Cutting Foam: Tips and Tricks for Using a Table Saw

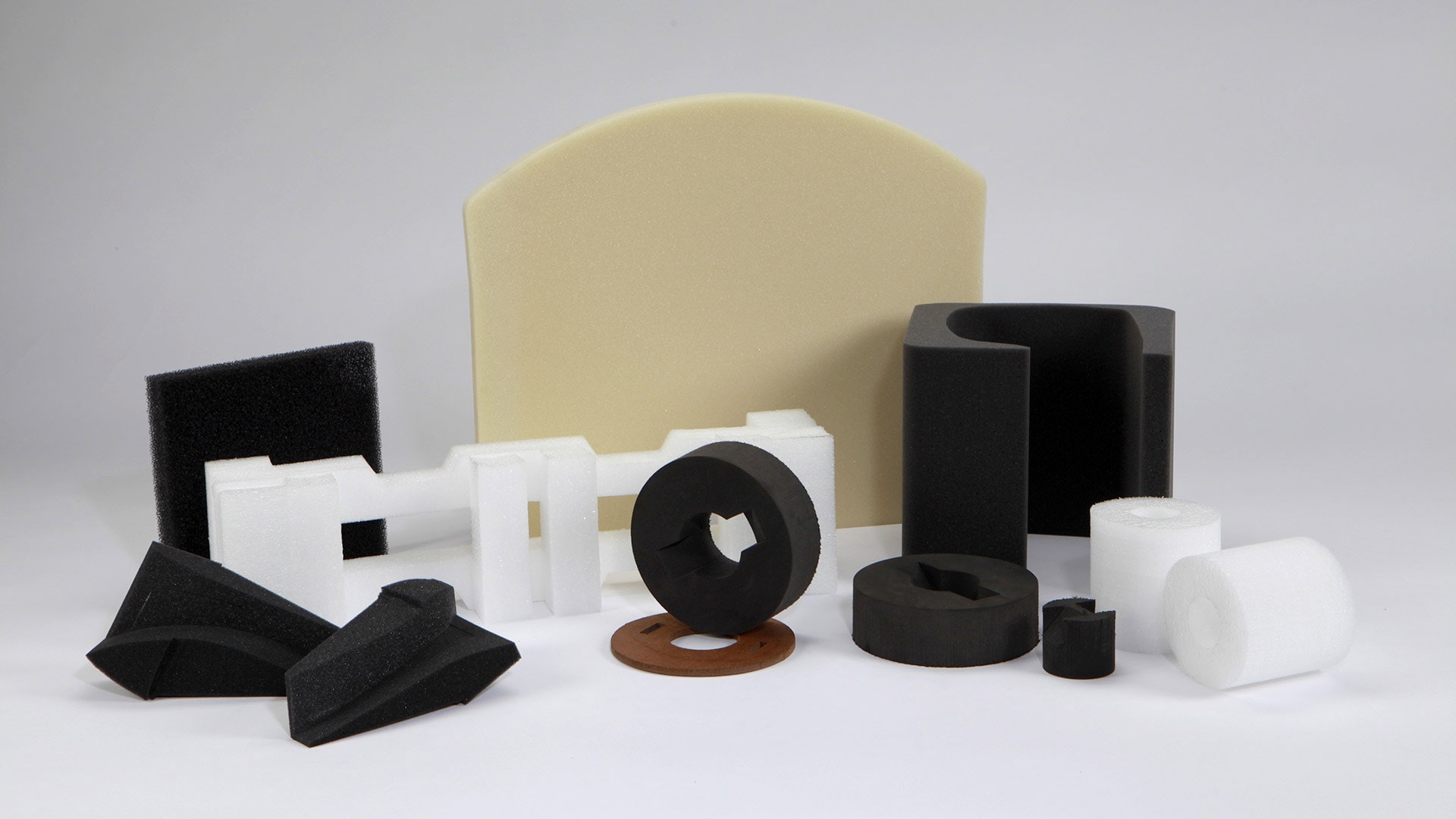

If you're planning on making a new mattress or revamping an old one, cutting foam to the right size is an essential step. While there are many tools that can be used for this task, using a table saw is one of the most efficient and precise methods. In this article, we'll share the top 10 tips for cutting foam with a table saw that will help you achieve the best results.

