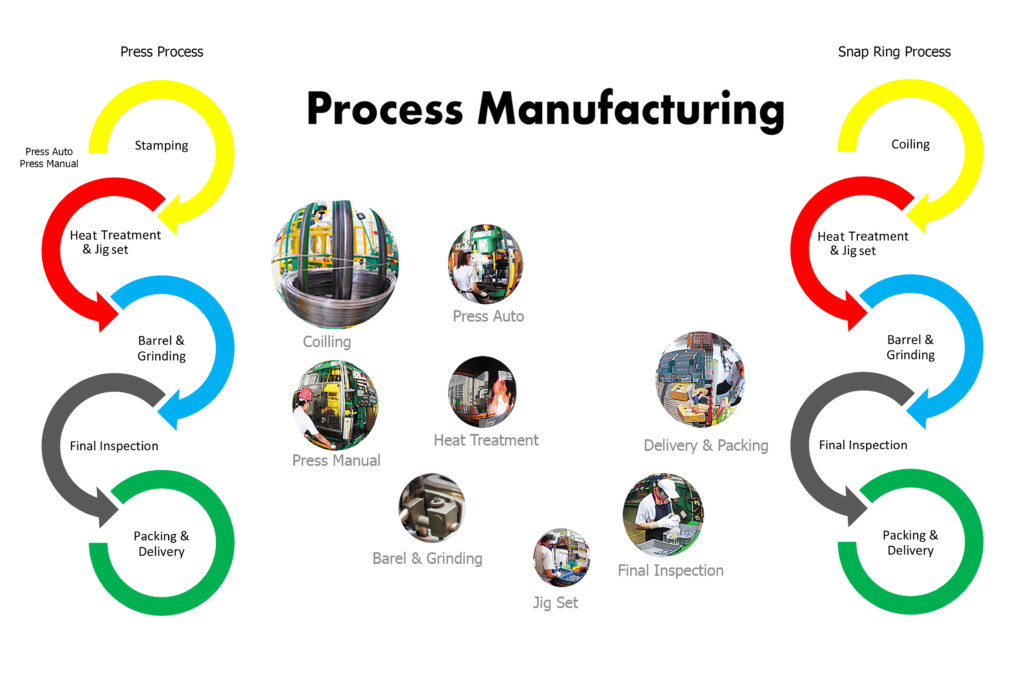

Spring mattresses have been a popular choice for comfortable and supportive sleep for decades. But have you ever wondered how these mattresses are made? The manufacturing process of a spring mattress is a complex and intricate one, involving various materials and techniques. In this article, we will take a closer look at the top 10 main manufacturing processes of spring mattresses.1. Spring Mattress Manufacturing Process Overview

