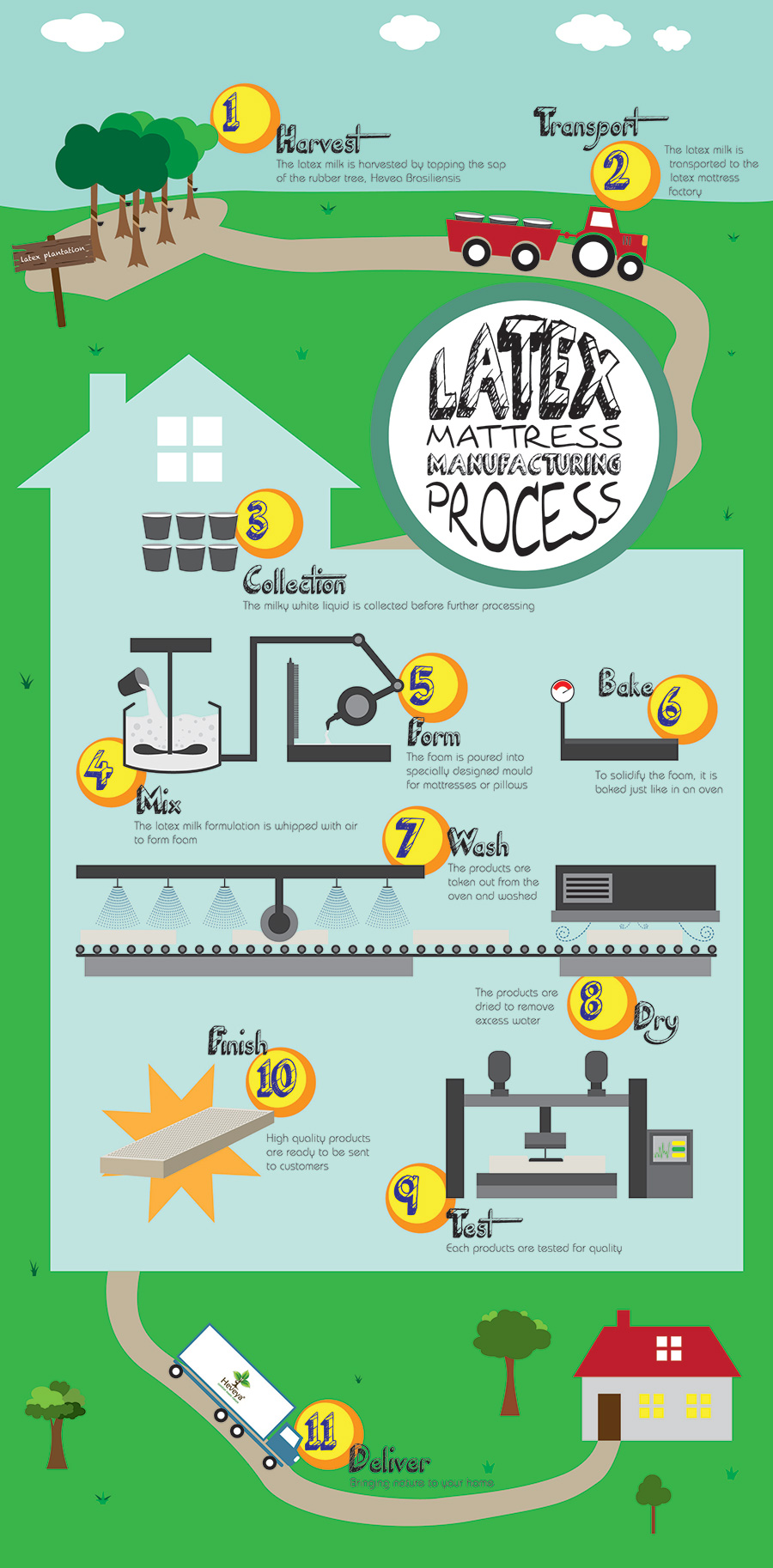

Latex Foam Production Process

Latex mattresses are becoming increasingly popular for their natural and sustainable materials, as well as their comfort and support. But have you ever wondered how these mattresses are made? In this article, we'll take a closer look at the top 10 steps in the latex mattress manufacturing process.

How Latex Mattresses are Made

The production of latex mattresses starts with the harvesting of rubber tree sap. This sap, also known as latex, is collected and processed into a foam material that is used in mattresses. Let's dive into the details of the manufacturing process to better understand how these mattresses are made.

Manufacturing Process of Latex Mattresses

The manufacturing process of latex mattresses involves several steps, from collecting the raw material to packaging the final product. Let's break down each step in detail.

Latex Mattress Production Steps

Step 1: Harvesting the Rubber Tree Sap

The first step in making a latex mattress is harvesting the rubber tree sap, also known as latex. This sap is collected by making small cuts in the bark of the rubber tree and allowing the sap to flow into cups or containers.

Step 2: Coagulation

The collected sap is then treated with chemicals to coagulate or solidify it. This process removes any impurities and helps to create a more consistent material for the next steps.

Step 3: Washing and Drying

Once coagulated, the latex is washed and dried to remove any remaining impurities and moisture. This ensures a pure and clean material for the next step.

