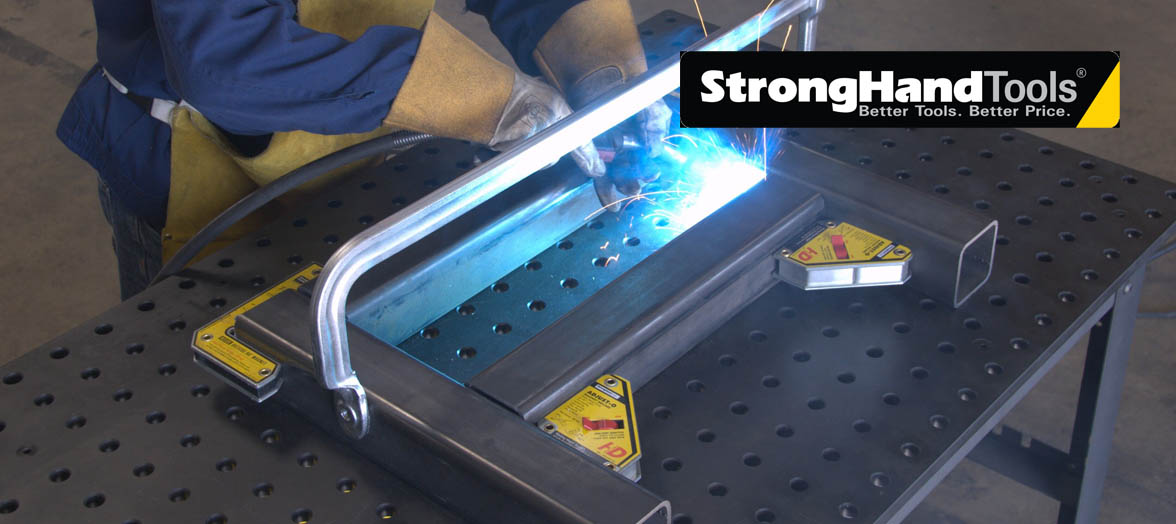

When it comes to welding, having a sturdy and reliable work surface is crucial for achieving quality results. That's where stainless steel kitchen tables come in. These versatile tables are not only used for food prep and storage, but they also make for great welding tables. Welding Tables Direct offers a wide range of stainless steel tables specifically designed for welding. Let's take a closer look at how you can use these tables for welding projects.1. Stainless Steel Kitchen Tables for Welding | Welding Tables Direct

MillerWelds, a leading manufacturer of welding equipment, recommends using a stainless steel table for welding due to its durability and resistance to heat and sparks. The smooth surface of the table allows for easy clean-up and prevents welding spatter from sticking. Plus, the material is less likely to warp or become damaged from the intense heat of welding.2. Welding on a Stainless Steel Table | MillerWelds

The short answer is yes, you can weld on a stainless steel table. In fact, it is a popular choice for many welders due to its strength and durability. However, it's important to note that not all stainless steel tables are suitable for welding. Look for tables that are specifically designed for welding and have a thickness of at least 16 gauge for optimal results.3. Can You Weld on a Stainless Steel Table? | WeldingBoss.com