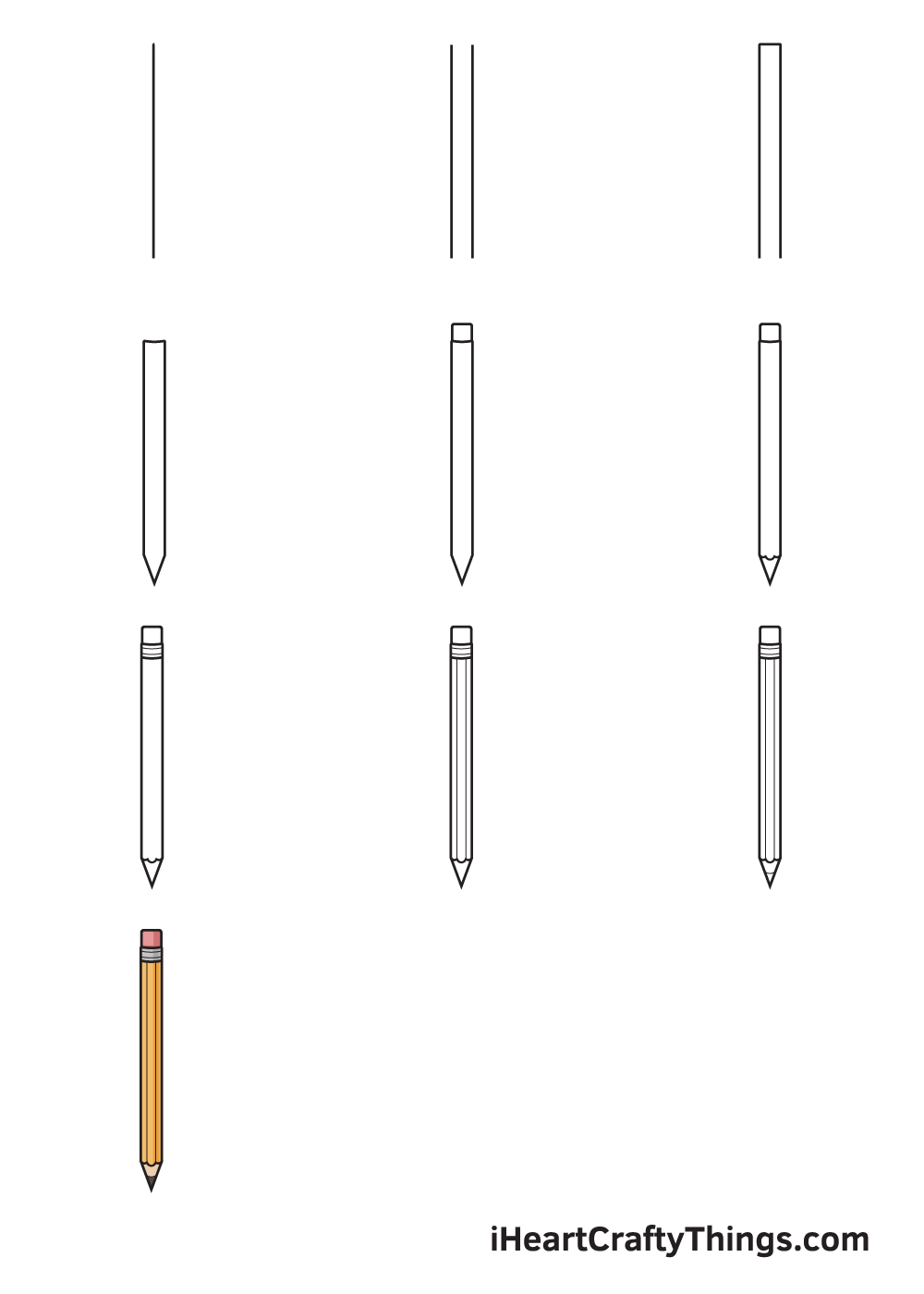

The first step in the manufacturing process of a spring mattress is designing the product. This involves deciding on the size, shape, and number of coils, as well as the type and thickness of the padding. Once the design is finalized, the actual production process begins.2. How Spring Mattresses are Made