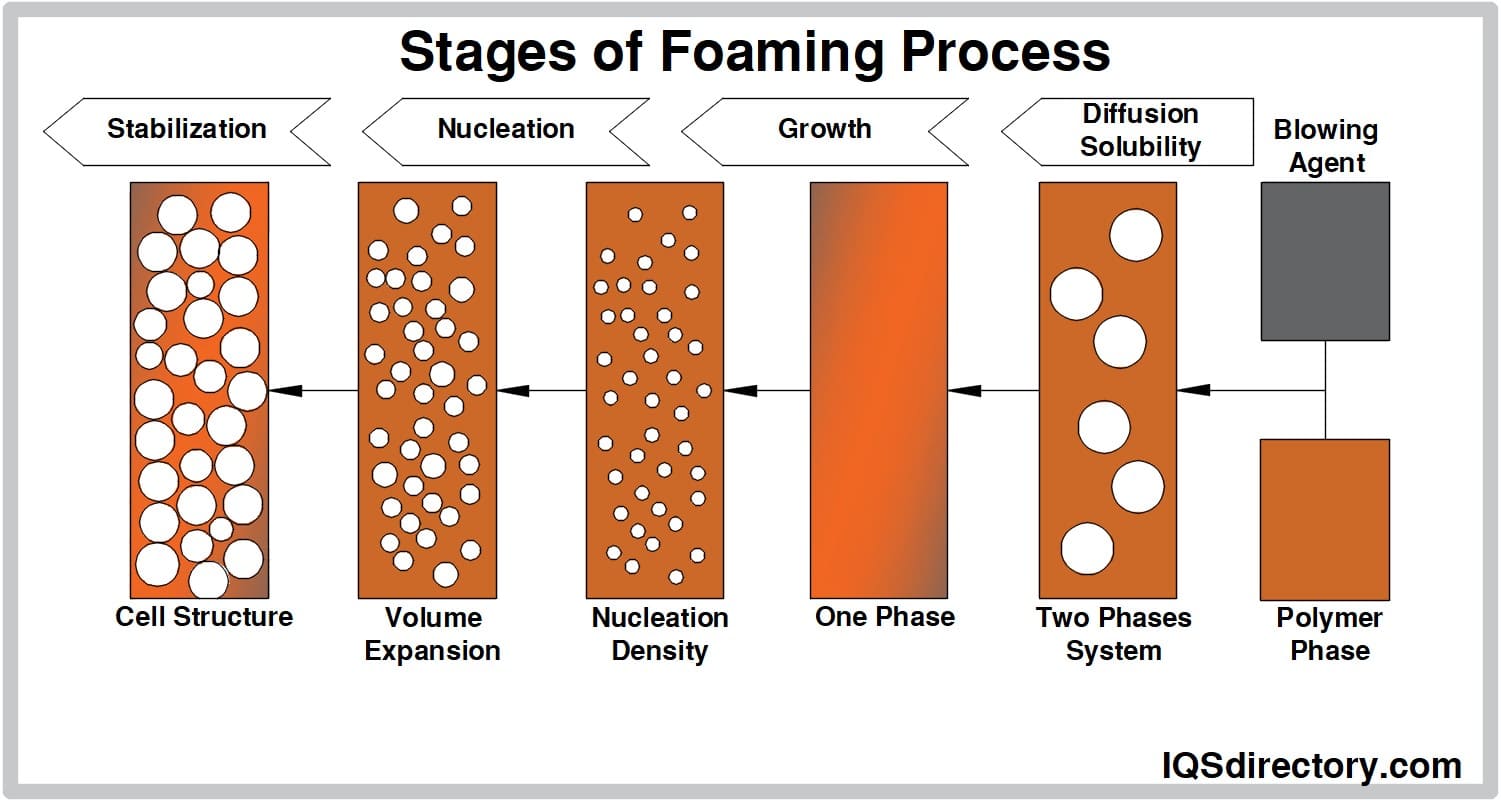

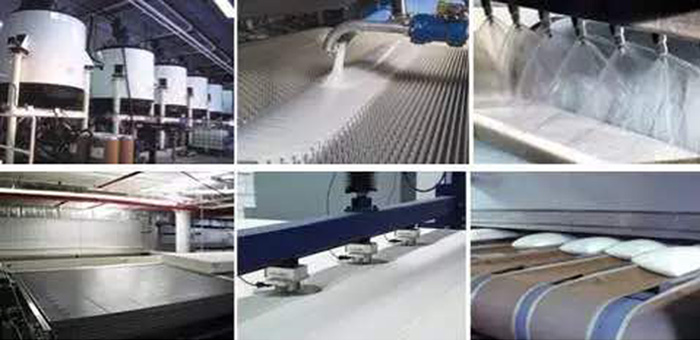

Step 4: Mixing and Foaming

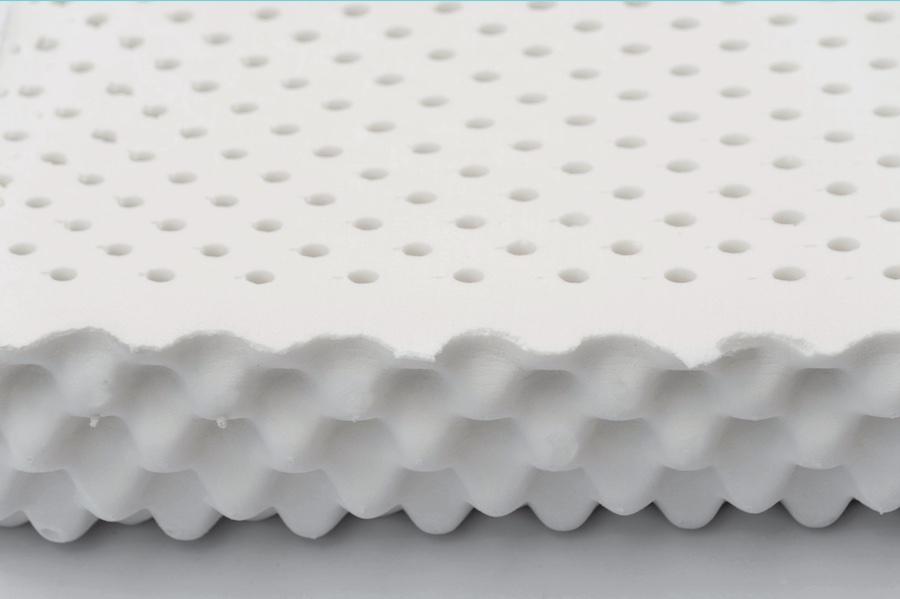

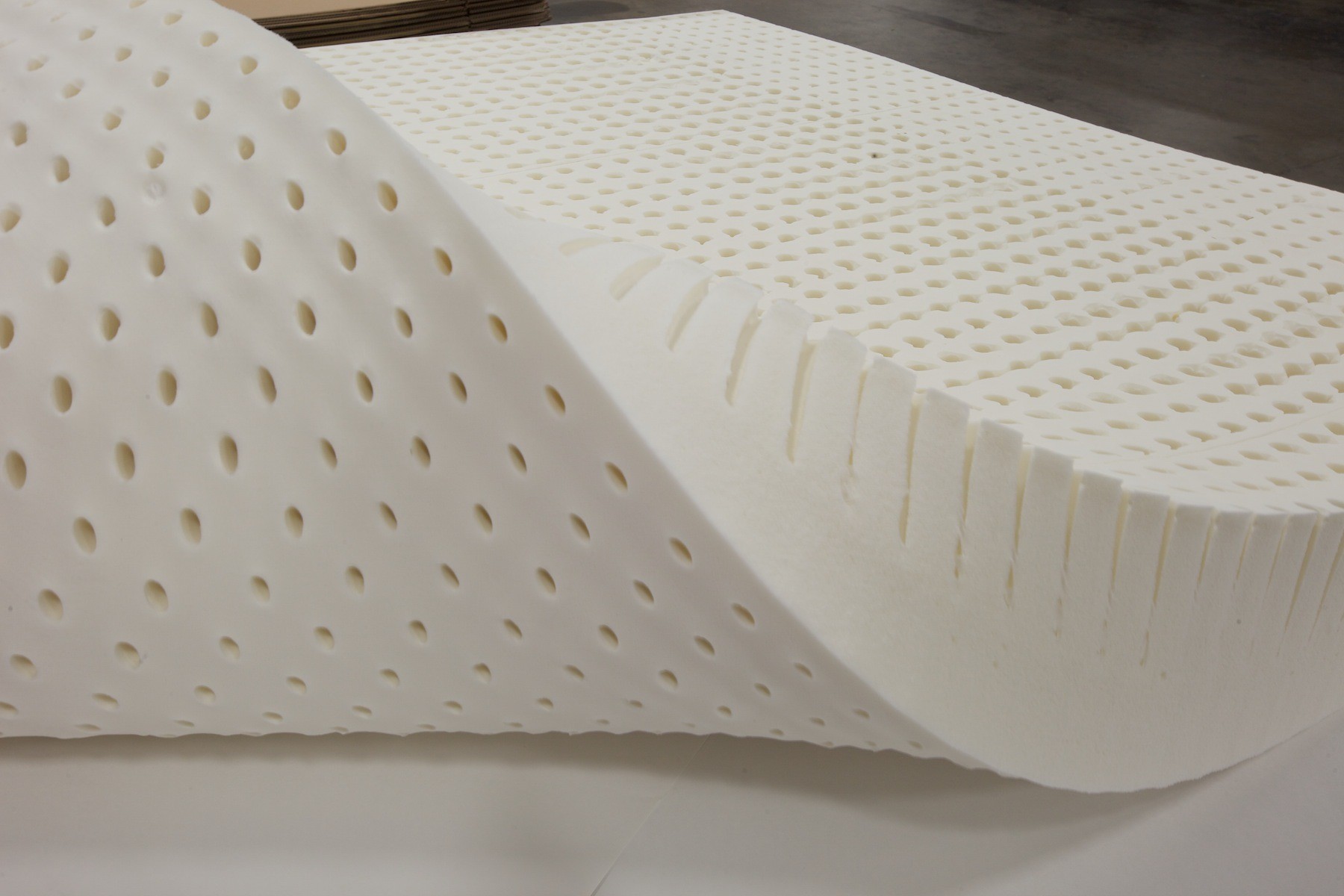

The dried latex is then mixed with air and other materials to create a foam-like consistency. This foam is then poured into molds, and the air is removed to create a solid material.

