Foam Mattress Manufacturing Process

Foam mattresses have become increasingly popular in recent years due to their comfort, durability, and ability to relieve pressure on the body. But have you ever wondered how these mattresses are made? In this article, we will take a closer look at the top 10 manufacturing processes for foam mattresses.

How Foam Mattresses are Made

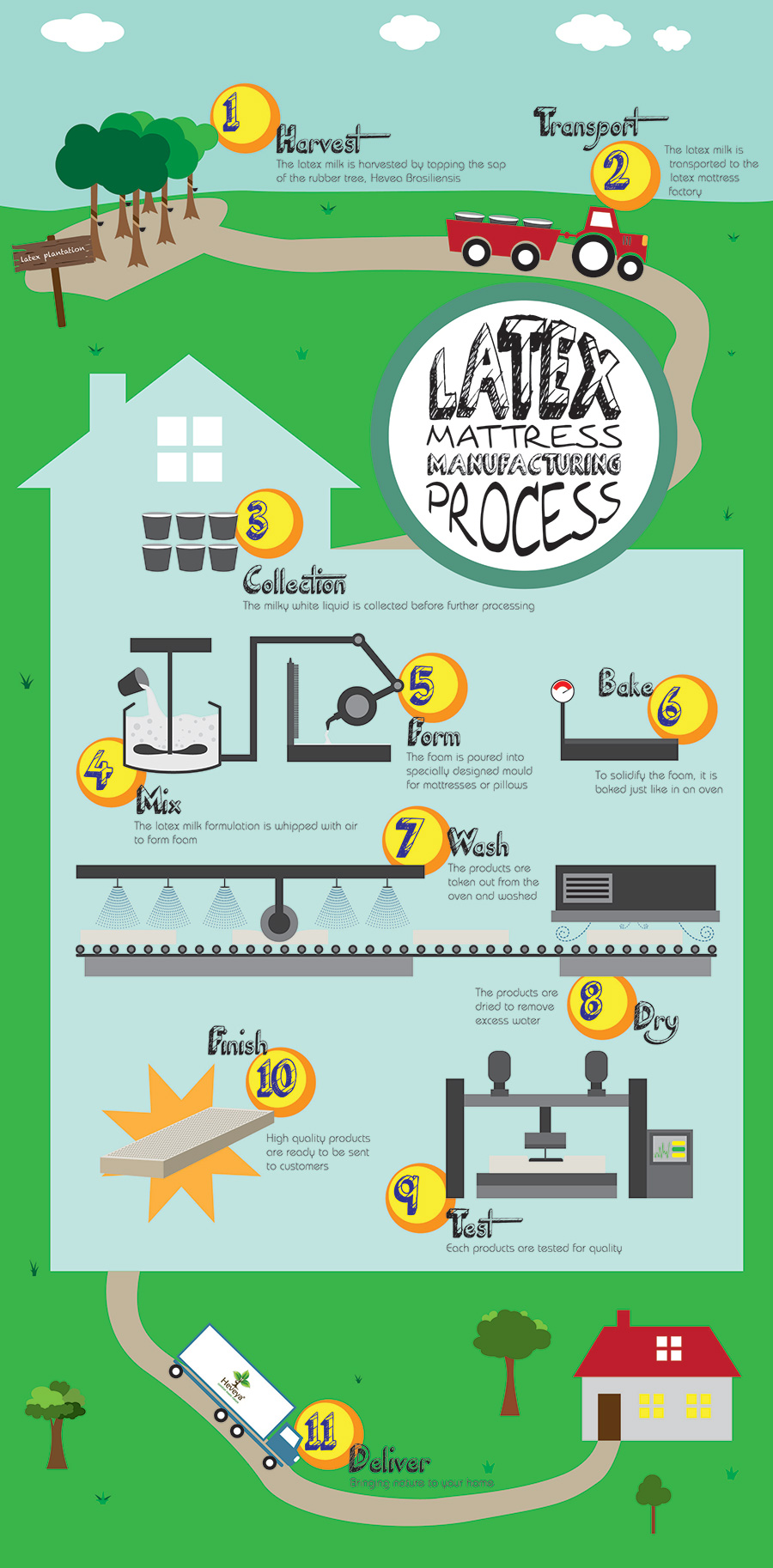

The manufacturing process of foam mattresses involves several steps and techniques to create the perfect sleeping surface. The type of foam used, the manufacturing equipment, and the quality control measures all play a crucial role in creating a high-quality foam mattress.