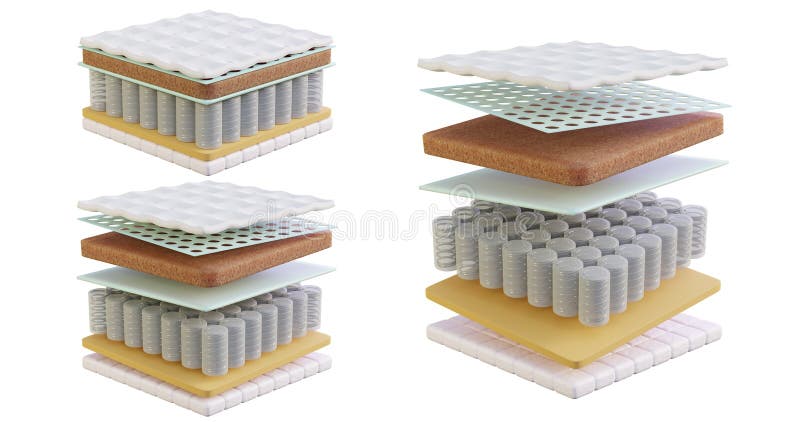

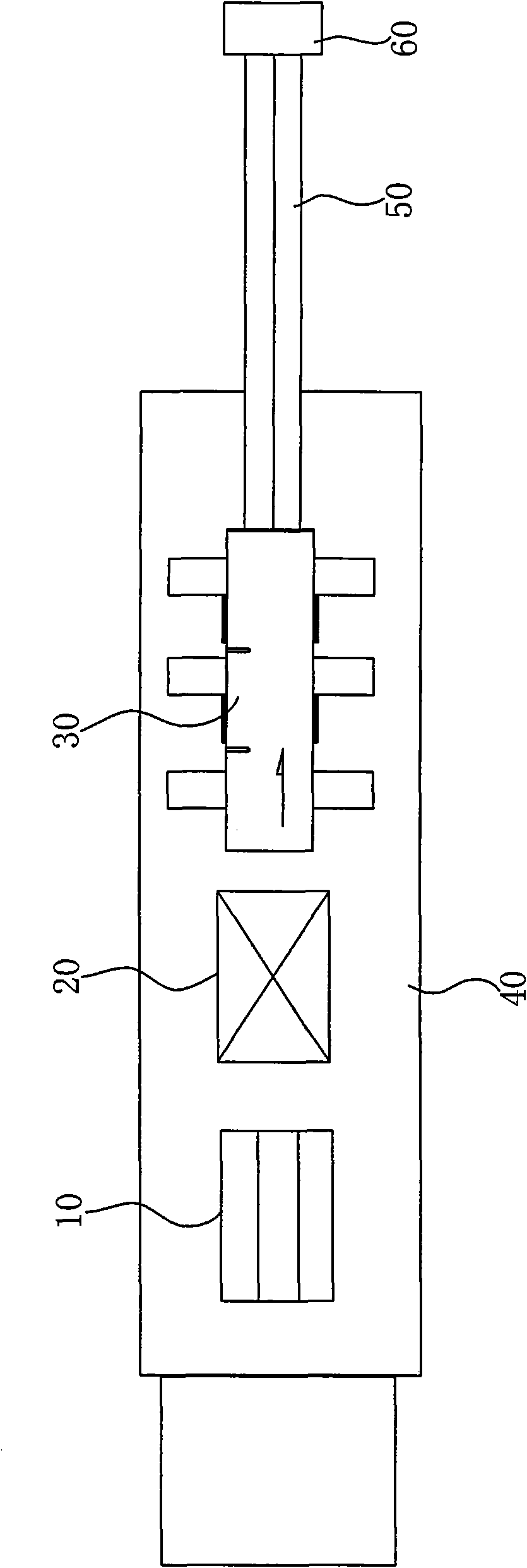

The manufacturing process of a spring mattress starts with assembling the coils. These coils are made of high-quality steel wire and are formed into the desired shape using specialized machines. The coils are then connected using helical wires to form a supportive and durable structure. Next, the coils are placed into a wooden or metal frame, which acts as the base of the mattress. This frame is then padded with layers of foam, cotton, or other materials for added comfort. The padding is glued or stitched onto the frame to keep it in place. The final step in the manufacturing process is attaching the top and bottom layers of fabric to the frame. These layers are sewn together and then attached to the frame using a specialized machine. The edges are then stitched or glued together to give the mattress a clean and finished look.3. Step-by-Step Guide to Manufacturing a Spring Mattress

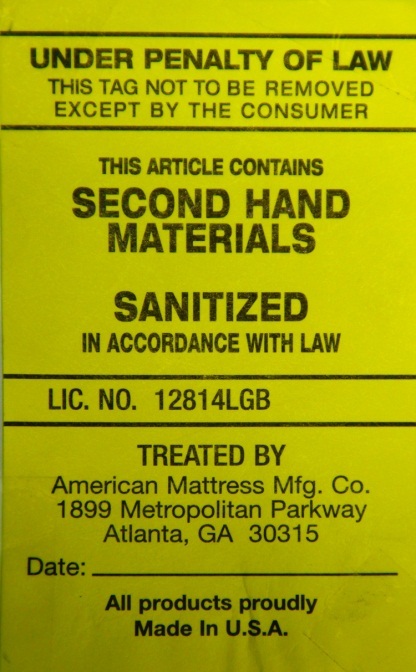

The materials used in the manufacturing of a spring mattress are crucial in determining its quality and comfort level. The most commonly used materials include high-quality steel wire for the coils, various types of foam for padding, and layers of fabric for the outer cover. The type and quality of these materials can vary, depending on the manufacturer and the price point of the mattress. However, it is important to note that higher-quality materials often result in a more comfortable and durable mattress.4. Materials Used in the Manufacturing of Spring Mattresses