The Benefits of Using a Table Saw for Foam Cutting

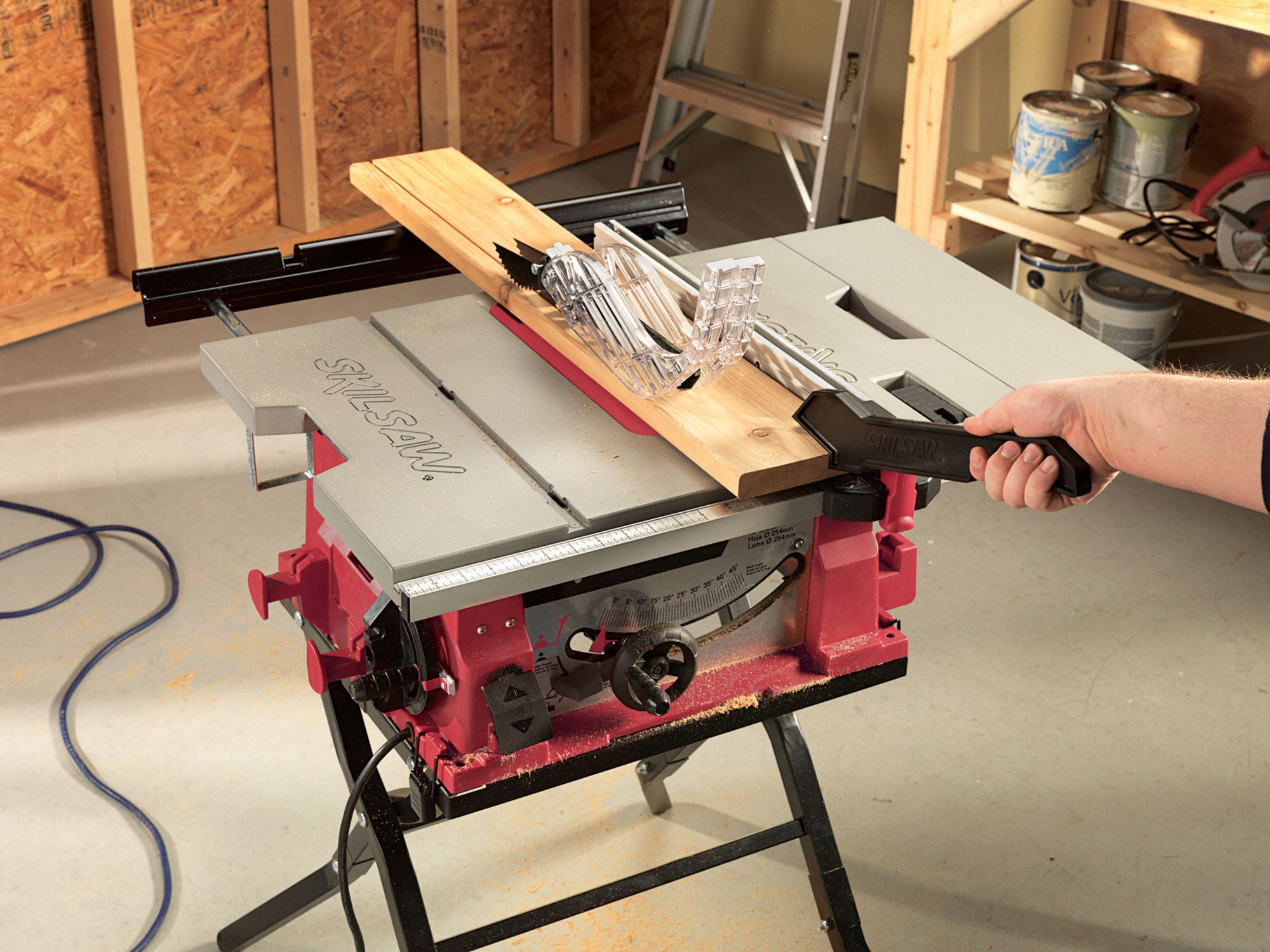

Before we dive into the tips, let's briefly discuss why a table saw is a great choice for cutting foam. Firstly, it allows for straight and accurate cuts, which is crucial for creating a well-fitted mattress. Secondly, it can make quick work of larger pieces of foam, saving you time and effort. Lastly, table saws are easy to use and can be adjusted to different thicknesses and angles, making them versatile for various foam cutting projects.

