When it comes to kitchen sinks, durability and functionality are key factors to consider. This is where welding stainless steel kitchen sinks come into play. Not only does it ensure a strong and long-lasting sink, but it also adds a sleek and modern touch to your kitchen. In this article, we will explore the top 10 reasons why welding stainless steel kitchen sink is important.Why Welding Stainless Steel Kitchen Sink is Important

Stainless steel is known for its strength and durability, making it the perfect material for kitchen sinks. However, without proper welding, the sink may not be able to withstand heavy use and could easily develop cracks or breaks. By welding the sink, it ensures that all the parts are securely joined together, creating a sturdy and durable sink that can withstand daily wear and tear.1. Superior Strength and Durability

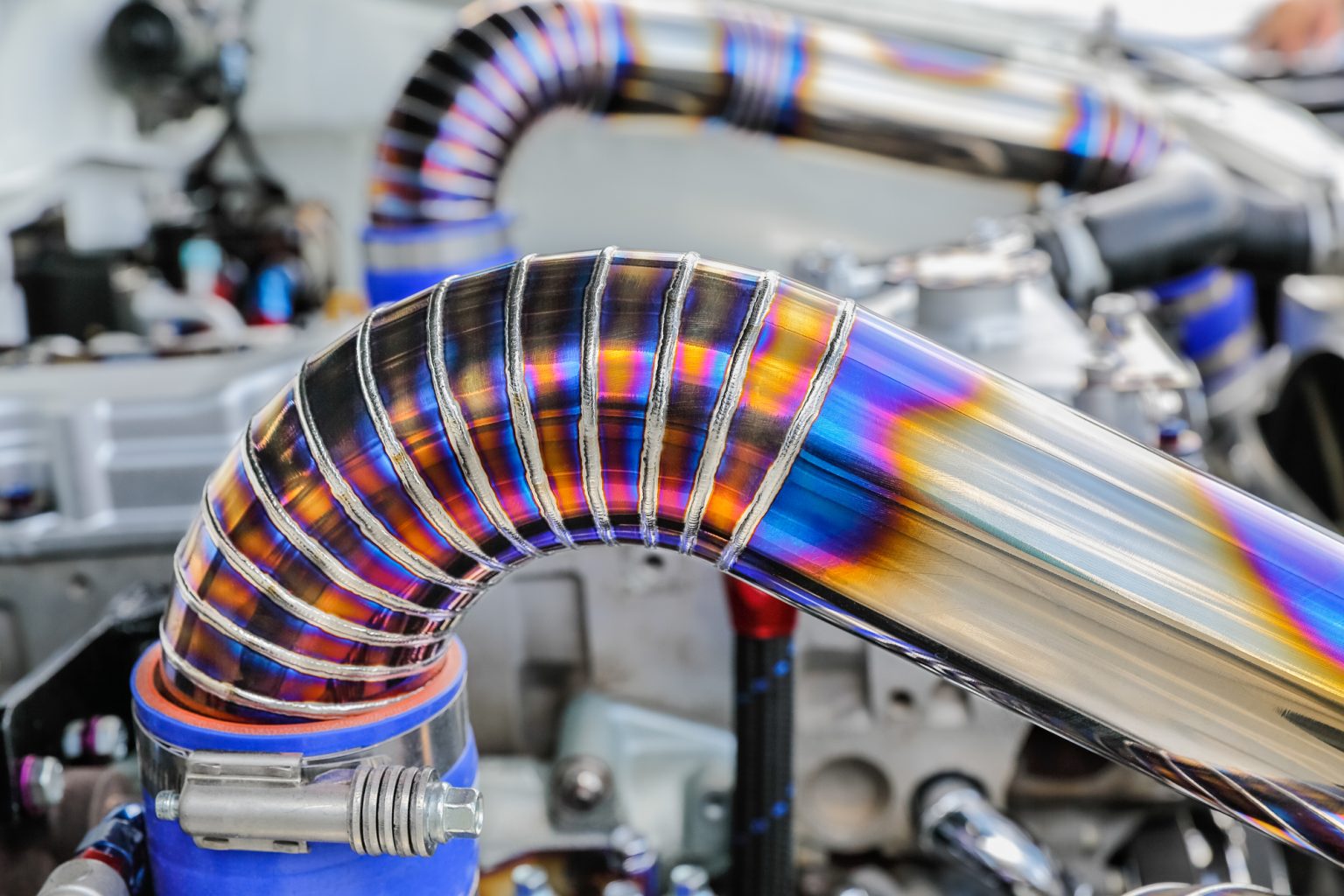

One of the main benefits of welding a stainless steel kitchen sink is the ability to create a seamless design. This means that there are no visible seams or joints, giving the sink a sleek and modern look. This not only adds to the overall aesthetics of your kitchen but also makes cleaning and maintenance much easier as there are no crevices for dirt and grime to build up.2. Seamless Design

Welding allows for more flexibility in terms of design and customization. You can choose the size, shape, and depth of your sink, as well as any additional features such as built-in draining boards or cutting boards. This ensures that your sink fits perfectly into your kitchen and meets all your specific needs and preferences.3. Customizable Options

Stainless steel is naturally resistant to water and stains, but welding takes it a step further. By welding the sink, it eliminates the need for any sealants or adhesives that could potentially wear off over time and cause water damage or stains. This makes your sink more hygienic and easier to maintain, making it a top choice for kitchen sinks.4. Water and Stain Resistant

