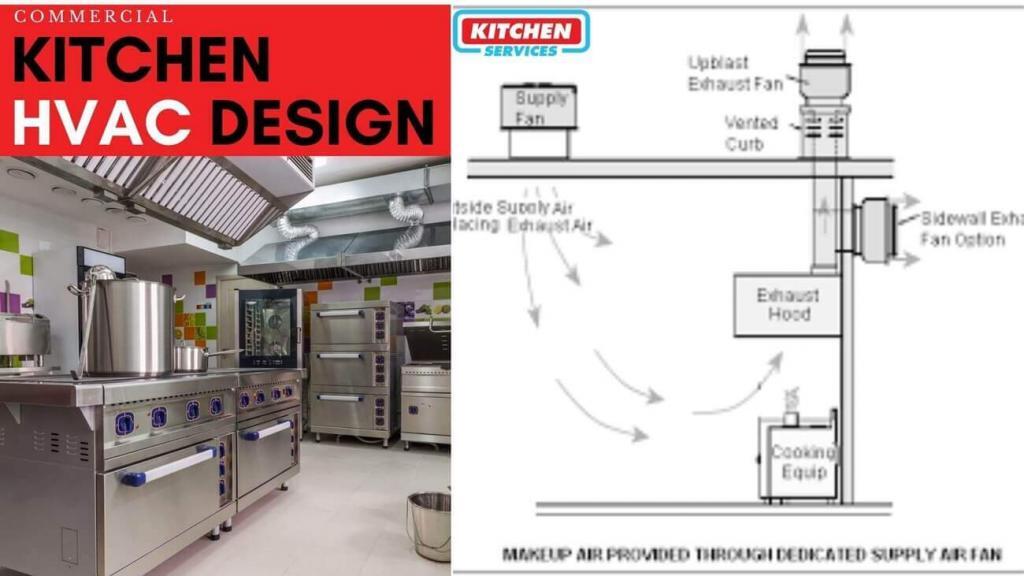

The National Fire Protection Association (NFPA) 96 is a comprehensive standard that outlines the minimum requirements for ventilation and fire protection systems in commercial cooking operations. It covers all aspects of kitchen hood design, from the type and size of the hood to the materials used for construction and installation. According to NFPA 96, the main purpose of a commercial kitchen hood is to remove heat, smoke, and grease-laden vapors from the cooking area. This is crucial for the safety of both the kitchen staff and the building itself. The standard also specifies the minimum airflow rates and exhaust rates for different types of cooking equipment. Featured keywords: NFPA 96, ventilation, fire protection, commercial cooking operations, kitchen hood design, minimum requirements, safety, airflow rates, exhaust rates. 1. NFPA 96: Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

The American National Standards Institute (ANSI) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) have jointly developed Standard 154, which provides guidelines for the design and installation of ventilation systems in commercial kitchens. This standard covers a wide range of topics, including the design and construction of kitchen hoods, ductwork, and exhaust fans. It also includes recommendations for the use of energy-efficient equipment and the maintenance of ventilation systems. Featured keywords: ANSI/ASHRAE Standard 154, ventilation systems, commercial kitchens, design, installation, kitchen hoods, ductwork, exhaust fans, energy-efficient equipment, maintenance. 2. ANSI/ASHRAE Standard 154: Ventilation for Commercial Cooking Operations