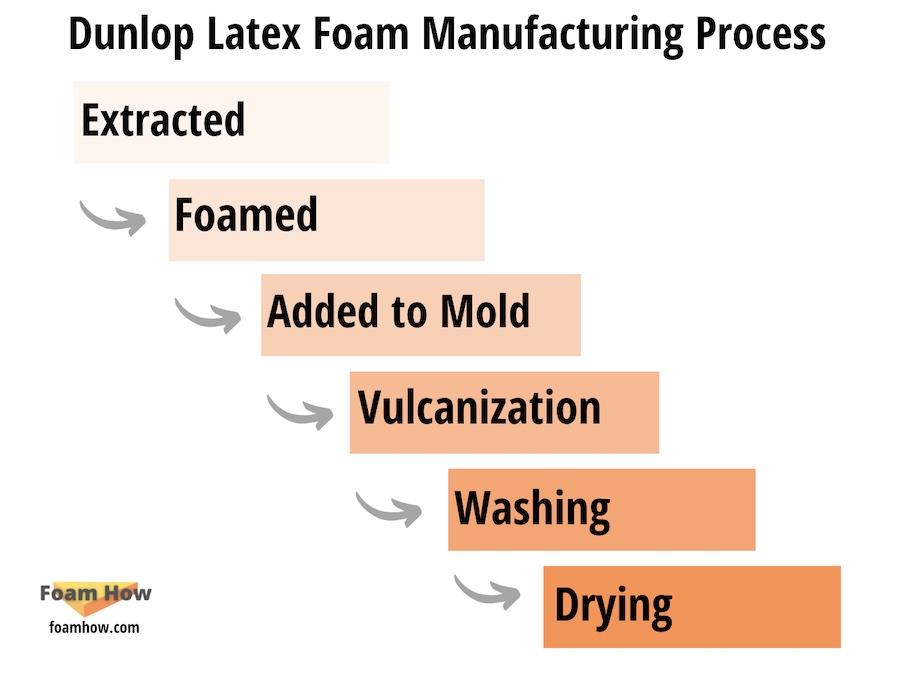

Step 5: Vulcanization

The latex foam is then heated and cured in a process called vulcanization. This helps to strengthen the material and make it more durable.

Step 6: Cutting and Shaping

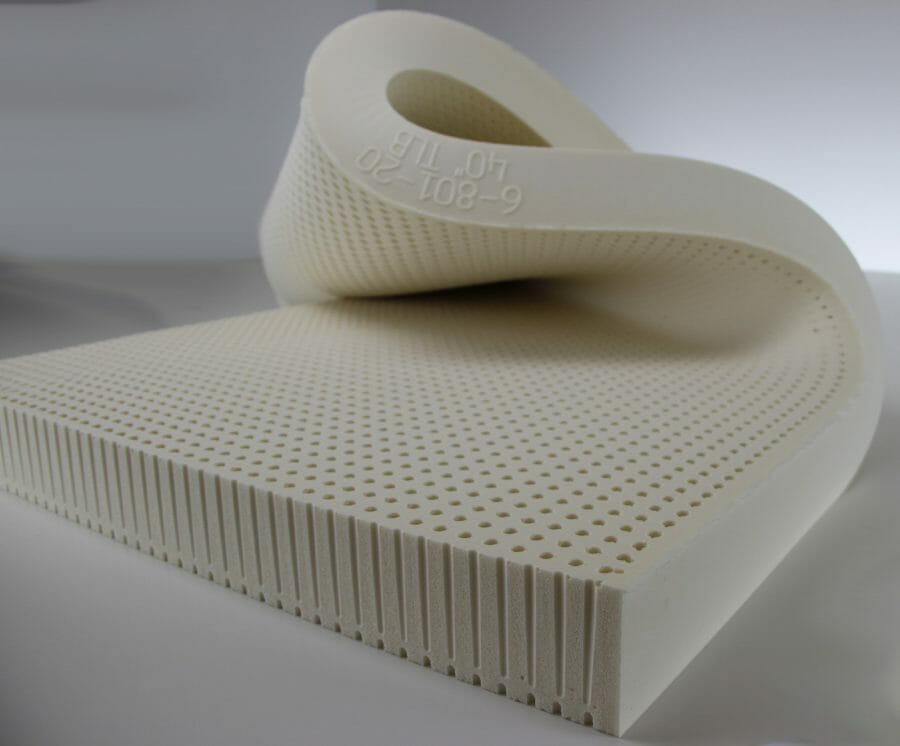

After vulcanization, the latex foam is cut and shaped into the desired size and shape for the mattress. This can be done using various cutting and shaping techniques, depending on the manufacturer.

