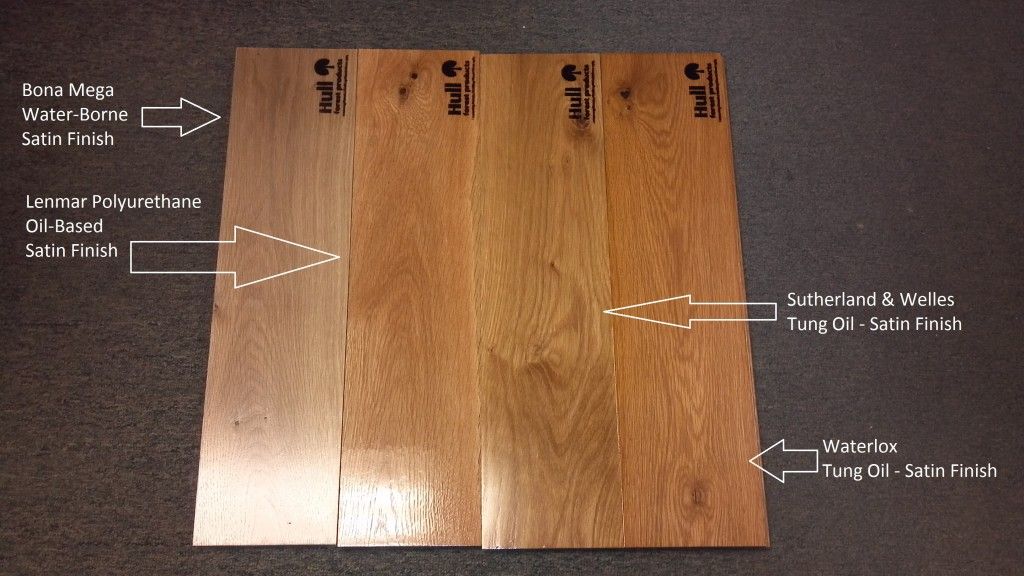

Polyurethane is a popular choice for finishing oak kitchen tables due to its durability and resistance to scratches and stains. It is also available in a variety of finishes, from matte to high gloss, making it a versatile option for any style of kitchen. This finish is applied in multiple coats, with each coat adding to the overall protection and shine of the table. It is important to properly sand and clean the table before applying polyurethane to ensure a smooth and even finish.1. Polyurethane

Tung oil is a natural finish that is derived from the tung tree and is known for its water-resistant properties. It is a great option for oak kitchen tables as it enhances the natural beauty of the wood and provides a warm, rich finish. Tung oil is easy to apply and requires little maintenance, making it a popular choice among DIY enthusiasts. However, it may take longer to dry compared to other finishes and may require multiple coats for optimal protection.2. Tung oil

Danish oil is a blend of linseed oil and varnish, making it a great choice for those looking for a natural finish with added durability. It penetrates deep into the wood, enhancing the grain and color while also providing protection against stains and water damage. Danish oil is easy to apply and dries quickly, making it a convenient option for those looking to finish their oak kitchen table in a timely manner.3. Danish oil

Linseed oil is a traditional finish that has been used for centuries to protect wood surfaces. It is a natural oil that is extracted from flax seeds and provides a warm, amber hue to oak tables. Linseed oil is easy to apply and can be buffed to a desired level of shine. However, it may require regular maintenance and reapplication, as it is not as durable as other finishes.4. Linseed oil

Shellac is a classic finish that is derived from the resin secreted by the female lac bug. It is a quick-drying and durable finish that gives oak kitchen tables a beautiful, glossy finish. Shellac is available in a variety of shades, from clear to amber, and can be easily applied with a brush or cloth. However, it may not be as resistant to heat and water damage as other finishes and may require regular maintenance.5. Shellac

Lacquer is a synthetic finish that is known for its quick-drying and durable properties. It provides a high-gloss finish that is perfect for modern and contemporary kitchen designs. Lacquer is available in spray form, making it easy to apply and providing a smooth, even finish. However, it may be more challenging to repair if damaged and may require a well-ventilated area for application due to its strong odor.6. Lacquer