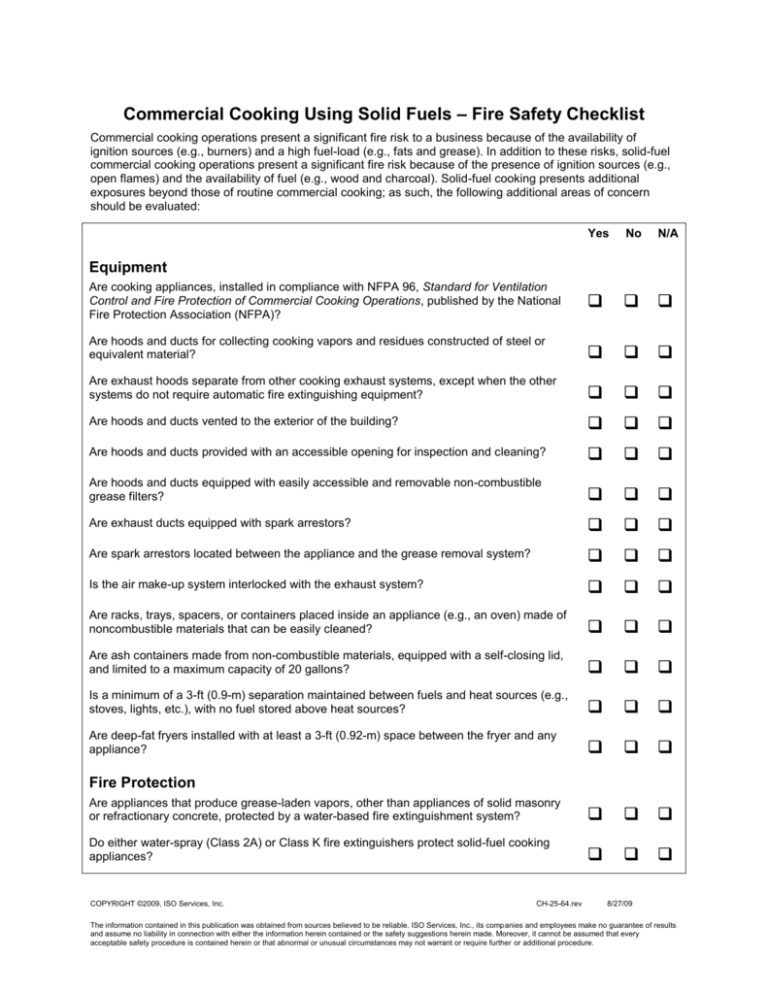

The International Mechanical Code (IMC) is a model code that is adopted by many states and municipalities in the United States. Section 507 of the IMC covers the design and installation requirements for commercial kitchen hoods. It specifies the minimum exhaust rates based on the type of cooking equipment and the size of the cooking area. The code also requires the use of fire suppression systems and the installation of make-up air systems to maintain proper air balance in the kitchen. Featured keywords: International Mechanical Code, Section 507, commercial kitchen hoods, design, installation requirements, exhaust rates, cooking equipment, fire suppression systems, make-up air systems, air balance. 3. International Mechanical Code (IMC) Section 507: Commercial Kitchen Hoods

The National Fire Code of Canada (NFCC) is another important standard that outlines the requirements for commercial kitchen hoods and ventilation systems. Section 2.8 of the code covers the design, installation, and maintenance of these systems. The NFCC requires that all commercial kitchens have a ventilation system that is capable of removing heat, smoke, and grease vapors. It also specifies the placement of exhaust hoods and ductwork to ensure effective ventilation. Featured keywords: National Fire Code of Canada, Section 2.8, commercial kitchen hoods, ventilation systems, design, installation, maintenance, heat, smoke, grease vapors, exhaust hoods, ductwork. 4. National Fire Code of Canada (NFCC) Section 2.8: Commercial Cooking Equipment and Ventilation Systems

Underwriters Laboratories (UL) is a global safety certification organization that tests and certifies products for compliance with safety standards. UL 710 is the standard for the safety of exhaust hoods for commercial cooking equipment. This standard covers the construction, materials, and performance of kitchen hoods to ensure they are safe for use in commercial kitchens. It also requires that hoods are tested and certified by a third-party organization before they can be installed. Featured keywords: UL 710, standard for safety, exhaust hoods, commercial cooking equipment, Underwriters Laboratories, construction, materials, performance, third-party organization, installation. 5. UL 710: Standard for Safety for Exhaust Hoods for Commercial Cooking Equipment

The International Fire Code (IFC) is another set of model regulations for fire safety in buildings. Section 609 of the IFC covers the design and installation requirements for commercial kitchen hoods. This code requires that all commercial kitchens have a ventilation system that is capable of removing heat, smoke, and grease vapors. It also specifies the placement of exhaust hoods and ductwork to ensure effective ventilation. Featured keywords: International Fire Code, Section 609, commercial kitchen hoods, design, installation requirements, heat, smoke, grease vapors, exhaust hoods, ductwork, ventilation system. 6. International Fire Code (IFC) Section 609: Commercial Kitchen Hoods

