Latex foam mattresses have become increasingly popular in recent years due to their superior comfort and support. But have you ever wondered how these mattresses are made? In this article, we will take a closer look at the top 10 main latex foam mattress manufacturing processes.1. The Basics of Latex Foam Mattress Manufacturing Process

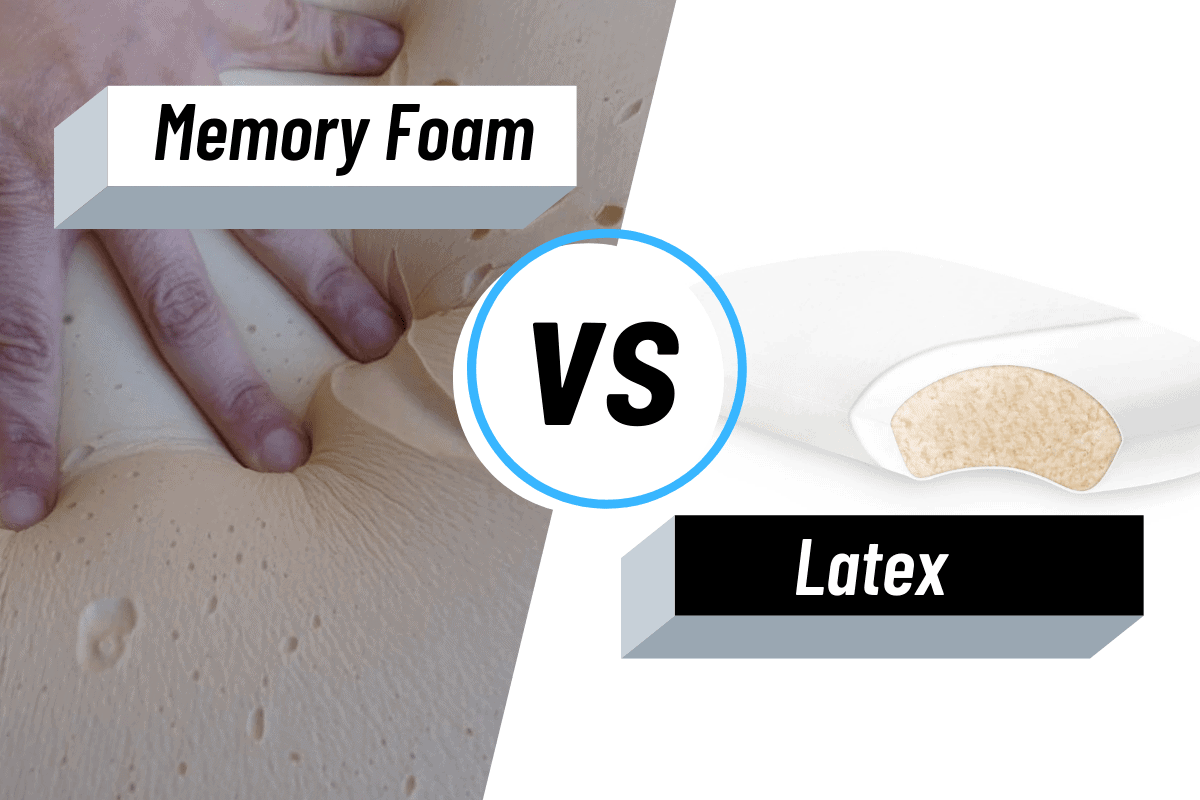

Before diving into the manufacturing process, it is important to understand what latex foam actually is. Latex foam is made from the sap of rubber trees and is known for its natural elasticity and durability. This makes it an ideal material for mattresses as it can provide both comfort and support.2. Understanding Latex Foam

Latex foam is a key component in the production of high-quality mattresses. When combined with other materials such as coils or memory foam, it can provide a supportive and comfortable sleep surface. The manufacturing process of latex foam mattresses involves several steps that are crucial in producing a high-quality product.3. The Role of Latex Foam in Mattress Manufacturing