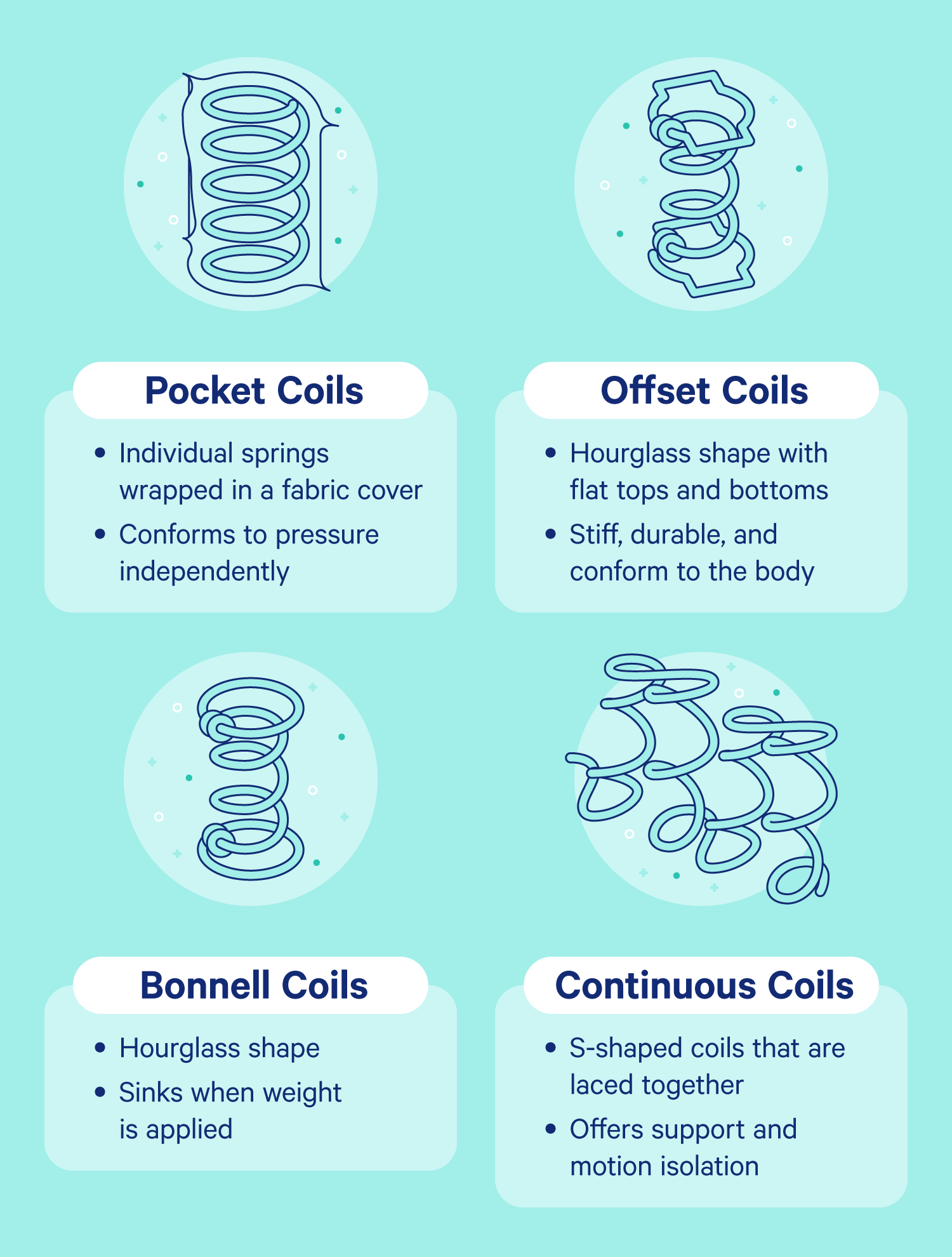

The coils are the backbone of a spring mattress and play a crucial role in providing support and stability. The type and arrangement of coils can vary, with some mattresses using Bonnell coils, while others use pocketed coils. These coils are designed to distribute weight evenly and reduce motion transfer, resulting in a comfortable and undisturbed sleep.5. The Role of Coils in the Manufacturing Process of Spring Mattresses

