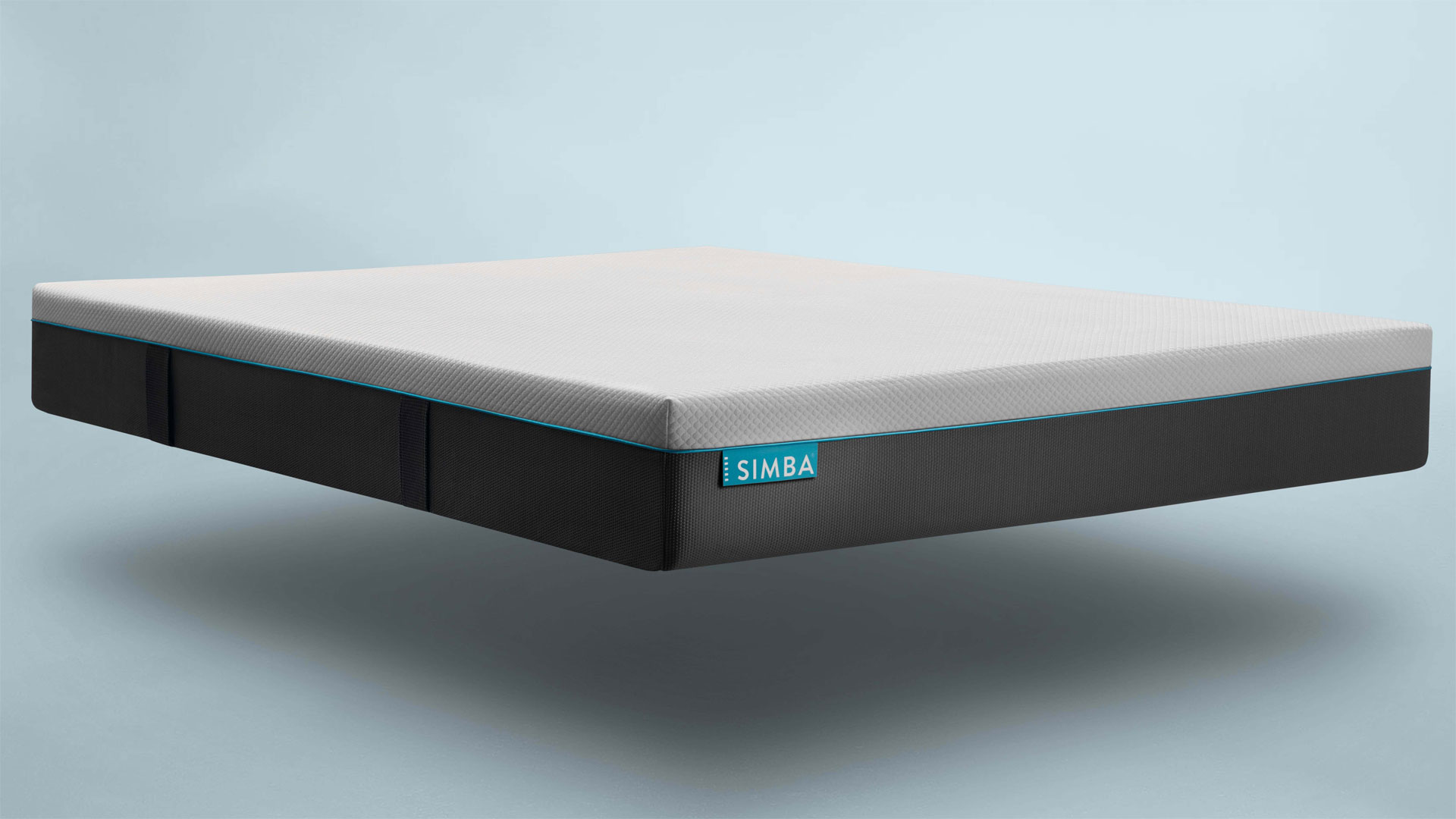

When it comes to getting a good night's sleep, a comfortable and supportive mattress is crucial. And one type of mattress that has gained popularity in recent years is the foam mattress. Made from layers of foam, these mattresses offer a unique combination of comfort and support. But have you ever wondered how these mattresses are made? In this article, we will take a closer look at the top 10 main processes of making a foam mattress.Foam Mattress Manufacturing Process