Tip #1: Choose the Right Blade

The type of blade you use on your table saw can greatly affect the quality of your foam cuts. For foam cutting, a blade with a high tooth count is recommended, as it will create smoother, cleaner cuts. A blade with carbide tips is also a good choice, as it will last longer and maintain its sharpness.

Tip #2: Adjust the Blade Height

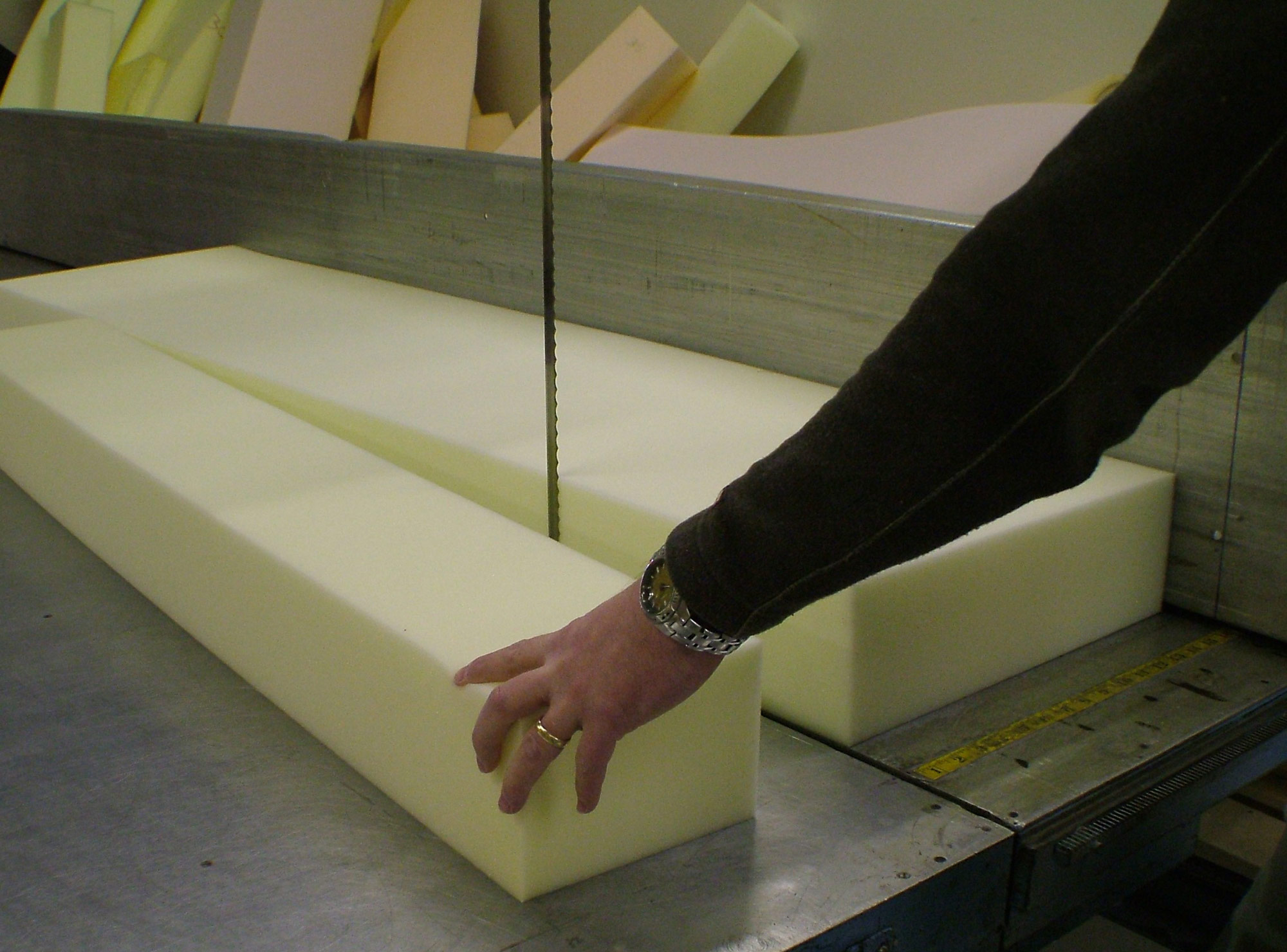

Before starting the cutting process, make sure to adjust the height of your blade accordingly. The blade should be raised just enough to cut through the thickness of the foam, but not too high that it creates too much friction and heat. This will help prevent melting and warping of the foam.

