Leather sofas are a popular choice for furniture due to their durability, comfort, and timeless style. But have you ever wondered how these luxurious pieces of furniture are made? In this article, we will take a closer look at the top 10 main steps in the leather sofa manufacturing process.Leather Sofa Manufacturing Process

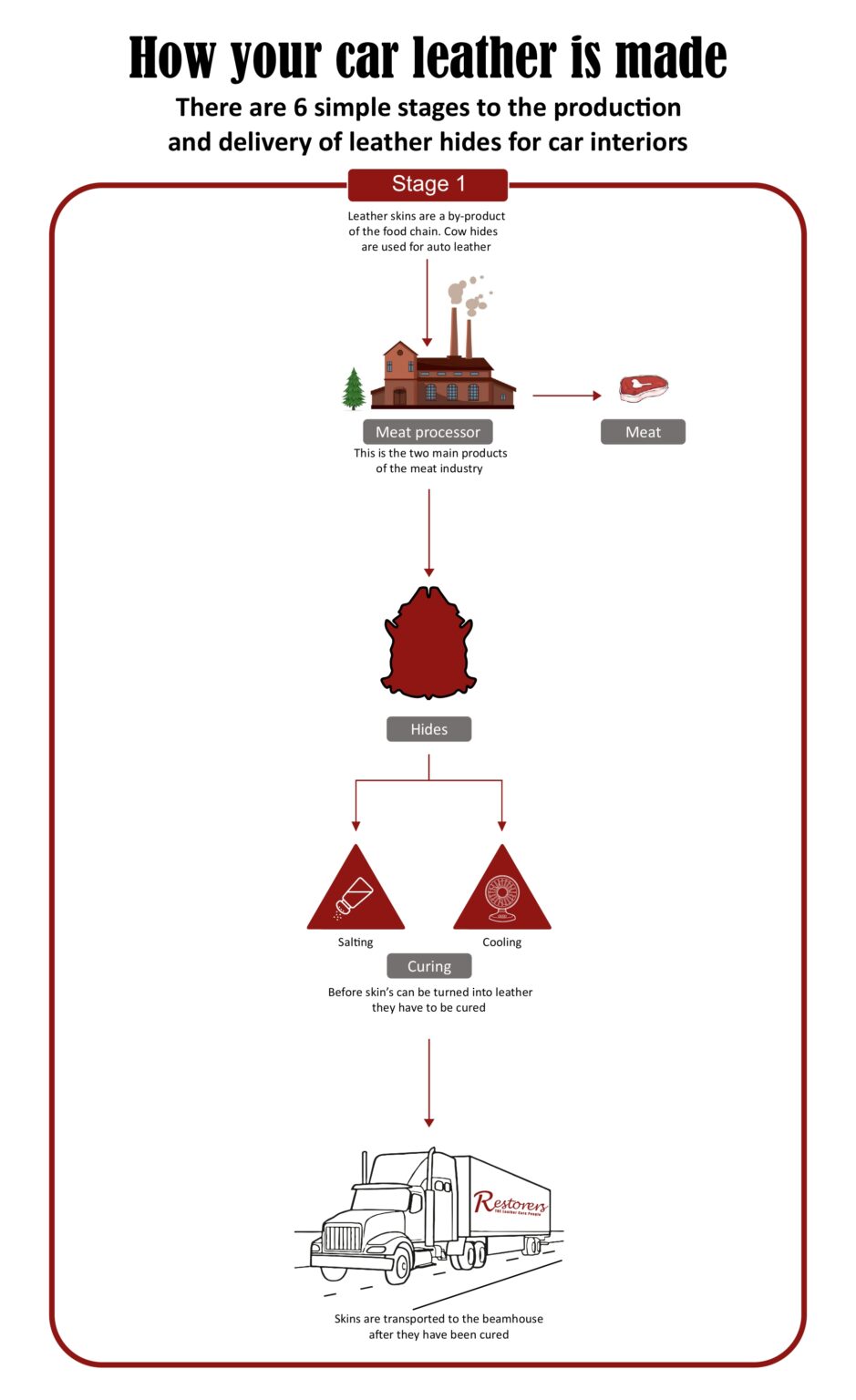

The first step in the production of leather sofas is sourcing the materials. High-quality leather is the key to creating a durable and luxurious sofa. Manufacturers carefully select leather hides from reputable suppliers, ensuring that they meet the required standards for color, texture, and thickness.Leather Sofa Production

Once the leather has been sourced, it is sent to the manufacturing facility where the production process begins. The leather is inspected for any imperfections or damages, and then it is cut into the desired shape and size for the sofa.Leather Furniture Manufacturing

The next step is the assembly of the sofa. The wooden frame is constructed, and the leather is stretched and secured to the frame. The cushioning is then added, providing the comfortable padding that makes leather sofas so desirable.Leather Sofa Assembly

The construction of a leather sofa is a crucial step in the manufacturing process. Skilled craftsmen carefully stitch the leather pieces together, ensuring that the seams are strong and the sofa is structurally sound. This is where the design and style of the sofa are brought to life.Leather Sofa Construction

The design of a leather sofa is just as important as its construction. Designers work closely with manufacturers to create unique and attractive styles that will appeal to customers. From traditional to modern designs, there is a leather sofa for every taste and preference.Leather Sofa Design