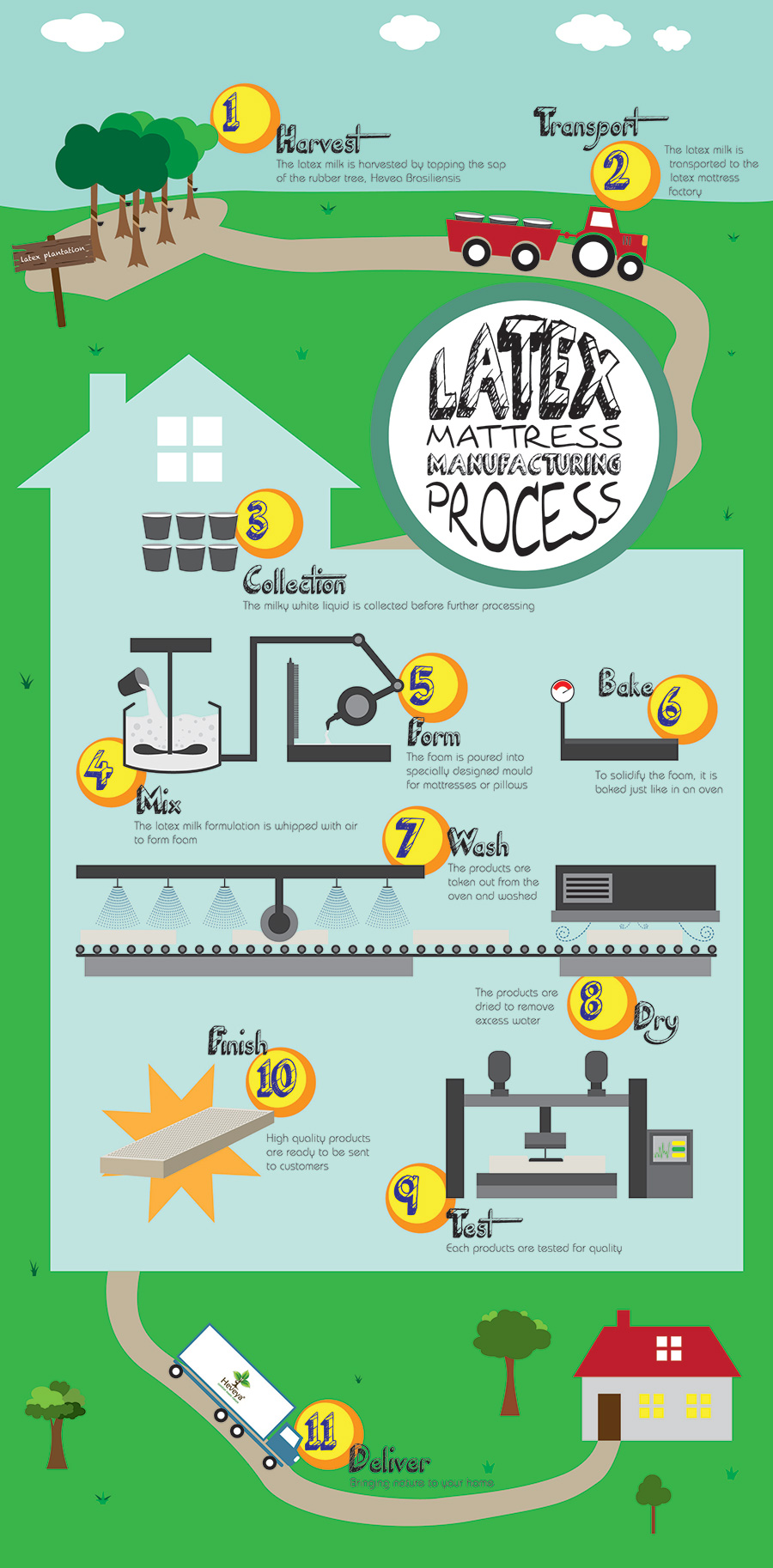

The first step in the latex foam mattress manufacturing process is harvesting the latex sap from rubber trees. This is typically done by making a small cut in the tree's bark and collecting the milky white sap that oozes out. This process does not harm the tree and can be repeated every few days.4. Harvesting Latex Sap

