Interior Doors Manufacturing Machines

Interior doors manufacturing machines are essential for any company that produces these important home fixtures. These machines help increase production efficiency and ensure high-quality results. With the right equipment, interior doors can be manufactured quickly and accurately, meeting the demands of the market and consumers.

Investing in interior doors manufacturing machines is a wise decision for any company in the industry. These machines not only save time and labor costs, but they also improve the overall quality and consistency of the finished products. Let's take a look at the top 10 machines that are used in the production of interior doors.

Interior Doors Production Equipment

The production of interior doors requires a variety of specialized equipment to get the job done efficiently and effectively. This includes machines for cutting, sanding, painting, finishing, and more. Each piece of equipment plays a crucial role in the production process and contributes to the overall quality of the final product.

Interior doors production equipment includes CNC routers, panel saws, lamination machines, veneer press machines, and edge banding machines. These machines work together to produce high-quality interior doors that meet the demands of the market and satisfy customers' needs.

Interior Doors Assembly Machines

Once the components of the interior door are cut and sanded, they need to be assembled to create the final product. This is where interior doors assembly machines come in. These machines help streamline the assembly process, ensuring that the final product is sturdy and well-constructed.

Assembly machines can include hinge insertion machines, door frame assembly machines, and door panel assembly machines. These machines help speed up the production process and reduce the risk of human error, resulting in a more consistent and high-quality finished product.