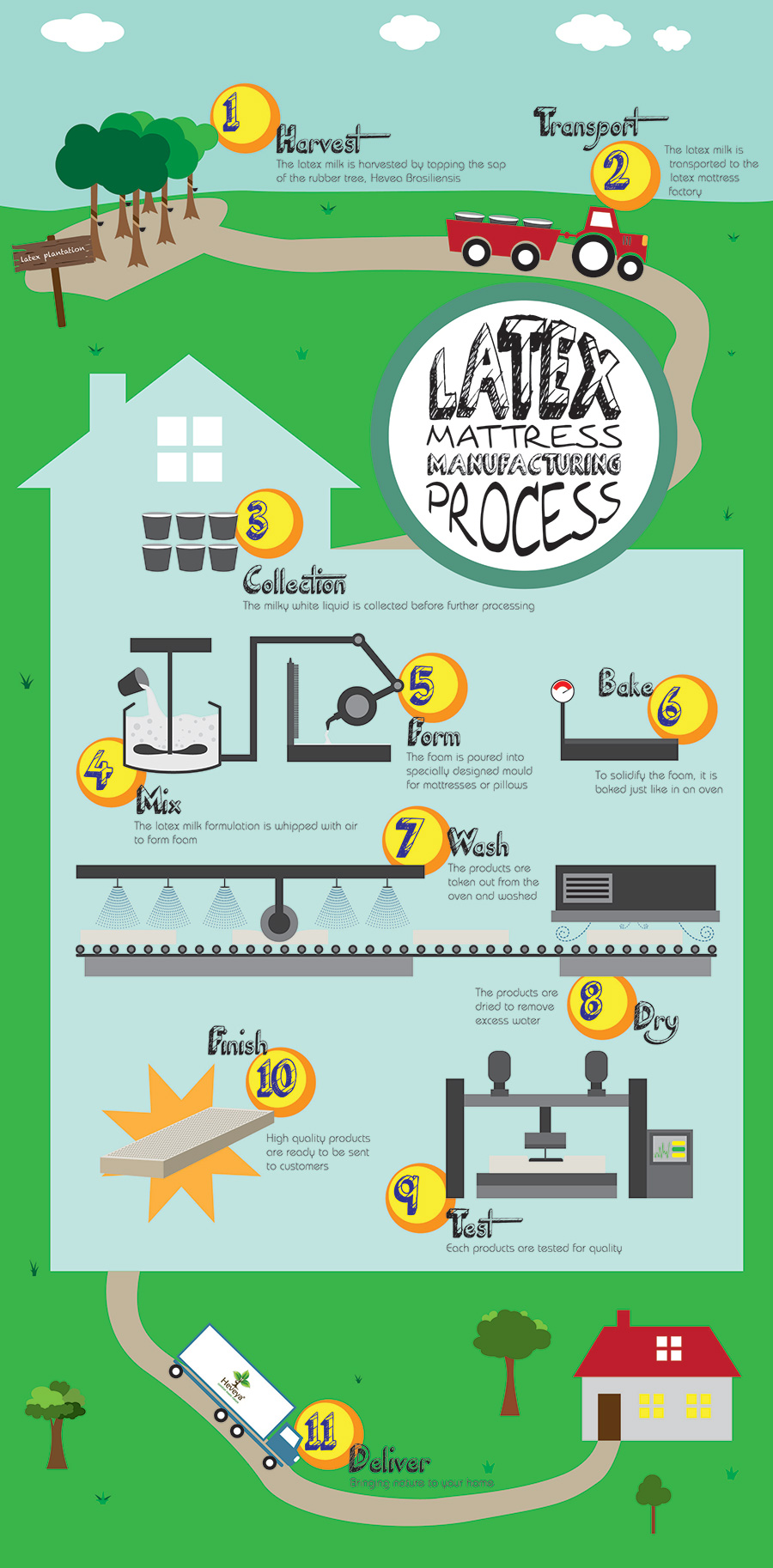

The process of making a foam mattress involves several steps and requires specialized equipment. The following are the main steps involved in the manufacturing process of a foam mattress:How to Make a Foam Mattress

