When it comes to creating a comfortable and supportive mattress, the manufacturing process is key. In this article, we will take a closer look at the top 10 steps involved in the production of polyurethane foam mattresses.Polyurethane Foam Mattress Manufacturing Process

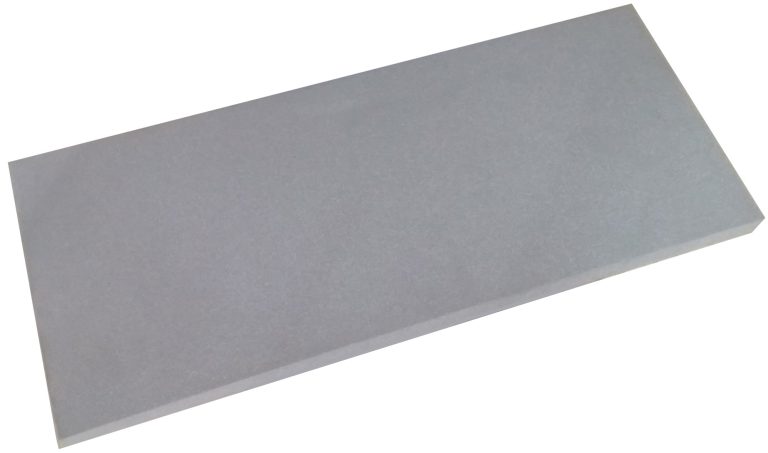

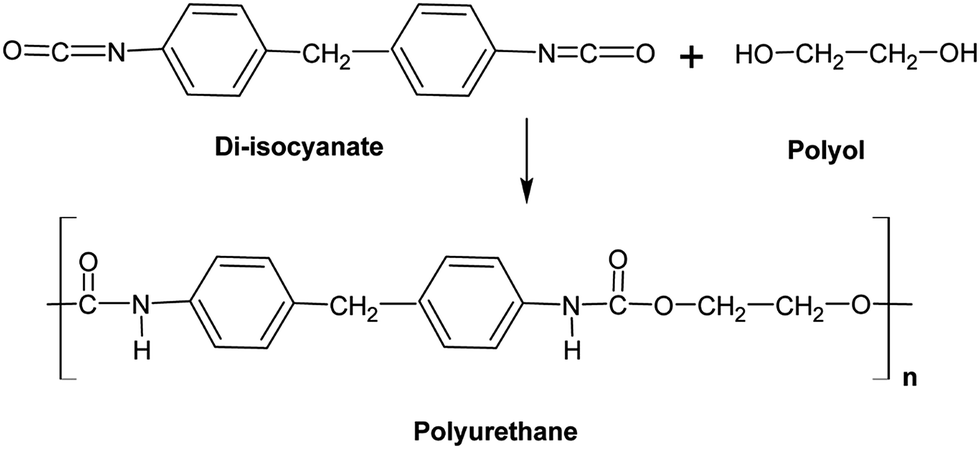

