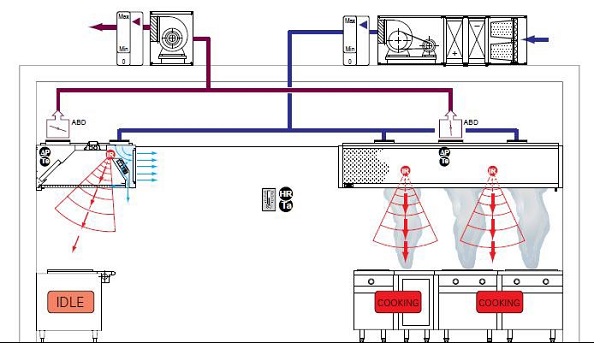

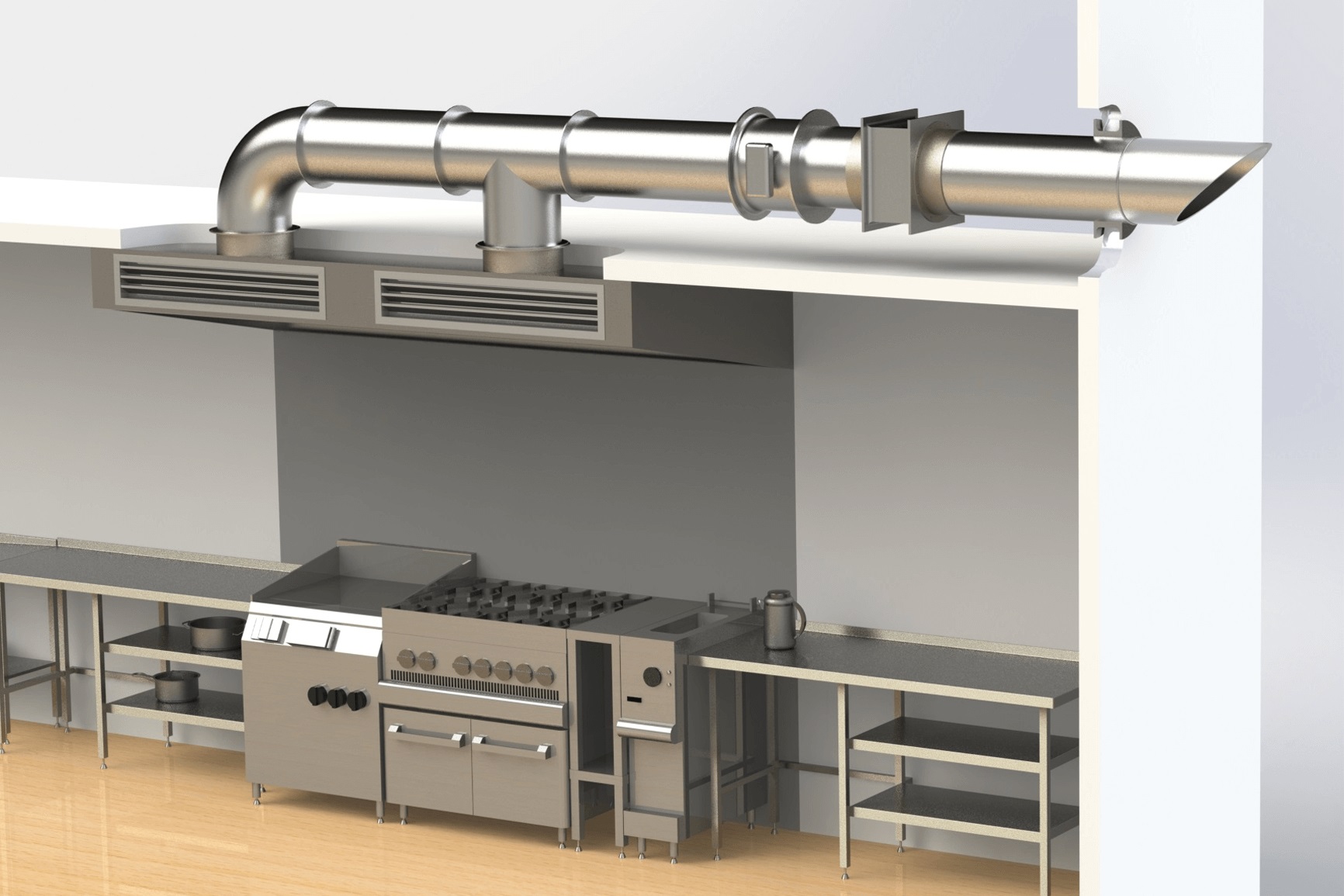

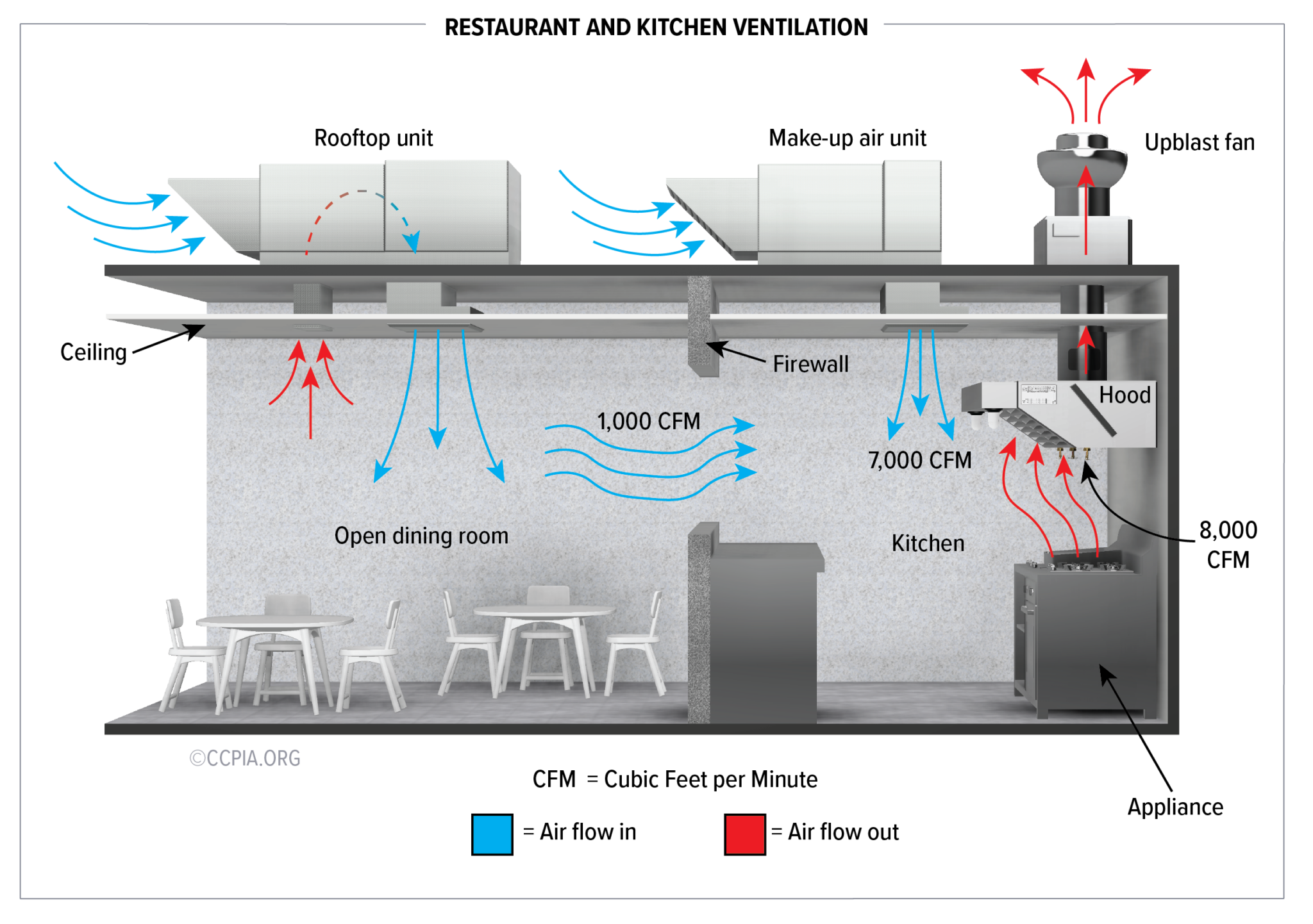

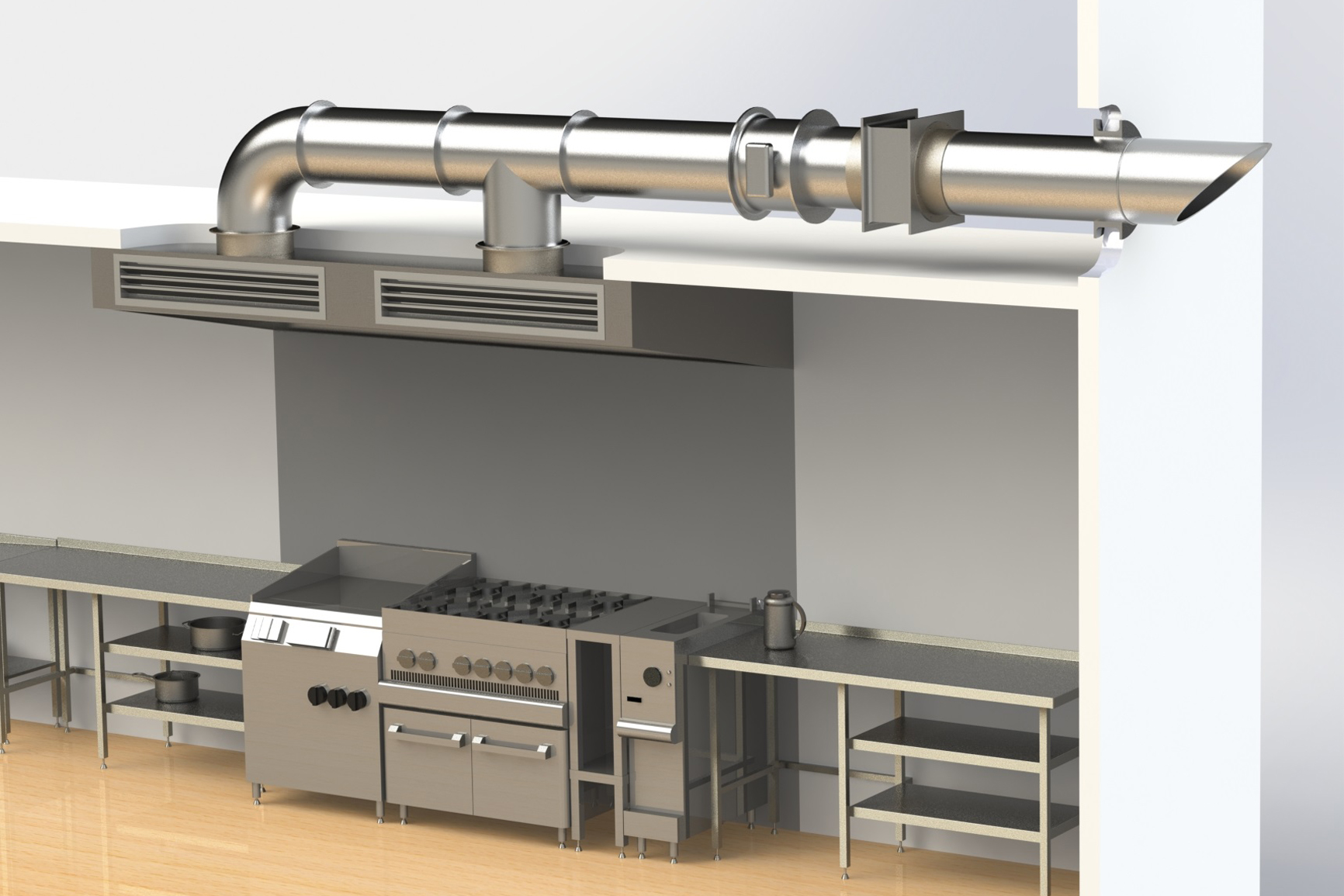

When it comes to designing a commercial kitchen, one of the most important aspects to consider is the ventilation system. A well-designed ventilation system is essential for the safety and efficiency of the kitchen. It helps to remove heat, smoke, and grease from the cooking area, keeping the air clean and comfortable for the kitchen staff and customers. When designing a kitchen ventilation system, there are a few key factors to keep in mind. These include the type and size of the kitchen, the type of cooking equipment being used, and the local building codes and regulations. It is important to consult with a professional engineer or HVAC specialist to ensure that the design meets all requirements. Some common components of a kitchen ventilation system include exhaust hoods, ductwork, exhaust fans, and make-up air systems. These work together to effectively remove and filter out the pollutants from the kitchen air.1. Kitchen Ventilation System Design