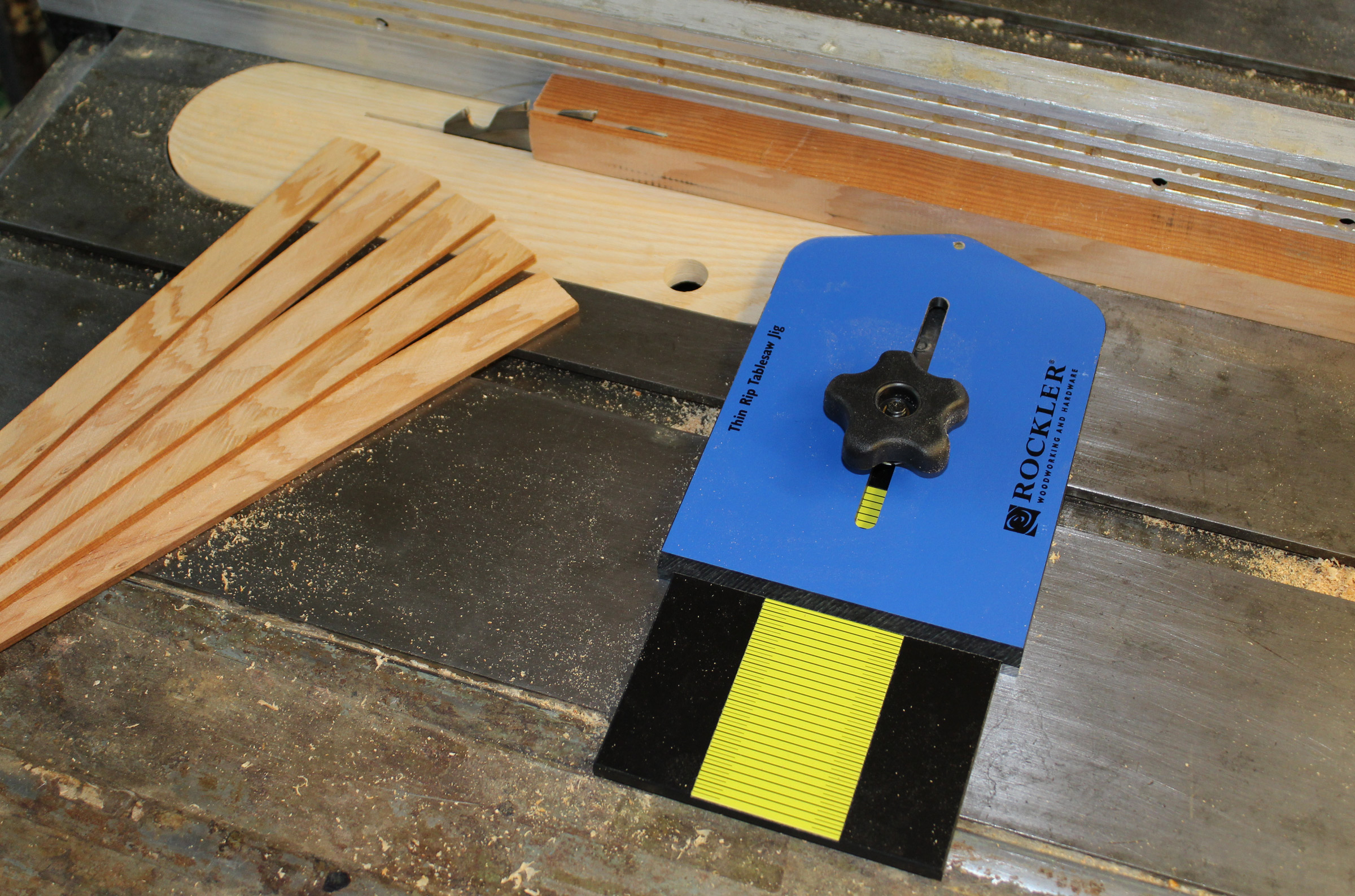

Tip #3: Use a Fence

A fence is a helpful tool for guiding your foam through the table saw and ensuring a straight cut. You can use a straight piece of wood or a commercially made fence specifically designed for foam cutting. Make sure to secure the fence tightly to the table saw to prevent any movement while cutting.