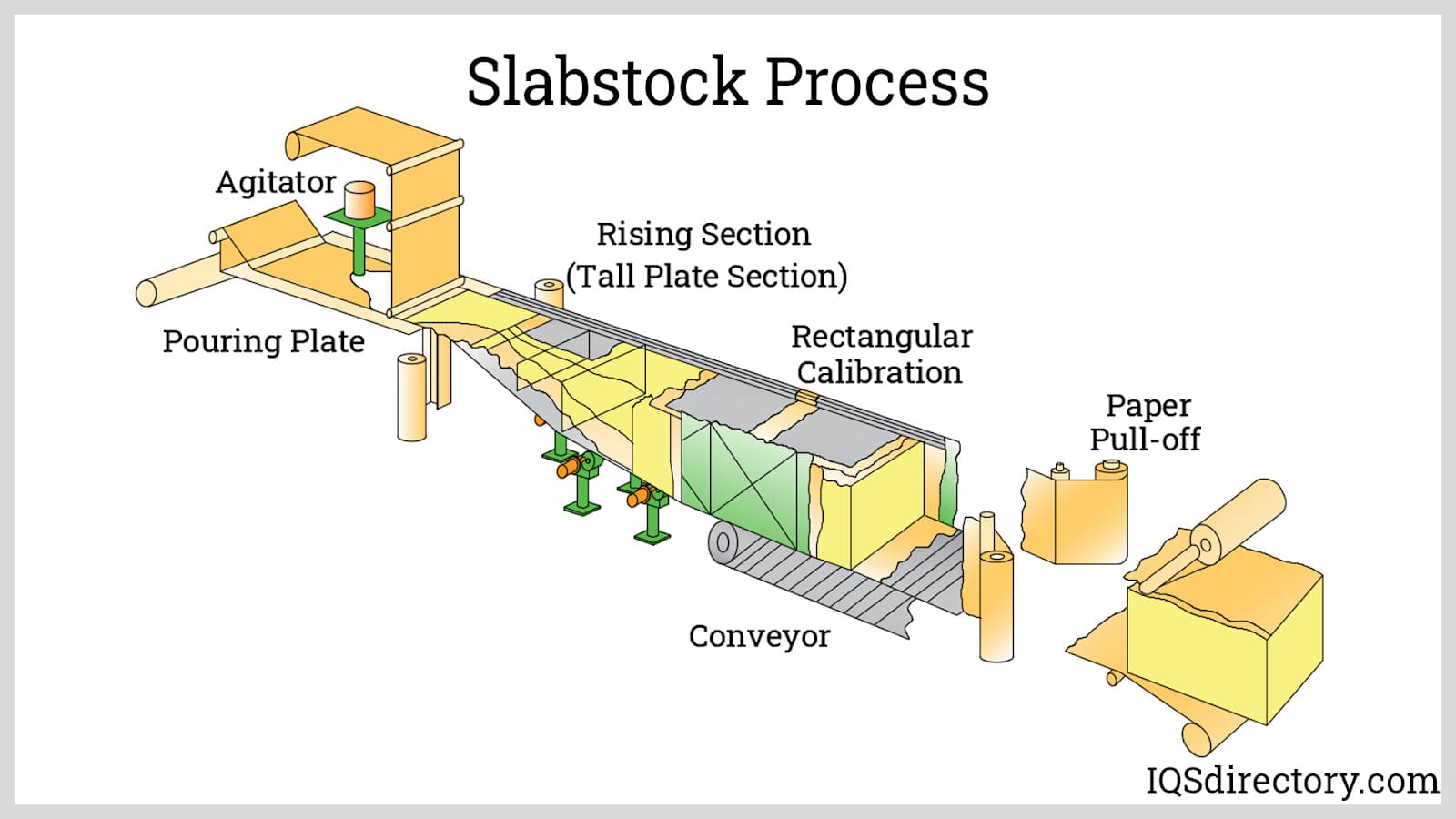

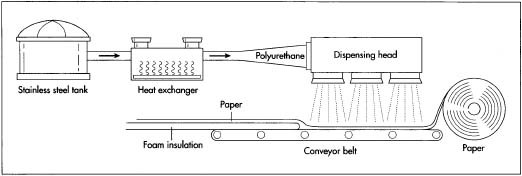

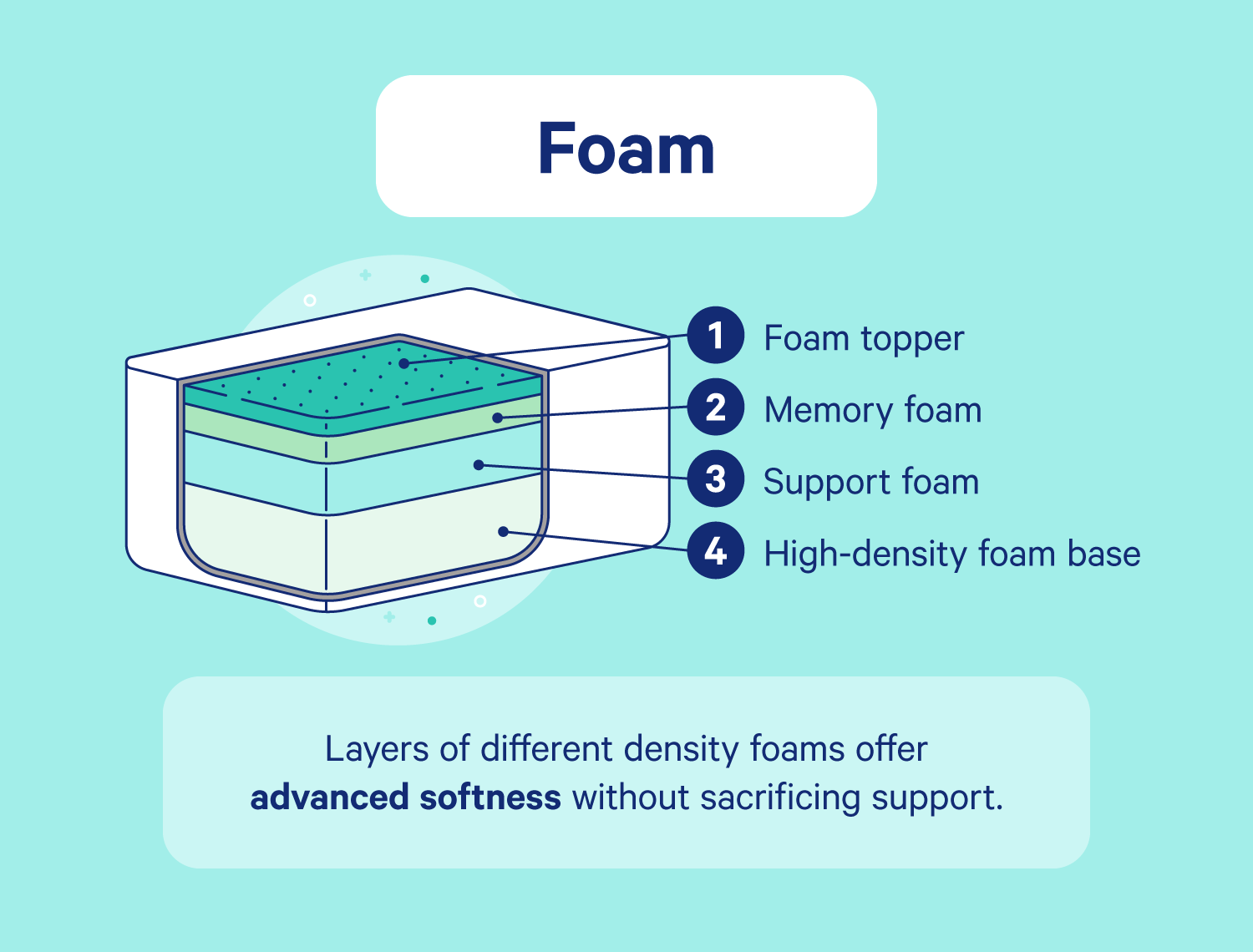

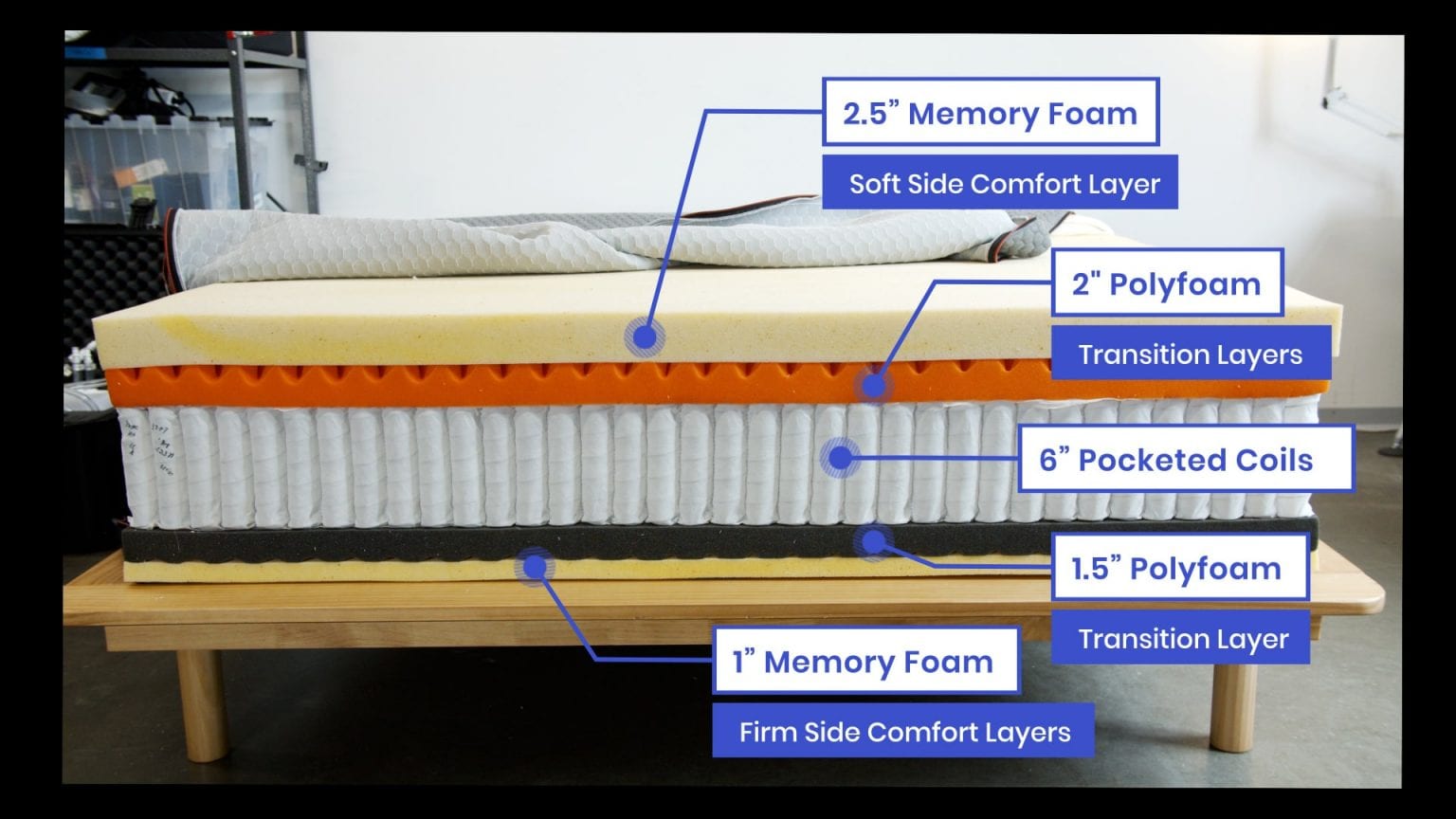

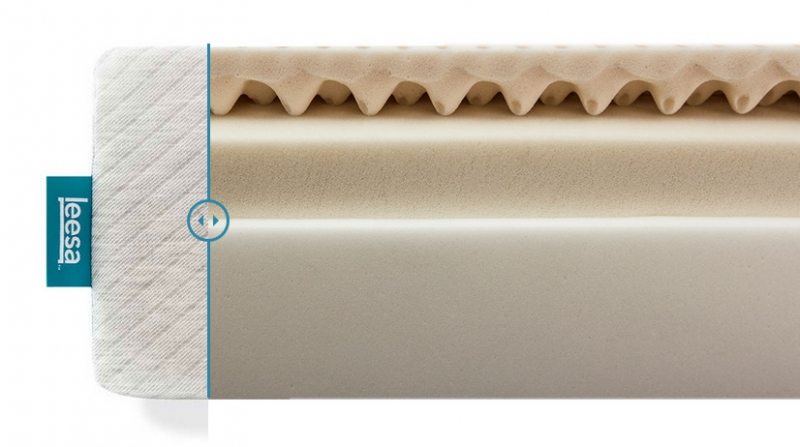

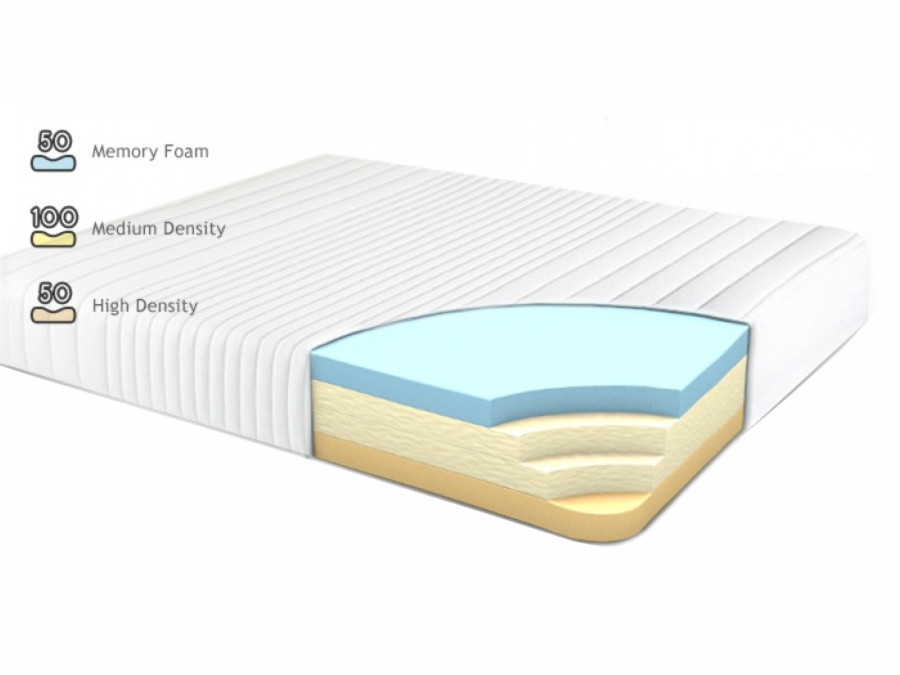

Step 1: Cutting the foam The first step in making a foam mattress is cutting the foam into the desired sizes and shapes. This is done with the help of machines that can precisely cut the foam to the required dimensions. Step 2: Preparing the cover The cover of the mattress is an important aspect of its construction. It not only provides a protective layer but also enhances the overall look of the mattress. The cover is prepared by stitching together different fabrics and materials, such as cotton, polyester, or bamboo, depending on the type of mattress being made. Step 3: Applying adhesive Once the