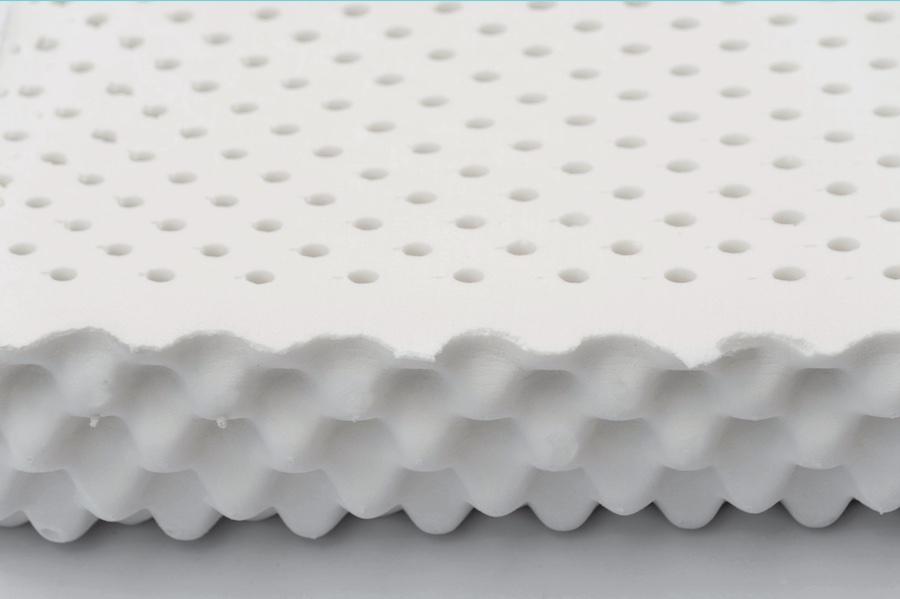

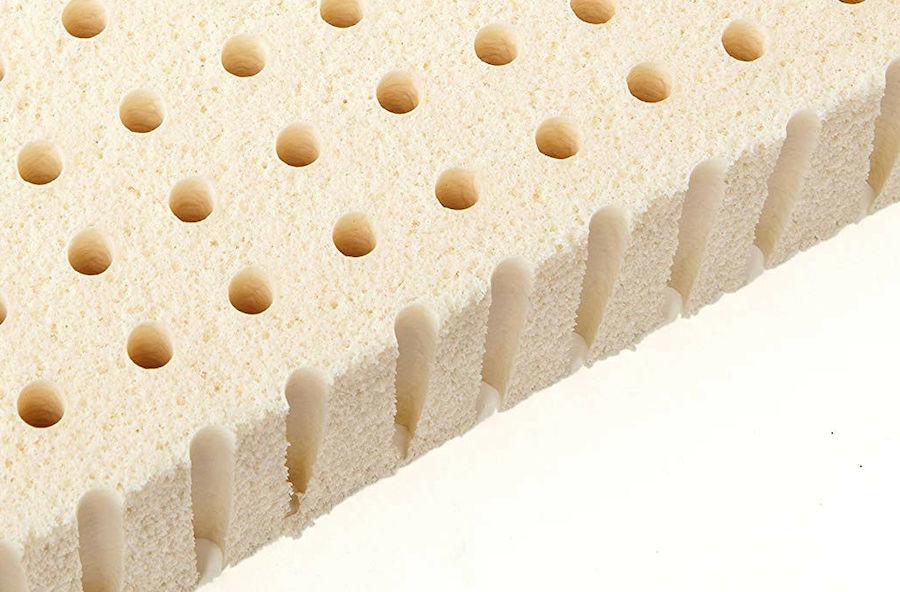

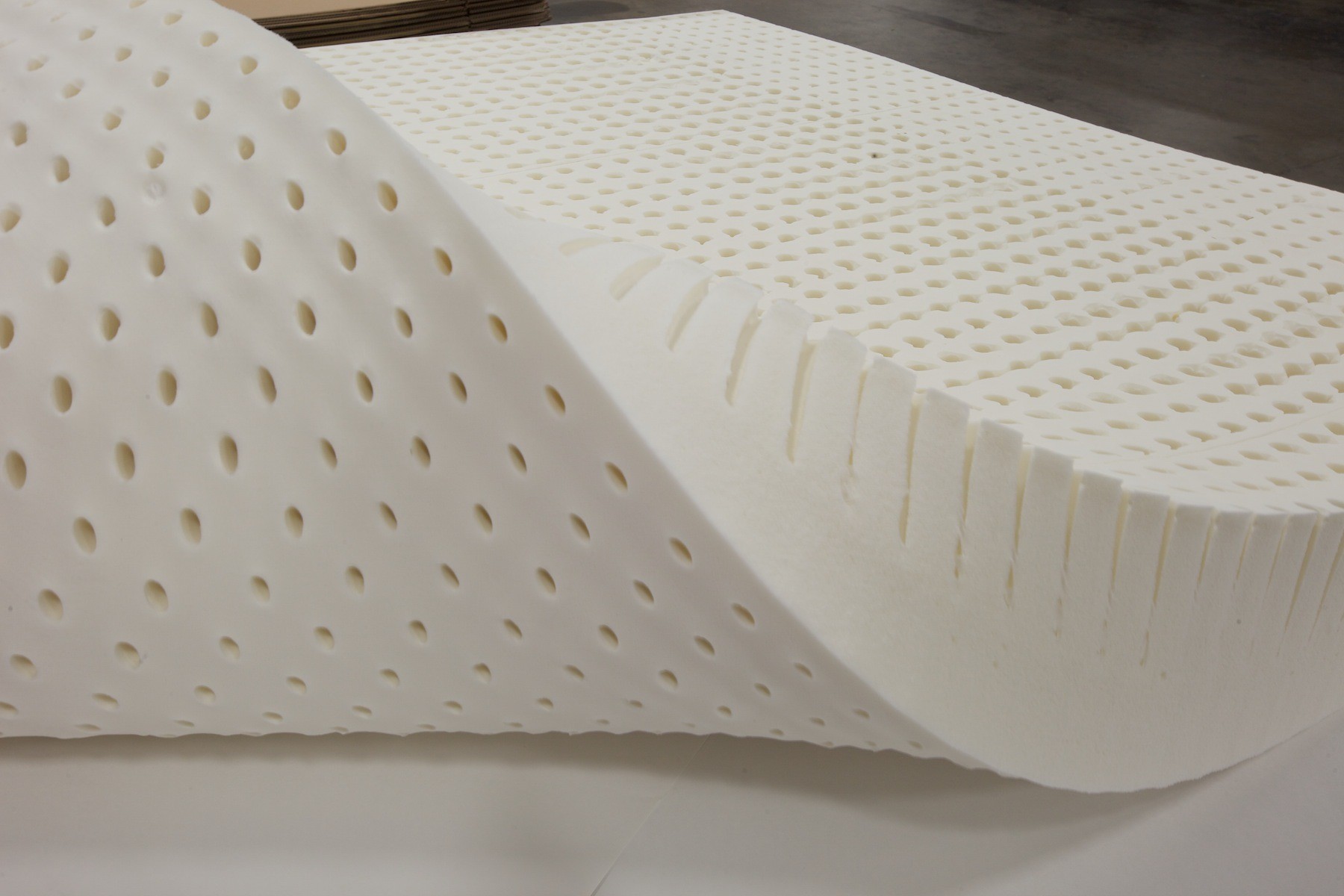

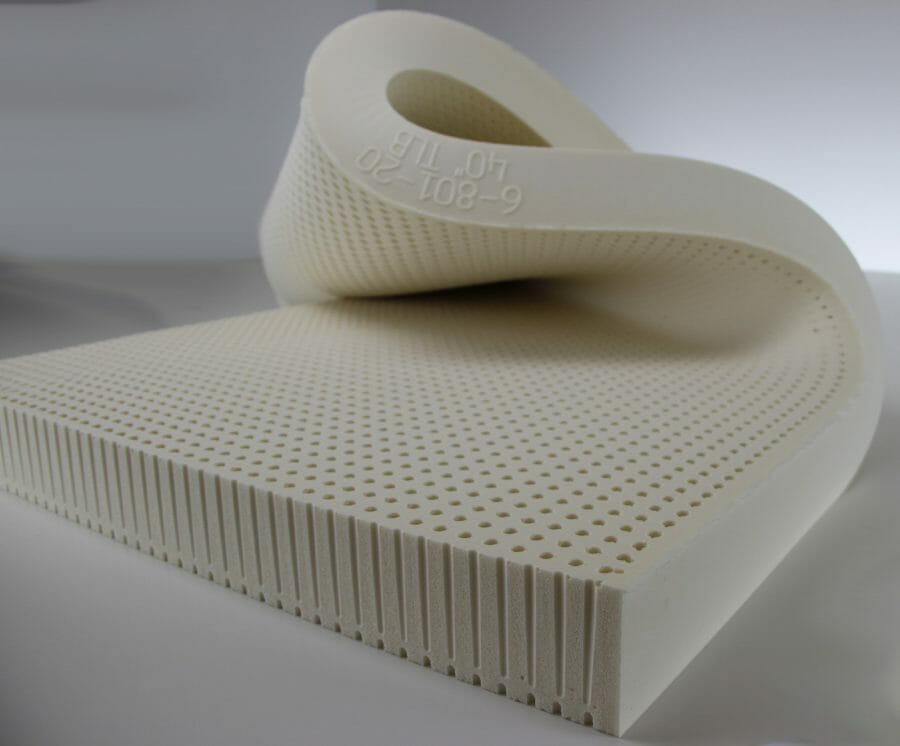

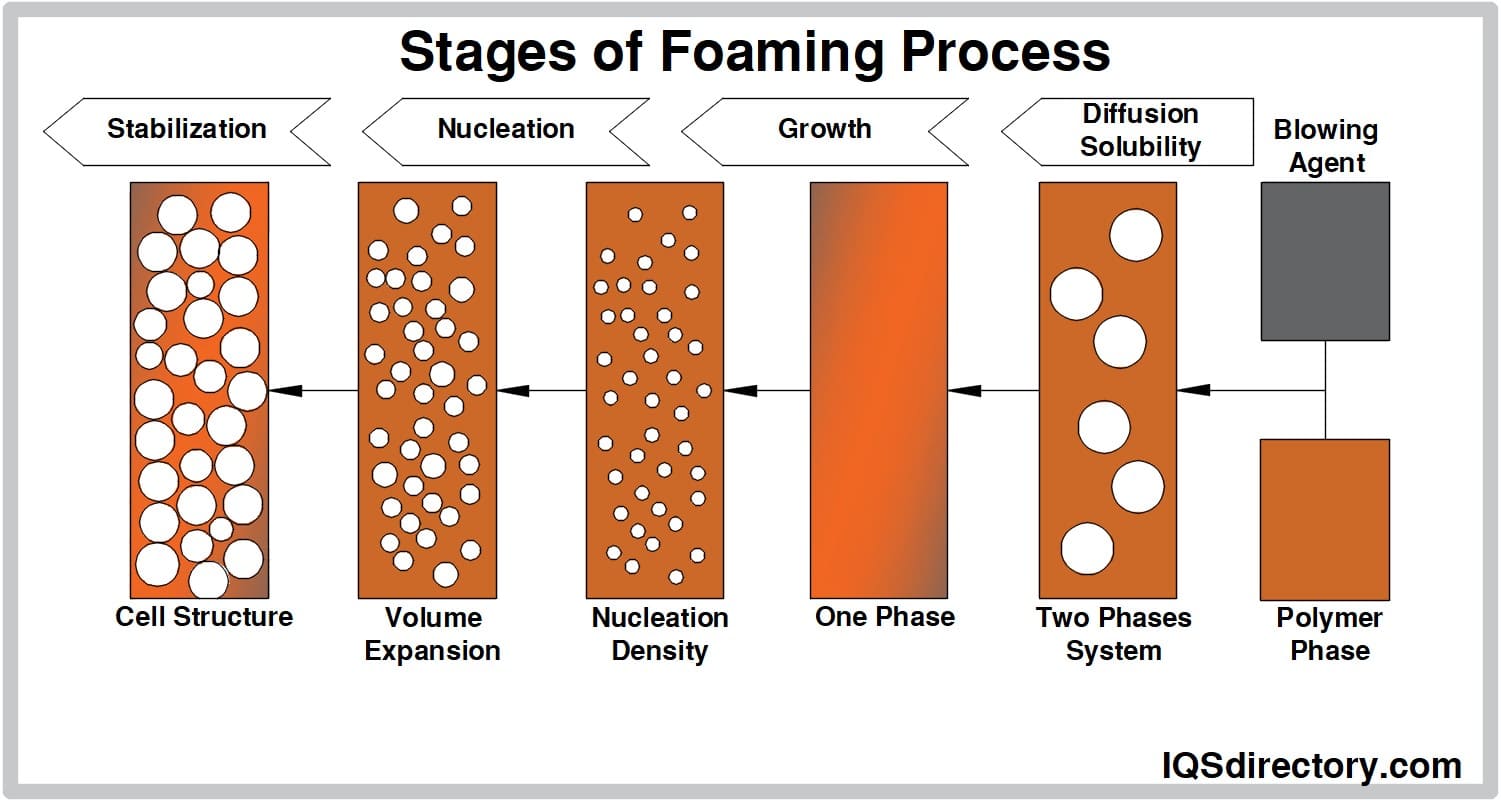

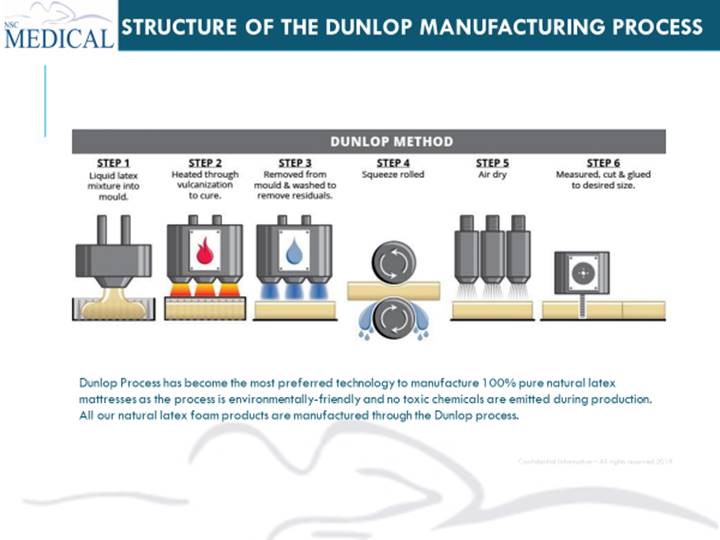

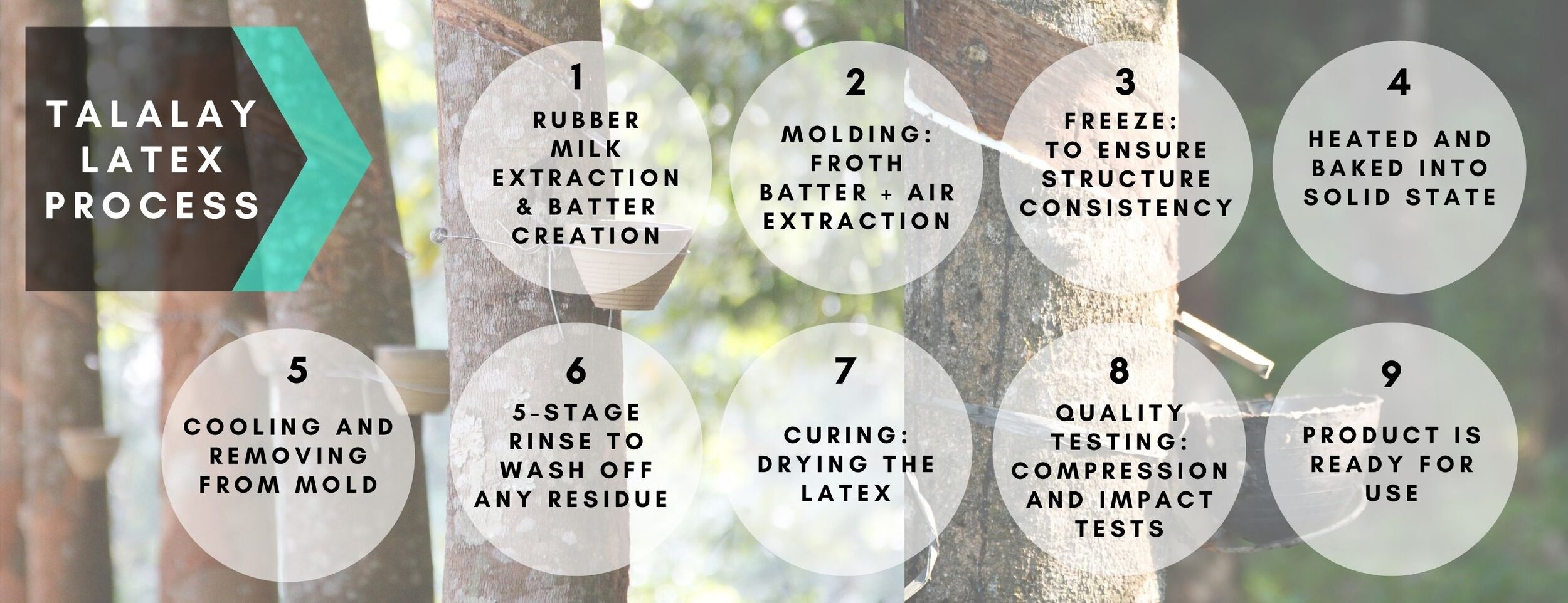

The collected latex sap is then whipped into a frothy liquid and mixed with air. This creates a foam-like substance that is then poured into molds to create the desired mattress size and shape. The foam is then left to set for a few hours to achieve the desired firmness.5. Turning Sap into Foam

Once the latex foam has set, it is removed from the molds and can be further processed. Depending on the type of mattress being made, other materials such as coils or memory foam may be added to provide additional support and comfort.6. Adding Other Materials