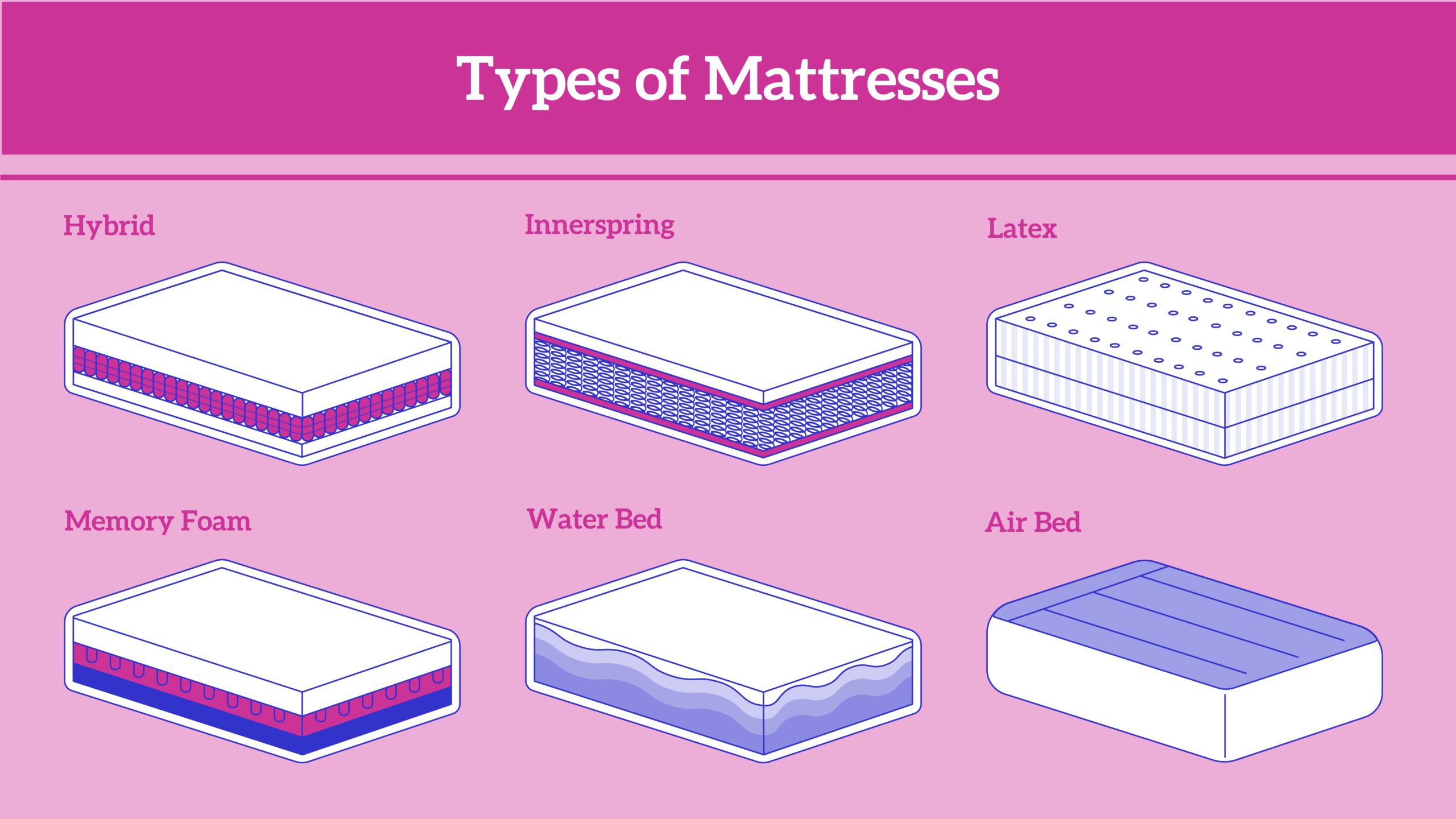

There are several types of spring mattresses available in the market, each with its own unique manufacturing process. Traditional innerspring mattresses use a system of interconnected coils, while pocketed coil mattresses have individual coils encased in fabric pockets for better support and motion isolation. Hybrid mattresses combine both springs and foam for a balance of comfort and support.6. Different Types of Spring Mattresses and Their Manufacturing Processes

