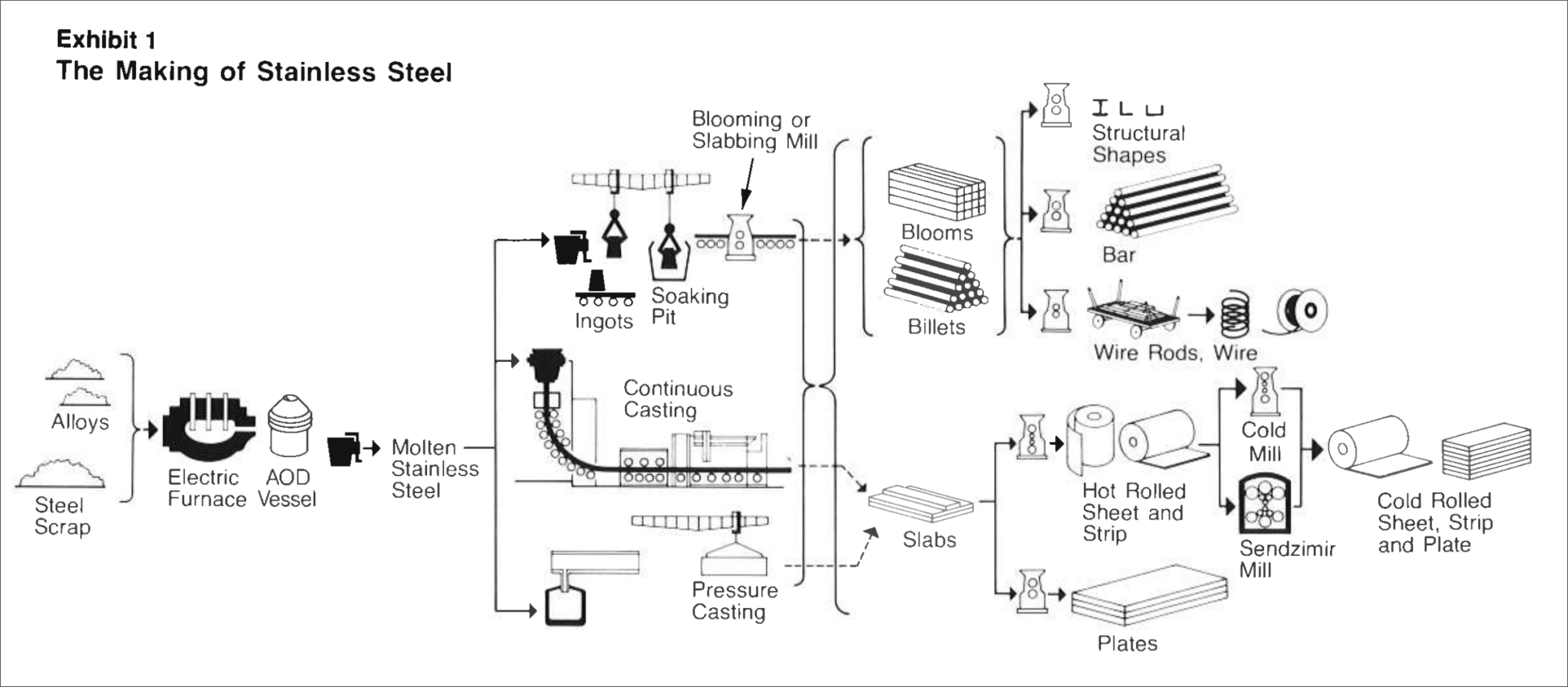

Stainless steel kitchen sinks have become a staple in modern homes due to their durability, versatility, and sleek design. But have you ever wondered how these sinks are made? In this article, we will take a closer look at the top 10 main steps of the stainless steel kitchen sink manufacturing process.Stainless Steel Kitchen Sink Manufacturing Process

The production of stainless steel kitchen sinks involves several stages, from raw materials to the final product. Let's explore the production process in detail.Stainless Steel Kitchen Sink Production

The first step in manufacturing a stainless steel kitchen sink is to select the appropriate grade of stainless steel. The most commonly used grades are 304 and 316, known for their high strength and corrosion resistance.Stainless Steel Sink Manufacturing

Once the grade of stainless steel is determined, the production process begins with cutting the stainless steel sheets into the required size and shape. This is usually done using a laser cutting machine, which ensures precision and accuracy.Stainless Steel Sink Production Process