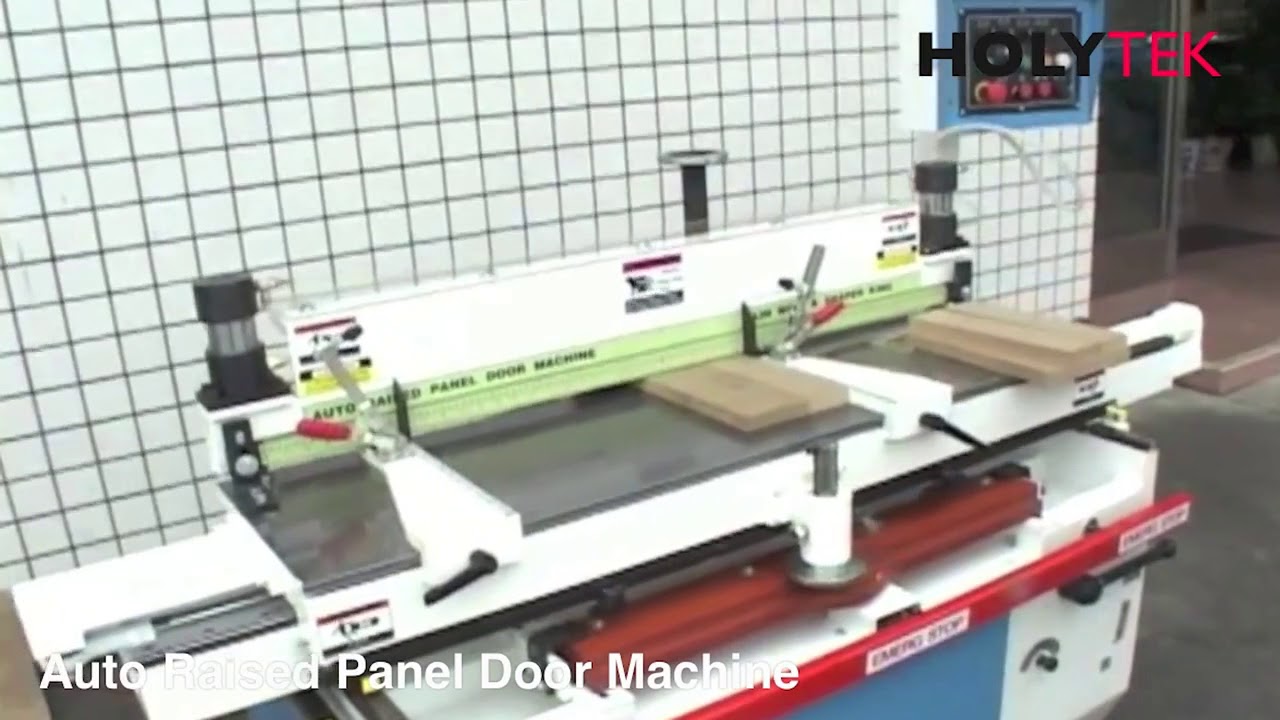

Interior Doors Cutting Machines

Cutting is a crucial step in the production of interior doors. It is essential to have precise and accurate cuts to create a well-fitting and visually appealing door. Interior doors cutting machines use advanced technology to make precise cuts quickly and efficiently.

Cutting machines can include CNC routers, which use computer-controlled cutting tools to create intricate designs and shapes. Panel saws are also commonly used to make straight and precise cuts on large pieces of wood or other materials.

Interior Doors Sanding Machines

After the cutting process, interior doors need to be sanded to achieve a smooth and even surface. This not only improves the appearance of the door but also prepares it for painting or finishing. Interior doors sanding machines help speed up this process and ensure a consistent finish.

Sanding machines can include belt sanders, orbital sanders, and drum sanders. These machines use different techniques to remove imperfections and create a smooth surface on the door.

Interior Doors Painting Machines

Painting is often the final step in the production of interior doors. It is essential to have a clean and even coat of paint for a professional-looking finish. Interior doors painting machines help achieve this quickly and efficiently.

Painting machines can include spray guns and paint booths. These machines use advanced technology to evenly coat the door with paint, resulting in a smooth and professional finish.

Interior Doors Finishing Machines

Finishing is the process of adding a protective layer to the surface of the interior door. This helps enhance the appearance of the door and protect it from damage. Interior doors finishing machines are used to apply this protective layer quickly and evenly.

Finishing machines can include UV curing machines, which use ultraviolet light to quickly dry and cure the finish, and lacquering machines, which apply a thin layer of lacquer onto the door's surface.

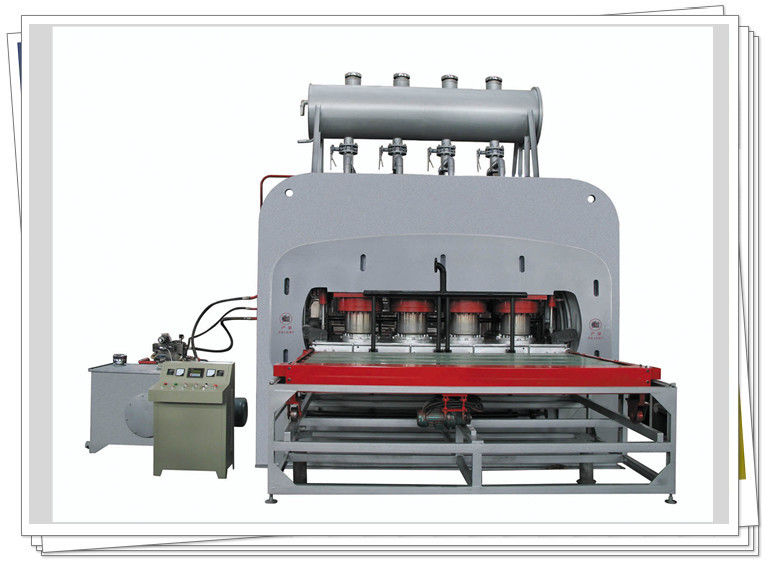

Interior Doors Lamination Machines

Lamination is the process of applying a thin layer of material, such as vinyl or wood veneer, onto the surface of the interior door. This not only enhances the appearance of the door but also provides additional protection. Interior doors lamination machines make this process quick and efficient.

Lamination machines can include hot press machines, which use heat and pressure to bond the layer onto the door's surface, and cold press machines, which use adhesive to bond the layer onto the door.

Interior Doors Veneer Press Machines

Many interior doors are made with a thin layer of wood veneer on the surface for a more natural and elegant look. Interior doors veneer press machines are used to apply this veneer quickly and accurately.