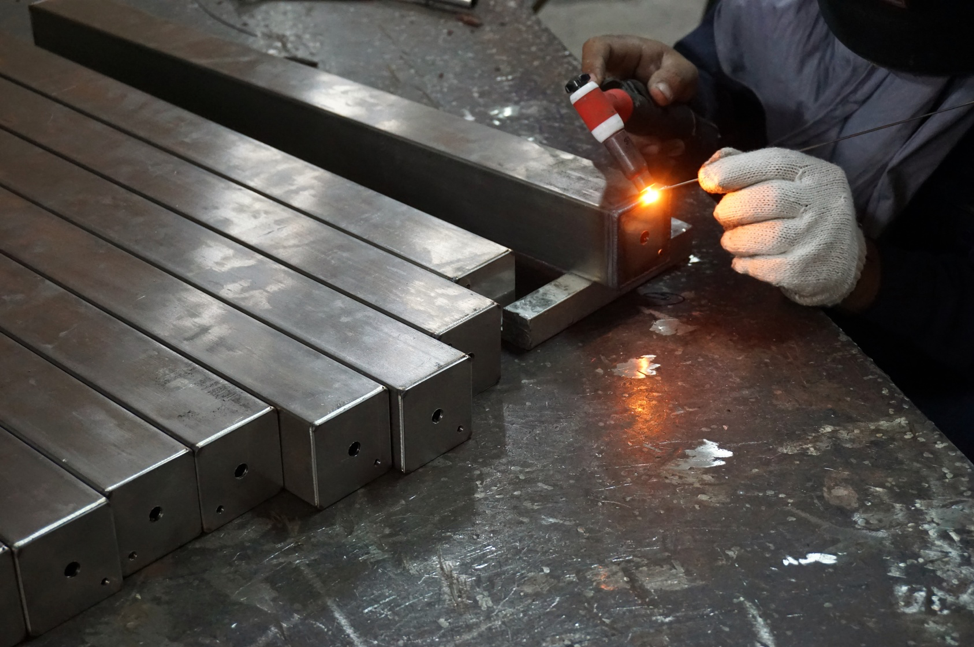

Before you begin welding on your stainless steel table, it's important to properly prepare the surface. Start by cleaning the table with a degreaser to remove any oils or residue. Next, use a wire brush to remove any rust or debris. You can also use sandpaper to smooth out any rough spots. Once the surface is clean and smooth, you're ready to start welding.4. How to Use a Stainless Steel Table for Welding | Welding Tips and Tricks

