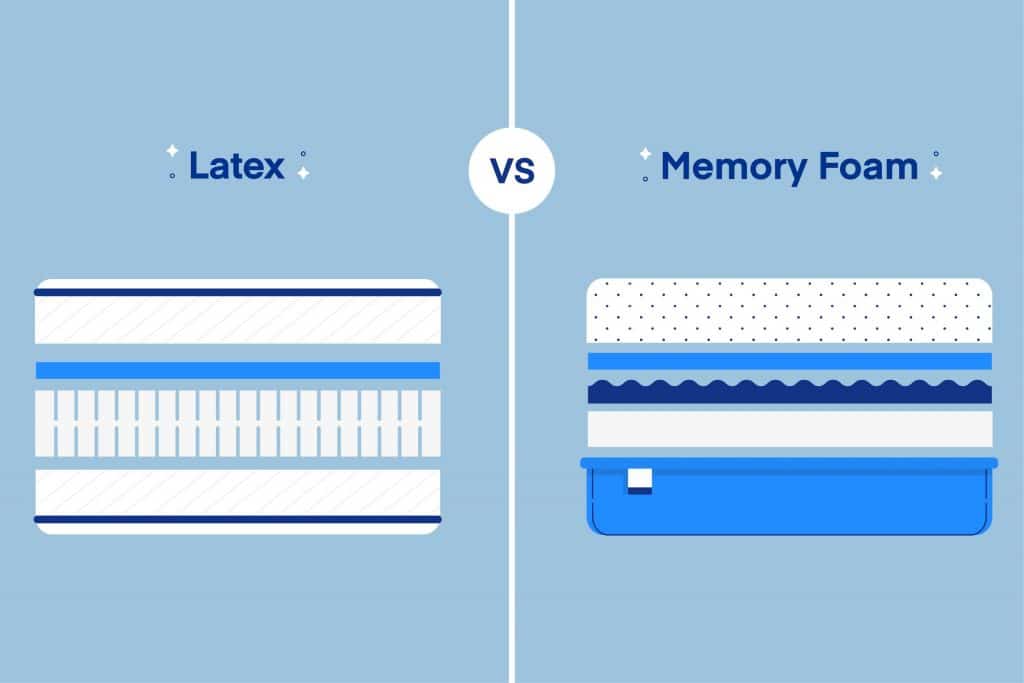

Spring mattresses also offer a wide variety of options to suit different preferences and needs. They come in different firmness levels, from soft to extra firm, allowing individuals to choose the level of support that works best for them. They also come in different sizes, including twin, full, queen, and king, making it easy to find the perfect fit for any bedroom. Additionally, spring mattresses can be combined with other materials, such as memory foam or latex, to create a customized sleeping experience.

Spring mattresses also offer a wide variety of options to suit different preferences and needs. They come in different firmness levels, from soft to extra firm, allowing individuals to choose the level of support that works best for them. They also come in different sizes, including twin, full, queen, and king, making it easy to find the perfect fit for any bedroom. Additionally, spring mattresses can be combined with other materials, such as memory foam or latex, to create a customized sleeping experience.

Affordable and Accessible

Spring mattresses are also a more affordable and accessible option compared to other types of mattresses. They are widely available in various furniture stores, online retailers, and even department stores. This makes it easier for individuals to find and purchase a spring mattress that fits their budget and needs. With its combination of comfort, support, durability, and variety, it's no wonder that spring mattresses remain a top choice for house design.

Spring mattresses are also a more affordable and accessible option compared to other types of mattresses. They are widely available in various furniture stores, online retailers, and even department stores. This makes it easier for individuals to find and purchase a spring mattress that fits their budget and needs. With its combination of comfort, support, durability, and variety, it's no wonder that spring mattresses remain a top choice for house design.

In Conclusion

In summary, spring mattresses are a crucial component of house design, offering enhanced comfort, support, durability, variety, and accessibility. Whether you are looking for a new mattress for your own bedroom or for your guests, a spring mattress is a reliable and affordable option that can provide a restful and comfortable sleep for years to come. So if you are in the market for a new mattress, be sure to consider the benefits of a spring mattress and choose the one that best fits your needs and preferences.

In summary, spring mattresses are a crucial component of house design, offering enhanced comfort, support, durability, variety, and accessibility. Whether you are looking for a new mattress for your own bedroom or for your guests, a spring mattress is a reliable and affordable option that can provide a restful and comfortable sleep for years to come. So if you are in the market for a new mattress, be sure to consider the benefits of a spring mattress and choose the one that best fits your needs and preferences.