When it comes to producing high-quality interior doors, having the right equipment is crucial. Without the proper tools, it can be challenging to meet the demand for these essential household items. That's why interior doors manufacturing equipment is a vital investment for any company in the industry. From saws and drills to sanders and finishers, there are many types of equipment available to streamline the production process and ensure top-notch results.Interior Doors Manufacturing Equipment

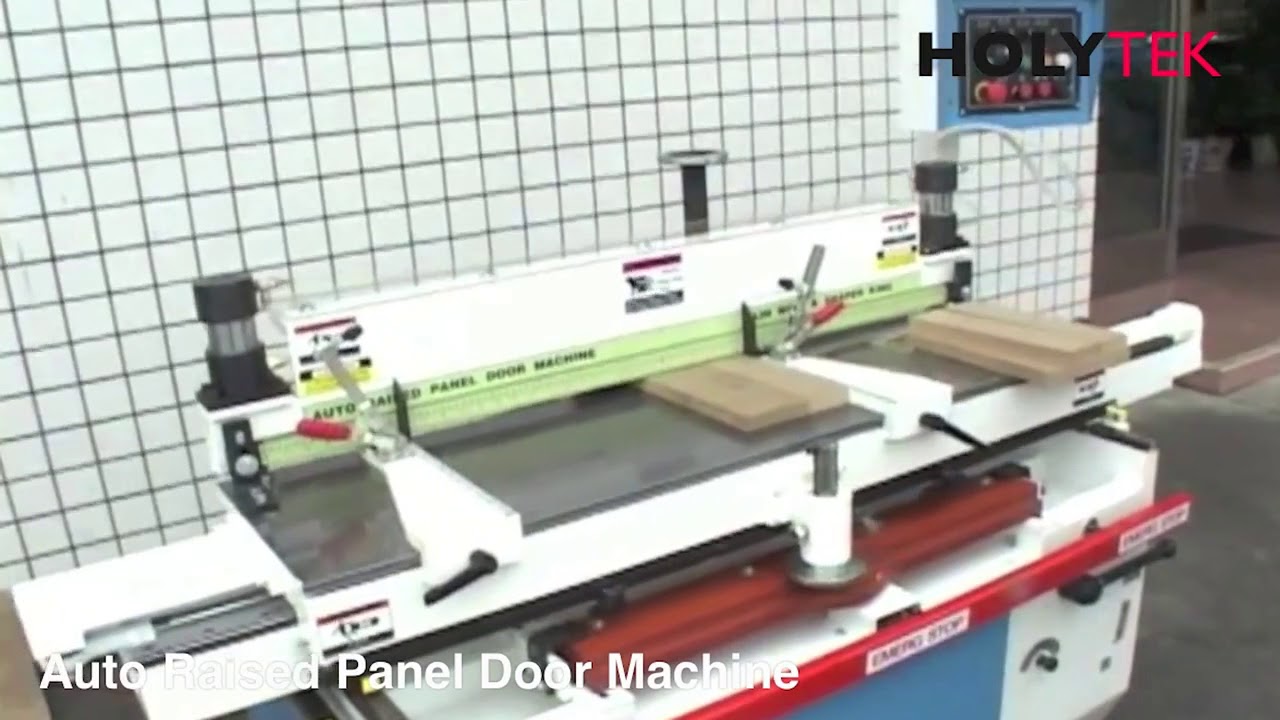

In addition to equipment, interior doors manufacturing machinery is another essential aspect of the production process. These machines can handle large volumes of work, making them ideal for mass-producing interior doors. With the use of advanced technology and precision engineering, interior doors manufacturing machinery can create doors with intricate designs and smooth finishes. This results in high-quality products that are both durable and visually appealing.Interior Doors Manufacturing Machinery

For companies focused on the production of interior doors, having the right equipment is crucial. Interior doors production equipment is designed to handle the specific needs of the production process, ensuring efficiency and accuracy. From cutting and shaping to sanding and finishing, there are various types of production equipment available to help companies meet the demand for interior doors effectively.Interior Doors Production Equipment

Similar to manufacturing machinery, interior doors production machinery is designed to handle large volumes of work. These machines have advanced capabilities that allow for the creation of intricate designs and high-quality finishes. With the help of interior doors production machinery, companies can produce doors efficiently and cost-effectively, ultimately leading to increased profits and customer satisfaction.Interior Doors Production Machinery

Aside from large equipment and machinery, there are also various interior doors manufacturing tools that are essential for the production process. These tools include hand-held saws, drills, sanders, and other handheld equipment that can assist in creating precise cuts and finishes. With the help of these tools, manufacturers can ensure that their interior doors meet the highest standards of quality and craftsmanship.Interior Doors Manufacturing Tools

In addition to manufacturing tools, there are also various production tools that are essential for creating high-quality interior doors. These tools include precision measuring instruments, gluing and clamping tools, and finishing tools. With the use of these tools, companies can ensure that each door is produced with accuracy and attention to detail, resulting in a superior final product.Interior Doors Production Tools

Having the right supplies is crucial for any manufacturing process, and the production of interior doors is no exception. Interior doors manufacturing supplies include materials such as wood, glass, and hardware, as well as adhesives, finishes, and other necessary components. By having a reliable and consistent supply of these materials, manufacturers can ensure that their production process is never interrupted, and their products are of the highest quality.Interior Doors Manufacturing Supplies

In addition to manufacturing supplies, there are also various production supplies that are essential for creating interior doors. These supplies include items such as sandpaper, brushes, and rollers, which are used during the finishing process. With the use of these supplies, manufacturers can ensure that their doors have a smooth and flawless finish, making them more appealing to customers.Interior Doors Production Supplies