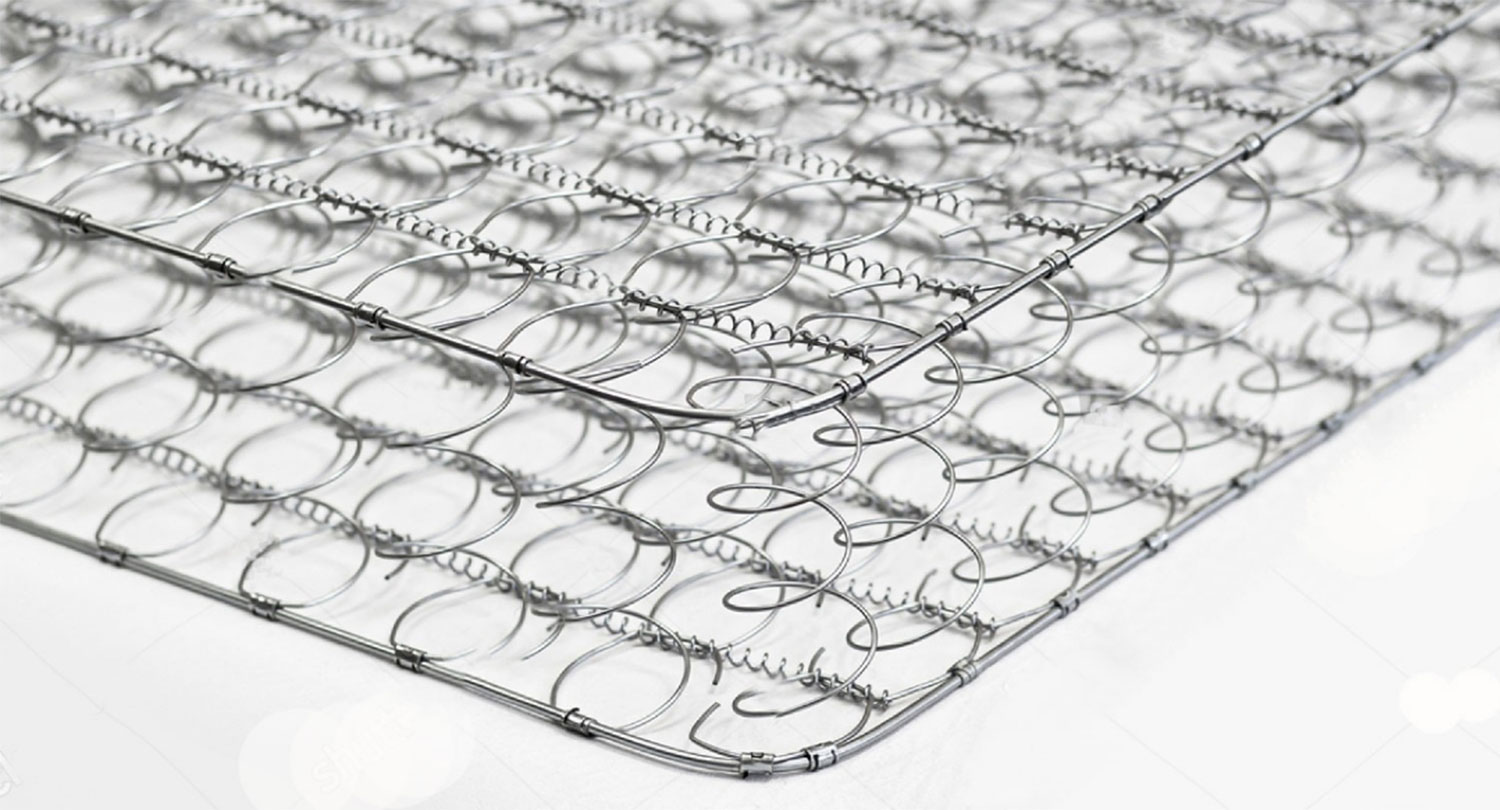

WeldingWeb, a popular online forum for welders, recommends using a stainless steel table for welding due to its resistance to heat and sparks. However, it's important to protect the table's surface from damage by using a welding mat or heat-resistant welding cloth. These materials will prevent the intense heat from warping or damaging the table.5. Welding on a Stainless Steel Table | WeldingWeb