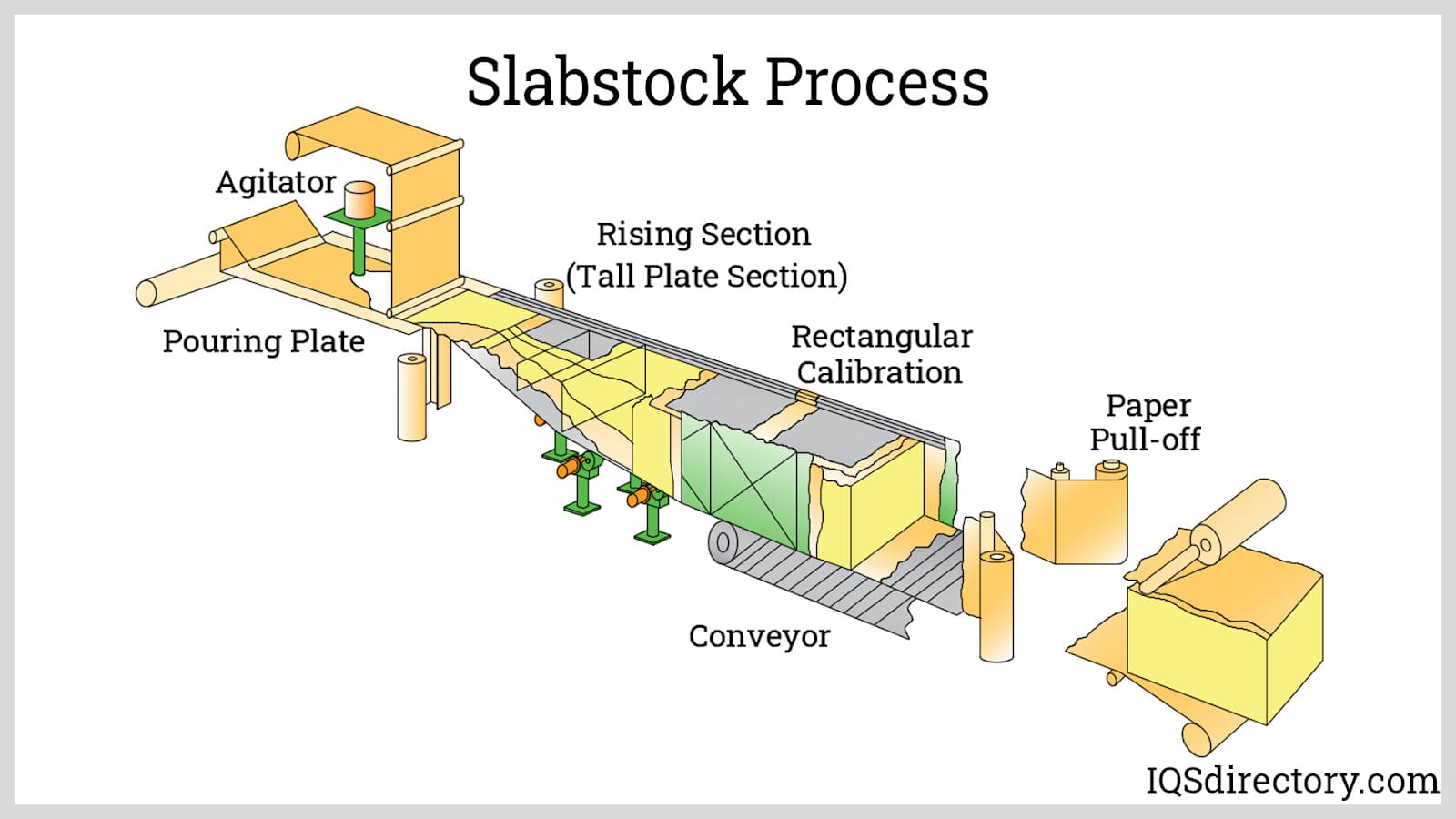

The first step in creating a polyurethane foam mattress is the production of the foam itself. This involves combining polyols and isocyanates to create a liquid foam mixture. This mixture is then poured into molds and allowed to expand and cure.Polyurethane Foam Mattress Production