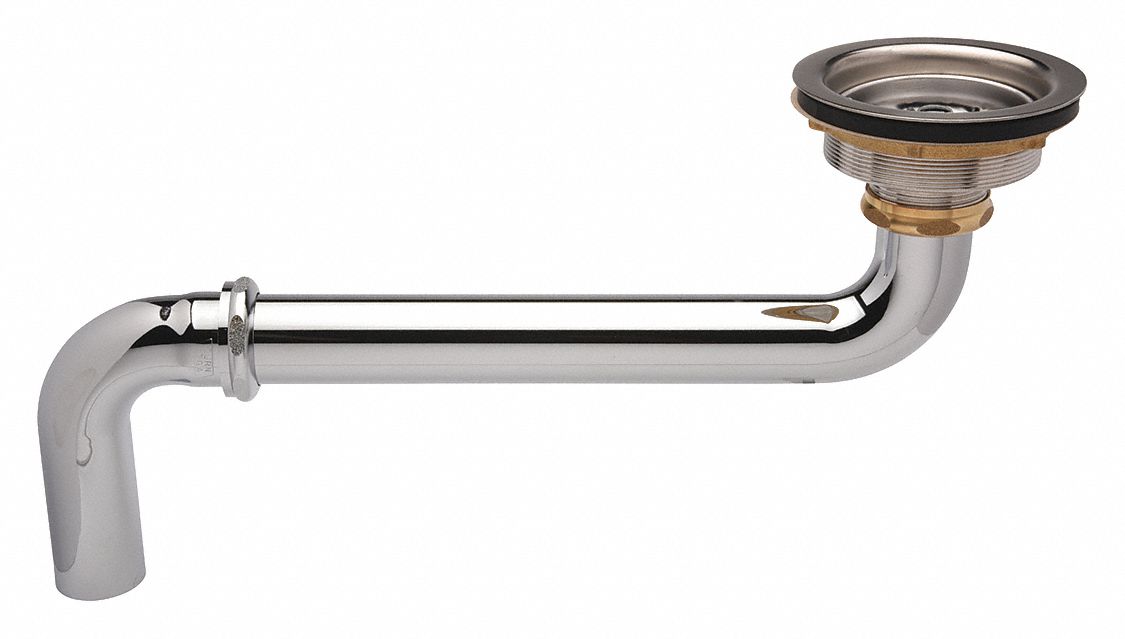

The next step is to form the sink bowl and its various features, such as the drain hole and faucet holes. This is done using a hydraulic press, which molds the stainless steel sheets into the desired shape. The edges of the sink are then smoothened using a deburring machine.Stainless Steel Sink Manufacturing Steps

After the sink bowl is formed, the next step is to weld the various components together. This includes welding the sink bowl to the rim, attaching the drain holes, and welding the faucet holes. This is a crucial step as it ensures the sink is leak-proof and sturdy.How Stainless Steel Sinks are Made

Once the sink is welded, it is then polished to achieve a smooth and shiny surface. This is done using a series of grinding and buffing machines. The sink is then inspected for any imperfections and repaired if necessary.Stainless Steel Sink Fabrication Process