Veneer press machines use heat and pressure to bond the veneer onto the door's surface, resulting in a smooth and consistent finish. This process can also be used to create different patterns or designs on the door's surface.

Interior Doors Edge Banding Machines

Edge banding is the process of applying a thin layer of material, such as PVC, onto the edges of the interior door to create a clean and finished look. Interior doors edge banding machines are used to apply this layer quickly and accurately.

Edge banding machines use heat and pressure to bond the material onto the door's edges, resulting in a seamless and professional finish. This process is especially important for doors with exposed edges.

In conclusion, interior doors manufacturing machines play a crucial role in the production of high-quality interior doors. These machines not only improve efficiency and reduce labor costs, but they also ensure a consistent and professional finish. By investing in these top 10 machines, companies can produce interior doors that meet the demands of the market and satisfy customers' needs.

Advancements in Interior Door Manufacturing Machines: Revolutionizing House Design

The Evolution of Interior Door Manufacturing

The interior design industry has come a long way in terms of innovation and technology. With the rise of modern architecture and the demand for sleek and stylish interiors, the manufacturing of interior doors has undergone a significant transformation. From traditional wooden doors to the latest automated machines, the production process has become more efficient and precise. These advancements in interior door manufacturing machines have not only revolutionized the production process but also greatly impacted the overall house design.

The interior design industry has come a long way in terms of innovation and technology. With the rise of modern architecture and the demand for sleek and stylish interiors, the manufacturing of interior doors has undergone a significant transformation. From traditional wooden doors to the latest automated machines, the production process has become more efficient and precise. These advancements in interior door manufacturing machines have not only revolutionized the production process but also greatly impacted the overall house design.

Efficiency and Precision

Gone are the days of manual labor and time-consuming production processes. With the introduction of

automated interior door manufacturing machines

, the entire production process has become more efficient and precise. These machines are equipped with advanced technology and computer numerical control (CNC) systems, allowing for accurate measurements and cutting of materials. This not only reduces production time but also eliminates the margin of error, resulting in high-quality interior doors.

Gone are the days of manual labor and time-consuming production processes. With the introduction of

automated interior door manufacturing machines

, the entire production process has become more efficient and precise. These machines are equipped with advanced technology and computer numerical control (CNC) systems, allowing for accurate measurements and cutting of materials. This not only reduces production time but also eliminates the margin of error, resulting in high-quality interior doors.