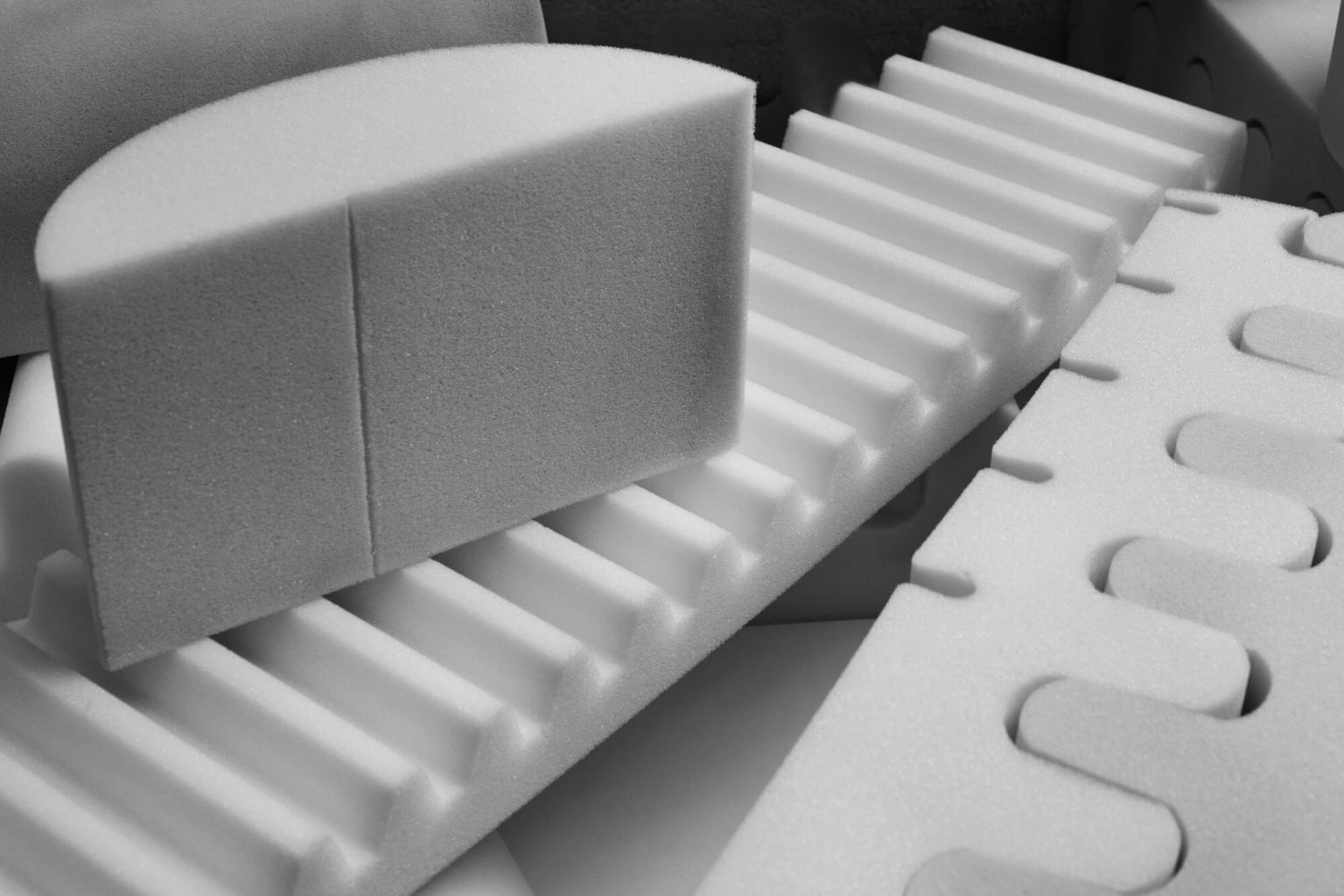

Once the foam has cured, it is removed from the molds and cut into the appropriate sizes for the mattress. These pieces are then assembled together to form the base layer of the mattress.Polyurethane Foam Mattress Assembly