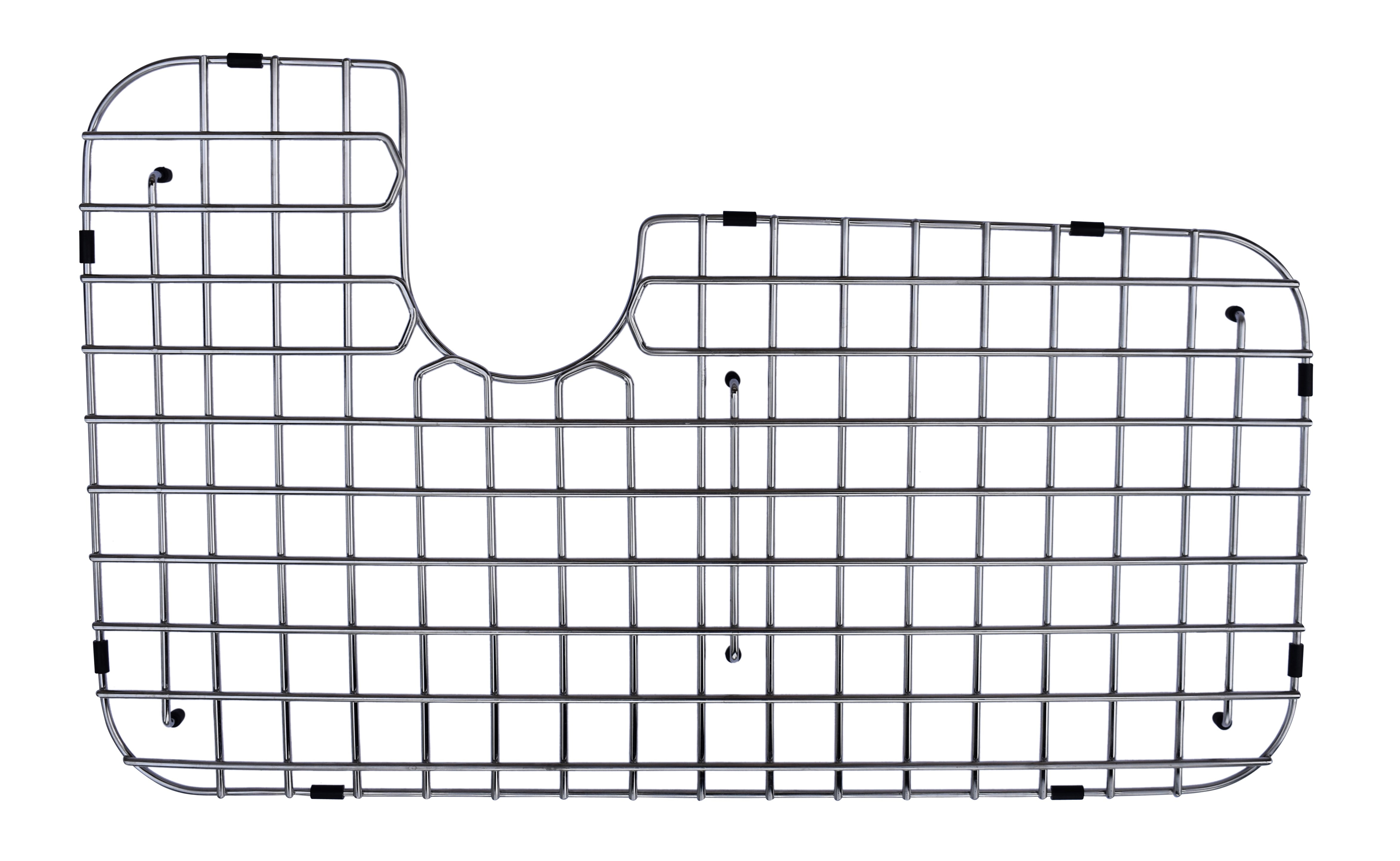

One of the key techniques used in the production of stainless steel kitchen sinks is the use of a sound deadening pad. This is a layer of insulation material applied to the underside of the sink to reduce noise when water flows or dishes are being washed.Stainless Steel Sink Manufacturing Techniques

The production of stainless steel kitchen sinks requires specialized equipment such as laser cutting machines, hydraulic presses, and various grinding and polishing machines. These machines ensure the sinks are made with precision and efficiency.Stainless Steel Sink Manufacturing Equipment

Quality control is an essential aspect of the manufacturing process. Each sink goes through rigorous testing to ensure it meets the required standards for strength, durability, and appearance. This includes testing for water and air leaks, as well as inspecting the sink's finish.Stainless Steel Sink Manufacturing Quality Control

The Importance of Choosing a High-Quality Stainless Steel Kitchen Sink

Why Stainless Steel?

When it comes to the construction and design of a house, every aspect needs to be carefully considered and chosen. From the colors of the walls to the type of flooring, every detail plays a crucial role in creating a functional and aesthetically pleasing living space. One aspect that often gets overlooked is the kitchen sink. However, choosing the right kitchen sink is essential as it is one of the most frequently used fixtures in any household. This is where stainless steel kitchen sinks come into the picture.

Stainless steel

is a popular material used in various industries, from construction to manufacturing, due to its durability, strength, and corrosion-resistant properties. These same qualities make it an ideal material for kitchen sinks.

Stainless steel kitchen sinks

are not only visually appealing but also highly functional and practical. They can withstand heavy usage and resist scratches, stains, and heat, making them the perfect choice for a busy kitchen.