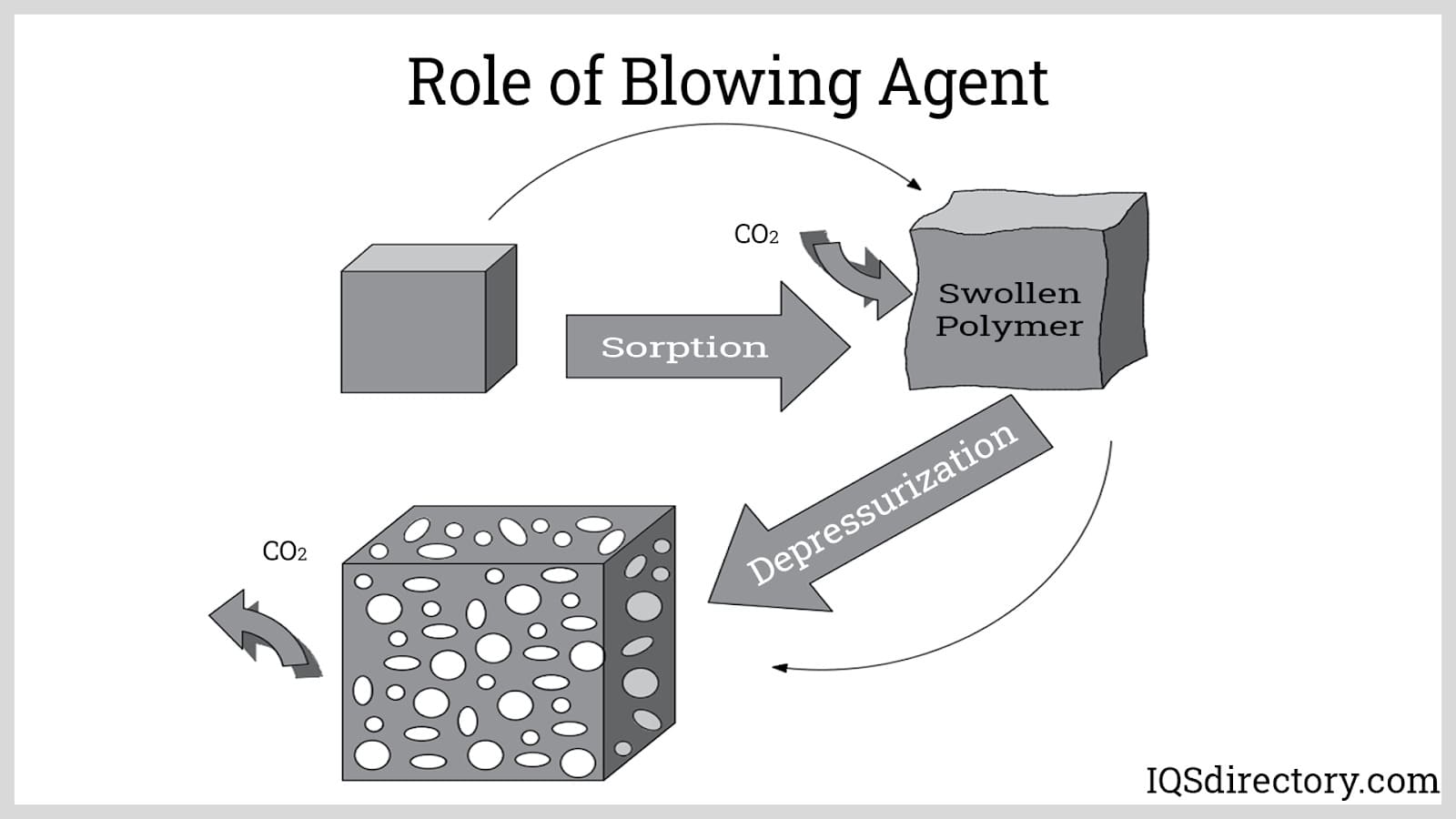

In order to make the latex foam more durable, it undergoes a process called vulcanization. This involves heating the foam to a high temperature, which creates chemical bonds between the rubber particles. This results in a more durable and supportive foam.7. Vulcanization Process

Once the foam has been vulcanized, it is ready to be cut and shaped into the final product. This is typically done using large machines that can precisely cut the foam into the desired size and shape. The foam may also undergo additional processes such as quilting or tufting to further enhance its comfort and appearance.8. Cutting and Shaping

Before the mattresses are packaged and shipped to retailers, they undergo a thorough quality control process. This involves checking for any defects or imperfections in the foam or materials. Only after passing this quality control can the mattresses be deemed ready for sale.9. Quality Control

After the manufacturing process is complete, the final product is a high-quality latex foam mattress that provides both comfort and support for a restful night's sleep. The manufacturing process of latex foam mattresses is a complex and detailed one, but the end result is a product that is worth the effort. In conclusion, the manufacturing process of latex foam mattresses involves several steps that are crucial in creating a high-quality product. From harvesting the latex sap to adding other materials and undergoing quality control, each step plays a crucial role in producing a durable and comfortable mattress. So the next time you lay down on your latex foam mattress, you can appreciate the intricate process that went into making it.10. The Final Product

The Importance of Choosing a Latex Foam Mattress for Your House Design

Why Latex Foam Mattresses Stand Out

When it comes to choosing the perfect mattress for your house, there are numerous options available in the market. However,

latex foam mattresses

stand out from the rest due to their unique manufacturing process and superior qualities. These mattresses are made from

natural latex

, which is derived from the sap of rubber trees. This makes them an eco-friendly and sustainable choice for your home.

When it comes to choosing the perfect mattress for your house, there are numerous options available in the market. However,

latex foam mattresses

stand out from the rest due to their unique manufacturing process and superior qualities. These mattresses are made from

natural latex

, which is derived from the sap of rubber trees. This makes them an eco-friendly and sustainable choice for your home.