Steps in Manufacturing a Foam Mattress

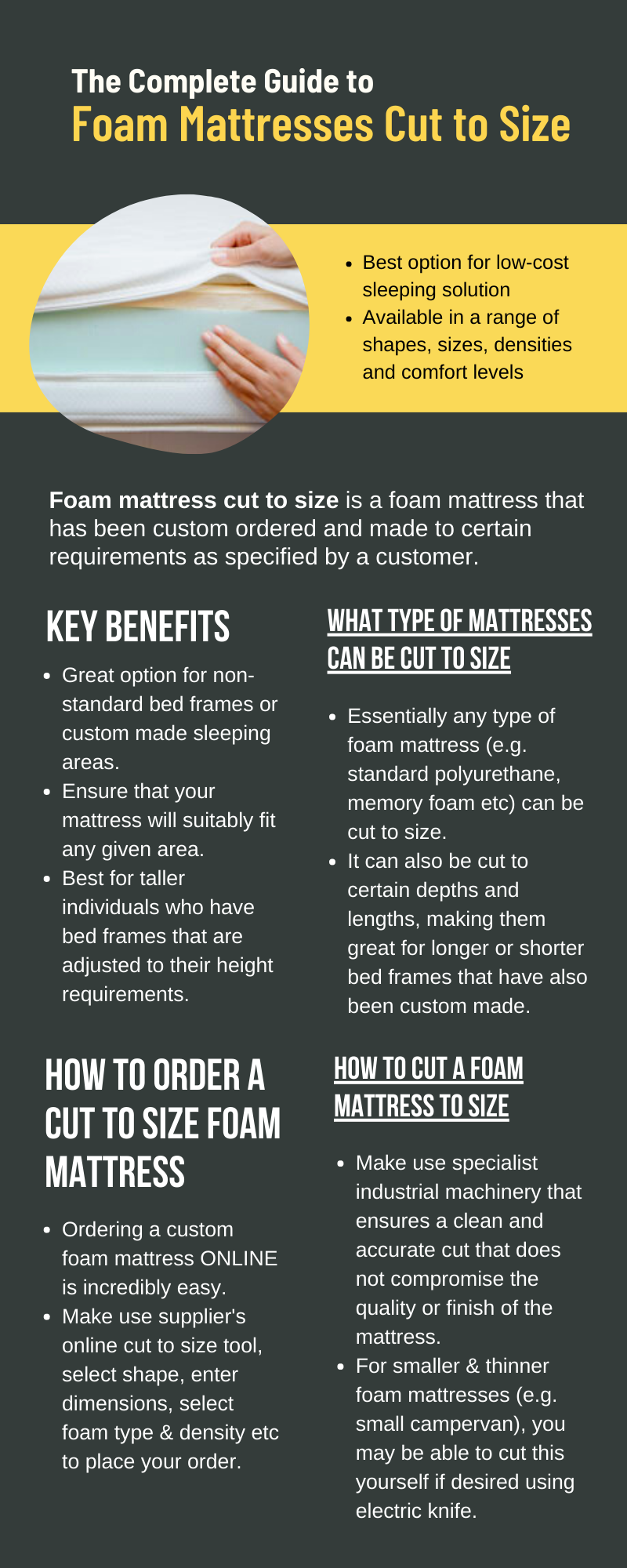

The first step in manufacturing a foam mattress is selecting the type of foam to be used. The most common types of foam used are memory foam, latex foam, and polyurethane foam. Each type has its unique properties and benefits, which determine the overall feel and comfort of the mattress.

Next, the foam is cut into the desired size and shape using specialized cutting machines. This step is crucial as it determines the dimensions and contours of the mattress. The foam is then placed in a mold and heated to a specific temperature to expand and take its final shape.

After the foam has cooled down, it is trimmed and inspected for any imperfections. The mattress is then covered with a fabric or knit cover and stitched together using heavy-duty sewing machines. The final product is then compressed and packaged for shipping.

Foam Mattress Production

The production of foam mattresses involves a combination of manual labor and advanced machinery. Skilled workers are responsible for cutting, trimming, and inspecting the foam, while machines are used for heating, compressing, and packaging the mattresses.

Foam Mattress Manufacturing Techniques

Manufacturers use various techniques to create foam mattresses that meet the desired comfort and support levels. For example, memory foam mattresses are made using a process called viscoelasticity, where the foam responds to body heat and pressure to conform to the sleeper's body.