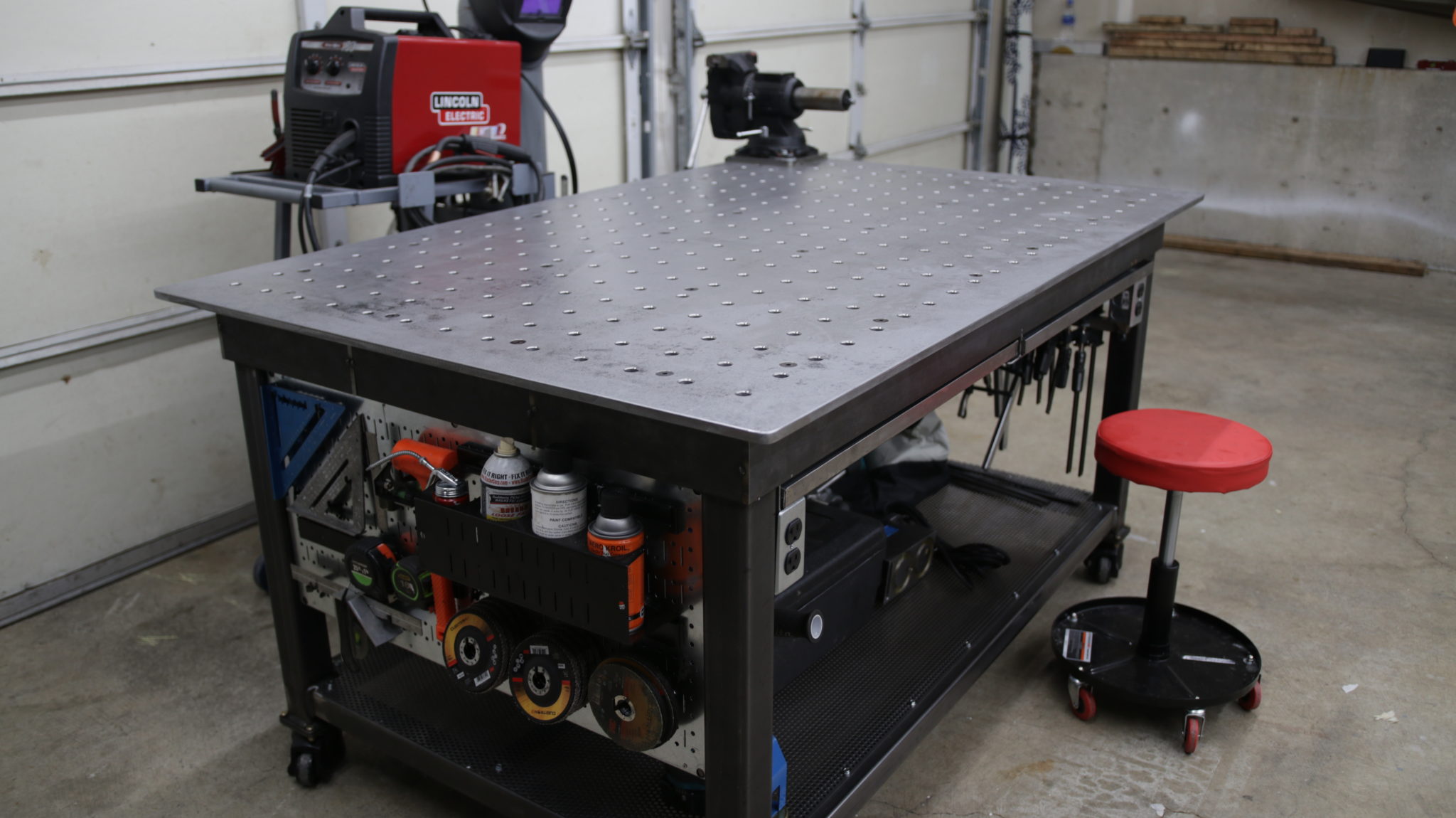

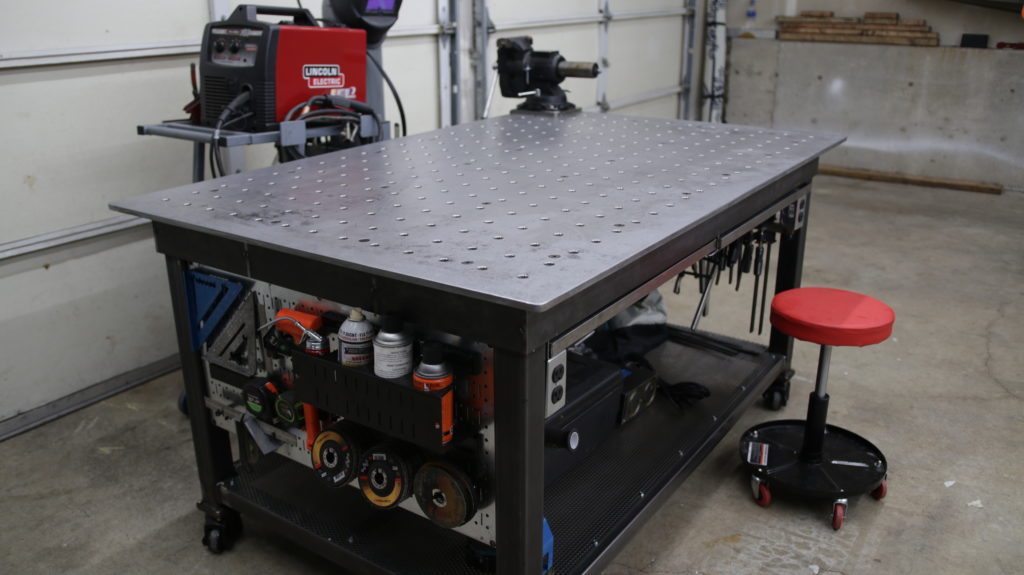

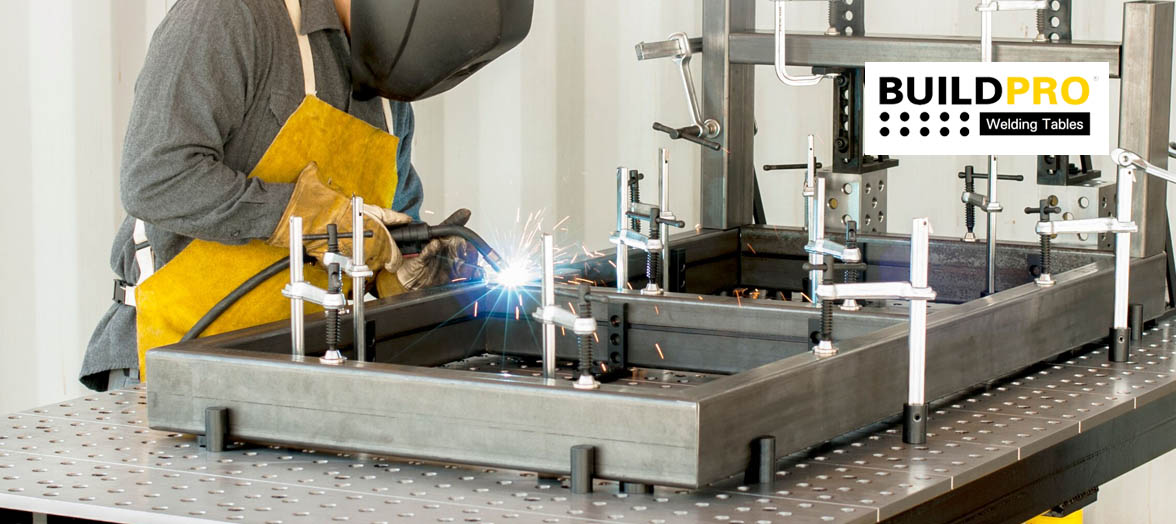

There are a few key factors to consider when choosing a stainless steel table for welding. The first is the thickness of the table, which should be at least 16 gauge. Additionally, look for tables with a smooth surface and rounded edges to prevent scratching or snagging. It's also important to consider the size and weight capacity of the table to ensure it can handle your welding projects.6. Choosing the Right Welding Table | Lincoln Electric

If you're in the market for a stainless steel welding table, Eastwood has a helpful buying guide to assist you in making the right choice. They recommend looking for tables with a brushed or polished finish, as these surfaces are less likely to reflect light and cause glare while welding. They also suggest choosing a table with adjustable feet for added stability and convenience.7. Welding Table Buying Guide | Eastwood

Stainless steel welding tables come in a variety of sizes, shapes, and price points. The Fabricator, a leading publication for the metal forming and fabricating industry, highlights a range of options for every budget. From affordable DIY options to high-end professional tables, there's a stainless steel table suitable for any welding project.8. Welding Table Options for Every Budget | The Fabricator

For those who prefer a more hands-on approach, DIY Welding Plans offers a step-by-step guide on how to build your own welding table using stainless steel. The plans include detailed measurements, materials list, and instructions for creating a sturdy and functional welding table. This is a great option for those on a budget or looking for a custom table to fit their specific needs.9. How to Build a Welding Table | DIY Welding Plans

Once you have your stainless steel welding table, it's important to properly set it up and maintain it. Welding Supplies from IOC recommends keeping the surface clean and free of debris, as well as regularly checking for any signs of damage or wear. It's also important to protect the table from extreme temperatures and store it in a dry and secure location when not in use. In conclusion, a stainless steel kitchen table can certainly be used for welding projects. It offers a strong and durable surface that can withstand the intense heat and sparks of welding. When choosing a table, consider the thickness, surface finish, and weight capacity to ensure it meets your needs. With proper setup and maintenance, your stainless steel welding table will serve as a reliable work surface for all your welding projects. 10. Welding Table Setup and Maintenance | Welding Supplies from IOC

Can You Use a Stainless Steel Kitchen Table for Welding?

