When it comes to producing high-quality foam mattresses, having a reliable and efficient production line is essential. A foam mattress production line is a system of interconnected machines and equipment that work together to produce foam mattresses in a streamlined and automated process. This type of production line is designed to handle large quantities of materials, resulting in faster production times and higher quality products. Let's take a closer look at the top 10 main components of a foam mattress production line. Foam Mattress Production Line

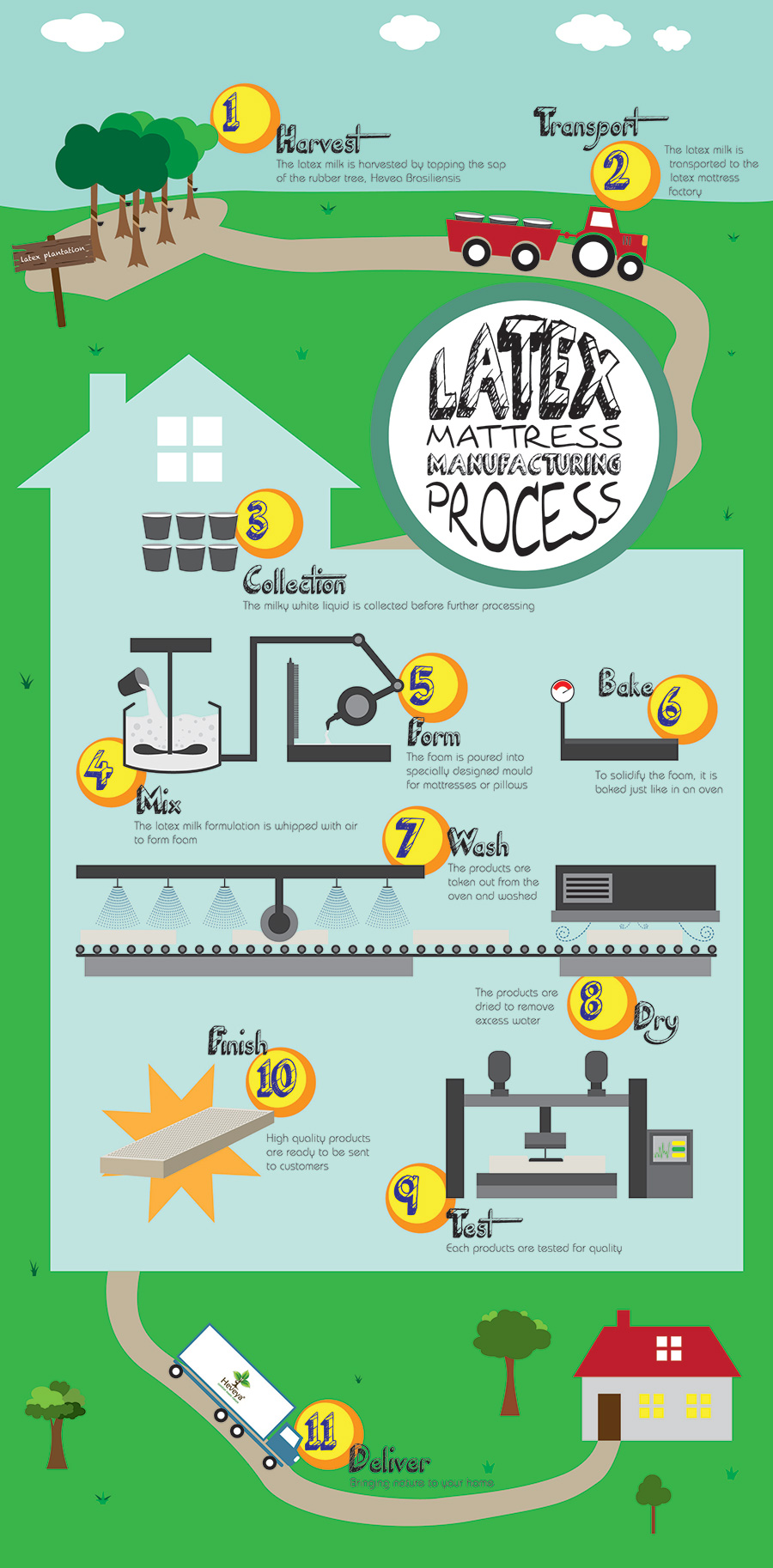

The first step in the foam mattress production line is the manufacturing process. This is where the raw materials, such as foam and fabric, are transformed into the components needed to make a mattress. The manufacturing process involves cutting, shaping, and molding the foam to the desired size and shape, as well as sewing and attaching the fabric cover. The use of high-quality materials and precise manufacturing techniques is crucial to creating a durable and comfortable foam mattress. Foam Mattress Manufacturing