Latex foam mattresses, on the other hand, are made using a process called vulcanization, where the foam is treated with heat and chemicals to create a more durable and elastic material. Polyurethane foam mattresses are made using a combination of chemicals and additives to create a foam with varying levels of density and firmness.

Foam Mattress Manufacturing Equipment

The manufacturing equipment used for foam mattresses includes cutting machines, molds, and sewing machines, among others. Advanced machinery, such as CNC cutting machines and automated sewing machines, have revolutionized the manufacturing process, resulting in more precise and efficient production.

Foam Mattress Manufacturing Materials

The main materials used in manufacturing foam mattresses are foam, fabric or knit covers, and adhesives. Foam is the primary component of the mattress and can be made from various materials, such as polyurethane, latex, or gel-infused memory foam. The cover is usually made from a combination of polyester, cotton, and other natural or synthetic fibers. Adhesives are used to bond different layers of foam and attach the cover to the mattress.

Foam Mattress Manufacturing Quality Control

Quality control is a crucial aspect of foam mattress manufacturing as it ensures that each mattress meets the necessary standards for comfort, durability, and safety. Manufacturers use various methods, such as visual inspection, pressure tests, and durability tests, to ensure that the mattresses are of the highest quality.

Foam Mattress Manufacturing Automation

With the advancement of technology, more and more manufacturers are turning to automation to improve the efficiency and consistency of their foam mattress production. Automated cutting and sewing machines have reduced the need for manual labor, resulting in faster production times and fewer errors.

Foam Mattress Manufacturing Sustainability

Sustainability is a growing concern in the manufacturing industry, and foam mattresses are no exception. Many manufacturers are implementing sustainable practices, such as using eco-friendly materials and reducing waste, to create more environmentally friendly products. Some companies even offer mattress recycling programs to reduce the impact on the environment.

In conclusion, the manufacturing process of foam mattresses involves a combination of skilled labor, advanced machinery, and quality control measures. Each step is crucial in creating a comfortable, durable, and sustainable sleeping surface. We hope this article has given you a better understanding of the top 10 manufacturing processes for foam mattresses.

The Manufacturing Process of Foam Mattresses

Creating the Foam

Foam mattresses

have become increasingly popular in recent years due to their comfort and support. They are made from a type of polyurethane foam that is specially designed for

mattress

use. The first step in the

manufacturing process

is creating the foam itself.

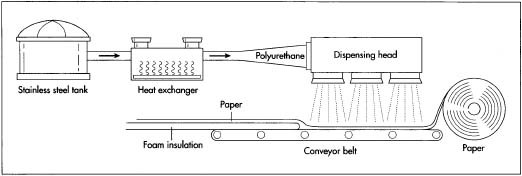

The foam is created by mixing chemicals, including polyol and diisocyanate, together in a large tank. These chemicals react and expand, creating a foam-like substance. The foam is then poured into a mold and heated to a specific temperature to set and cure the foam. This process creates the signature

memory foam

that is known for its pressure-relieving properties.

Foam mattresses

have become increasingly popular in recent years due to their comfort and support. They are made from a type of polyurethane foam that is specially designed for

mattress

use. The first step in the

manufacturing process

is creating the foam itself.

The foam is created by mixing chemicals, including polyol and diisocyanate, together in a large tank. These chemicals react and expand, creating a foam-like substance. The foam is then poured into a mold and heated to a specific temperature to set and cure the foam. This process creates the signature

memory foam

that is known for its pressure-relieving properties.