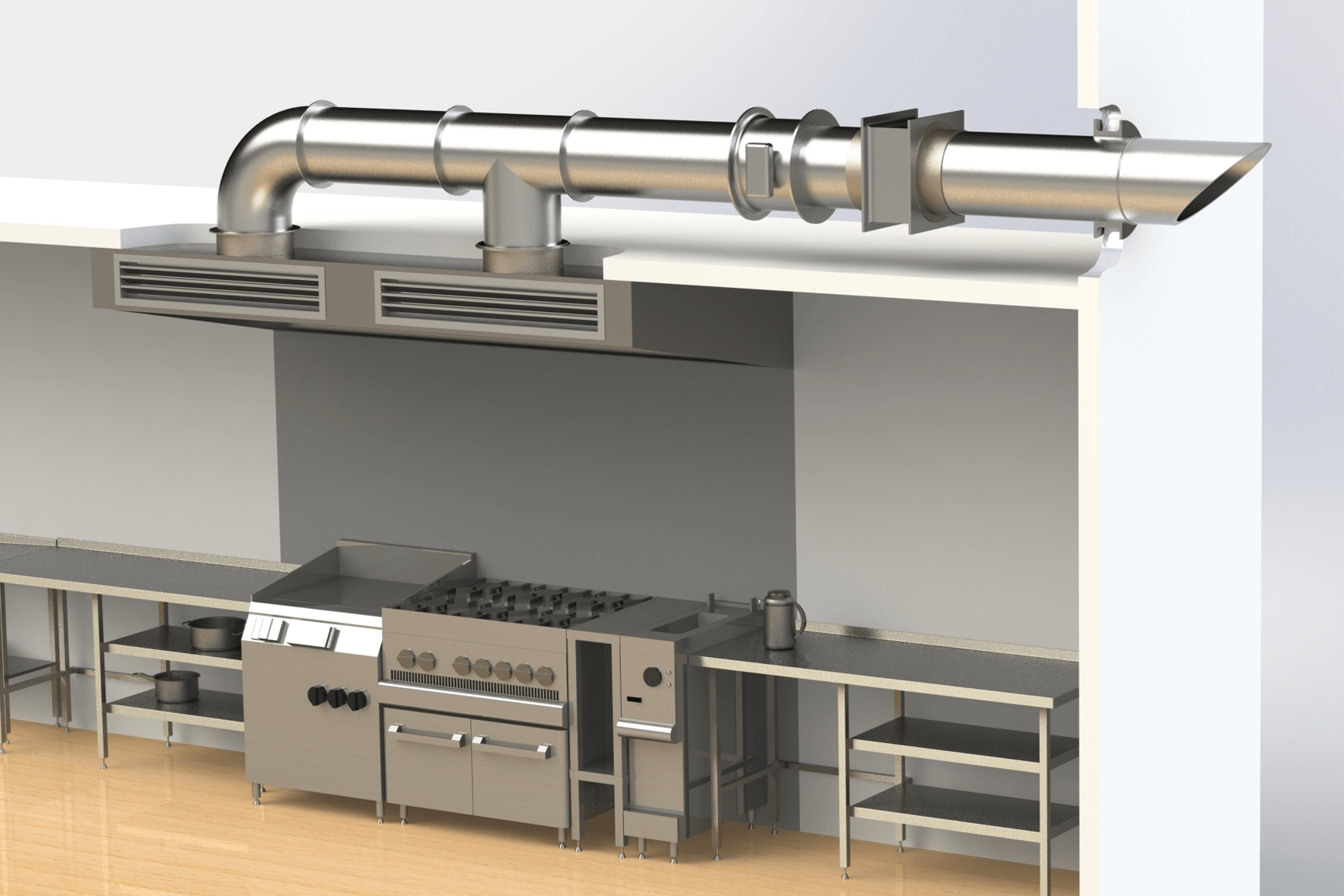

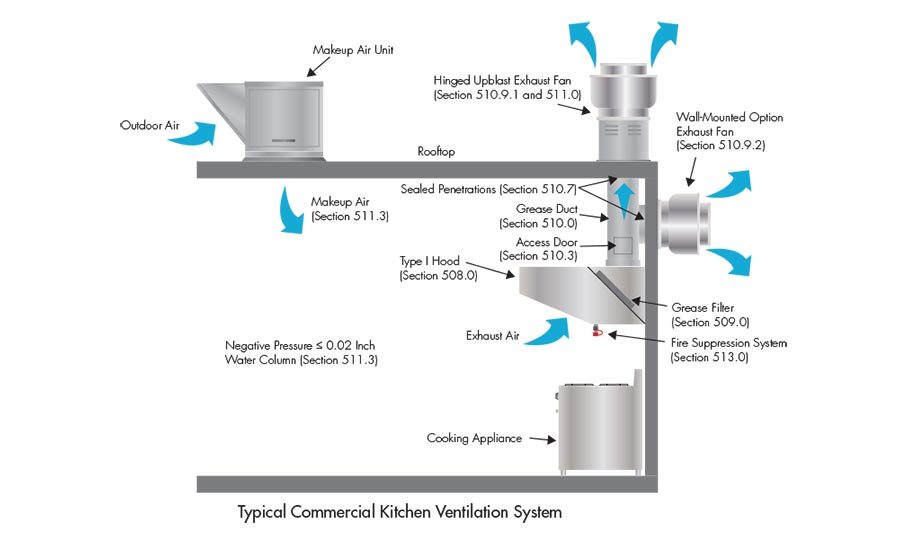

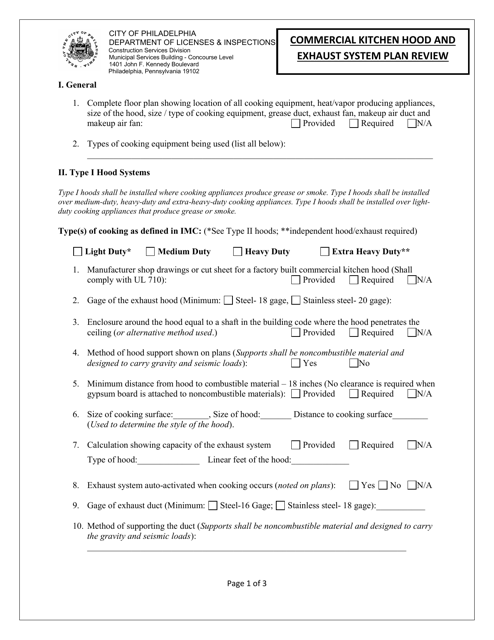

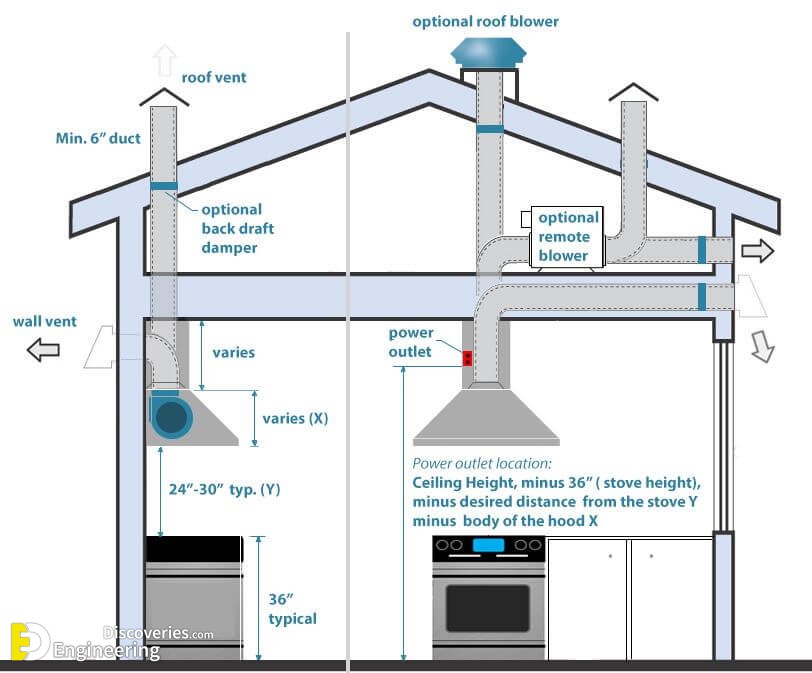

The exhaust hood is the most visible component of a kitchen ventilation system. It is a canopy-shaped structure that is installed above the cooking equipment to capture and remove the hot air, smoke, and grease generated during cooking. A well-designed exhaust hood not only improves the air quality in the kitchen but also helps to maintain the temperature and humidity levels. When designing a commercial kitchen exhaust hood, it is important to consider the type of cooking equipment being used and the heat and smoke output. The size of the hood should be large enough to cover all the cooking equipment and extend beyond the edges to effectively capture the pollutants. The hood should also be placed at a suitable height to ensure maximum efficiency. Modern exhaust hoods also come with features such as built-in fire suppression systems, heat sensors, and variable fan speeds, making them more efficient and safe for use in commercial kitchens.2. Commercial Kitchen Exhaust Hood Design