Once the components are manufactured, they are sent to the assembly line. This is where the different parts of the mattress, including the foam layers, fabric cover, and any additional features, are put together. An efficient assembly line is crucial to ensure that all the components are correctly assembled and that the final product meets the desired specifications. Foam Mattress Assembly Line

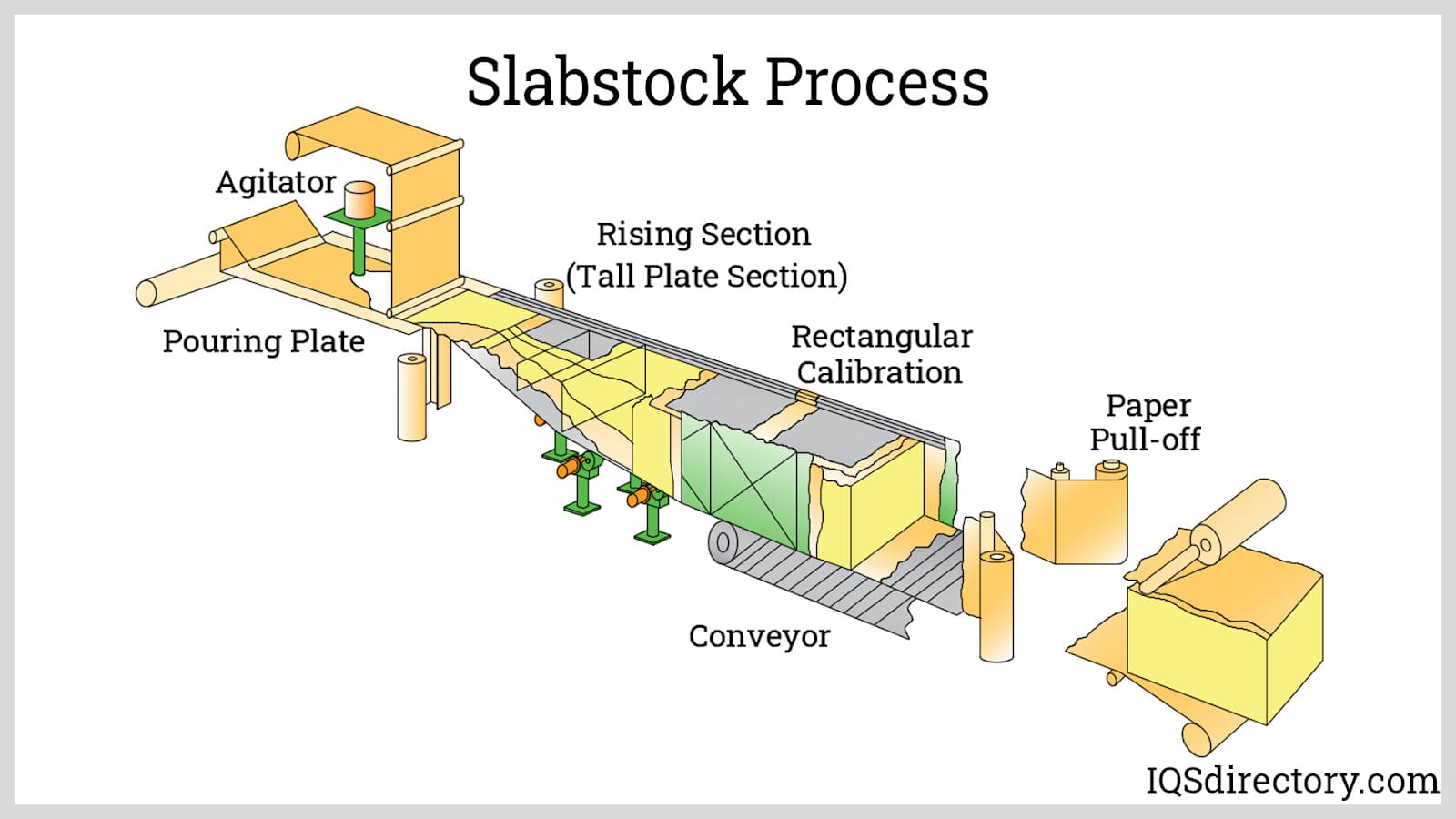

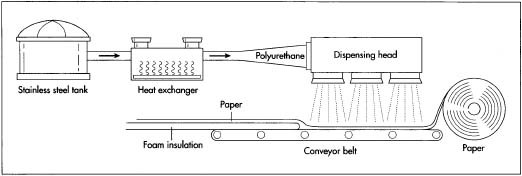

There are various types of equipment used in a foam mattress production line. These include cutting machines, sewing machines, and gluing machines, among others. Each piece of equipment plays a vital role in the production process, and having high-quality and well-maintained equipment is essential to ensure smooth and efficient production. Foam Mattress Production Equipment