The ASHRAE Handbook is a comprehensive guide for HVAC (Heating, Ventilating, and Air Conditioning) professionals. Chapter 45 of the handbook focuses on commercial kitchen ventilation and provides guidance on the design, installation, and operation of these systems. It covers topics such as hood sizing, ductwork design, and exhaust fan selection. The chapter also includes information on energy efficiency and indoor air quality in commercial kitchens. Featured keywords: ASHRAE Handbook, HVAC Applications, Chapter 45, commercial kitchen ventilation, design, installation, operation, hood sizing, ductwork design, exhaust fan selection, energy efficiency, indoor air quality. 7. ASHRAE Handbook: HVAC Applications, Chapter 45: Commercial Kitchen Ventilation

The International Building Code (IBC) is another model code that is widely adopted in the United States. Section 506 of the IBC covers the design, installation, and maintenance requirements for commercial kitchen hoods. This code specifies the minimum exhaust rates based on the type of cooking equipment and the size of the cooking area. It also requires the use of fire suppression systems and the installation of make-up air systems to maintain proper air balance in the kitchen. Featured keywords: International Building Code, Section 506, commercial kitchen hoods, design, installation, maintenance requirements, exhaust rates, cooking equipment, fire suppression systems, make-up air systems, air balance. 8. International Building Code (IBC) Section 506: Commercial Kitchen Hoods

The Food Code is a set of guidelines developed by the U.S. Food and Drug Administration (FDA) to ensure food safety in commercial kitchens. Chapter 6 of the code covers the physical facilities of a kitchen, including the requirements for ventilation hood systems. Section 6-202.11 outlines the design and installation requirements for these systems, as well as the minimum exhaust rates based on the type of cooking equipment and the size of the cooking area. Featured keywords: Food Code, Chapter 6, Physical Facilities, Section 6-202.11, ventilation hood systems, design, installation requirements, exhaust rates, cooking equipment, size, food safety. 9. Food Code: Chapter 6: Physical Facilities, Section 6-202.11: Ventilation Hood Systems

The National Restaurant Association (NRA) is the leading trade association for the restaurant industry in the United States. They have developed comprehensive guidelines for the design and installation of commercial kitchen hoods. These guidelines cover all aspects of kitchen hood design, including the type and size of the hood, the placement of exhaust vents, and the use of fire suppression systems. They also provide recommendations for regular maintenance and cleaning of kitchen hoods to ensure their proper functioning. Featured keywords: Commercial Kitchen Hood Design and Installation Guidelines, National Restaurant Association, kitchen hood design, placement, exhaust vents, fire suppression systems, maintenance, cleaning, proper functioning. 10. Commercial Kitchen Hood Design and Installation Guidelines from the National Restaurant Association

Understanding the Importance of Commercial Kitchen Hood Design Requirements

Why Do Commercial Kitchens Need Proper Hood Design?

When it comes to designing a commercial kitchen, one of the most crucial aspects to consider is the

hood design

. A proper hood design is essential for any commercial kitchen as it plays a vital role in ensuring the safety and efficiency of the kitchen. A commercial kitchen is a busy and fast-paced environment, where cooking is done on a large scale. With the extensive use of various cooking appliances, there is a high risk of fire hazards, smoke, and grease buildup. This is where a

commercial kitchen hood

comes into play. It is designed to extract the heat, smoke, and grease generated during cooking, keeping the kitchen clean, safe, and comfortable for the staff.

When it comes to designing a commercial kitchen, one of the most crucial aspects to consider is the

hood design

. A proper hood design is essential for any commercial kitchen as it plays a vital role in ensuring the safety and efficiency of the kitchen. A commercial kitchen is a busy and fast-paced environment, where cooking is done on a large scale. With the extensive use of various cooking appliances, there is a high risk of fire hazards, smoke, and grease buildup. This is where a

commercial kitchen hood

comes into play. It is designed to extract the heat, smoke, and grease generated during cooking, keeping the kitchen clean, safe, and comfortable for the staff.