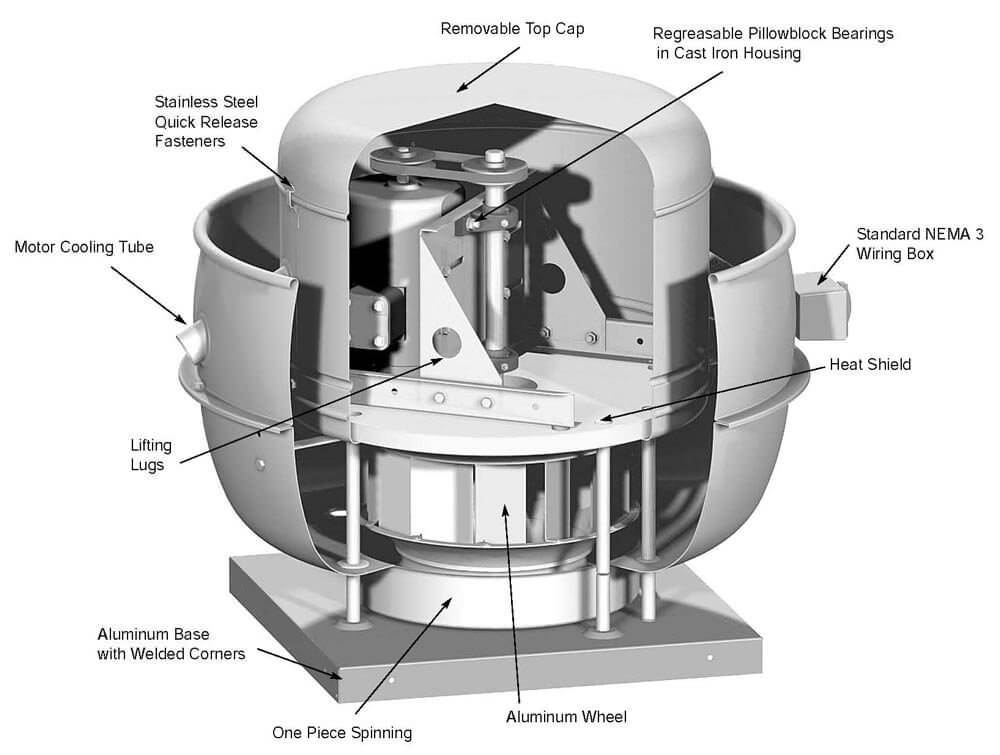

The exhaust fan is a crucial component of the kitchen ventilation system as it is responsible for pulling out the contaminated air from the kitchen and pushing it outside. When designing a commercial kitchen exhaust system, it is important to choose the right size and type of exhaust fan to ensure proper air flow and removal of pollutants. The size of the exhaust fan depends on the size of the kitchen, the type of cooking equipment, and the type of hood being used. A professional engineer or HVAC specialist can help determine the appropriate fan size based on these factors. It is important to note that an undersized fan will not be able to effectively remove the pollutants, while an oversized fan can create negative pressure and cause backdraft issues. Additionally, it is important to choose an exhaust fan with a high enough CFM (cubic feet per minute) rating to ensure adequate air flow. The fan should also be properly installed and maintained for optimal performance.3. Exhaust Fan Sizing for Commercial Kitchens