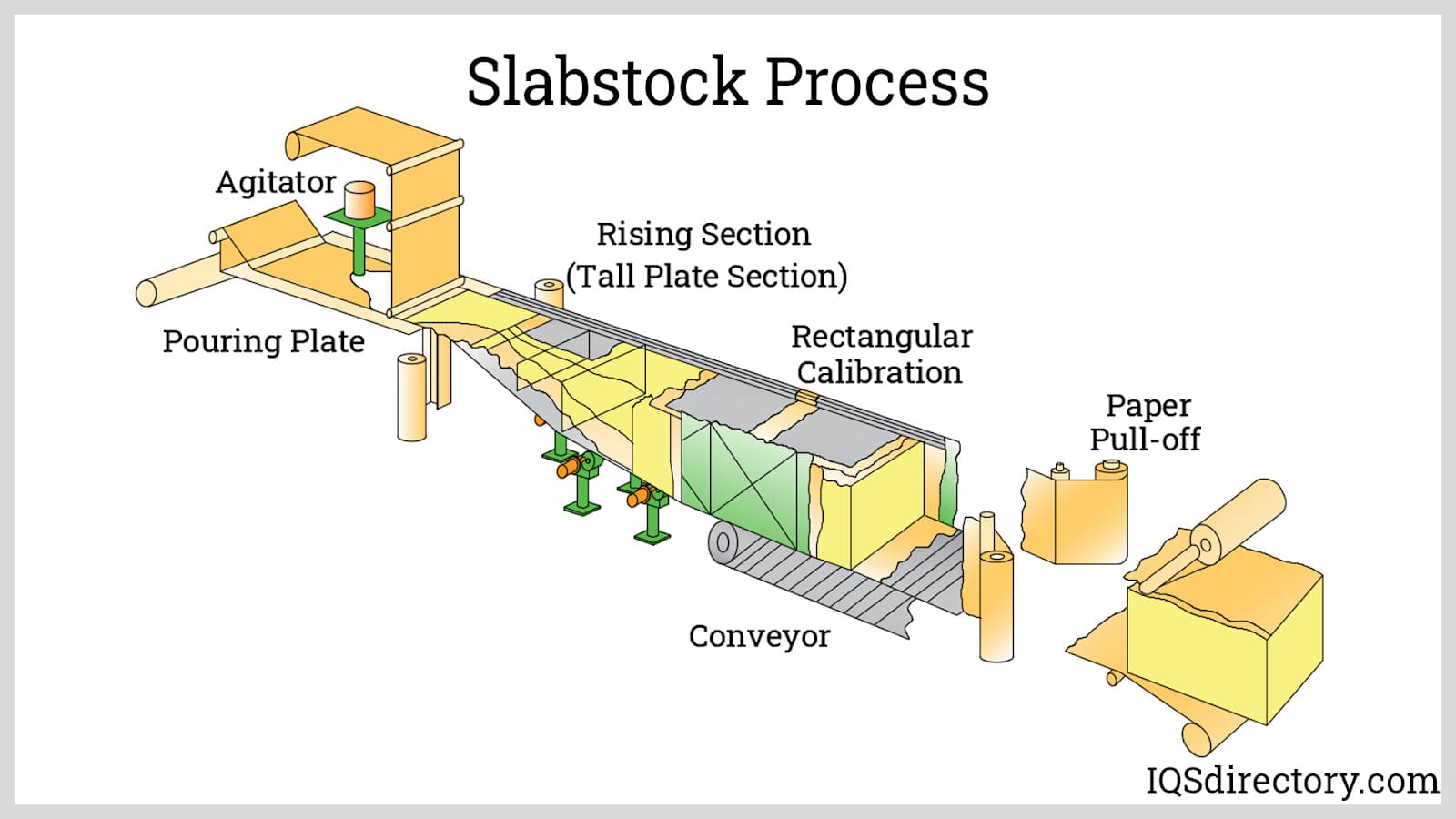

Cutting and Shaping

Once the foam has been created and cured, it is removed from the mold and cut into the desired shape and size for the

mattress

. This can be done manually or with the use of computer-controlled machines for precise cutting.

The foam is then shaped to the desired firmness level by adjusting the foam's density and the size and shape of the air pockets within the foam. This is an important step in the

manufacturing process

, as it determines the overall comfort and support of the

mattress

.

Once the foam has been created and cured, it is removed from the mold and cut into the desired shape and size for the

mattress

. This can be done manually or with the use of computer-controlled machines for precise cutting.

The foam is then shaped to the desired firmness level by adjusting the foam's density and the size and shape of the air pockets within the foam. This is an important step in the

manufacturing process

, as it determines the overall comfort and support of the

mattress

.