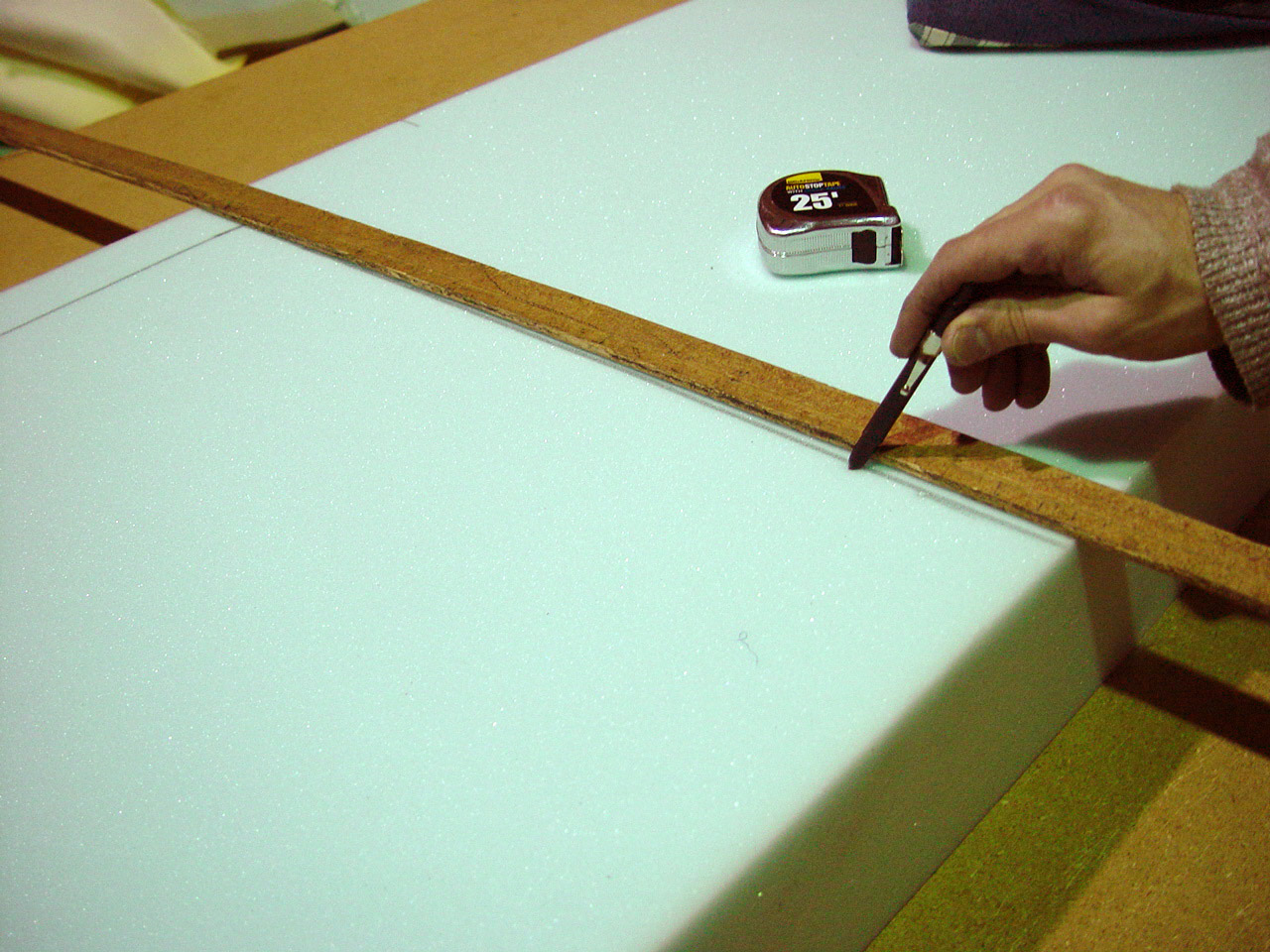

Tip #4: Mark Your Cuts

Before cutting, it's important to mark your foam with the desired measurements and lines. This will serve as a guide and help you stay on track while cutting. You can use a permanent marker or chalk to make these markings.

Tip #5: Cut Slowly

When cutting foam with a table saw, it's important to work slowly and carefully. This will help prevent mistakes and ensure a clean cut. Rushing the process can lead to uneven cuts or jagged edges, which can affect the overall look and feel of your mattress.

Tip #6: Use a Push Stick

A push stick is a safety tool that is used to push the foam through the table saw. This will help keep your hands at a safe distance from the blade and prevent any accidents. You can make your own push stick or purchase one from a hardware store.

Tip #7: Keep the Foam Cool

As mentioned earlier, using a blade that is too high can create too much heat, which can cause the foam to melt or warp. To prevent this, you can use a spray bottle filled with water to keep the foam cool while cutting. Simply spray the foam lightly as you cut to maintain a cool temperature.

Tip #8: Vacuum the Sawdust

Foam cutting can create a lot of sawdust, which can make it difficult to see your cutting lines and measurements. To avoid this, regularly vacuum the sawdust from your table saw. This will also help prevent the sawdust from clogging the saw and affecting the quality of your cuts.

Cutting Mattress Foam with a Table Saw: A Practical Solution for House Designers

When it comes to designing a house, the details matter. Every element, from the paint color to the furniture, contributes to the overall aesthetic and functionality of a space. One often overlooked aspect of house design is the mattress foam used for furniture and bedding. While many designers simply purchase pre-cut foam, using a table saw to cut your own foam can provide a more precise and customizable result. In this article, we will explore the benefits of cutting mattress foam with a table saw and provide tips for achieving professional results.