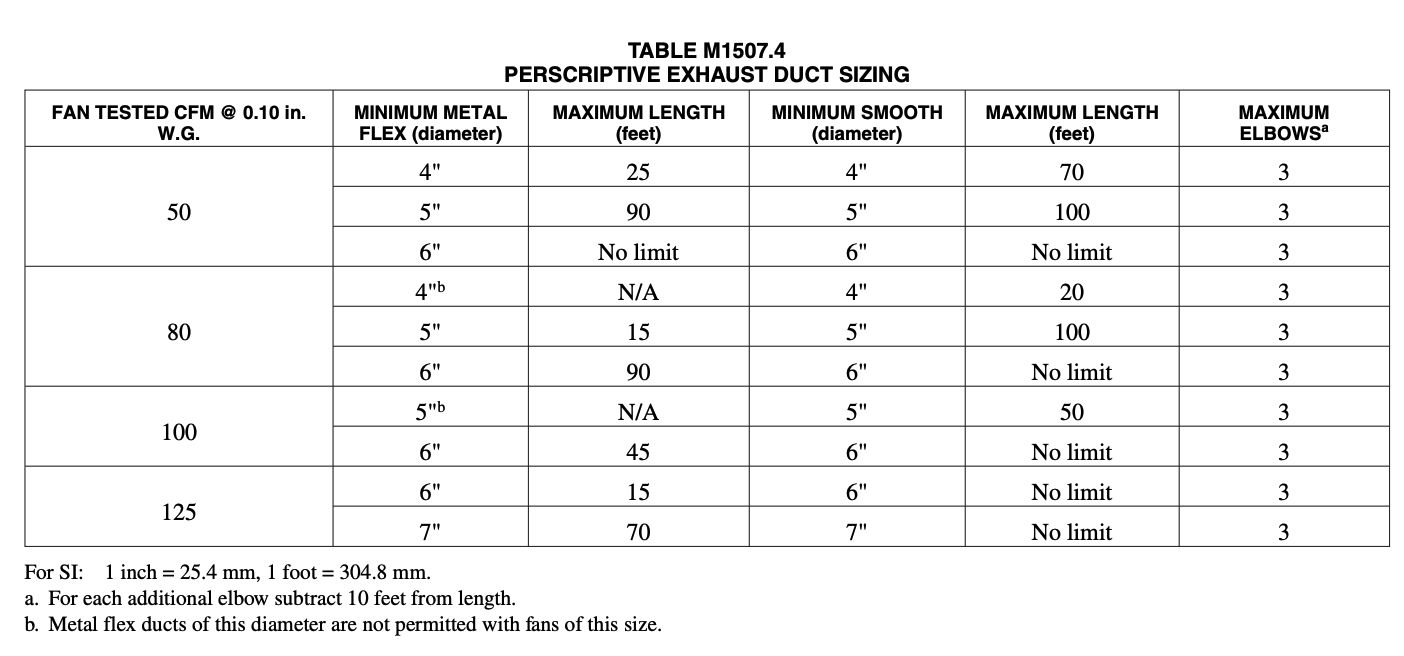

The exhaust duct is responsible for transporting the contaminated air from the kitchen to the outside. It is important to design the duct system in a way that minimizes resistance and maximizes air flow. This can be achieved by keeping the duct straight and avoiding any sharp turns or bends. The size of the duct should also be carefully determined based on the size of the kitchen, the type of cooking equipment, and the CFM rating of the exhaust fan. A duct that is too small can restrict air flow, while a duct that is too large can result in reduced air velocity and ineffective pollutant removal. It is also important to insulate the duct to prevent heat loss and condensation, which can lead to mold and mildew growth. Regular cleaning and maintenance of the duct are also crucial to ensure the proper functioning of the kitchen ventilation system.4. Kitchen Exhaust Duct Design

There are several regulations and guidelines that must be followed when designing a commercial kitchen exhaust system. These requirements are in place to ensure the safety and health of the kitchen staff and customers, as well as the proper functioning of the kitchen equipment. Some common requirements for commercial kitchen ventilation include the installation of UL-listed hoods and exhaust fans, the use of stainless steel for all components, and the installation of fire suppression systems. The ductwork must also comply with local building codes and regulations to prevent any potential fire hazards. It is important to consult with a professional engineer or HVAC specialist to ensure that all ventilation requirements are met when designing a commercial kitchen exhaust system.5. Commercial Kitchen Ventilation Requirements

When it comes to designing a commercial kitchen exhaust system, the hood and exhaust system must work together seamlessly to effectively remove heat, smoke, and grease from the kitchen. This requires careful consideration of the hood and exhaust fan placement, as well as the size and type of each component. The hood and exhaust system should also be designed in a way that does not interfere with the flow of the kitchen. This means avoiding any obstructions or obstacles that may impede the movement of kitchen staff or equipment. Proper placement of the hood and exhaust fan can also help to reduce noise levels in the kitchen. It is important to work with a professional engineer or HVAC specialist to ensure that the hood and exhaust system are designed and installed correctly for maximum efficiency and safety.6. Hood and Exhaust System Design for Commercial Kitchens

The design of a commercial kitchen exhaust system must comply with certain standards to ensure the safety and health of the kitchen staff and customers. These standards are set by organizations such as the National Fire Protection Association (NFPA) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). Some key standards to keep in mind when designing a kitchen exhaust system include the installation of fire suppression systems, proper duct sizing, and the use of UL-listed hoods and exhaust fans. These standards are regularly updated to reflect new technology and best practices, so it is important to stay informed and up-to-date. Complying with these standards not only ensures the safety and efficiency of the kitchen but also helps to avoid costly penalties and fines for non-compliance.7. Kitchen Exhaust System Design Standards

The design of a commercial kitchen exhaust system is not just about compliance with regulations and standards. It is also about creating a safe and healthy environment for the kitchen staff and customers, as well as ensuring the efficiency and longevity of the kitchen equipment. A well-designed exhaust system can help to reduce the risk of fire hazards, improve air quality, and maintain comfortable temperature and humidity levels in the kitchen. This not only keeps the kitchen staff happy and healthy but also creates a more enjoyable dining experience for customers. Additionally, a properly designed and maintained exhaust system can also help to reduce energy costs and prolong the lifespan of kitchen equipment by reducing the build-up of grease and other contaminants.8. Designing a Safe and Efficient Commercial Kitchen Exhaust System