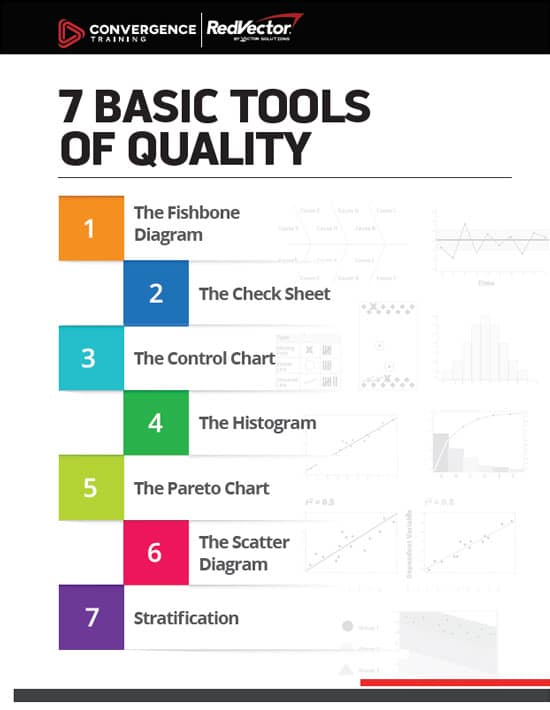

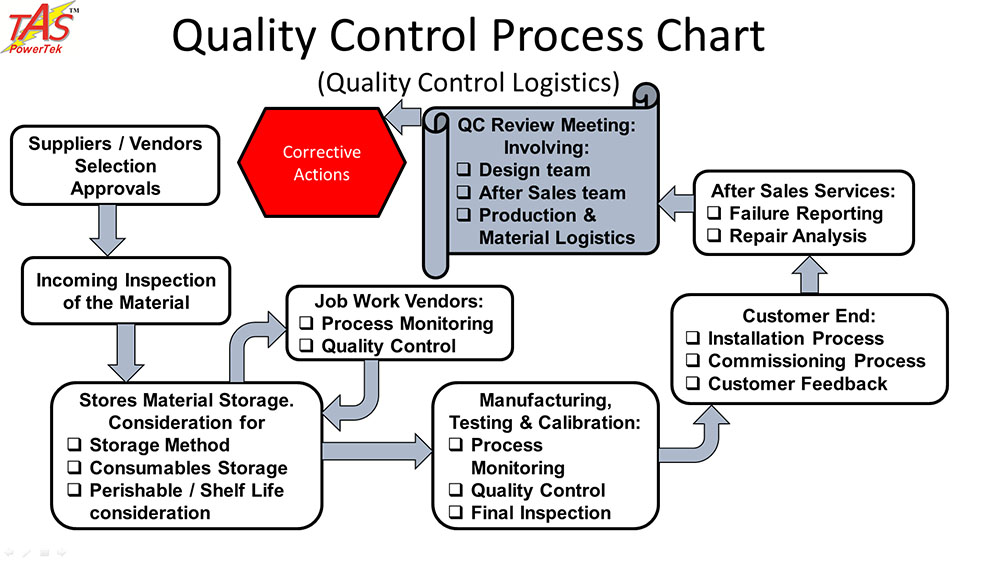

As with any product, quality control is an essential aspect of the manufacturing process of spring mattresses. Manufacturers have strict guidelines and standards in place to ensure that each mattress meets the necessary requirements for comfort, support, and durability. These quality control measures involve testing the materials used in the mattress, as well as the finished product, for factors such as firmness, support, and durability. This ensures that customers receive a high-quality product that meets their expectations.7. Quality Control in the Manufacturing of Spring Mattresses

With advancements in technology, the manufacturing process of spring mattresses has become more automated. This has resulted in increased efficiency and production speed, as well as improved consistency in the final product. Automated machines can now perform tasks such as assembling coils, attaching fabric layers, and stitching edges, which were previously done manually. This not only saves time and labor costs but also allows for a more precise and consistent end product.8. Automation in the Spring Mattress Manufacturing Process