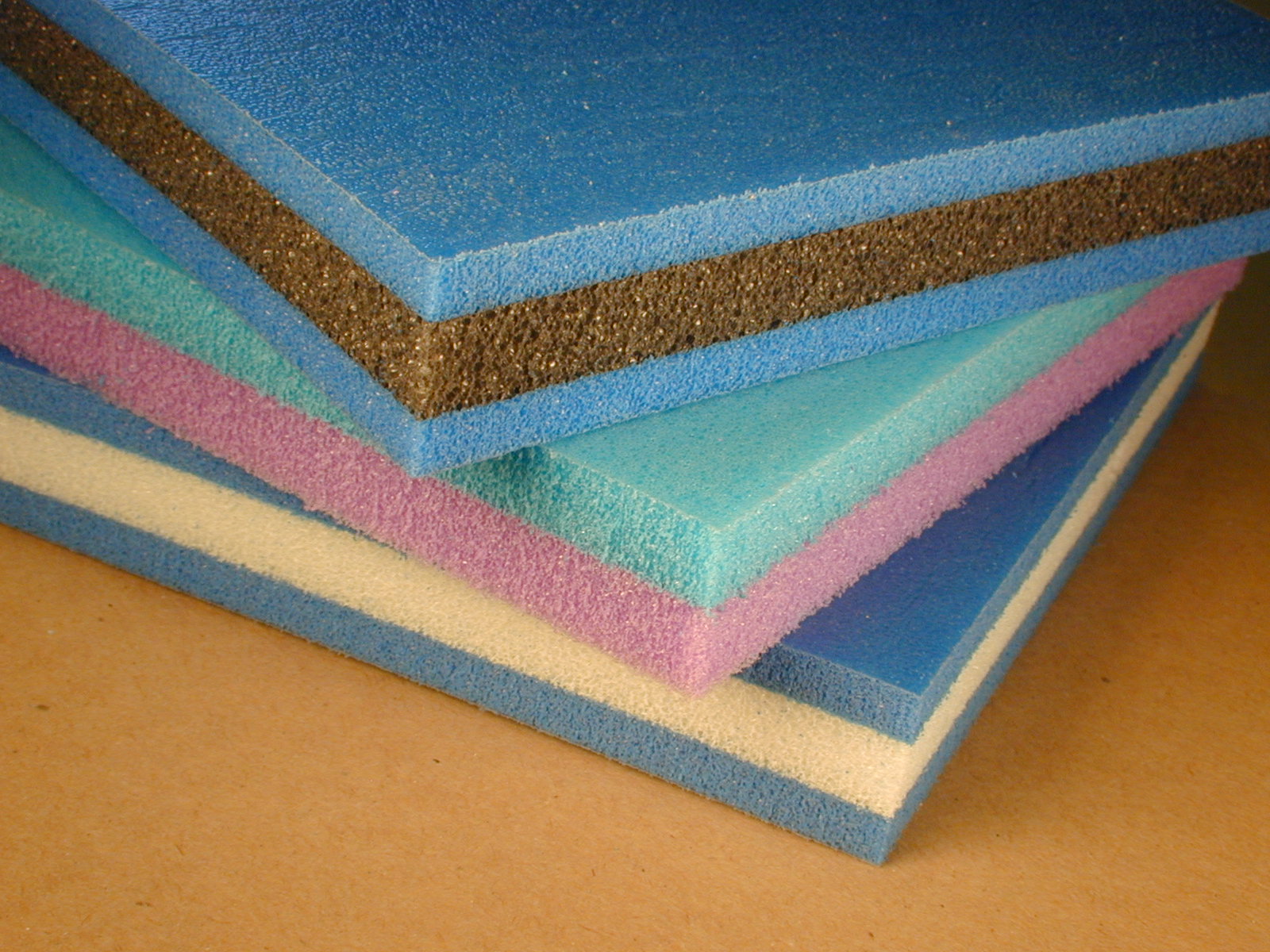

The next step is the fabrication of the foam layers that will make up the comfort and support layers of the mattress. This involves cutting and shaping the foam to the desired dimensions and densities.Polyurethane Foam Mattress Fabrication