The foam mattress manufacturing process involves several steps, each of which is crucial to producing a high-quality product. This includes cutting the foam layers to the correct size and shape, attaching the fabric cover, and adding any special features, such as cooling gel or memory foam. Each step in the process requires precision and attention to detail to create a comfortable and durable foam mattress. Foam Mattress Manufacturing Process

In addition to equipment, there is also specialized machinery used in foam mattress production. This includes computer-controlled machines that can cut foam layers to precise measurements and sewing machines that can handle heavy-duty sewing of the mattress cover. These machines are designed to increase efficiency and accuracy in the production process, resulting in consistent and high-quality products. Foam Mattress Production Machinery

Some companies have dedicated production plants solely for foam mattress production. These plants are designed to handle large quantities of materials and have specialized machinery and equipment to streamline the production process. Having a dedicated production plant allows for greater control over the production process and ensures that all products meet the company's standards. Foam Mattress Production Plant

A foam mattress production system refers to the overall process of producing foam mattresses, from the manufacturing of materials to the assembly and packaging of the final product. A well-designed production system is crucial to ensure that all the components work together seamlessly and that the end result is a high-quality foam mattress. Foam Mattress Production System

Similar to a production plant, a foam mattress production factory is a dedicated facility for producing foam mattresses. These factories typically have a larger production capacity and can handle multiple production lines at once. This allows for increased efficiency and the ability to meet high-demand for foam mattresses. Foam Mattress Production Factory

Automation plays a significant role in foam mattress production, from cutting and shaping foam layers to sewing and attaching the fabric cover. Automation not only increases efficiency but also reduces the risk of human error, resulting in consistent and high-quality products. With the advancement of technology, more and more production processes are becoming automated, making foam mattress production faster and more precise than ever before. Foam Mattress Production Automation

The Benefits of Using a Foam Mattress Production Line for Your House Design

Enhanced Comfort and Support

One of the main advantages of using a foam mattress production line for your house design is the enhanced comfort and support it provides. Foam mattresses are known for their ability to conform to the shape of your body, providing personalized support for a restful night's sleep. The production line ensures that each mattress is made with high-quality foam and precise measurements, resulting in a comfortable and supportive sleep surface.

One of the main advantages of using a foam mattress production line for your house design is the enhanced comfort and support it provides. Foam mattresses are known for their ability to conform to the shape of your body, providing personalized support for a restful night's sleep. The production line ensures that each mattress is made with high-quality foam and precise measurements, resulting in a comfortable and supportive sleep surface.

Durability and Longevity

Another key benefit of using a foam mattress production line is the durability and longevity of the mattresses produced. Foam mattresses are known for their durability, with the ability to maintain their shape and support for many years. The production line uses advanced technology and materials to ensure that each mattress is built to last, making it a wise investment for your house design.

Another key benefit of using a foam mattress production line is the durability and longevity of the mattresses produced. Foam mattresses are known for their durability, with the ability to maintain their shape and support for many years. The production line uses advanced technology and materials to ensure that each mattress is built to last, making it a wise investment for your house design.

Customization Options

With a foam mattress production line, you have the option to customize your mattress to fit your specific needs and preferences. This includes the firmness level, size, and even special features such as cooling gel or hypoallergenic materials. By having the ability to customize your mattress, you can ensure that it not only fits seamlessly into your house design but also provides you with the best sleep experience possible.

With a foam mattress production line, you have the option to customize your mattress to fit your specific needs and preferences. This includes the firmness level, size, and even special features such as cooling gel or hypoallergenic materials. By having the ability to customize your mattress, you can ensure that it not only fits seamlessly into your house design but also provides you with the best sleep experience possible.

Cost-Effective Solution

Investing in a foam mattress production line for your house design can also be a cost-effective solution in the long run. While the initial cost may be higher than a traditional mattress, the durability and longevity of foam mattresses mean that you will not have to replace them as frequently. This can save you money in the long term and make it a worthwhile investment for your house design.

Investing in a foam mattress production line for your house design can also be a cost-effective solution in the long run. While the initial cost may be higher than a traditional mattress, the durability and longevity of foam mattresses mean that you will not have to replace them as frequently. This can save you money in the long term and make it a worthwhile investment for your house design.

Conclusion

In conclusion, a foam mattress production line offers numerous benefits for your house design. From enhanced comfort and support to durability, customization options, and cost-effectiveness, it is a wise choice for anyone looking to create a comfortable and functional sleep space. Consider incorporating a foam mattress into your house design and experience the difference it can make in your daily life.

In conclusion, a foam mattress production line offers numerous benefits for your house design. From enhanced comfort and support to durability, customization options, and cost-effectiveness, it is a wise choice for anyone looking to create a comfortable and functional sleep space. Consider incorporating a foam mattress into your house design and experience the difference it can make in your daily life.

.jpg?fit=fill&bg=0FFF&w=1500&h=1000&auto=format,compress)