The manufacturing process of spring mattresses can have a significant impact on the environment, as it involves the use of various materials and resources. However, many manufacturers are now taking steps to reduce their environmental footprint by using eco-friendly materials and implementing sustainable practices. Some manufacturers also offer recycling programs for their old mattresses, which helps reduce waste and promotes a circular economy. By choosing a mattress from a company that prioritizes sustainability, you can help reduce your carbon footprint.9. Environmental Impact of Spring Mattress Manufacturing

Lastly, advancements in technology have led to innovative manufacturing techniques for spring mattresses. Companies are now using 3D printing technology to create customized and personalized mattresses for their customers. Additionally, smart mattresses that track sleep patterns and adjust firmness and support levels are also gaining popularity. These innovations not only improve the overall sleep experience but also make the manufacturing process more efficient and cost-effective. In conclusion, the manufacturing process of a spring mattress involves several steps and utilizes various materials and technologies. By understanding this process, you can make a more informed decision when choosing the perfect spring mattress for your needs.10. Innovations in Spring Mattress Manufacturing Technology

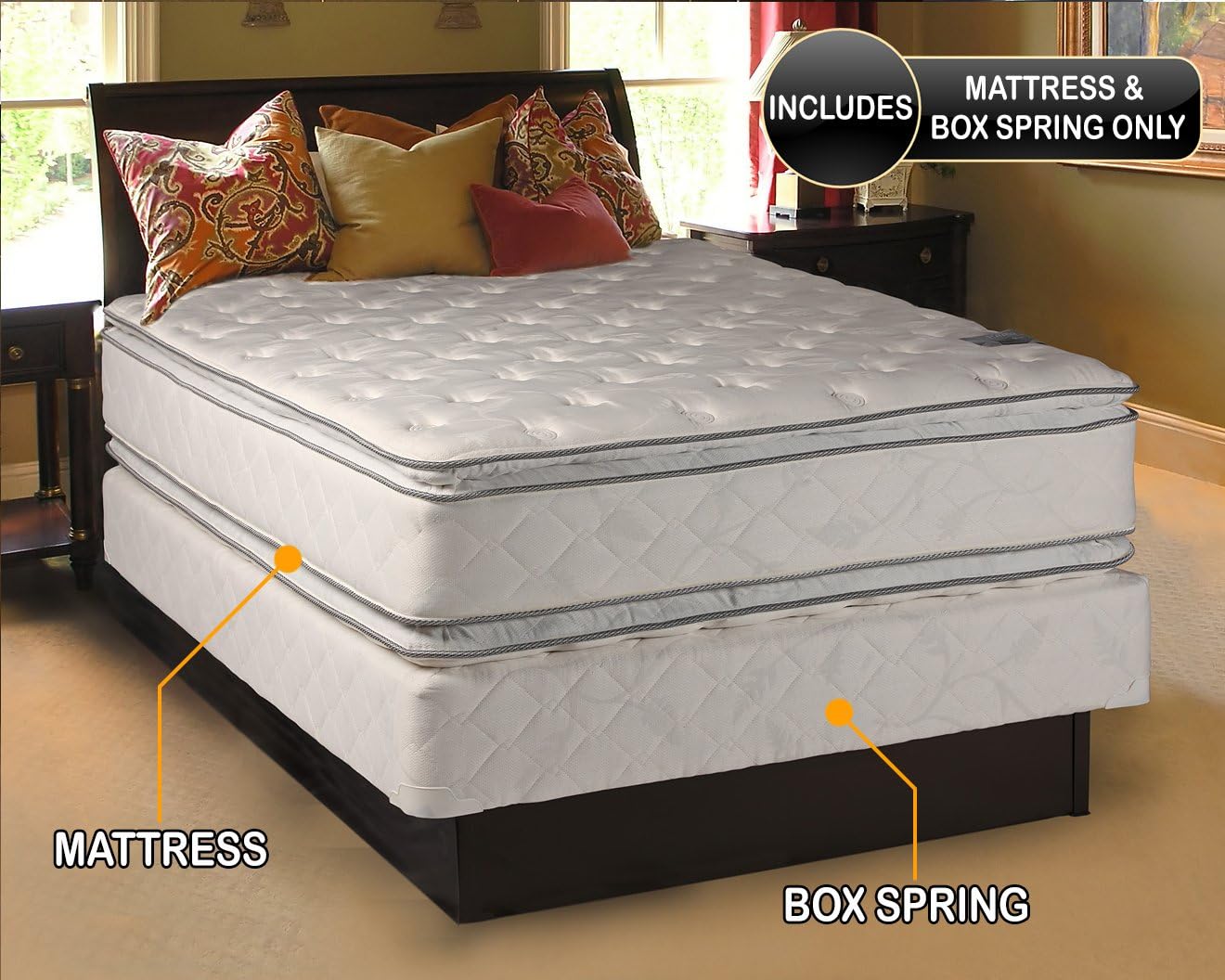

The Importance of Choosing the Right Spring Mattress for Your Home

Why a Spring Mattress?

When it comes to choosing a mattress for your home, there are many options available in the market. However, one of the most popular and time-tested choices is a spring mattress.

Spring mattresses have been a staple in the bedding industry for decades

and for good reason. These mattresses offer the perfect balance of support and comfort, making them a popular choice for people of all ages and body types.

When it comes to choosing a mattress for your home, there are many options available in the market. However, one of the most popular and time-tested choices is a spring mattress.

Spring mattresses have been a staple in the bedding industry for decades

and for good reason. These mattresses offer the perfect balance of support and comfort, making them a popular choice for people of all ages and body types.

The Manufacturing Process of Spring Mattresses

So, how exactly are spring mattresses made? The process begins with

carefully chosen high-quality materials

, such as steel coils, foam, and fabric. These materials are then assembled and arranged in a specific pattern to create the core of the mattress. The coils are carefully placed and connected to each other to provide the right amount of support and durability.

Once the core is assembled, it is then surrounded by layers of foam and fabric, creating a soft and comfortable surface for sleeping. The fabric used in spring mattresses is usually a blend of natural and synthetic fibers, providing a balance of breathability and durability. The foam layers also play a crucial role in providing comfort and support, as they contour to the body's shape and relieve pressure points.

