When you lay on a Purple mattress, you immediately feel the difference in comfort and support. But have you ever wondered how these innovative mattresses are made? The manufacturing process behind Purple mattresses is truly unique and one-of-a-kind, and it's what sets them apart from other mattress brands. The purple mattress manufacturing process begins with the selection of high-quality raw materials. Purple uses a patented Hyper-Elastic Polymer material, which is a stretchy, durable, and temperature-neutral material. This material is the key to the signature Purple Grid that makes their mattresses so comfortable and supportive. Once the raw materials are selected, they go through a rigorous testing process to ensure they meet Purple's high standards. This includes testing for durability, elasticity, and temperature regulation. Only the best materials make it to the next stage of the manufacturing process.1. Purple Mattress Manufacturing Process: How It's Made

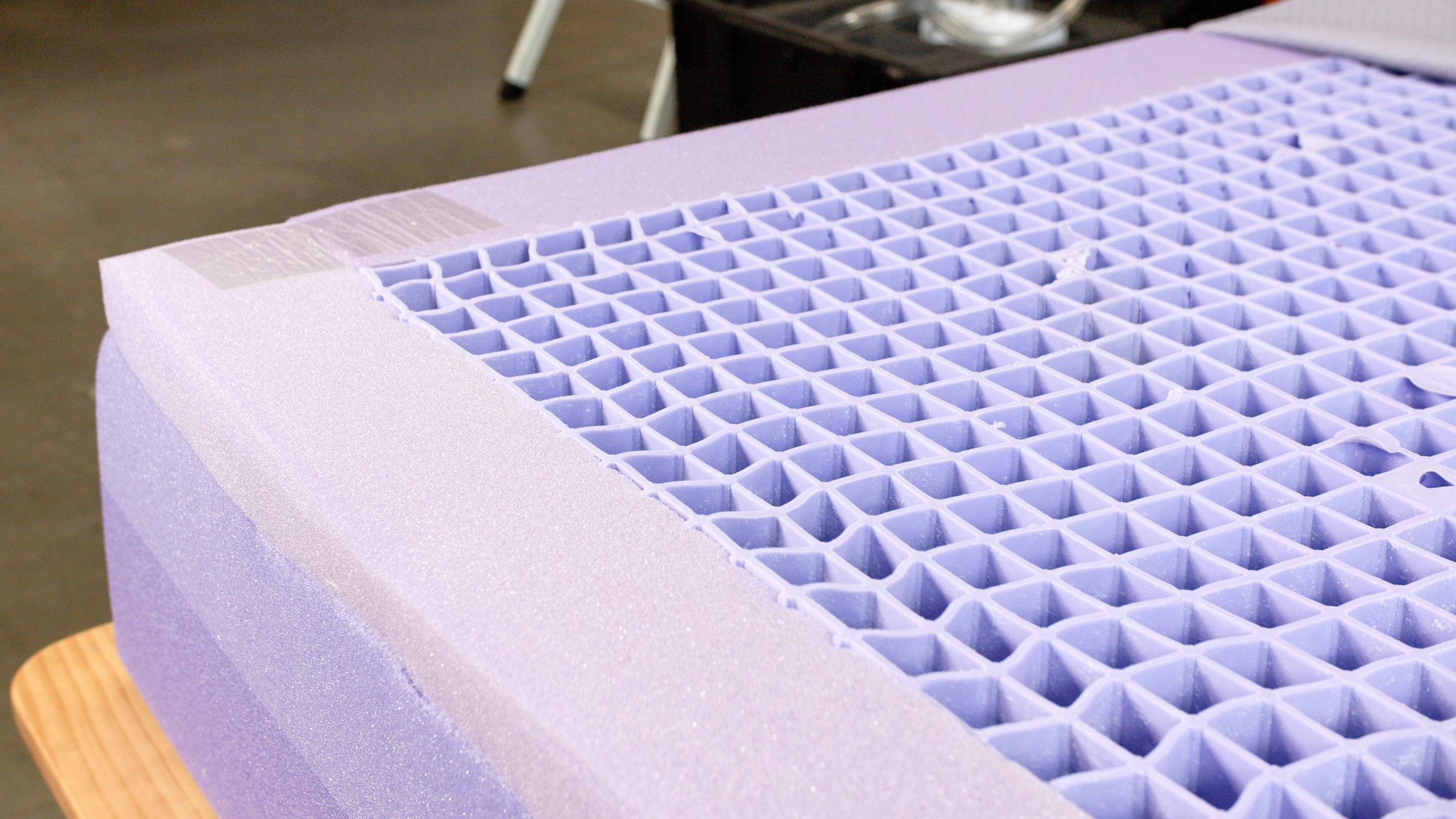

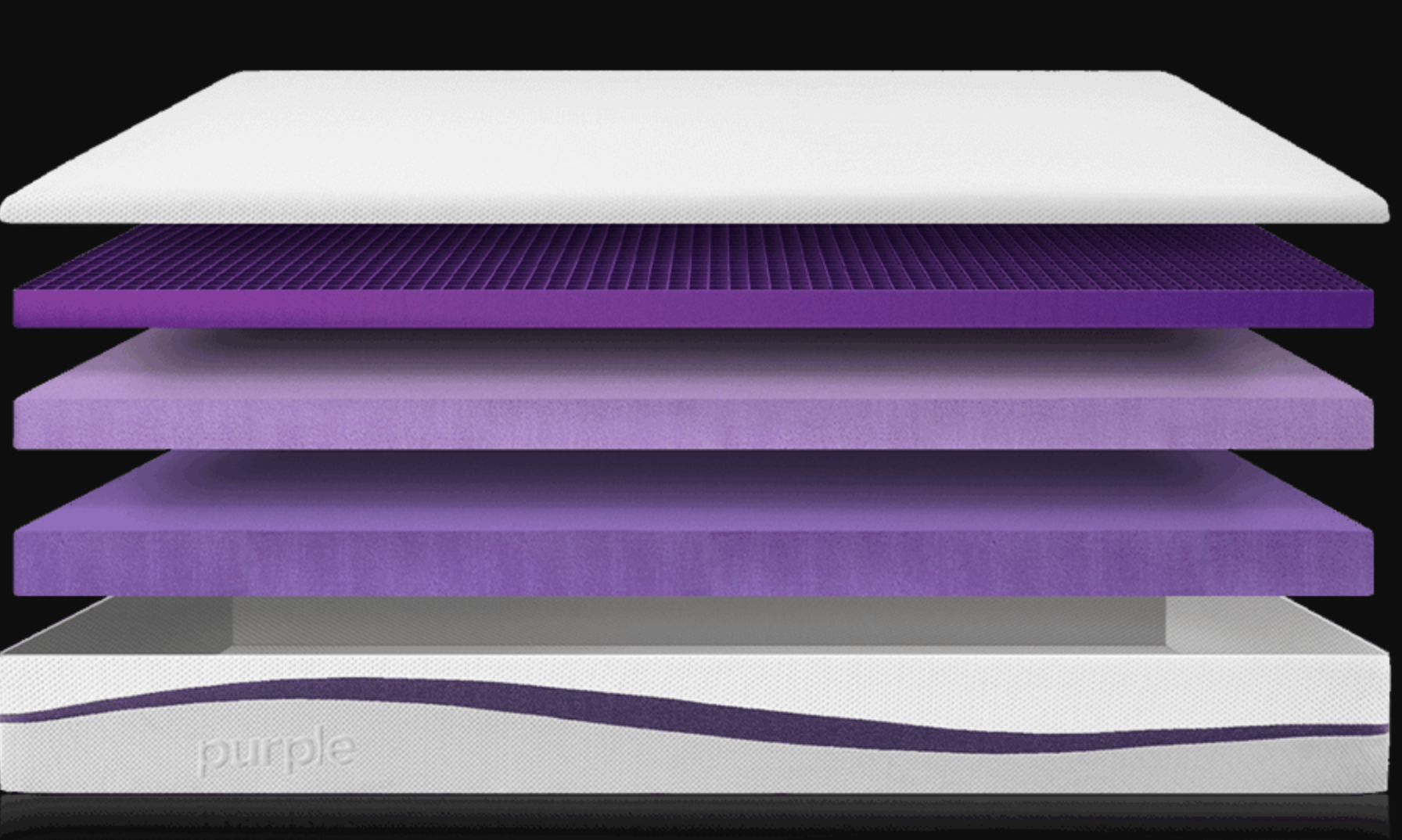

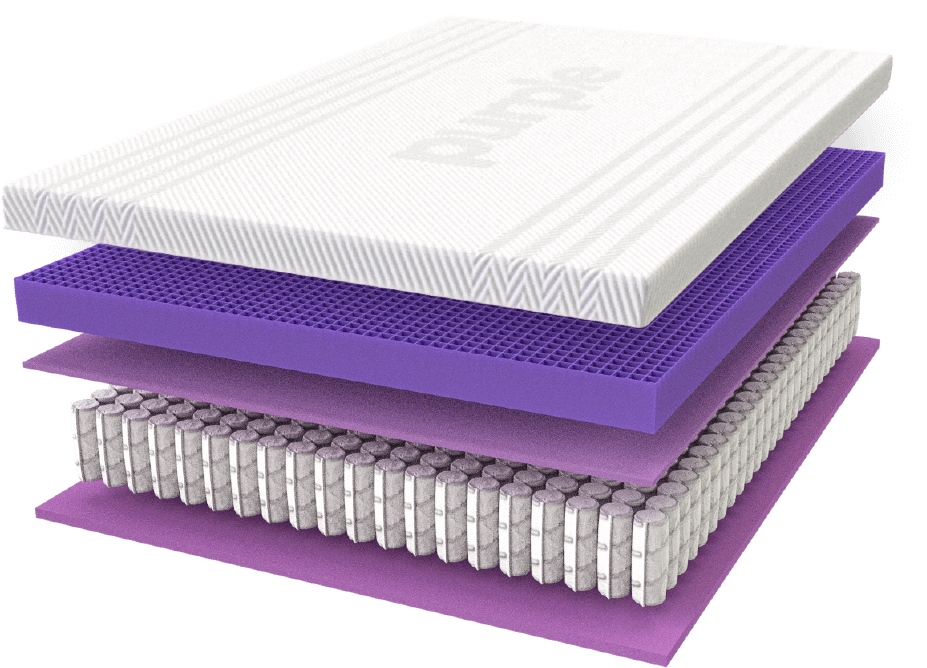

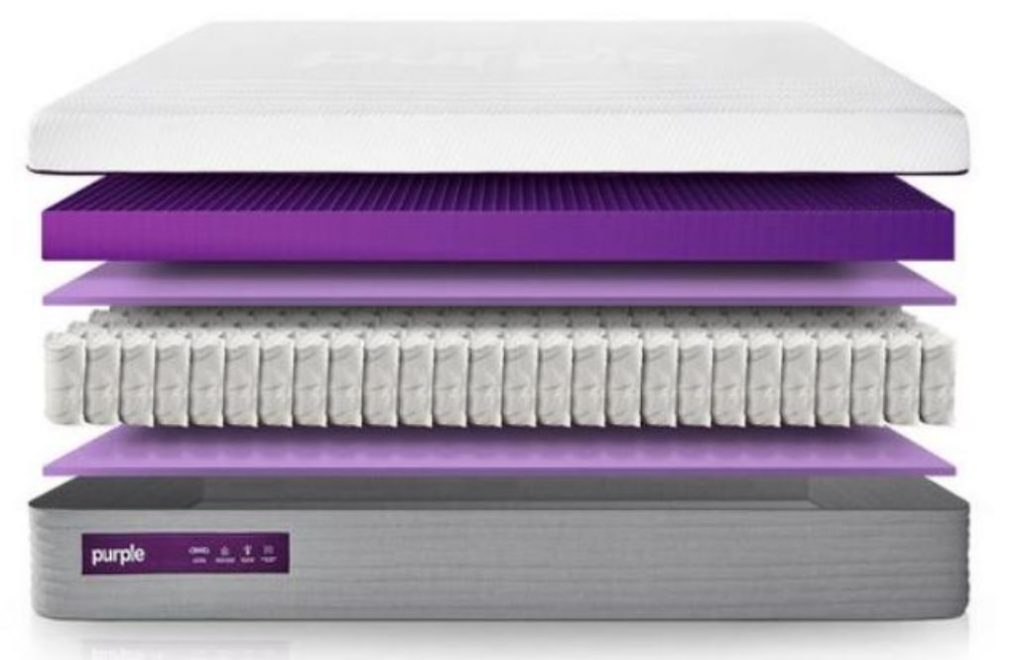

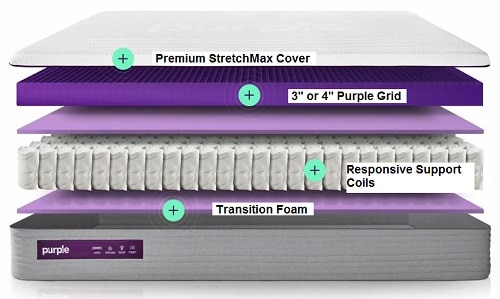

Purple mattresses are not just made with any ordinary foam or spring materials. The team at Purple has spent years researching and developing the perfect combination of materials to create their unique mattresses. The result is a scientifically engineered sleep surface that provides optimal comfort and support for all body types. The key to the Purple mattress is the Purple Grid, which is made up of hundreds of small squares of Hyper-Elastic Polymer. This grid is designed to adapt to your body's pressure points and provide targeted support and pressure relief. It also allows for airflow to keep you cool throughout the night. But the science doesn't stop there. Purple also uses a layer of high-density polyurethane foam for additional support, as well as a soft, breathable cover made from a blend of polyester, viscose, and Lycra. All of these elements work together to create a truly unique and comfortable sleep experience.2. The Science Behind Purple Mattresses