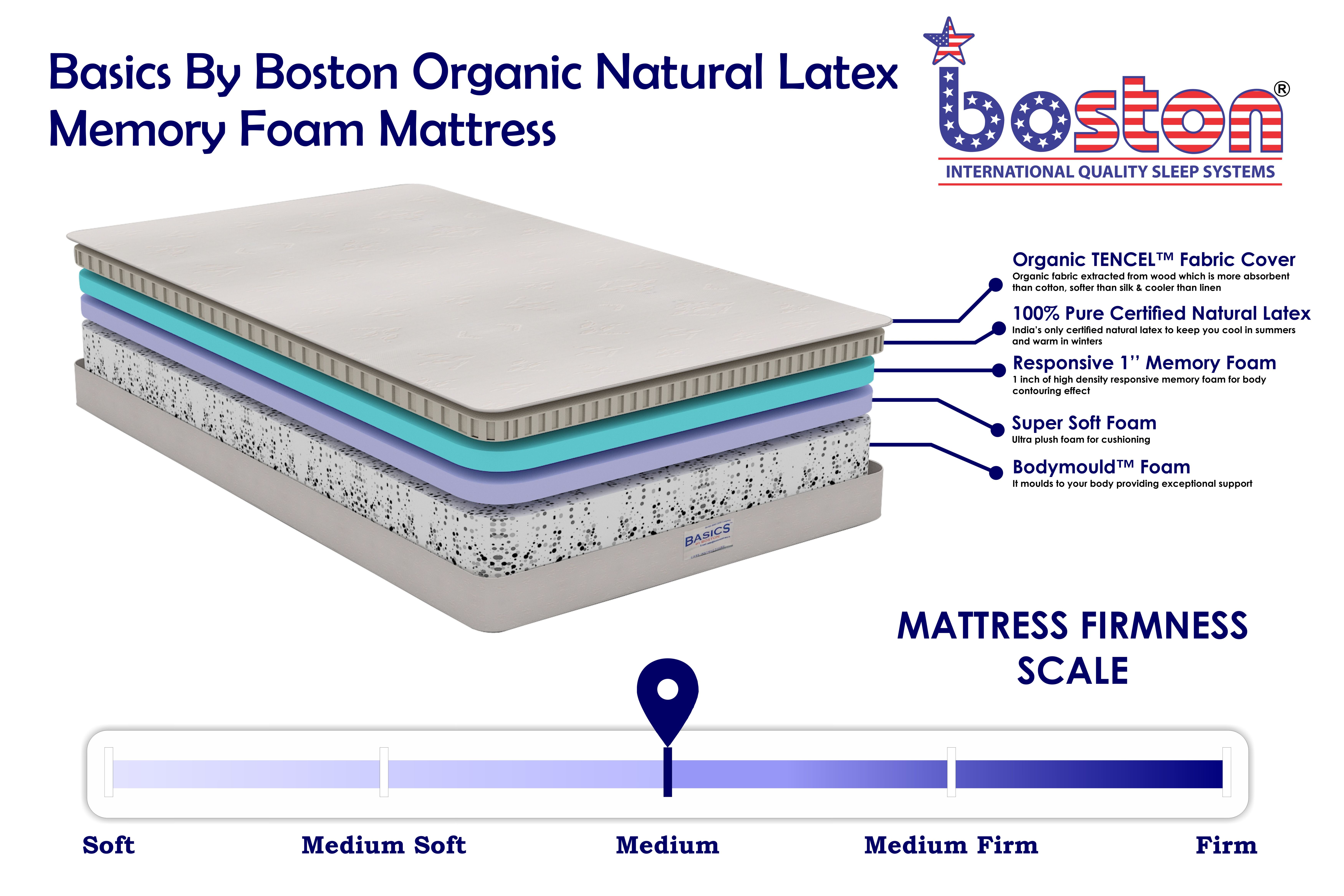

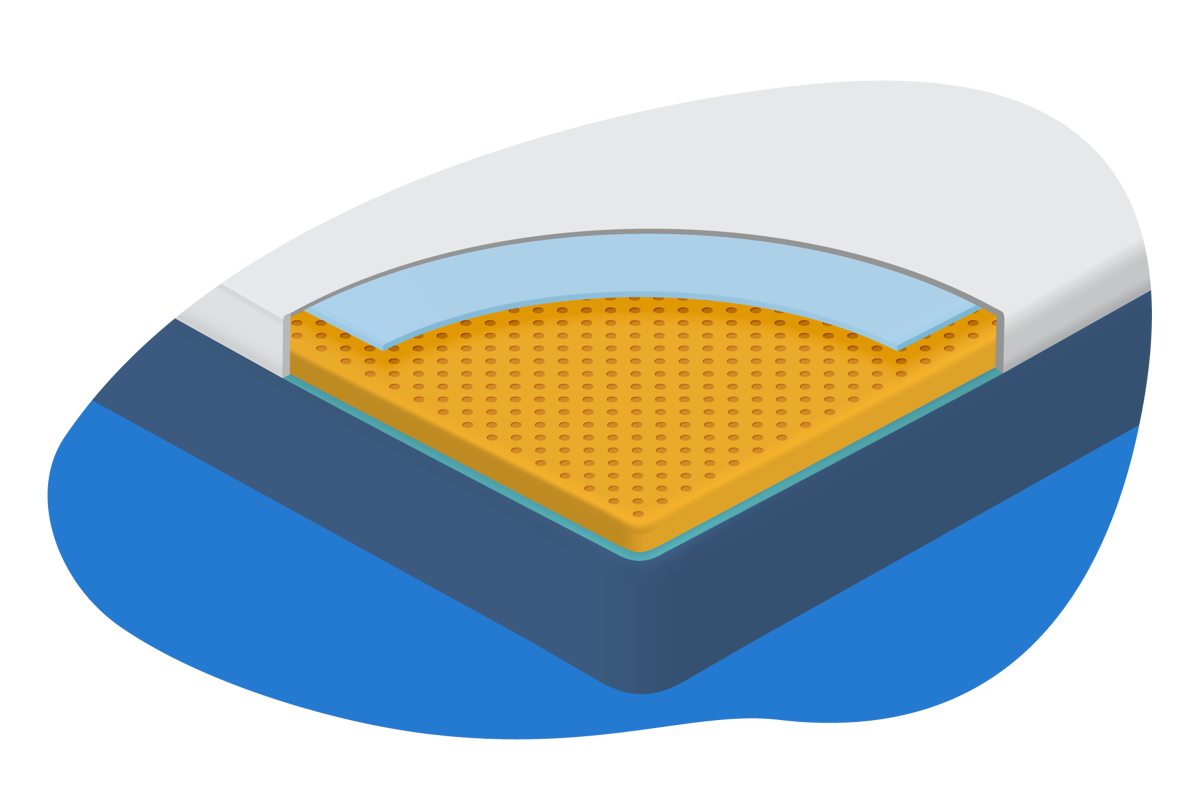

Step 7: Layering

Some latex mattresses are made with multiple layers of foam to provide different levels of support and comfort. In this step, the different layers are stacked and bonded together using adhesive.