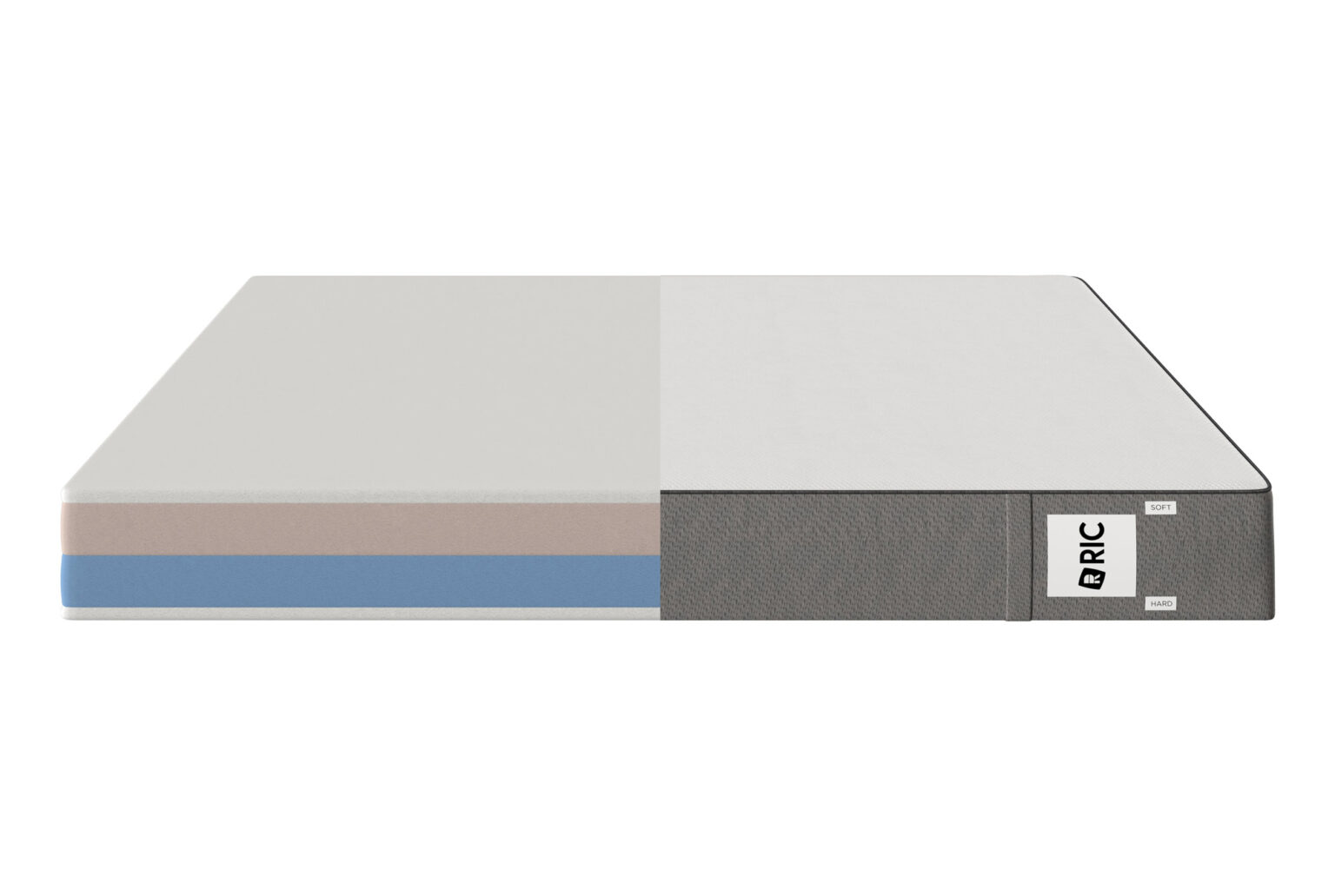

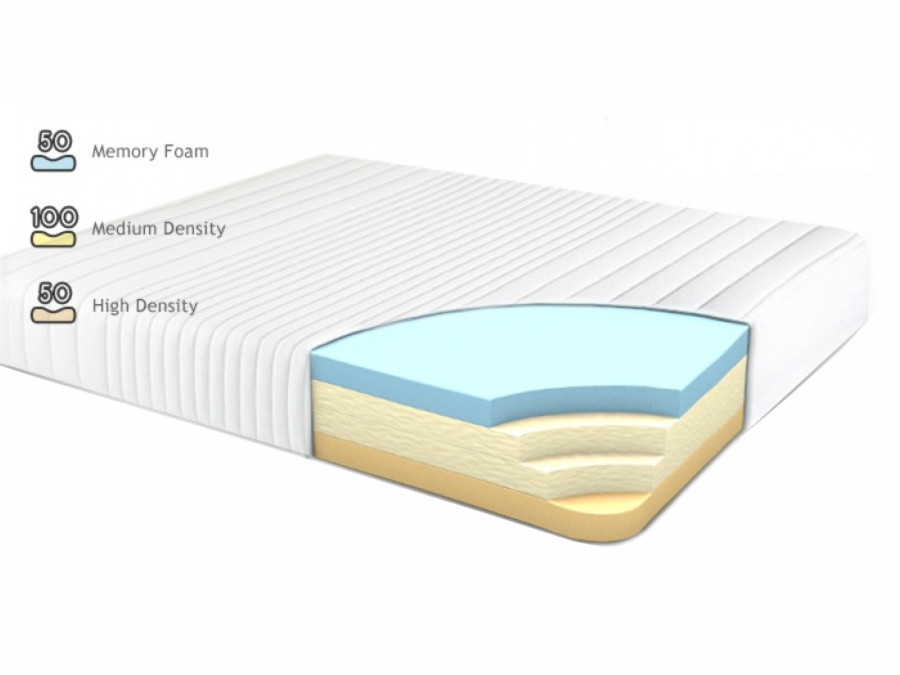

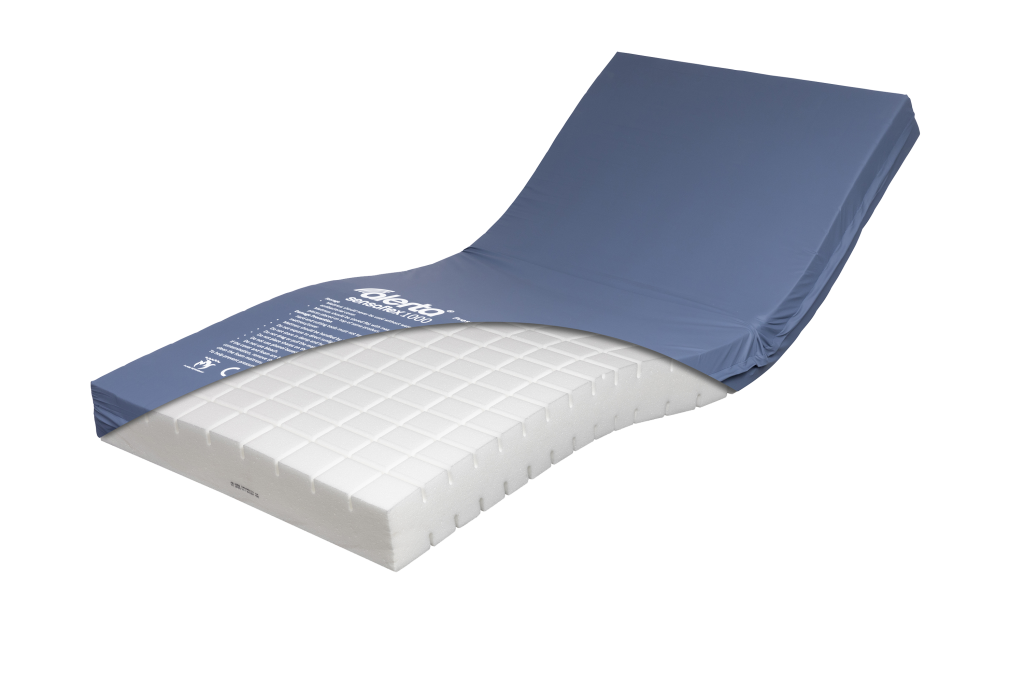

Adding Layers and Finishing Touches

To enhance the comfort and durability of the

foam mattress

, additional layers may be added during the

manufacturing process

. These layers can include a base layer for added support, a cooling gel layer for temperature regulation, and a cover for protection and aesthetics.

Once all the layers have been added, the

mattress

is then sealed and compressed for shipping. This allows for easy transportation and also helps to maintain the

mattress's

shape and integrity.

In conclusion, the

manufacturing process

of foam mattresses is a highly technical and precise process that results in a high-quality and comfortable sleeping surface. From creating the foam itself to shaping and adding finishing touches, each step plays a crucial role in producing a

mattress

that provides optimal comfort and support for a good night's sleep.

To enhance the comfort and durability of the

foam mattress

, additional layers may be added during the

manufacturing process

. These layers can include a base layer for added support, a cooling gel layer for temperature regulation, and a cover for protection and aesthetics.

Once all the layers have been added, the

mattress

is then sealed and compressed for shipping. This allows for easy transportation and also helps to maintain the

mattress's

shape and integrity.

In conclusion, the

manufacturing process

of foam mattresses is a highly technical and precise process that results in a high-quality and comfortable sleeping surface. From creating the foam itself to shaping and adding finishing touches, each step plays a crucial role in producing a

mattress

that provides optimal comfort and support for a good night's sleep.