The journey of a Purple mattress begins with the selection of high-quality raw materials. These materials are then sent to the Purple factory, where they go through a multi-step process to become a finished mattress. The first step is to create the Purple Grid. This involves heating and molding the Hyper-Elastic Polymer material into the signature grid shape. Once the grid is formed, it goes through a series of tests to ensure it meets Purple's high standards for comfort and durability. Next, the grid is combined with the layer of high-density foam and wrapped in the soft, breathable cover. The mattress is then compressed and rolled for shipping, making it easier and more convenient to deliver to your doorstep.3. From Raw Materials to Finished Product: The Purple Mattress Journey

Stepping inside the Purple mattress factory is like entering a world of innovation and technology. The factory is equipped with state-of-the-art machinery and equipment that helps create the signature Purple Grid and other components of the mattress. One of the most interesting machines in the factory is the Purple Grid machine, which uses heat and pressure to mold the Hyper-Elastic Polymer into the unique grid shape. This machine is operated by skilled technicians who ensure each grid is made to perfection. The factory also has a quality control team that conducts frequent checks throughout the manufacturing process to ensure the mattresses meet Purple's high standards. This includes testing for durability, comfort, and overall quality.4. Inside the Purple Mattress Factory: A Look at the Manufacturing Process

So, what exactly makes Purple mattresses so comfortable? The secret lies in the manufacturing process. Unlike traditional memory foam mattresses that can leave you feeling trapped and hot, Purple mattresses use the power of science and technology to provide a truly comfortable sleep experience. The Purple Grid is designed to adapt to your body's unique shape and provide targeted support where you need it most. This means that no matter your sleeping position, your body will be properly supported and aligned, leading to a more restful and comfortable night's sleep. The combination of the Purple Grid, high-density foam, and soft cover all work together to create a mattress that is both comfortable and supportive. And the best part? This technology is backed by scientific research and customer satisfaction.5. The Secret to Purple Mattress's Unique Comfort: A Breakdown of the Manufacturing Process

Let's break down the Purple mattress manufacturing process step-by-step: Step 1: Select high-quality raw materials, including the patented Hyper-Elastic Polymer. Step 2: Heat and mold the Hyper-Elastic Polymer into the signature Purple Grid shape. Step 3: Combine the Purple Grid with a layer of high-density foam and a soft, breathable cover. Step 4: Test the mattress for durability, comfort, and overall quality. Step 5: Compress and roll the mattress for shipping. Step 6: Deliver the mattress to your doorstep for a convenient and hassle-free experience.6. How Purple Mattresses are Made: A Step-by-Step Guide

Purple is known for its innovative and technologically advanced mattresses, and this is all thanks to the cutting-edge technology used in their manufacturing process. From the Purple Grid machine to the quality control checks, every step of the process is backed by technology and innovation. But it's not just about the technology used in the factory. Purple also utilizes advanced sleep science to create mattresses that are not only comfortable but also promote better sleep and overall health. This combination of technology and science has made Purple a leader in the mattress industry.7. The Technology and Innovation Behind Purple Mattress Manufacturing

Quality control is an essential part of the Purple mattress manufacturing process. Every mattress goes through a series of tests and checks to ensure it meets the company's high standards for comfort, durability, and overall quality. The quality control team is made up of skilled technicians who are trained to identify any flaws or defects in the mattresses. This ensures that only the best mattresses make it to the market and into customers' homes. This commitment to quality control is what has earned Purple a loyal customer base and a reputation for producing top-notch mattresses.8. The Importance of Quality Control in Purple Mattress Manufacturing

Purple is not only committed to providing customers with the best sleep experience but also to reducing their environmental impact. The company uses eco-friendly production methods and materials, such as their patented Hyper-Elastic Polymer, which is made without harmful chemicals. The manufacturing process also produces minimal waste, and any excess materials are recycled or repurposed. This commitment to sustainability is just another reason to feel good about investing in a Purple mattress.9. The Environmental Impact of Purple Mattress Manufacturing