Step 8: Quilting and Covering

The mattress is then quilted and covered with a fabric cover, typically made from organic cotton or bamboo. This cover helps to protect the mattress and add an extra layer of comfort.

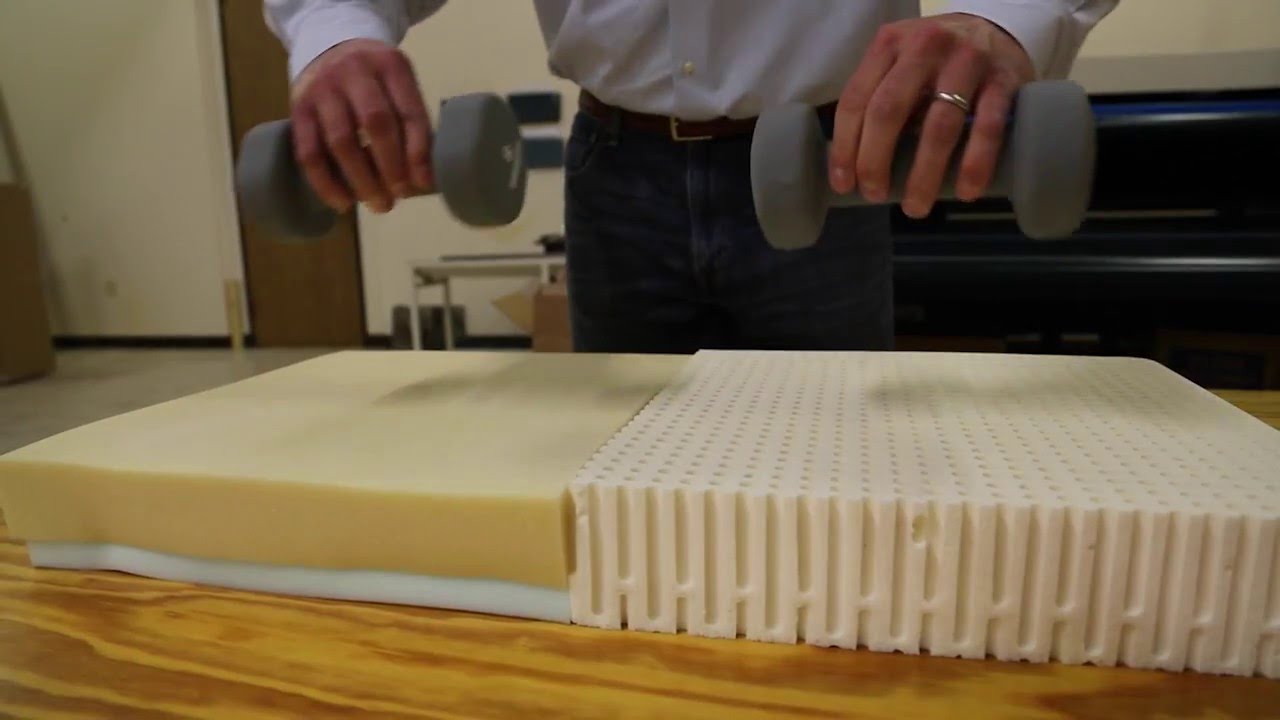

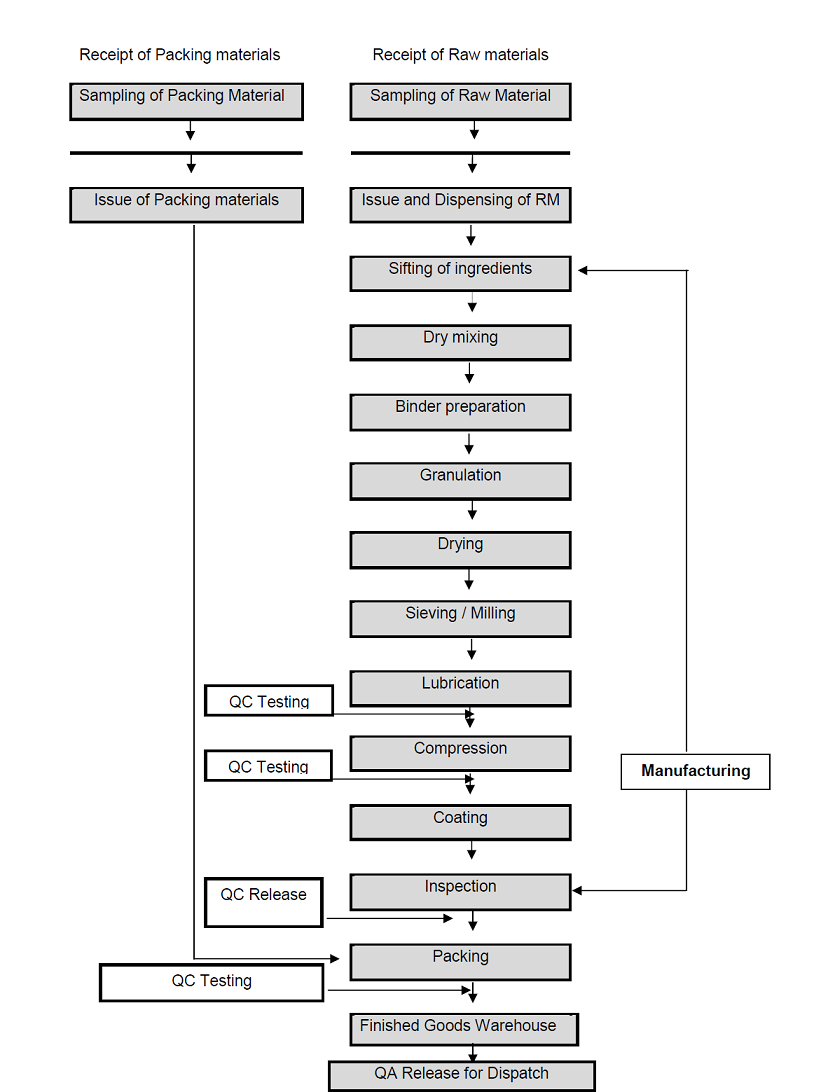

Step 9: Quality Control and Testing

Before packaging, the mattress goes through a series of quality control tests to ensure it meets the manufacturer's standards. This includes checking for any defects, inconsistencies, or imperfections.

Step 10: Packaging and Shipping

Once the mattress passes all quality control tests, it is packaged and shipped to retailers or directly to customers.

Latex Mattress Manufacturing Techniques

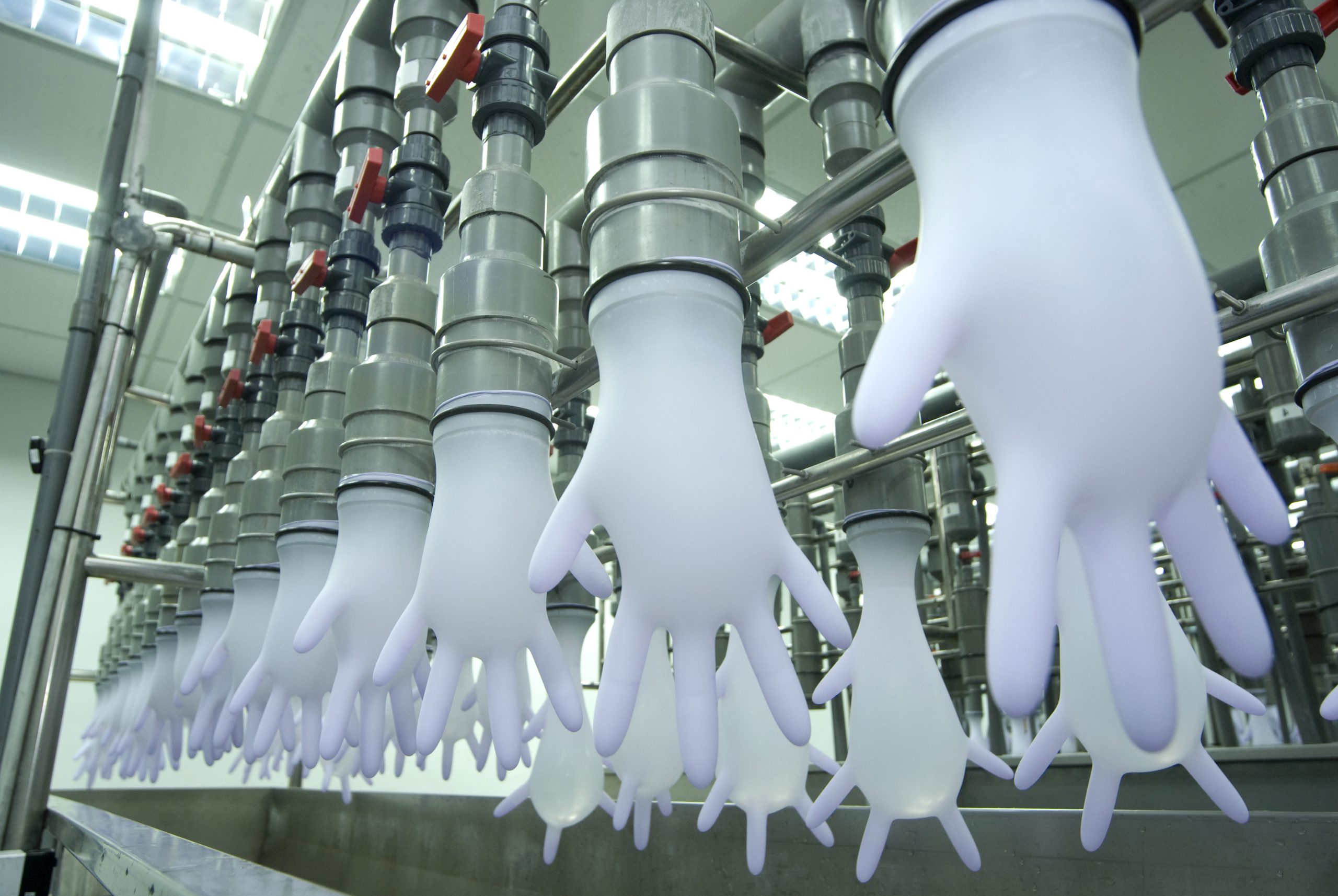

The manufacturing process of latex mattresses involves a combination of traditional and modern techniques. This includes hand harvesting the sap, but also using advanced machinery for mixing, shaping, and vulcanization.

Latex Mattress Production Line

The production line for latex mattresses typically involves several stages, from collecting the raw material to packaging the final product. Each stage is crucial in creating a high-quality and comfortable mattress that meets industry standards.

Latex Mattress Manufacturing Equipment

The equipment used in latex mattress manufacturing varies depending on the manufacturer and their specific processes. However, some common equipment includes molds, cutting and shaping tools, and machinery used for mixing, vulcanization, and testing.