So, how exactly are spring mattresses made? The process begins with

carefully chosen high-quality materials

, such as steel coils, foam, and fabric. These materials are then assembled and arranged in a specific pattern to create the core of the mattress. The coils are carefully placed and connected to each other to provide the right amount of support and durability.

Once the core is assembled, it is then surrounded by layers of foam and fabric, creating a soft and comfortable surface for sleeping. The fabric used in spring mattresses is usually a blend of natural and synthetic fibers, providing a balance of breathability and durability. The foam layers also play a crucial role in providing comfort and support, as they contour to the body's shape and relieve pressure points.

The Benefits of a Spring Mattress

There are many benefits to choosing a spring mattress for your home. One of the main advantages is its

durability and longevity

. Due to its sturdy construction, a spring mattress can last for many years without losing its shape or support. Additionally, the coils in a spring mattress provide

optimal support for the body

, promoting proper spinal alignment and reducing aches and pains.

Another benefit of spring mattresses is their

breathability

. The open structure of the coils allows for better air circulation, keeping the mattress cool and preventing the buildup of heat and moisture. This makes spring mattresses a great choice for hot sleepers.

There are many benefits to choosing a spring mattress for your home. One of the main advantages is its

durability and longevity

. Due to its sturdy construction, a spring mattress can last for many years without losing its shape or support. Additionally, the coils in a spring mattress provide

optimal support for the body

, promoting proper spinal alignment and reducing aches and pains.

Another benefit of spring mattresses is their

breathability

. The open structure of the coils allows for better air circulation, keeping the mattress cool and preventing the buildup of heat and moisture. This makes spring mattresses a great choice for hot sleepers.

In Conclusion

In conclusion, a spring mattress is a great choice for anyone looking for a comfortable and durable mattress for their home. Its manufacturing process and high-quality materials ensure that you get the best sleep experience possible. So, when it comes to choosing a mattress for your home, consider a spring mattress for its numerous benefits and superior quality.

In conclusion, a spring mattress is a great choice for anyone looking for a comfortable and durable mattress for their home. Its manufacturing process and high-quality materials ensure that you get the best sleep experience possible. So, when it comes to choosing a mattress for your home, consider a spring mattress for its numerous benefits and superior quality.