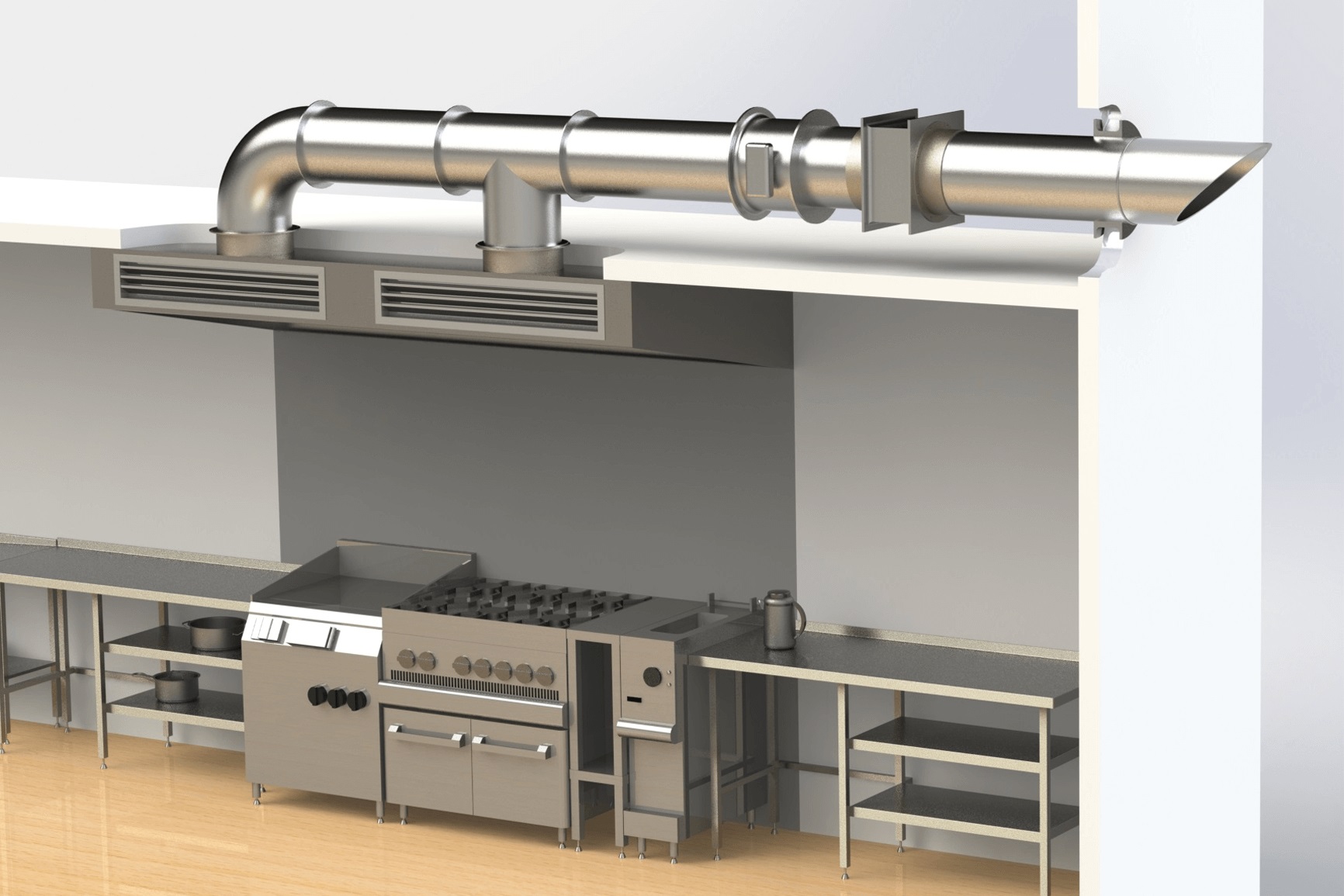

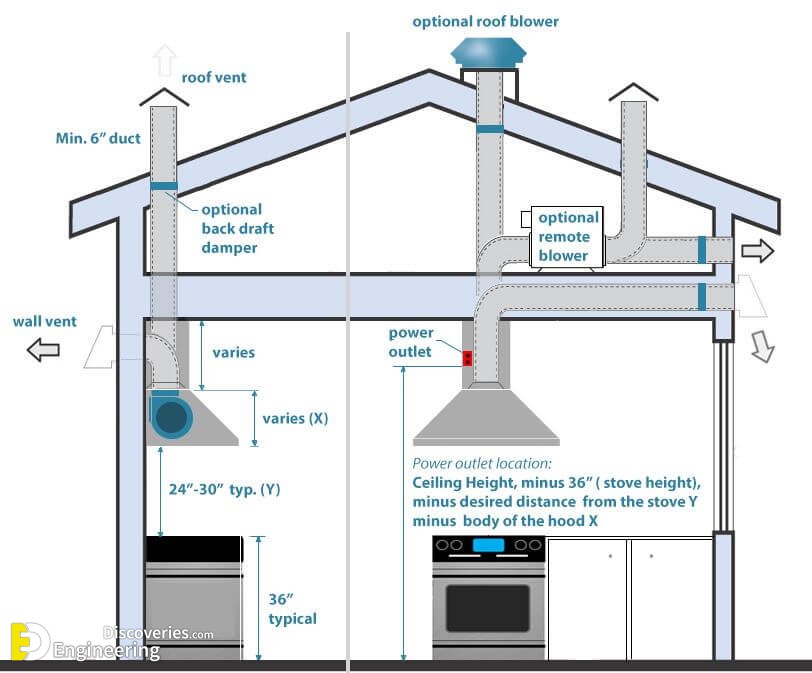

The Key Components of Commercial Kitchen Hood Design

To understand the requirements of commercial kitchen hood design, it is essential to know its key components. The first and most crucial element is the

hood canopy

, which is the large, metal box-like structure that hangs over the cooking equipment. It is connected to a ventilation system that draws in the hot air, smoke, and grease. The second component is the

exhaust fan

, which creates negative air pressure, pulling out the contaminated air. The third component is the

grease filters

, which are essential for trapping grease and preventing it from entering the ventilation system.

To understand the requirements of commercial kitchen hood design, it is essential to know its key components. The first and most crucial element is the

hood canopy

, which is the large, metal box-like structure that hangs over the cooking equipment. It is connected to a ventilation system that draws in the hot air, smoke, and grease. The second component is the

exhaust fan

, which creates negative air pressure, pulling out the contaminated air. The third component is the

grease filters

, which are essential for trapping grease and preventing it from entering the ventilation system.

Meeting the Design Requirements

To meet the design requirements for a commercial kitchen hood, there are several factors to consider. Firstly, the hood must be appropriately sized and placed above the cooking equipment. It should also be installed at the correct height, typically between 6-8 feet above the cooking surface. The exhaust fan should be powerful enough to extract all the contaminants, and the ventilation system should be regularly maintained to ensure its effectiveness.

Fire suppression systems

are also a crucial requirement for commercial kitchen hood design, as they can quickly extinguish any fire that may occur.

To meet the design requirements for a commercial kitchen hood, there are several factors to consider. Firstly, the hood must be appropriately sized and placed above the cooking equipment. It should also be installed at the correct height, typically between 6-8 feet above the cooking surface. The exhaust fan should be powerful enough to extract all the contaminants, and the ventilation system should be regularly maintained to ensure its effectiveness.