In addition to high-quality leather, other materials are used in the production of a leather sofa. This includes the wooden frame, cushioning, and decorative elements such as buttons and studs. These materials are carefully selected and tested to ensure they meet the required standards for durability and safety.Leather Sofa Materials

Quality control is an essential step in the leather sofa manufacturing process. Every sofa goes through a rigorous inspection to ensure that it meets the company's high standards before it is released for sale. This includes checking for any defects, ensuring the sofa is comfortable and properly constructed, and verifying that it matches the design and specifications.Leather Sofa Quality Control

After passing quality control, the leather sofa is ready for finishing. This involves adding any final touches, such as polishing the wooden frame and adding decorative elements to enhance the overall appearance of the sofa.Leather Sofa Finishing

The final step in the manufacturing process is packaging the leather sofa for delivery. The sofa is carefully wrapped and protected to ensure it arrives at its destination in pristine condition. This includes using specially designed covers and packaging materials to prevent any damage during transportation.Leather Sofa Packaging

The Importance of High-Quality Leather for Sofa Manufacturing

Choosing the Right Leather

When it comes to manufacturing a leather sofa, one of the most crucial steps is selecting the right type of leather. Not all leather is created equal, and the type of leather used can greatly affect the overall quality and durability of the sofa.

Full-grain leather

is considered the highest quality and most durable type of leather. It is made from the top layer of the hide, which contains the strongest and most durable fibers.

Top-grain leather

, on the other hand, is slightly lower in quality as it is made from the second layer of the hide and may have been sanded or buffed to remove imperfections. It is still a good option for a sofa, but may not be as durable as full-grain leather.

Bonded leather

, while the most affordable option, is made from leftover pieces of leather that are bonded together with adhesives. It is the lowest quality and least durable option for a leather sofa.

Choosing the right type of leather is essential for creating a high-quality and long-lasting sofa.

When it comes to manufacturing a leather sofa, one of the most crucial steps is selecting the right type of leather. Not all leather is created equal, and the type of leather used can greatly affect the overall quality and durability of the sofa.

Full-grain leather

is considered the highest quality and most durable type of leather. It is made from the top layer of the hide, which contains the strongest and most durable fibers.

Top-grain leather

, on the other hand, is slightly lower in quality as it is made from the second layer of the hide and may have been sanded or buffed to remove imperfections. It is still a good option for a sofa, but may not be as durable as full-grain leather.

Bonded leather

, while the most affordable option, is made from leftover pieces of leather that are bonded together with adhesives. It is the lowest quality and least durable option for a leather sofa.

Choosing the right type of leather is essential for creating a high-quality and long-lasting sofa.

Tanning Process

Once the leather has been selected, it goes through a tanning process to prepare it for use. This process involves treating the leather with chemicals to prevent it from deteriorating and to give it the desired color and texture. This is an important step as it not only affects the appearance of the leather, but also its durability and resistance to wear and tear.

Chrome tanning

is the most commonly used method, as it is quick and produces a wide range of colors and textures. However, it can also be harsh on the environment.

Veg-tanning

, on the other hand, is a more natural and eco-friendly process, but it takes longer and produces a more limited range of colors and textures.

Whichever tanning method is used, it is important that it is done properly to ensure the leather is of high quality and suitable for use in a sofa.

Once the leather has been selected, it goes through a tanning process to prepare it for use. This process involves treating the leather with chemicals to prevent it from deteriorating and to give it the desired color and texture. This is an important step as it not only affects the appearance of the leather, but also its durability and resistance to wear and tear.

Chrome tanning

is the most commonly used method, as it is quick and produces a wide range of colors and textures. However, it can also be harsh on the environment.

Veg-tanning

, on the other hand, is a more natural and eco-friendly process, but it takes longer and produces a more limited range of colors and textures.

Whichever tanning method is used, it is important that it is done properly to ensure the leather is of high quality and suitable for use in a sofa.

Expert Craftsmanship

The final step in the leather sofa manufacturing process is the skilled craftsmanship that goes into creating the sofa. This involves cutting the leather to the desired shape and size, stitching it together with strong and durable thread, and adding any additional details such as tufting or piping. This step requires a high level of expertise and attention to detail to ensure the sofa is not only visually appealing, but also structurally sound.

Expert craftsmanship is what sets a high-quality leather sofa apart from a mediocre one.

In conclusion, the process of manufacturing a leather sofa involves carefully selecting the right type of leather, properly tanning it, and skilled craftsmanship. Each step is crucial in creating a high-quality and durable sofa that will not only add style to your home design but also stand the test of time.

Investing in a leather sofa made with top-quality leather and expert craftsmanship is a wise choice for any homeowner looking to elevate their living space.

The final step in the leather sofa manufacturing process is the skilled craftsmanship that goes into creating the sofa. This involves cutting the leather to the desired shape and size, stitching it together with strong and durable thread, and adding any additional details such as tufting or piping. This step requires a high level of expertise and attention to detail to ensure the sofa is not only visually appealing, but also structurally sound.

Expert craftsmanship is what sets a high-quality leather sofa apart from a mediocre one.

In conclusion, the process of manufacturing a leather sofa involves carefully selecting the right type of leather, properly tanning it, and skilled craftsmanship. Each step is crucial in creating a high-quality and durable sofa that will not only add style to your home design but also stand the test of time.

Investing in a leather sofa made with top-quality leather and expert craftsmanship is a wise choice for any homeowner looking to elevate their living space.

.jpeg?w=1700&h=2550)