foam is cut and the cover is prepared, the next step is to apply adhesive to the foam. This is done to ensure that the different layers of foam stick together securely and create a solid base for the mattress. Step 4: Layering the foam After the adhesive is applied, the foam is stacked in layers on top of each other. The number of layers and the type of foam used can vary depending on the desired firmness and comfort level of the mattress. Step 5: Compression Once the foam layers are stacked, they are compressed to remove any air pockets and create a uniform density throughout the mattress. This is an important step in ensuring that the mattress is comfortable and supportive. Step 6: Adding gel or other materials Some foam mattresses may also have added materials such as gel or memory foam to enhance their comfort and cooling properties. These materials are added in a specific layer and can also be compressed to ensure they are evenly distributed. Step 7: Quilting After the foam layers are compressed, the cover is placed on top and the entire mattress is then quilted together. This is usually done with a machine that creates a quilted pattern, adding to the overall design of the mattress. Step 8: Trimming Once the quilting is complete, the excess fabric is trimmed off and the edges of the mattress are given a clean and neat finish. Step 9: Quality check Before the mattress is packaged and shipped, it goes through a thorough quality check to ensure that it meets the company's standards and is ready to provide a comfortable sleep experience to its users. Step 10: Packaging and shipping The final step in the manufacturing process is packaging the mattress and shipping it to the retailers or directly to the customers.Steps for Making a Foam Mattress

The production of foam mattresses requires precision and attention to detail to ensure that each mattress is of the highest quality. From cutting the foam to packaging the final product, each step is carefully executed to create a comfortable and durable mattress.Foam Mattress Production

Creating a foam mattress is a complex process that involves several steps and specialized equipment. From cutting the foam to adding materials and quilting, each step plays a crucial role in creating a comfortable and supportive mattress.Creating a Foam Mattress

The construction of a foam mattress is a combination of science and art. The materials used, the layering process, and the quilting technique all come together to create a functional and aesthetically pleasing mattress.Foam Mattress Construction