Another advantage of welding a stainless steel kitchen sink is its heat resistance. Stainless steel can withstand high temperatures without warping or melting, making it ideal for use in the kitchen. This means you can place hot pots and pans directly onto the sink without worrying about damaging it.5. Heat Resistant

Compared to other materials, stainless steel is a more cost-effective option for kitchen sinks. It is a durable material that can last for many years, making it a great investment for your home. By welding the sink, it ensures that it will last even longer, reducing the need for repairs or replacements in the future.6. Cost-Effective

Stainless steel is also known for its corrosion resistance, making it a popular choice for kitchen sinks. However, if not properly welded, it can still be susceptible to corrosion at the joints and seams. By welding the sink, it creates a strong and seamless surface that is highly resistant to corrosion.7. Corrosion Resistant

Stainless steel is a non-porous material, meaning it does not harbor bacteria or germs. This makes it a great choice for kitchen sinks, as it is easy to clean and maintain, ensuring a hygienic environment for food preparation. Welding the sink eliminates any potential crevices where bacteria could grow, making it an even more hygienic option.8. Hygienic Material

Stainless steel is a versatile material that is compatible with a wide range of kitchen appliances. By welding the sink, it ensures a seamless integration with other stainless steel appliances, creating a cohesive and modern look in your kitchen.9. Compatibility with Other Appliances

Why Choose Stainless Steel for Your Kitchen Sink?

Durability and Longevity

Stainless steel is a popular choice for kitchen sinks due to its durability and longevity. It is a strong and sturdy material that can withstand everyday wear and tear, making it perfect for a busy kitchen. Unlike other materials such as porcelain or granite, stainless steel is highly resistant to scratches, stains, and corrosion. This means your kitchen sink will maintain its pristine appearance for years to come, even with heavy daily use.

Stainless steel is a popular choice for kitchen sinks due to its durability and longevity. It is a strong and sturdy material that can withstand everyday wear and tear, making it perfect for a busy kitchen. Unlike other materials such as porcelain or granite, stainless steel is highly resistant to scratches, stains, and corrosion. This means your kitchen sink will maintain its pristine appearance for years to come, even with heavy daily use.

Easy Maintenance and Hygiene

Another advantage of choosing a stainless steel kitchen sink is its easy maintenance and hygiene. The smooth, non-porous surface of stainless steel makes it easy to clean and maintain. A simple wipe down with a mild detergent and water is all it takes to keep your sink looking brand new. Additionally, stainless steel is non-porous, which means it does not harbor bacteria or germs. This makes it a hygienic choice for your kitchen, where food preparation and clean-up are frequent.

Another advantage of choosing a stainless steel kitchen sink is its easy maintenance and hygiene. The smooth, non-porous surface of stainless steel makes it easy to clean and maintain. A simple wipe down with a mild detergent and water is all it takes to keep your sink looking brand new. Additionally, stainless steel is non-porous, which means it does not harbor bacteria or germs. This makes it a hygienic choice for your kitchen, where food preparation and clean-up are frequent.

Modern and Versatile Design

Stainless steel kitchen sinks offer a sleek and modern look that can complement any kitchen design. With a variety of styles, sizes, and installation options available, you can easily find a stainless steel sink that fits your personal taste and kitchen layout. Plus, its neutral color can easily blend in with any color scheme, making it a versatile choice for any kitchen renovation or remodel.

Stainless steel kitchen sinks offer a sleek and modern look that can complement any kitchen design. With a variety of styles, sizes, and installation options available, you can easily find a stainless steel sink that fits your personal taste and kitchen layout. Plus, its neutral color can easily blend in with any color scheme, making it a versatile choice for any kitchen renovation or remodel.

Welding Stainless Steel for a Seamless Look

If you're looking to achieve a seamless and integrated look in your kitchen, welding stainless steel is the way to go. This process involves using heat to join two pieces of stainless steel together, creating a smooth and seamless finish. This is especially beneficial for undermount sinks, where the sink is installed beneath the countertop for a clean and modern look.

If you're looking to achieve a seamless and integrated look in your kitchen, welding stainless steel is the way to go. This process involves using heat to join two pieces of stainless steel together, creating a smooth and seamless finish. This is especially beneficial for undermount sinks, where the sink is installed beneath the countertop for a clean and modern look.

The Benefits of Welding Stainless Steel for Your Kitchen Sink

Welding stainless steel for your kitchen sink offers several benefits. Firstly, it eliminates the need for visible seams or caulk lines, creating a more visually appealing and seamless look. It also makes cleaning and maintenance easier, as there are no crevices where dirt and grime can accumulate. Additionally, welding stainless steel ensures a strong and secure bond, making your sink more durable and long-lasting.

In conclusion, choosing a stainless steel kitchen sink and opting for welding can greatly enhance the overall look and functionality of your kitchen. With its durability, easy maintenance, and modern design, stainless steel is a timeless choice for any kitchen renovation. So why wait? Upgrade your kitchen sink now and enjoy the numerous benefits of welding stainless steel.

Welding stainless steel for your kitchen sink offers several benefits. Firstly, it eliminates the need for visible seams or caulk lines, creating a more visually appealing and seamless look. It also makes cleaning and maintenance easier, as there are no crevices where dirt and grime can accumulate. Additionally, welding stainless steel ensures a strong and secure bond, making your sink more durable and long-lasting.

In conclusion, choosing a stainless steel kitchen sink and opting for welding can greatly enhance the overall look and functionality of your kitchen. With its durability, easy maintenance, and modern design, stainless steel is a timeless choice for any kitchen renovation. So why wait? Upgrade your kitchen sink now and enjoy the numerous benefits of welding stainless steel.