When designing a commercial kitchen ventilation system, it is important to consider the specific needs and requirements of the kitchen. This includes the type of food being cooked, the frequency and volume of cooking, and the layout of the kitchen. For example, a restaurant that specializes in heavy frying will require a more powerful exhaust system than a café that serves mostly cold sandwiches. The ventilation design should also take into account the cooking equipment used, as different types of equipment produce different levels of heat and smoke. A customized ventilation design can help to ensure that the kitchen is properly ventilated and that the exhaust system is efficient and cost-effective.9. Ventilation Design for Commercial Kitchens

When it comes to designing a commercial kitchen exhaust system, there are some best practices that should be followed to ensure the safety, efficiency, and longevity of the system. These include regular cleaning and maintenance of all components, proper placement of the hood and exhaust fan, and compliance with regulations and standards. It is also important to choose high-quality and properly sized components and to work with a professional engineer or HVAC specialist to design and install the system. Following these best practices can help to prevent issues such as poor air flow, backdraft, and excess noise, and ensure that the kitchen runs smoothly and safely. In conclusion, a well-designed commercial kitchen exhaust system is crucial for the safety, health, and efficiency of any commercial kitchen. By following these key principles and best practices, and working with a professional, you can ensure that your kitchen ventilation system is the best it can be.10. Best Practices for Commercial Kitchen Exhaust System Design

Importance of Proper Commercial Kitchen Exhaust System Design

Efficient Ventilation System

Proper ventilation is crucial for any commercial kitchen. Without it, the air inside can quickly become stagnant and filled with harmful fumes, smoke, and grease. This not only poses a health and safety risk for employees but can also affect the quality of the food being prepared. A well-designed kitchen exhaust system ensures that these pollutants are removed from the air, creating a cleaner and healthier environment for everyone.

Proper ventilation is crucial for any commercial kitchen. Without it, the air inside can quickly become stagnant and filled with harmful fumes, smoke, and grease. This not only poses a health and safety risk for employees but can also affect the quality of the food being prepared. A well-designed kitchen exhaust system ensures that these pollutants are removed from the air, creating a cleaner and healthier environment for everyone.

Compliance with Regulations

Commercial kitchen exhaust systems are subject to strict regulations and codes set by local authorities. These regulations aim to ensure the safety and well-being of both kitchen staff and customers. Failure to comply with these regulations can result in fines, penalties, and even the closure of your business. By investing in a properly designed exhaust system, you can avoid these consequences and ensure that your kitchen is up to code.

Commercial kitchen exhaust systems are subject to strict regulations and codes set by local authorities. These regulations aim to ensure the safety and well-being of both kitchen staff and customers. Failure to comply with these regulations can result in fines, penalties, and even the closure of your business. By investing in a properly designed exhaust system, you can avoid these consequences and ensure that your kitchen is up to code.

Fire Safety

One of the biggest risks in a commercial kitchen is the potential for fires, which can be caused by the build-up of grease and other flammable materials in the exhaust system. A well-designed exhaust system includes features such as grease traps and fire suppression systems, which help prevent fires from starting and quickly extinguish them if they do occur. This not only protects your employees and customers but also your business and livelihood.

One of the biggest risks in a commercial kitchen is the potential for fires, which can be caused by the build-up of grease and other flammable materials in the exhaust system. A well-designed exhaust system includes features such as grease traps and fire suppression systems, which help prevent fires from starting and quickly extinguish them if they do occur. This not only protects your employees and customers but also your business and livelihood.

Energy Efficiency

In addition to its primary function of removing pollutants from the air, a commercial kitchen exhaust system can also play a role in energy efficiency. By properly venting hot air and steam, the exhaust system can help regulate the temperature in the kitchen, reducing the need for excess air conditioning. This can lead to significant cost savings on energy bills, making it a wise investment for any business owner.

In conclusion,

a properly designed commercial kitchen exhaust system is essential for the success and safety of any restaurant or food service establishment. Not only does it ensure compliance with regulations and promote a healthy environment, but it also protects against fire hazards and can even save on energy costs. When designing a commercial kitchen, be sure to prioritize the exhaust system to reap all of these benefits.

In addition to its primary function of removing pollutants from the air, a commercial kitchen exhaust system can also play a role in energy efficiency. By properly venting hot air and steam, the exhaust system can help regulate the temperature in the kitchen, reducing the need for excess air conditioning. This can lead to significant cost savings on energy bills, making it a wise investment for any business owner.

In conclusion,

a properly designed commercial kitchen exhaust system is essential for the success and safety of any restaurant or food service establishment. Not only does it ensure compliance with regulations and promote a healthy environment, but it also protects against fire hazards and can even save on energy costs. When designing a commercial kitchen, be sure to prioritize the exhaust system to reap all of these benefits.