The Versatility of Stainless Steel

Stainless steel has become a popular material for many household items, from kitchen appliances to furniture. Its sleek and modern appearance, durability, and resistance to rust and corrosion make it a top choice for many homeowners. But can a stainless steel kitchen table be used for welding? The answer is yes, and it has many benefits for those looking to take on welding projects at home.

Stainless steel has become a popular material for many household items, from kitchen appliances to furniture. Its sleek and modern appearance, durability, and resistance to rust and corrosion make it a top choice for many homeowners. But can a stainless steel kitchen table be used for welding? The answer is yes, and it has many benefits for those looking to take on welding projects at home.

The Benefits of Using a Stainless Steel Kitchen Table for Welding

Stainless steel is a strong and sturdy material, making it ideal for welding projects. Its high melting point and low thermal expansion properties make it resistant to warping and distortion under high heat. This means that a stainless steel kitchen table can withstand the intense heat of welding without getting damaged, providing a stable and reliable work surface.

In addition to its durability, stainless steel also has excellent corrosion resistance. This means that it can withstand exposure to flux or other welding chemicals without getting damaged. It is also easy to clean and maintain, making it a practical choice for a workspace where sparks and debris from welding are common.

Stainless steel is a strong and sturdy material, making it ideal for welding projects. Its high melting point and low thermal expansion properties make it resistant to warping and distortion under high heat. This means that a stainless steel kitchen table can withstand the intense heat of welding without getting damaged, providing a stable and reliable work surface.

In addition to its durability, stainless steel also has excellent corrosion resistance. This means that it can withstand exposure to flux or other welding chemicals without getting damaged. It is also easy to clean and maintain, making it a practical choice for a workspace where sparks and debris from welding are common.

The Importance of a Stable Work Surface

When it comes to welding, having a stable work surface is crucial. Any movement or vibration can affect the quality of the weld, resulting in a weak or flawed final product. A stainless steel kitchen table is heavy and sturdy, providing a stable and secure work surface for welding projects. This ensures that your welds are strong and accurate, giving you the best results possible.

When it comes to welding, having a stable work surface is crucial. Any movement or vibration can affect the quality of the weld, resulting in a weak or flawed final product. A stainless steel kitchen table is heavy and sturdy, providing a stable and secure work surface for welding projects. This ensures that your welds are strong and accurate, giving you the best results possible.

A Multipurpose Solution

One of the great things about using a stainless steel kitchen table for welding is its versatility. When not in use for welding, it can function as a regular kitchen table, providing extra counter space and storage. This makes it a practical and cost-effective solution for those who have limited space or budget for a dedicated welding table.

One of the great things about using a stainless steel kitchen table for welding is its versatility. When not in use for welding, it can function as a regular kitchen table, providing extra counter space and storage. This makes it a practical and cost-effective solution for those who have limited space or budget for a dedicated welding table.

Conclusion

In conclusion, a stainless steel kitchen table can be an excellent choice for welding projects. Its durability, resistance to heat and chemicals, stability, and versatility make it a practical and reliable work surface for any DIY welder. So if you're looking to take on some welding projects at home, consider using your stainless steel kitchen table as your work surface. With proper care and maintenance, it can last for years and provide you with a convenient and efficient workspace for all your welding needs.

In conclusion, a stainless steel kitchen table can be an excellent choice for welding projects. Its durability, resistance to heat and chemicals, stability, and versatility make it a practical and reliable work surface for any DIY welder. So if you're looking to take on some welding projects at home, consider using your stainless steel kitchen table as your work surface. With proper care and maintenance, it can last for years and provide you with a convenient and efficient workspace for all your welding needs.

)