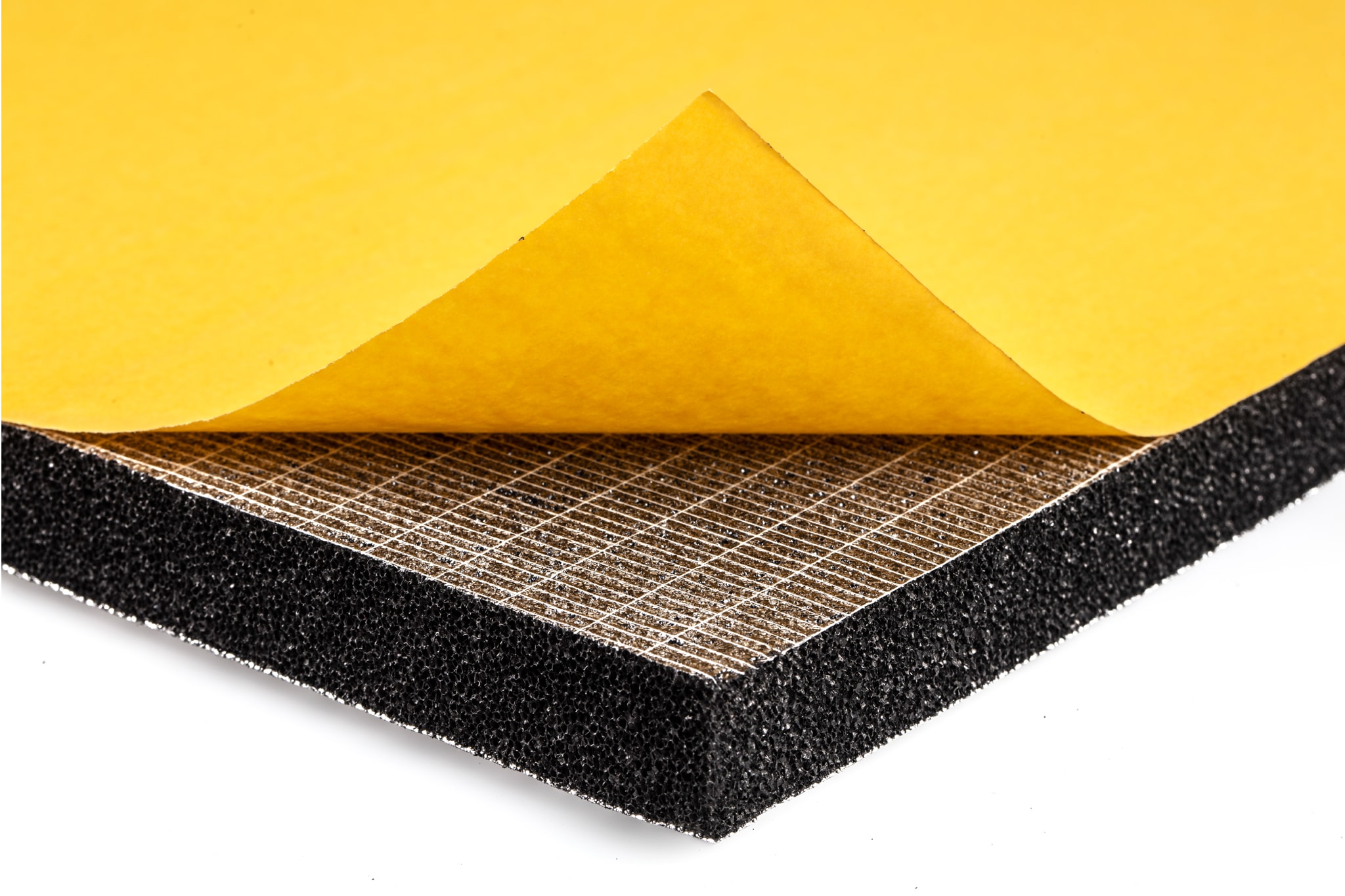

With the foam layers ready, the construction of the mattress can begin. The base layer is placed on the bottom, followed by the comfort and support layers. These layers are then glued or stitched together to create a cohesive mattress.Polyurethane Foam Mattress Construction

During the making process, the mattress is compressed and rolled for easier shipping and handling. This also allows the mattress to expand to its full size once it is removed from its packaging.Polyurethane Foam Mattress Making

Once the mattress is made, the next step is the creation of the cover. This involves sewing together fabric, typically a blend of polyester and cotton, to create a soft and durable cover for the mattress.Polyurethane Foam Mattress Creation

With the cover completed, it is time to put all the pieces together. The foam layers are placed inside the cover and the edges are sewn or zipped together to create the final product.Polyurethane Foam Mattress Formation

During the development stage, the mattress is inspected for quality and undergoes any necessary adjustments to ensure it meets the desired specifications. This can include adding or removing foam layers for different levels of firmness.Polyurethane Foam Mattress Development

The final step in the manufacturing process is building the finished product. The mattress is compressed, rolled, and packaged for shipping to retailers or directly to consumers.Polyurethane Foam Mattress Building

The Benefits of Polyurethane Foam Mattresses in House Design

Creating the Perfect Sleeping Environment

When it comes to designing the perfect home, creating a comfortable and inviting bedroom is essential. The right mattress plays a crucial role in achieving this, providing a restful and rejuvenating sleep experience. This is where polyurethane foam mattresses come in. These mattresses have gained immense popularity in recent years due to their unique manufacturing process and numerous benefits. Let's take a closer look at how polyurethane foam mattresses are made and why they are a great addition to any house design.

When it comes to designing the perfect home, creating a comfortable and inviting bedroom is essential. The right mattress plays a crucial role in achieving this, providing a restful and rejuvenating sleep experience. This is where polyurethane foam mattresses come in. These mattresses have gained immense popularity in recent years due to their unique manufacturing process and numerous benefits. Let's take a closer look at how polyurethane foam mattresses are made and why they are a great addition to any house design.