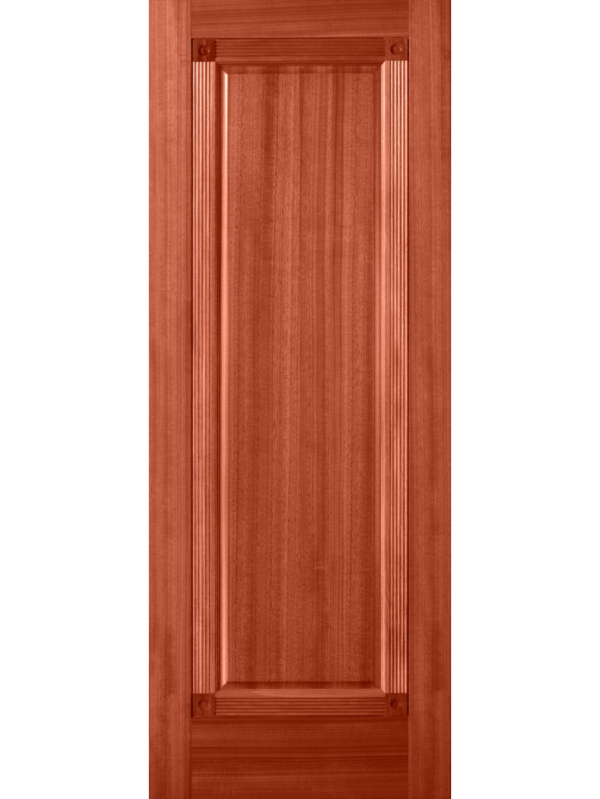

Of course, the most crucial aspect of producing interior doors is having the right materials. Interior doors manufacturing materials include wood, glass, and other materials used to create the doors' structure. These materials must be of high quality to ensure that the doors are durable and long-lasting. With the use of the right materials, manufacturers can produce doors that meet the highest standards of quality and craftsmanship.Interior Doors Manufacturing Materials

Similar to manufacturing materials, interior doors production materials are essential for creating high-quality doors. These materials are used during the finishing process and include items such as stains, paints, and varnishes. With the use of these materials, manufacturers can add the final touches to their doors, making them visually appealing and ready for installation in homes and businesses.Interior Doors Production Materials

Streamlining the Manufacturing Process for Interior Doors

The Importance of Efficient Equipment

When it comes to interior door manufacturing, having the right equipment is crucial. Not only does it ensure the quality and consistency of the final product, but it also plays a major role in streamlining the production process. With the demand for unique and aesthetically pleasing interior doors increasing, manufacturers must invest in modern and innovative equipment to stay competitive in the market.

When it comes to interior door manufacturing, having the right equipment is crucial. Not only does it ensure the quality and consistency of the final product, but it also plays a major role in streamlining the production process. With the demand for unique and aesthetically pleasing interior doors increasing, manufacturers must invest in modern and innovative equipment to stay competitive in the market.

Advanced Technology for Precision and Speed

One of the key factors in producing high-quality interior doors is precision. The use of advanced technology in manufacturing equipment allows for precise cutting, shaping, and finishing of the doors. This not only ensures a perfect fit and smooth operation but also reduces the risk of errors and wastage of materials. With the use of computer-aided design (CAD) software and computer numerical control (CNC) machines, manufacturers can create intricate and customized interior doors with ease and speed.

One of the key factors in producing high-quality interior doors is precision. The use of advanced technology in manufacturing equipment allows for precise cutting, shaping, and finishing of the doors. This not only ensures a perfect fit and smooth operation but also reduces the risk of errors and wastage of materials. With the use of computer-aided design (CAD) software and computer numerical control (CNC) machines, manufacturers can create intricate and customized interior doors with ease and speed.

Innovative Designs and Features

Interior door manufacturing equipment is constantly evolving to keep up with the latest trends and demands in house design. From traditional wooden designs to sleek and modern styles, manufacturers can now produce a wide range of doors with unique features such as glass panels, sliding mechanisms, and smart locks. With the right equipment, manufacturers have the flexibility to experiment with different materials and designs, offering customers a diverse selection of interior doors for their homes.

Interior door manufacturing equipment is constantly evolving to keep up with the latest trends and demands in house design. From traditional wooden designs to sleek and modern styles, manufacturers can now produce a wide range of doors with unique features such as glass panels, sliding mechanisms, and smart locks. With the right equipment, manufacturers have the flexibility to experiment with different materials and designs, offering customers a diverse selection of interior doors for their homes.

Efficiency and Cost-Effectiveness

Investing in modern interior door manufacturing equipment not only improves the quality and design of the final product, but it also increases efficiency and reduces costs. With the use of automated processes and advanced technology, manufacturers can produce more doors in less time, reducing labor costs and increasing productivity. This also allows for quicker turnaround times, meeting the demands of customers and ensuring timely delivery.

Investing in modern interior door manufacturing equipment not only improves the quality and design of the final product, but it also increases efficiency and reduces costs. With the use of automated processes and advanced technology, manufacturers can produce more doors in less time, reducing labor costs and increasing productivity. This also allows for quicker turnaround times, meeting the demands of customers and ensuring timely delivery.

Conclusion

In the competitive world of house design, having efficient and modern interior door manufacturing equipment is essential. It not only improves the quality and design of the final product but also increases efficiency, reduces costs, and offers a wide range of innovative features and designs. As the demand for unique and aesthetically pleasing interior doors continues to rise, investing in advanced equipment is crucial for manufacturers to stay ahead in the market.

In the competitive world of house design, having efficient and modern interior door manufacturing equipment is essential. It not only improves the quality and design of the final product but also increases efficiency, reduces costs, and offers a wide range of innovative features and designs. As the demand for unique and aesthetically pleasing interior doors continues to rise, investing in advanced equipment is crucial for manufacturers to stay ahead in the market.