The Advantages of Cutting Mattress Foam with a Table Saw

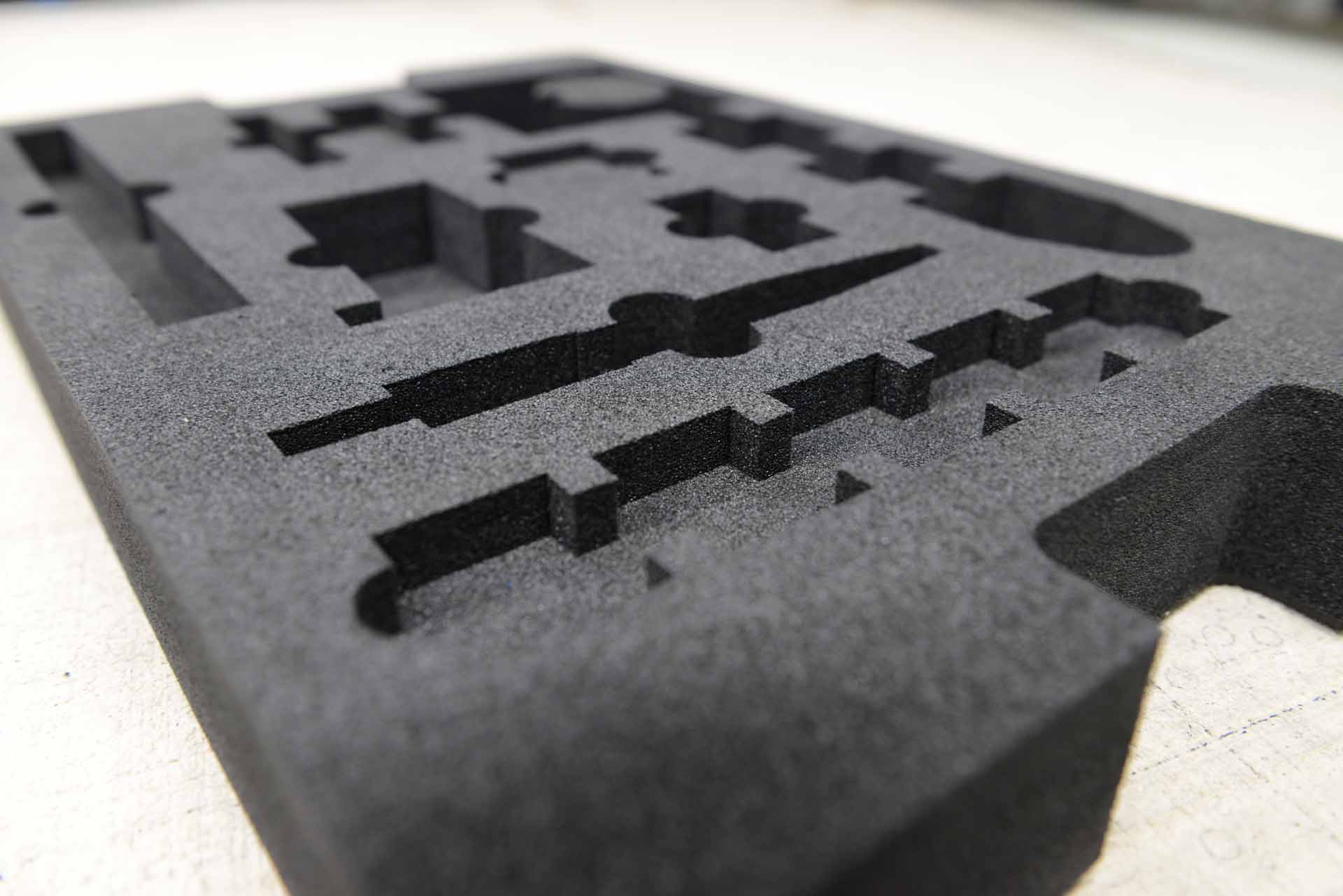

One of the main advantages of using a table saw to cut mattress foam is the level of control and precision it offers. Unlike scissors or a utility knife, a table saw allows for straight, clean cuts that can be easily adjusted for different thicknesses and shapes. This is especially important for designers who are looking to create custom pieces of furniture or bedding that require specific dimensions.

Another advantage is cost-effectiveness. By cutting your own foam, you can save money on purchasing pre-cut foam or paying a professional to do it for you. This is especially beneficial for designers who work with a lot of foam or who frequently need different sizes and shapes for their projects.

Tips for Cutting Mattress Foam with a Table Saw

While cutting foam with a table saw may seem daunting, with the right technique and safety precautions, it can be a simple and efficient process. First, make sure you have the right type of blade for cutting foam, such as a low-tooth count blade or a foam cutting blade. This will ensure clean, precise cuts without damaging the foam.

Next, it's important to secure the foam to the table saw before cutting. This can be done with clamps, double-sided tape, or even a non-slip mat. This will prevent the foam from shifting or moving during the cutting process.

When cutting, it's crucial to use a slow and steady pace. Rushing the process can lead to uneven or jagged cuts. It's also important to use a push stick or other safety device to keep your hands a safe distance from the blade.

In Conclusion

Cutting mattress foam with a table saw is a practical and cost-effective solution for house designers who want to achieve precise and customizable results. By following proper techniques and safety precautions, designers can create professional-looking pieces of furniture and bedding that will contribute to the overall aesthetic and functionality of a space. So next time you're working on a house design project, consider using a table saw to cut your foam and see the difference it can make.

:max_bytes(150000):strip_icc()/TableSawCuts1800x1200-56aa2c5e5f9b58b7d0016b77.jpg)