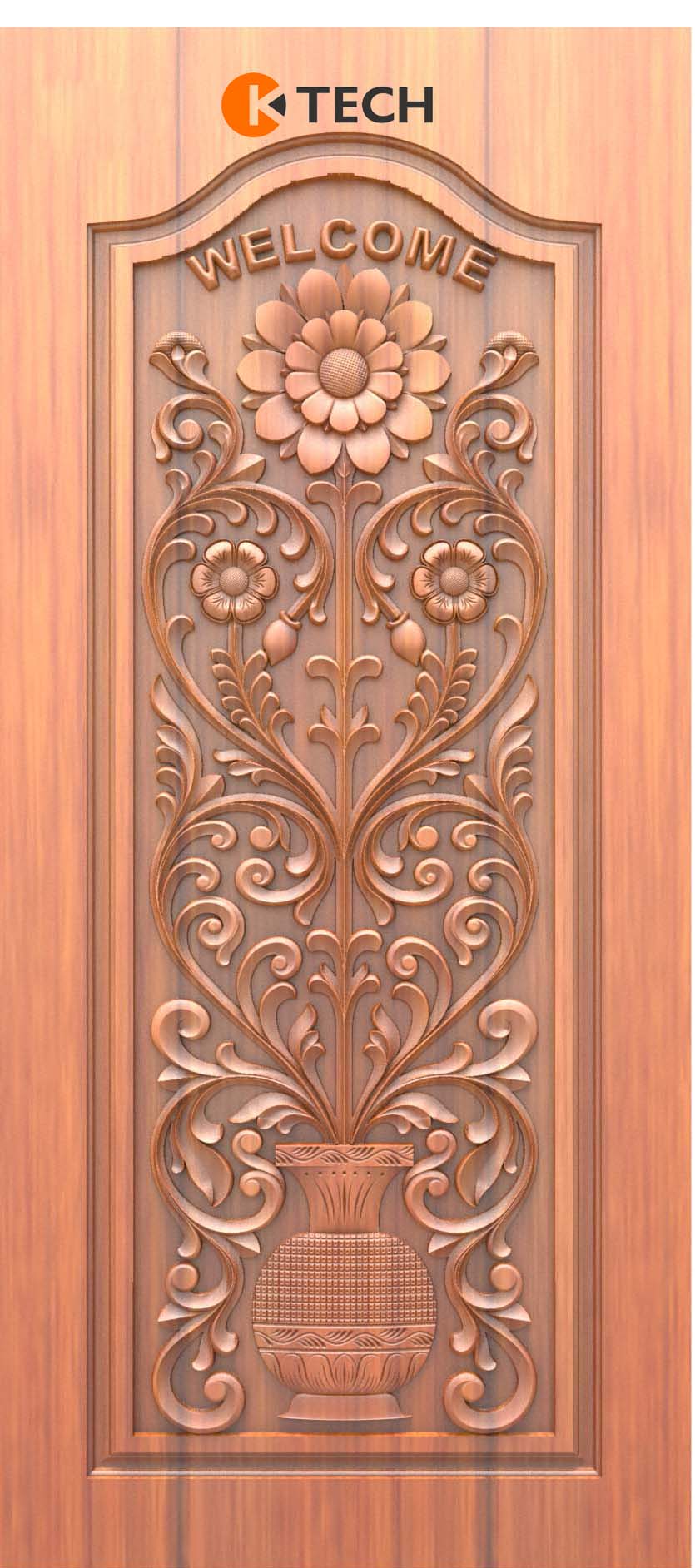

Endless Design Possibilities

One of the most significant benefits of using interior door manufacturing machines is the ability to create

customized designs

. With traditional methods, the design options were limited to simple shapes and styles. However, with the use of CNC systems, intricate designs and patterns can be easily programmed and produced. This allows for endless design possibilities, giving interior designers and homeowners the freedom to create unique and personalized interior doors that complement their house design.

One of the most significant benefits of using interior door manufacturing machines is the ability to create

customized designs

. With traditional methods, the design options were limited to simple shapes and styles. However, with the use of CNC systems, intricate designs and patterns can be easily programmed and produced. This allows for endless design possibilities, giving interior designers and homeowners the freedom to create unique and personalized interior doors that complement their house design.

Sustainability and Durability

In addition to efficiency and design flexibility, interior door manufacturing machines also offer

sustainability and durability

. Many of these machines are equipped with eco-friendly features, such as energy-saving motors and materials made from sustainable sources. This not only reduces the carbon footprint of the production process but also results in longer-lasting and more durable interior doors. These doors are not only aesthetically pleasing but also contribute to a more sustainable and environmentally friendly house design.

In addition to efficiency and design flexibility, interior door manufacturing machines also offer

sustainability and durability

. Many of these machines are equipped with eco-friendly features, such as energy-saving motors and materials made from sustainable sources. This not only reduces the carbon footprint of the production process but also results in longer-lasting and more durable interior doors. These doors are not only aesthetically pleasing but also contribute to a more sustainable and environmentally friendly house design.

Conclusion

In conclusion, the advancements in interior door manufacturing machines have greatly impacted the house design industry. These machines not only improve efficiency and precision but also offer endless design possibilities and sustainable options. With the continuous evolution of technology, we can expect even more innovative and advanced interior door manufacturing machines in the future, further pushing the boundaries of house design.

In conclusion, the advancements in interior door manufacturing machines have greatly impacted the house design industry. These machines not only improve efficiency and precision but also offer endless design possibilities and sustainable options. With the continuous evolution of technology, we can expect even more innovative and advanced interior door manufacturing machines in the future, further pushing the boundaries of house design.