Fire suppression systems

are also a crucial requirement for commercial kitchen hood design, as they can quickly extinguish any fire that may occur.

The Benefits of Proper Hood Design

A well-designed commercial kitchen hood not only ensures the safety of the kitchen and its staff but also offers several other benefits. It helps to maintain a clean, odor-free kitchen, reduces the risk of fire hazards, and improves the overall air quality. A proper hood design also helps to comply with building codes and regulations, avoiding any potential legal issues. Additionally, a well-designed hood can also improve the energy efficiency of the kitchen, reducing utility costs in the long run.

In conclusion, understanding and meeting the commercial kitchen hood design requirements is crucial for the smooth and safe operation of any commercial kitchen. It not only ensures the safety and well-being of the staff but also offers numerous benefits for the overall functioning of the kitchen. With proper design and installation, a commercial kitchen hood can effectively extract heat, smoke, and grease, keeping the kitchen clean, safe, and comfortable.

A well-designed commercial kitchen hood not only ensures the safety of the kitchen and its staff but also offers several other benefits. It helps to maintain a clean, odor-free kitchen, reduces the risk of fire hazards, and improves the overall air quality. A proper hood design also helps to comply with building codes and regulations, avoiding any potential legal issues. Additionally, a well-designed hood can also improve the energy efficiency of the kitchen, reducing utility costs in the long run.

In conclusion, understanding and meeting the commercial kitchen hood design requirements is crucial for the smooth and safe operation of any commercial kitchen. It not only ensures the safety and well-being of the staff but also offers numerous benefits for the overall functioning of the kitchen. With proper design and installation, a commercial kitchen hood can effectively extract heat, smoke, and grease, keeping the kitchen clean, safe, and comfortable.

.jpg?1657117561)