The Manufacturing Process

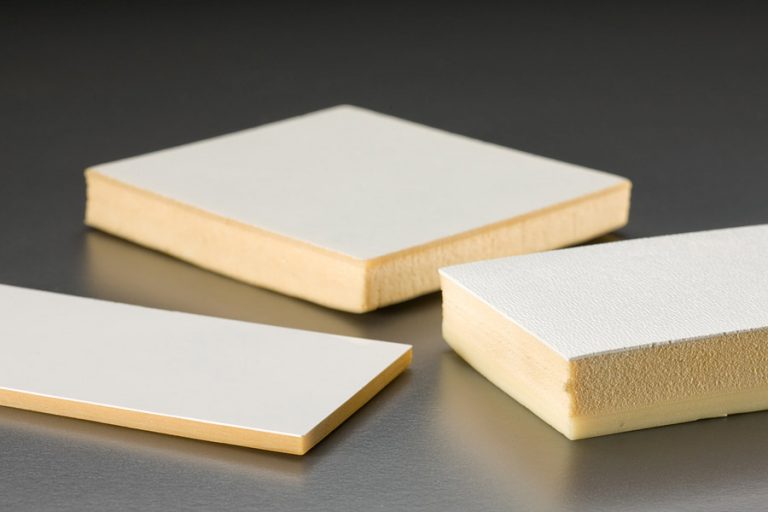

Polyurethane foam mattresses are made using a process known as "foaming." This involves mixing two chemical components, polyol and isocyanate, which react and expand to form a foam. The foam is then poured into a mold and left to cure, resulting in the final product – a high-density, supportive, and durable mattress.

Polyol and isocyanate

are the two main components used in the manufacturing process, and their quality and quantity play a significant role in the final product's comfort and durability. This is why manufacturers pay great attention to sourcing high-quality materials and using precise measurements to ensure consistency and quality in every mattress produced.

Polyurethane foam mattresses are made using a process known as "foaming." This involves mixing two chemical components, polyol and isocyanate, which react and expand to form a foam. The foam is then poured into a mold and left to cure, resulting in the final product – a high-density, supportive, and durable mattress.

Polyol and isocyanate

are the two main components used in the manufacturing process, and their quality and quantity play a significant role in the final product's comfort and durability. This is why manufacturers pay great attention to sourcing high-quality materials and using precise measurements to ensure consistency and quality in every mattress produced.

The Benefits of Polyurethane Foam Mattresses

Polyurethane foam mattresses offer a wide range of benefits for house design, making them a popular choice among homeowners and interior designers. The foam's high density provides excellent support for the body, promoting proper spinal alignment and reducing pressure points. This not only leads to a more comfortable sleep but also helps alleviate body aches and pains.

Moreover, polyurethane foam mattresses are known for their excellent motion isolation properties. This means that when one person moves or shifts during sleep, the foam absorbs the motion, preventing it from disturbing their partner. This makes them an ideal choice for couples or anyone sharing a bed.

Lastly, polyurethane foam mattresses are highly durable, with a lifespan of 10-15 years. This makes them a cost-effective investment for house design, as they do not need to be replaced frequently.

In conclusion, polyurethane foam mattresses offer a unique blend of comfort, support, and durability, making them an excellent addition to any house design. With their innovative manufacturing process and numerous benefits, it's no wonder they have become a top choice for homeowners looking to create the perfect sleeping environment. So, if you're in the market for a new mattress, consider a polyurethane foam one, and experience the difference for yourself.

Polyurethane foam mattresses offer a wide range of benefits for house design, making them a popular choice among homeowners and interior designers. The foam's high density provides excellent support for the body, promoting proper spinal alignment and reducing pressure points. This not only leads to a more comfortable sleep but also helps alleviate body aches and pains.

Moreover, polyurethane foam mattresses are known for their excellent motion isolation properties. This means that when one person moves or shifts during sleep, the foam absorbs the motion, preventing it from disturbing their partner. This makes them an ideal choice for couples or anyone sharing a bed.

Lastly, polyurethane foam mattresses are highly durable, with a lifespan of 10-15 years. This makes them a cost-effective investment for house design, as they do not need to be replaced frequently.

In conclusion, polyurethane foam mattresses offer a unique blend of comfort, support, and durability, making them an excellent addition to any house design. With their innovative manufacturing process and numerous benefits, it's no wonder they have become a top choice for homeowners looking to create the perfect sleeping environment. So, if you're in the market for a new mattress, consider a polyurethane foam one, and experience the difference for yourself.