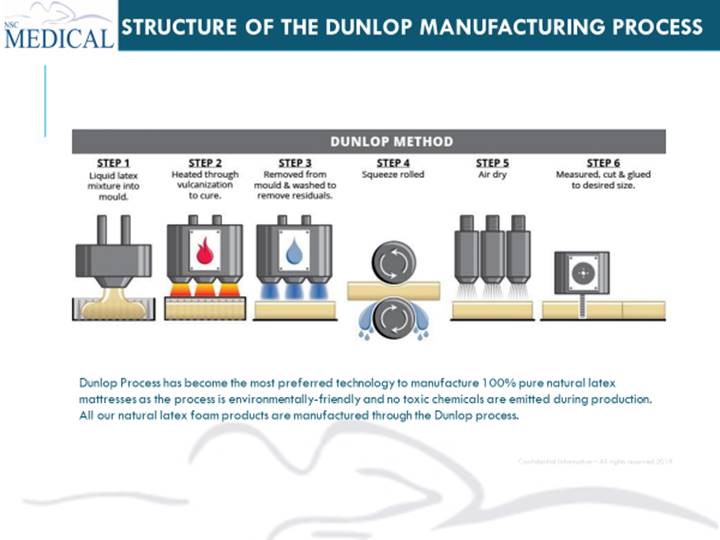

Latex Mattress Production Methods

There are two main production methods for latex mattresses: Dunlop and Talalay. The Dunlop method is the traditional method and involves pouring the latex foam into molds and allowing it to settle. The Talalay method is a newer and more advanced process that involves freezing the foam before vulcanization to create a more consistent and uniform material.

Latex Mattress Manufacturing Steps

The steps involved in manufacturing a latex mattress may vary slightly depending on the manufacturer and their specific processes. However, the general steps involve collecting and processing the raw material, shaping and curing the foam, and testing and packaging the final product.

Latex Mattress Production Process Explained

In summary, the production of latex mattresses involves a combination of traditional and modern techniques, from harvesting the rubber tree sap to packaging the final product. Each step is crucial in creating a high-quality and comfortable mattress that meets industry standards. So the next time you lay down on your latex mattress, you'll have a better understanding of the intricate process that went into making it.

The Importance of a Quality Latex Mattress in Your House Design

Why Choose a Latex Mattress?

When it comes to designing your dream house, one of the most important factors to consider is the quality of your mattress. After all, a good night's sleep is crucial for our overall health and well-being. With the increasing popularity of latex mattresses, it's important to understand the

manufacturing process

behind this

highly sought-after

bedding option.

When it comes to designing your dream house, one of the most important factors to consider is the quality of your mattress. After all, a good night's sleep is crucial for our overall health and well-being. With the increasing popularity of latex mattresses, it's important to understand the

manufacturing process

behind this

highly sought-after

bedding option.

The Manufacturing Process of Latex Mattresses

Unlike traditional mattresses, latex mattresses are made from the sap of rubber trees, which are mainly found in South-East Asia. The process begins with tapping the trees, where the sap is collected and then filtered to remove impurities. The

latex

is then whipped and poured into molds to create the desired shape and size of the mattress. The molds are then heated to cure the latex, resulting in a solid and durable mattress core.

Unlike traditional mattresses, latex mattresses are made from the sap of rubber trees, which are mainly found in South-East Asia. The process begins with tapping the trees, where the sap is collected and then filtered to remove impurities. The

latex

is then whipped and poured into molds to create the desired shape and size of the mattress. The molds are then heated to cure the latex, resulting in a solid and durable mattress core.

Benefits of a Latex Mattress

One of the main benefits of a latex mattress is its

durability

. The manufacturing process of latex mattresses creates a strong and resilient product that can last for up to 20 years. This makes it a great investment for your house design, as you won't have to worry about replacing your mattress every few years.

Another important factor to consider in house design is

comfort

. Latex mattresses offer excellent pressure relief, as they are able to contour to the shape of your body. This not only ensures a comfortable sleep, but also helps to alleviate any aches and pains you may have.

One of the main benefits of a latex mattress is its

durability

. The manufacturing process of latex mattresses creates a strong and resilient product that can last for up to 20 years. This makes it a great investment for your house design, as you won't have to worry about replacing your mattress every few years.

Another important factor to consider in house design is

comfort

. Latex mattresses offer excellent pressure relief, as they are able to contour to the shape of your body. This not only ensures a comfortable sleep, but also helps to alleviate any aches and pains you may have.

Environmental Impact

In today's world, it's important to consider the environmental impact of the products we use. Latex mattresses are an eco-friendly option, as the rubber trees used for production are grown in sustainable plantations. Additionally, the manufacturing process of latex mattresses produces minimal waste, making it a more environmentally responsible choice.

In today's world, it's important to consider the environmental impact of the products we use. Latex mattresses are an eco-friendly option, as the rubber trees used for production are grown in sustainable plantations. Additionally, the manufacturing process of latex mattresses produces minimal waste, making it a more environmentally responsible choice.

Conclusion

A quality latex mattress is a crucial component of any house design. Its durability, comfort, and eco-friendliness make it a top choice for many homeowners. By understanding the manufacturing process behind latex mattresses, you can make an informed decision on whether it's the right bedding option for your dream house.

A quality latex mattress is a crucial component of any house design. Its durability, comfort, and eco-friendliness make it a top choice for many homeowners. By understanding the manufacturing process behind latex mattresses, you can make an informed decision on whether it's the right bedding option for your dream house.