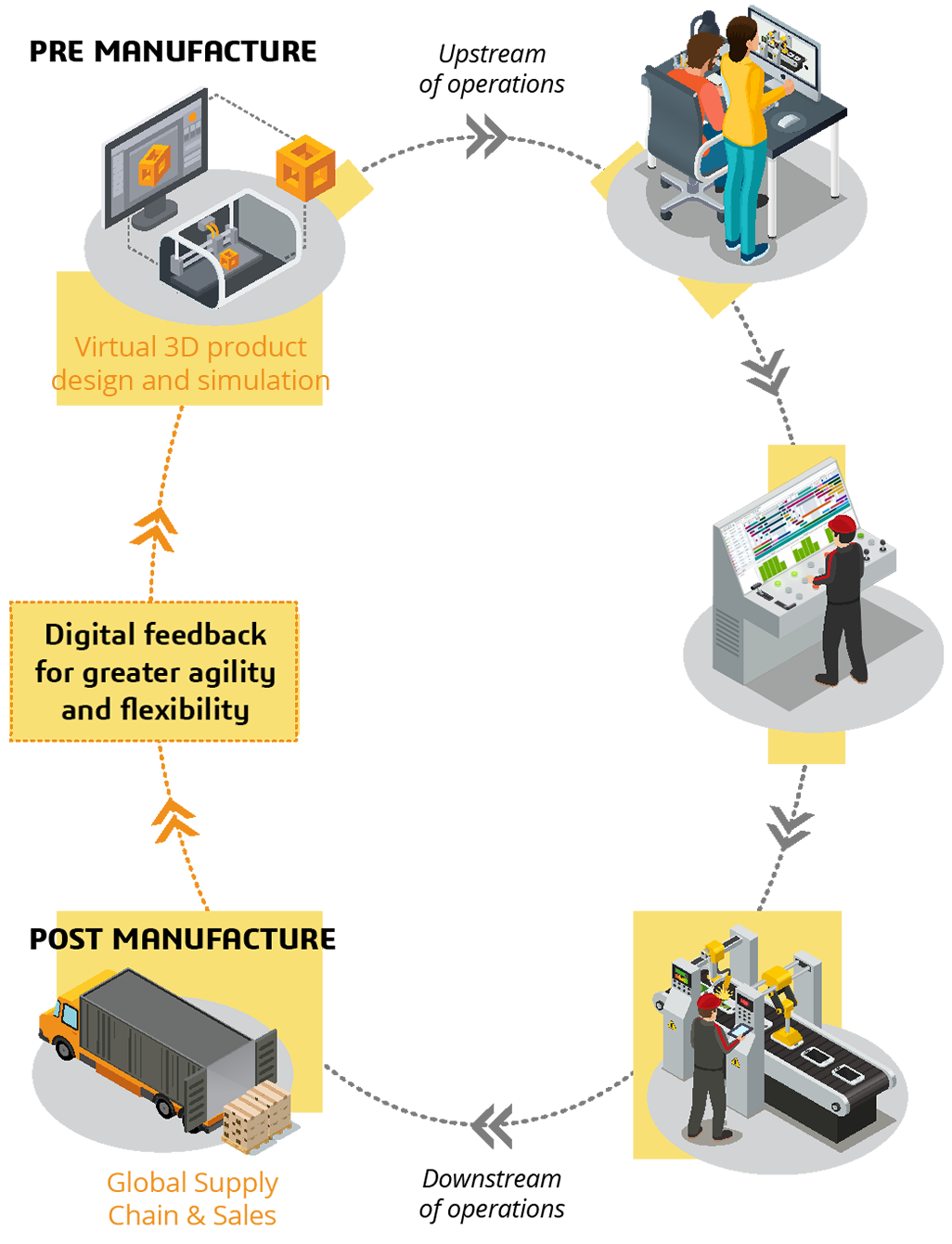

The Latex Foam Mattress Manufacturing Process

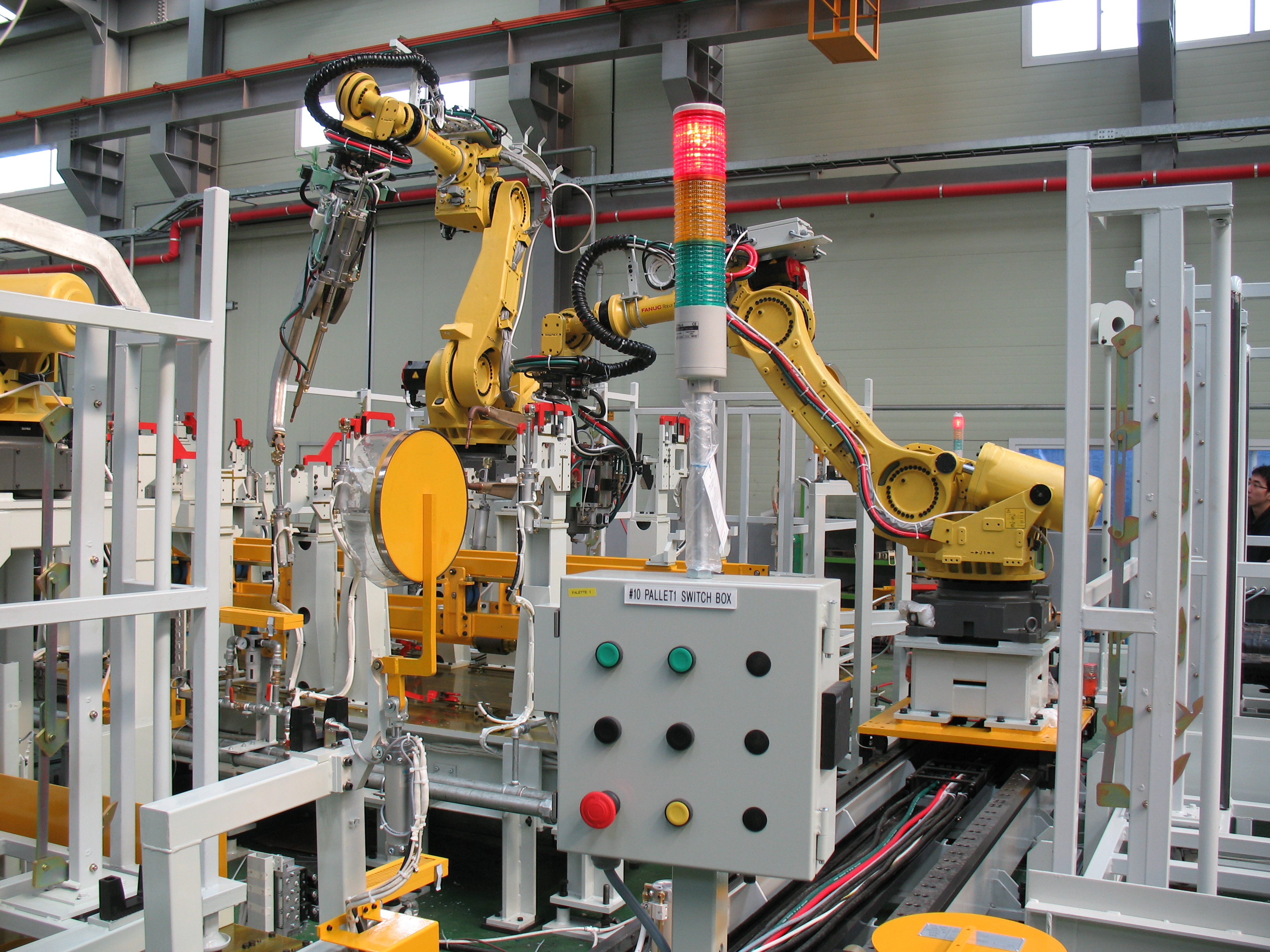

The manufacturing process of latex foam mattresses involves a combination of technology and craftsmanship. The first step is to extract the sap from rubber trees, which is then processed to create a

latex foam

material. This material is then poured into molds and undergoes a

vulcanization

process, which gives the mattress its shape and durability.