The assembly of a foam mattress is a delicate process that requires skilled workers and specialized equipment. Each layer of foam is carefully placed and compressed to create a balanced and comfortable mattress.Foam Mattress Assembly

The main ingredient in a foam mattress is, of course, foam. But not all foam is the same. Different types of foam, such as polyurethane foam, memory foam, and gel foam, are used in different layers to create a unique and comfortable sleeping experience.Foam Mattress Ingredients

The manufacturing of a foam mattress involves several steps that must be carefully followed to create a high-quality product. From cutting the foam to packaging the final product, each step plays an important role in the overall process.Foam Mattress Manufacturing Steps

The production process of foam mattresses is a well-oiled machine that requires coordination and precision. Each step, from cutting the foam to shipping the final product, is crucial in creating a comfortable and durable mattress. In conclusion, the process of making a foam mattress is a combination of technology, skilled labor, and attention to detail. It is this careful and meticulous process that ensures that every foam mattress provides the best possible sleep experience to its users. So the next time you lay down on your foam mattress, you can appreciate the intricate and complex process that went into creating it.Foam Mattress Production Process

The Benefits of a Foam Mattress

Superior Comfort and Support

A foam mattress is made from a specialized material that conforms to the shape of your body, providing a customized sleep experience. This allows for even weight distribution, reducing pressure points and providing support for your spine. The result is a comfortable and restful sleep, allowing you to wake up feeling refreshed and rejuvenated.

A foam mattress is made from a specialized material that conforms to the shape of your body, providing a customized sleep experience. This allows for even weight distribution, reducing pressure points and providing support for your spine. The result is a comfortable and restful sleep, allowing you to wake up feeling refreshed and rejuvenated.

Durability and Longevity

One of the key benefits of a foam mattress is its durability and longevity. Unlike traditional spring mattresses, foam mattresses are made from a single block of foam, eliminating the risk of sagging or coil damage. This means that your foam mattress can last for up to 10 years, making it a worthwhile investment for your sleep and overall health.

One of the key benefits of a foam mattress is its durability and longevity. Unlike traditional spring mattresses, foam mattresses are made from a single block of foam, eliminating the risk of sagging or coil damage. This means that your foam mattress can last for up to 10 years, making it a worthwhile investment for your sleep and overall health.

Hypoallergenic and Dust Mite Resistant

Foam mattresses are also a great option for those who suffer from allergies or asthma. The dense and compact structure of foam makes it difficult for dust mites and other allergens to penetrate, providing a healthier sleep environment. Additionally, foam mattresses are made without the use of harsh chemicals, making them a safer option for those with sensitivities.

Foam mattresses are also a great option for those who suffer from allergies or asthma. The dense and compact structure of foam makes it difficult for dust mites and other allergens to penetrate, providing a healthier sleep environment. Additionally, foam mattresses are made without the use of harsh chemicals, making them a safer option for those with sensitivities.

Easy Maintenance

Maintaining a foam mattress is also much easier compared to traditional mattresses. Foam mattresses do not require flipping or rotating, and most come with a removable and washable cover. This makes cleaning and maintaining your mattress a breeze, ensuring that it stays fresh and hygienic for years to come.

Maintaining a foam mattress is also much easier compared to traditional mattresses. Foam mattresses do not require flipping or rotating, and most come with a removable and washable cover. This makes cleaning and maintaining your mattress a breeze, ensuring that it stays fresh and hygienic for years to come.

Environmentally Friendly

Foam mattresses are also a more environmentally friendly option compared to traditional mattresses. They are made without the use of harmful chemicals and are biodegradable, making them a more sustainable choice for your home.

In conclusion, the process of making a foam mattress involves a specialized manufacturing process that results in a superior sleep experience. The benefits of a foam mattress include superior comfort and support, durability and longevity, hypoallergenic and dust mite resistance, easy maintenance, and environmental friendliness. Invest in a foam mattress today and experience the difference in your sleep and overall well-being.

Foam mattresses are also a more environmentally friendly option compared to traditional mattresses. They are made without the use of harmful chemicals and are biodegradable, making them a more sustainable choice for your home.

In conclusion, the process of making a foam mattress involves a specialized manufacturing process that results in a superior sleep experience. The benefits of a foam mattress include superior comfort and support, durability and longevity, hypoallergenic and dust mite resistance, easy maintenance, and environmental friendliness. Invest in a foam mattress today and experience the difference in your sleep and overall well-being.