Varnish is a popular finish for oak kitchen tables due to its durability and resistance to scratches and stains. It is available in a variety of finishes, from matte to high gloss, and can be easily applied with a brush or cloth. Varnish is also water-resistant, making it a great option for kitchen tables that are frequently exposed to spills and moisture. However, it may take longer to dry compared to other finishes and may require multiple coats for optimal protection.7. Varnish

Wax is a classic finish that has been used for centuries to protect and enhance the natural beauty of wood. It provides a soft, subtle shine to oak kitchen tables and is easy to apply with a cloth or brush. Wax is also available in a variety of shades, from clear to dark, allowing for customization of the final look. However, it may not be as durable as other finishes and may require regular reapplication to maintain its protective properties.8. Wax

Water-based finishes, such as acrylic and polyurethane, have gained popularity in recent years due to their low odor and environmental-friendly properties. They provide a clear, durable finish that is resistant to scratches and stains and is easy to clean with soap and water. Water-based finishes also dry quickly, allowing for a faster completion time for finishing oak kitchen tables. However, they may not enhance the natural beauty of the wood as much as other finishes and may require multiple coats for optimal protection.9. Water-based finish

Oil-based finishes, such as linseed and tung oil, have been used for centuries to protect and enhance the natural beauty of wood. They provide a warm, rich finish that penetrates deep into the wood, enhancing the grain and color. Oil-based finishes are also easy to apply and require little maintenance, making them a popular choice among DIY enthusiasts. However, they may take longer to dry compared to other finishes and may require regular reapplication to maintain their protective properties.10. Oil-based finish

The Best Top Finish for Your Oak Kitchen Table

Why the Right Top Finish is Important for Your Oak Kitchen Table

When it comes to designing your dream kitchen, the

oak kitchen table

is often the centerpiece. It's where your family gathers for meals, where you entertain guests, and where you may even work from home. As such, it's important to choose the right

top finish

for your

oak kitchen table

to ensure it not only looks great, but also stands up to the wear and tear of daily use.

When it comes to designing your dream kitchen, the

oak kitchen table

is often the centerpiece. It's where your family gathers for meals, where you entertain guests, and where you may even work from home. As such, it's important to choose the right

top finish

for your

oak kitchen table

to ensure it not only looks great, but also stands up to the wear and tear of daily use.

Factors to Consider When Choosing a Top Finish for Your Oak Kitchen Table

The Best Top Finish Options for Oak Kitchen Tables

After considering these factors, there are a few

top finish

options that stand out as the best choices for

oak kitchen tables

. These include:

1. Polyurethane

: This is a popular choice for its durability and ease of maintenance. It creates a hard, protective layer on top of the wood and is available in gloss, semi-gloss, and matte finishes.

2. Tung oil

: This natural oil finish brings out the natural beauty of

oak

wood and provides a more matte, natural look. It's also easy to maintain and can be reapplied as needed.

3. Conversion varnish

: This is a professional-grade finish that is known for its durability and resistance to moisture, chemicals, and heat. It also provides a smooth, glossy finish.

After considering these factors, there are a few

top finish

options that stand out as the best choices for

oak kitchen tables

. These include:

1. Polyurethane

: This is a popular choice for its durability and ease of maintenance. It creates a hard, protective layer on top of the wood and is available in gloss, semi-gloss, and matte finishes.

2. Tung oil

: This natural oil finish brings out the natural beauty of

oak

wood and provides a more matte, natural look. It's also easy to maintain and can be reapplied as needed.

3. Conversion varnish

: This is a professional-grade finish that is known for its durability and resistance to moisture, chemicals, and heat. It also provides a smooth, glossy finish.

Conclusion

Choosing the right

top finish

for your

oak kitchen table

is an important decision that can impact the look and longevity of your table. Consider the factors mentioned above and explore different finish options to find the perfect one for your needs and preferences. With the right top finish, your

oak kitchen table

will not only be a beautiful addition to your home, but also a functional and durable one.

Choosing the right

top finish

for your

oak kitchen table

is an important decision that can impact the look and longevity of your table. Consider the factors mentioned above and explore different finish options to find the perfect one for your needs and preferences. With the right top finish, your

oak kitchen table

will not only be a beautiful addition to your home, but also a functional and durable one.

/CND-Shellac-5894e83b3df78caebcf4f505.jpg)