The manufacturing process of latex foam mattresses involves a combination of technology and craftsmanship. The first step is to extract the sap from rubber trees, which is then processed to create a

latex foam

material. This material is then poured into molds and undergoes a

vulcanization

process, which gives the mattress its shape and durability.

The Benefits of Choosing a Latex Foam Mattress

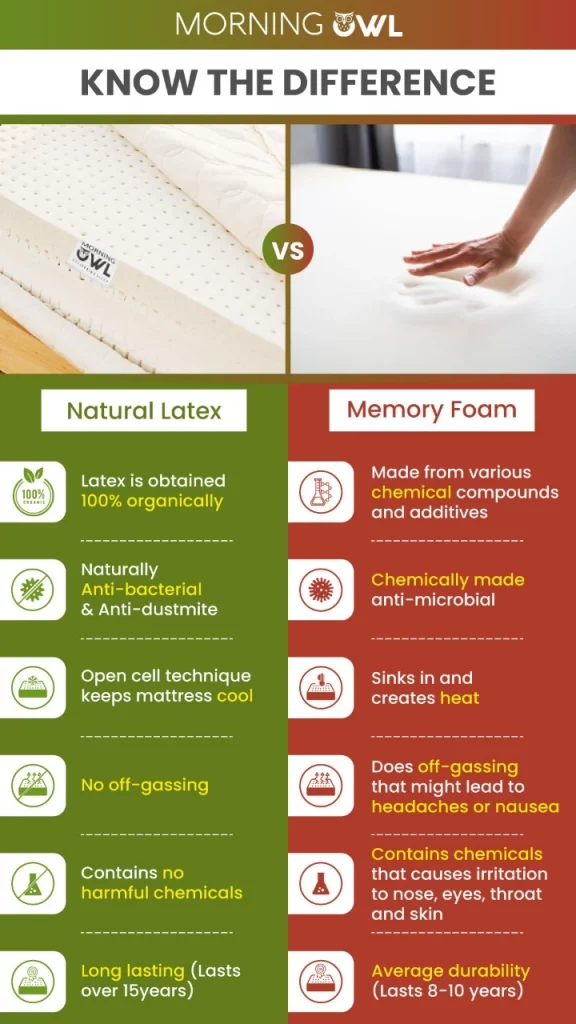

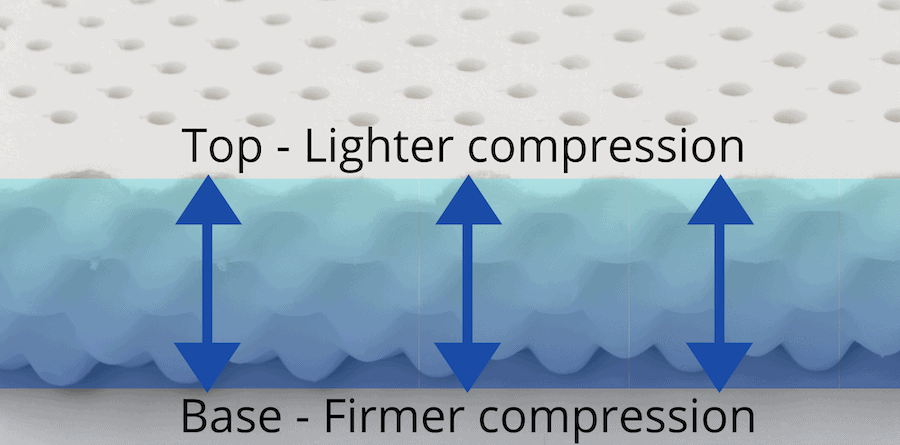

One of the main benefits of choosing a latex foam mattress for your house design is its

comfort and support

. The foam conforms to the shape of your body, providing pressure relief and ensuring a good night's sleep. It also offers

motion isolation

, making it an ideal choice for couples who may have different sleeping patterns.

Moreover, latex foam mattresses are

hypoallergenic

and

dust mite resistant

, making them a great option for those with allergies. They are also

breathable

, allowing for proper air circulation and keeping you cool during hot nights. With their

durability

and

longevity

, latex foam mattresses are a wise investment for your house design.

One of the main benefits of choosing a latex foam mattress for your house design is its

comfort and support

. The foam conforms to the shape of your body, providing pressure relief and ensuring a good night's sleep. It also offers

motion isolation

, making it an ideal choice for couples who may have different sleeping patterns.

Moreover, latex foam mattresses are

hypoallergenic

and

dust mite resistant

, making them a great option for those with allergies. They are also

breathable

, allowing for proper air circulation and keeping you cool during hot nights. With their

durability

and

longevity

, latex foam mattresses are a wise investment for your house design.

Conclusion

In conclusion, when it comes to choosing a mattress for your house design, a latex foam mattress should definitely be on your list of options. Its unique manufacturing process and numerous benefits make it a standout choice in the market. So why settle for anything less when you can have a comfortable, supportive, and eco-friendly mattress for your home?

In conclusion, when it comes to choosing a mattress for your house design, a latex foam mattress should definitely be on your list of options. Its unique manufacturing process and numerous benefits make it a standout choice in the market. So why settle for anything less when you can have a comfortable, supportive, and eco-friendly mattress for your home?