When it comes to the construction and design of a house, every aspect needs to be carefully considered and chosen. From the colors of the walls to the type of flooring, every detail plays a crucial role in creating a functional and aesthetically pleasing living space. One aspect that often gets overlooked is the kitchen sink. However, choosing the right kitchen sink is essential as it is one of the most frequently used fixtures in any household. This is where stainless steel kitchen sinks come into the picture.

Stainless steel

is a popular material used in various industries, from construction to manufacturing, due to its durability, strength, and corrosion-resistant properties. These same qualities make it an ideal material for kitchen sinks.

Stainless steel kitchen sinks

are not only visually appealing but also highly functional and practical. They can withstand heavy usage and resist scratches, stains, and heat, making them the perfect choice for a busy kitchen.

The Manufacturing Process

The process of manufacturing a stainless steel kitchen sink is a complex and precise one. It involves multiple steps and careful attention to detail to ensure the final product is of the highest quality. The first step is to choose the right

grade of stainless steel

for the sink, which can range from 16 to 22 gauge. The lower the number, the thicker and more durable the steel.

Once the steel is selected, it goes through a series of

cutting, bending, and welding

processes to create the shape and size of the sink. Each piece is then

polished and buffed

to give it a smooth and shiny finish. The sink is then

coated with a sound-dampening material

to reduce noise when it comes into contact with water or dishes.

Finally, the sink is

inspected for quality control

to ensure it meets the necessary standards. This includes checking for any imperfections or defects and making any necessary adjustments. Only after passing these rigorous tests is the stainless steel kitchen sink ready to be shipped out to customers.

The process of manufacturing a stainless steel kitchen sink is a complex and precise one. It involves multiple steps and careful attention to detail to ensure the final product is of the highest quality. The first step is to choose the right

grade of stainless steel

for the sink, which can range from 16 to 22 gauge. The lower the number, the thicker and more durable the steel.

Once the steel is selected, it goes through a series of

cutting, bending, and welding

processes to create the shape and size of the sink. Each piece is then

polished and buffed

to give it a smooth and shiny finish. The sink is then

coated with a sound-dampening material

to reduce noise when it comes into contact with water or dishes.

Finally, the sink is

inspected for quality control

to ensure it meets the necessary standards. This includes checking for any imperfections or defects and making any necessary adjustments. Only after passing these rigorous tests is the stainless steel kitchen sink ready to be shipped out to customers.

The Benefits of a High-Quality Stainless Steel Kitchen Sink

Investing in a high-quality stainless steel kitchen sink has many benefits. Not only do they add a touch of modern elegance to any kitchen, but they are also highly durable and easy to maintain. Unlike other materials, stainless steel is

non-porous

, which means it is resistant to bacteria and germs, making it a hygienic choice for a kitchen sink. They are also easy to clean and maintain, requiring only a simple wipe down with a mild detergent and water.

In addition, stainless steel kitchen sinks are

environmentally friendly

as they are made from recycled materials and can be recycled again at the end of their lifespan. They are also

budget-friendly

as they are relatively affordable compared to other materials and have a long lifespan, making them a cost-effective choice in the long run.

In conclusion, when it comes to choosing a kitchen sink for your home,

stainless steel

is the way to go. Not only does it offer a sleek and modern look, but it is also highly durable, easy to maintain, and environmentally friendly. With its

manufacturing process

ensuring a high-quality end product, a stainless steel kitchen sink is a wise investment for any household.

Investing in a high-quality stainless steel kitchen sink has many benefits. Not only do they add a touch of modern elegance to any kitchen, but they are also highly durable and easy to maintain. Unlike other materials, stainless steel is

non-porous

, which means it is resistant to bacteria and germs, making it a hygienic choice for a kitchen sink. They are also easy to clean and maintain, requiring only a simple wipe down with a mild detergent and water.

In addition, stainless steel kitchen sinks are

environmentally friendly

as they are made from recycled materials and can be recycled again at the end of their lifespan. They are also

budget-friendly

as they are relatively affordable compared to other materials and have a long lifespan, making them a cost-effective choice in the long run.

In conclusion, when it comes to choosing a kitchen sink for your home,

stainless steel

is the way to go. Not only does it offer a sleek and modern look, but it is also highly durable, easy to maintain, and environmentally friendly. With its

manufacturing process

ensuring a high-quality end product, a stainless steel kitchen sink is a wise investment for any household.