The Purple mattress factory is a bustling and exciting place to work. The skilled technicians and workers are dedicated to creating the best mattresses possible and take pride in their work. A typical day for a factory worker includes operating the Purple Grid machine, conducting quality control checks, and assembling the final product. They work closely with the technology and machinery to ensure each mattress is made to perfection. It takes a team of hardworking individuals to create a Purple mattress, and their passion for their work shines through in the final product.10. Behind the Scenes: A Day in the Life of a Purple Mattress Factory Worker

The Unique Manufacturing Process Behind Purple Mattresses

The Inspiration Behind Purple Mattresses

When it comes to house design, one of the most important elements is the furniture, especially the mattress. A good night's sleep is essential for overall health and well-being, and Purple has made it their mission to provide the most comfortable and supportive mattress on the market. The idea for Purple mattresses came from the founders' personal struggle to find a comfortable and supportive mattress that also helped with their chronic back pain. After extensive research and testing, they developed a unique manufacturing process that sets Purple mattresses apart from the rest.

When it comes to house design, one of the most important elements is the furniture, especially the mattress. A good night's sleep is essential for overall health and well-being, and Purple has made it their mission to provide the most comfortable and supportive mattress on the market. The idea for Purple mattresses came from the founders' personal struggle to find a comfortable and supportive mattress that also helped with their chronic back pain. After extensive research and testing, they developed a unique manufacturing process that sets Purple mattresses apart from the rest.

The Innovative Grid Technology

The key to Purple's success lies in their patented Smart Comfort Grid™. This innovative technology is made of a hyper-elastic polymer that is arranged in a grid-like pattern. This grid is designed to adapt to each individual's body shape and weight, providing customized support and pressure relief. The grid also promotes airflow, keeping the mattress cool and comfortable throughout the night.

Keywords: innovative technology, Smart Comfort Grid™, hyper-elastic polymer, customized support, pressure relief

The key to Purple's success lies in their patented Smart Comfort Grid™. This innovative technology is made of a hyper-elastic polymer that is arranged in a grid-like pattern. This grid is designed to adapt to each individual's body shape and weight, providing customized support and pressure relief. The grid also promotes airflow, keeping the mattress cool and comfortable throughout the night.

Keywords: innovative technology, Smart Comfort Grid™, hyper-elastic polymer, customized support, pressure relief

Quality Materials and Sustainable Practices

Purple mattresses are made with high-quality, CertiPUR-US certified materials that are free from harmful chemicals and toxins. This not only ensures a safe and healthy sleeping environment, but it also makes the mattresses more durable and long-lasting. In addition, Purple is committed to sustainability and uses eco-friendly practices in their manufacturing process. This includes recycling and repurposing materials whenever possible.

Keywords: CertiPUR-US certified, eco-friendly, sustainable, recycling, repurposing

Purple mattresses are made with high-quality, CertiPUR-US certified materials that are free from harmful chemicals and toxins. This not only ensures a safe and healthy sleeping environment, but it also makes the mattresses more durable and long-lasting. In addition, Purple is committed to sustainability and uses eco-friendly practices in their manufacturing process. This includes recycling and repurposing materials whenever possible.

Keywords: CertiPUR-US certified, eco-friendly, sustainable, recycling, repurposing

Handcrafted in the USA

Unlike many other mattress companies, Purple takes pride in the fact that their mattresses are handcrafted in the USA. This allows for strict quality control and ensures that each mattress meets their high standards. By keeping production local, Purple also supports the US economy and provides jobs for Americans.

Keywords: handcrafted, quality control, USA, support, economy

Unlike many other mattress companies, Purple takes pride in the fact that their mattresses are handcrafted in the USA. This allows for strict quality control and ensures that each mattress meets their high standards. By keeping production local, Purple also supports the US economy and provides jobs for Americans.

Keywords: handcrafted, quality control, USA, support, economy

A Mattress That Will Change Your Life

Purple's unique manufacturing process has resulted in a mattress that has changed the way people sleep. With its innovative technology, quality materials, and commitment to sustainability, Purple has truly revolutionized the mattress industry. Say goodbye to restless nights and hello to a comfortable and rejuvenating sleep experience with Purple mattresses.

Keywords: unique, revolutionized, rejuvenating, comfortable, sleep experience

Purple's unique manufacturing process has resulted in a mattress that has changed the way people sleep. With its innovative technology, quality materials, and commitment to sustainability, Purple has truly revolutionized the mattress industry. Say goodbye to restless nights and hello to a comfortable and rejuvenating sleep experience with Purple mattresses.

Keywords: unique, revolutionized, rejuvenating, comfortable, sleep experience