When it comes to running a successful food production facility, having a well-designed and efficient kitchen is crucial. The production kitchen design directly impacts the quality, efficiency, and cost-effectiveness of the production process. Therefore, it is essential to have a well-thought-out plan in place for the design of your production kitchen.1. Production Kitchen Design

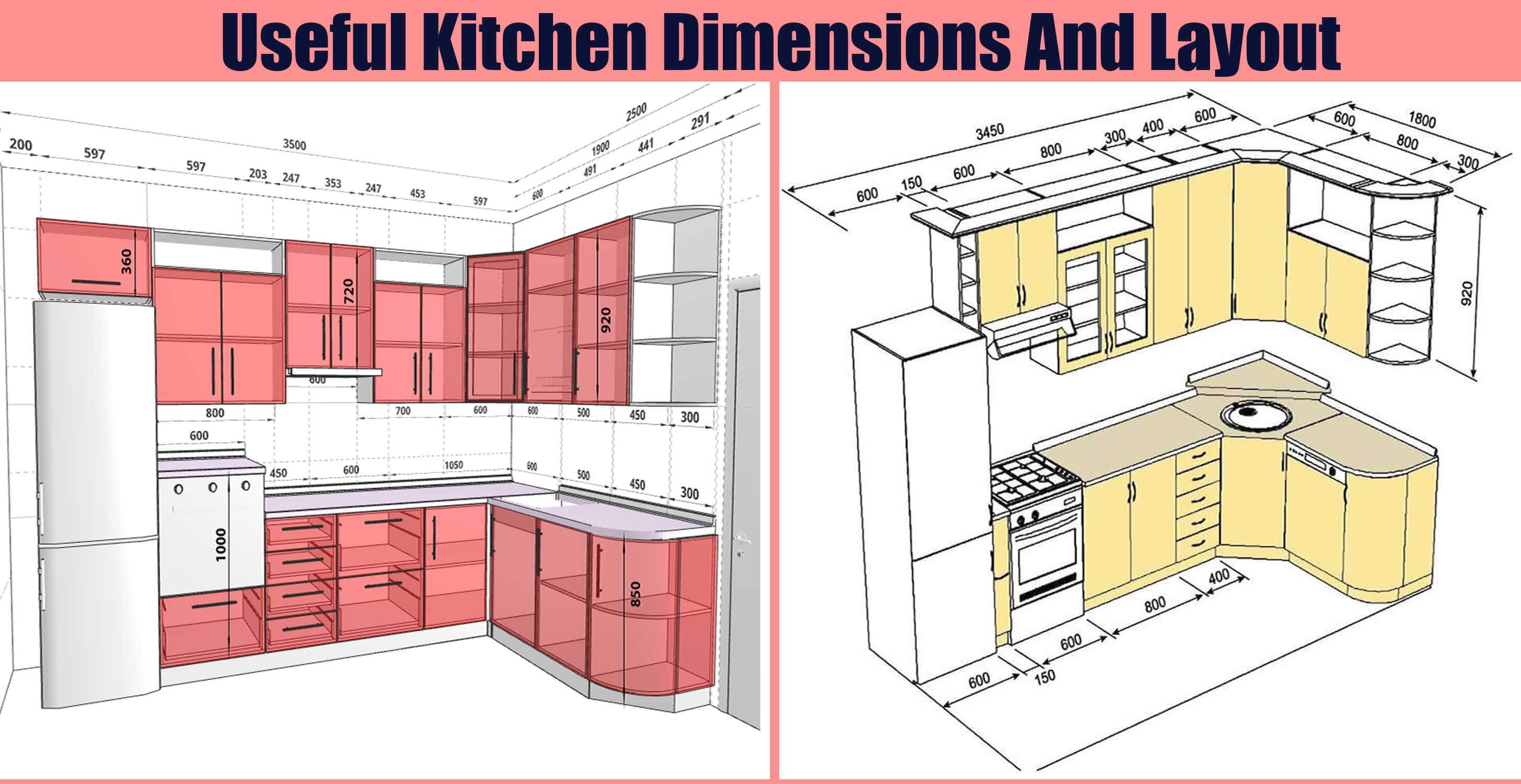

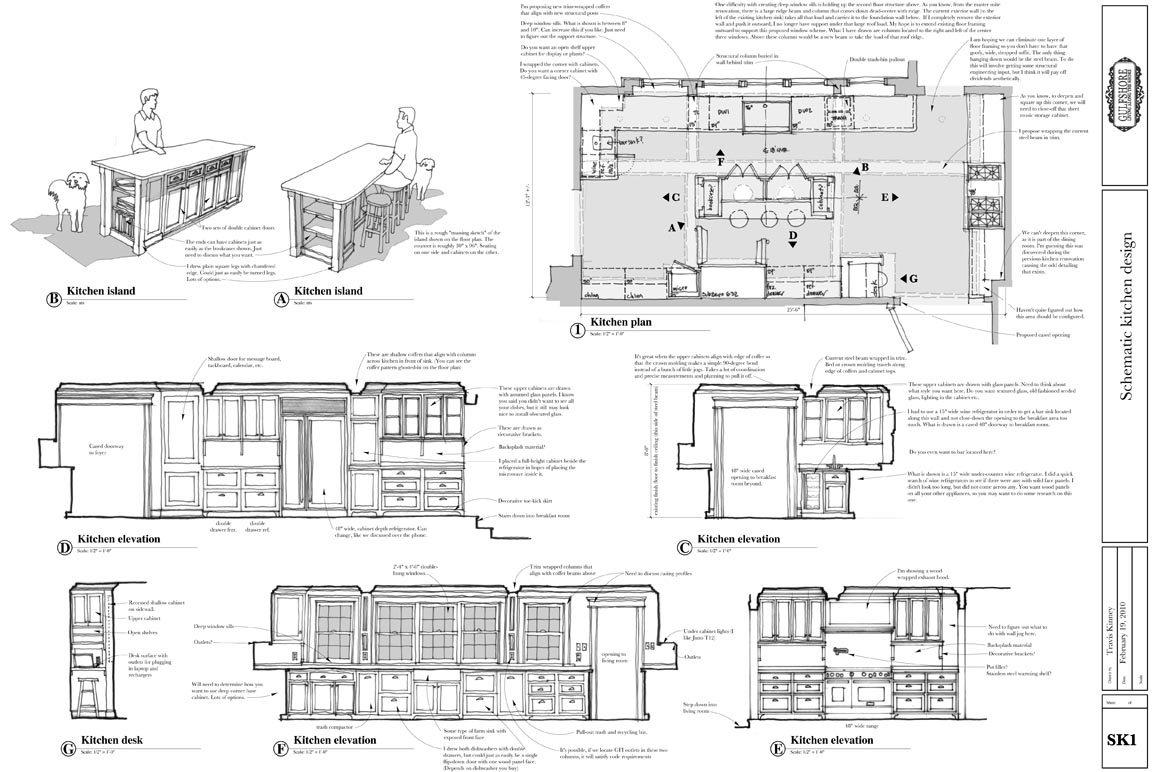

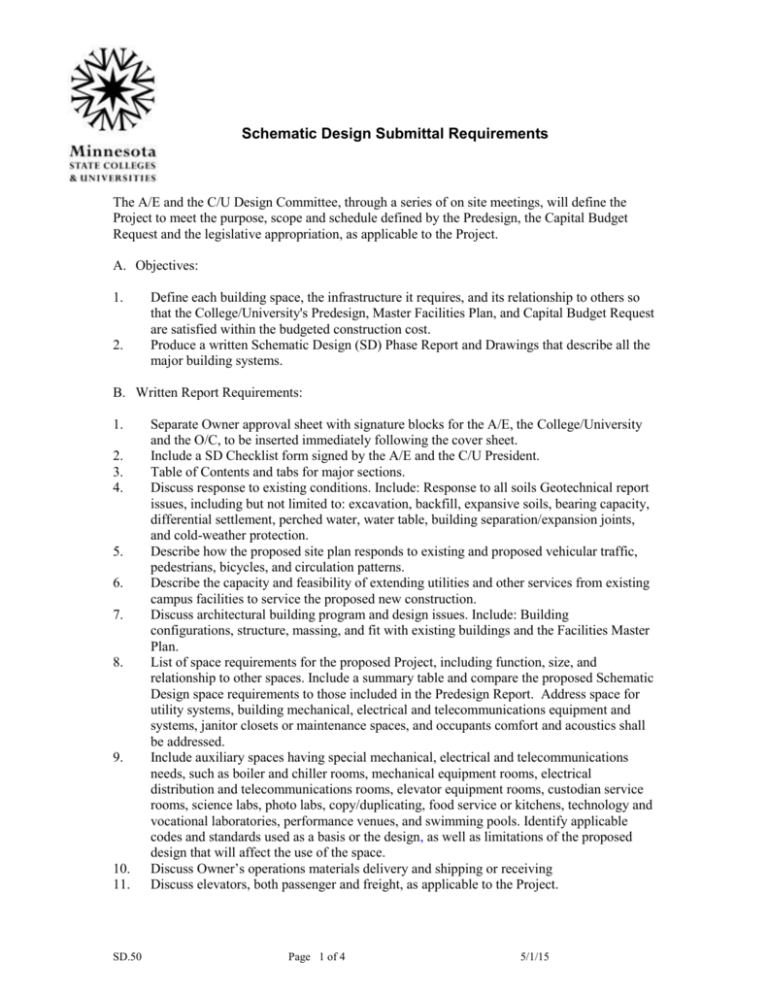

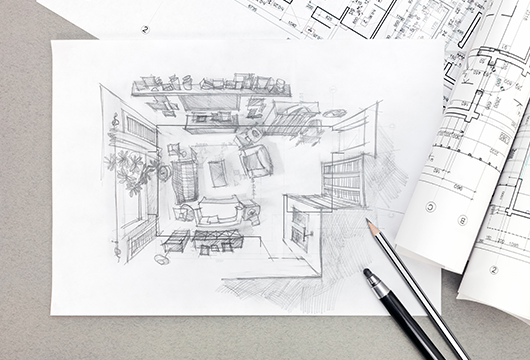

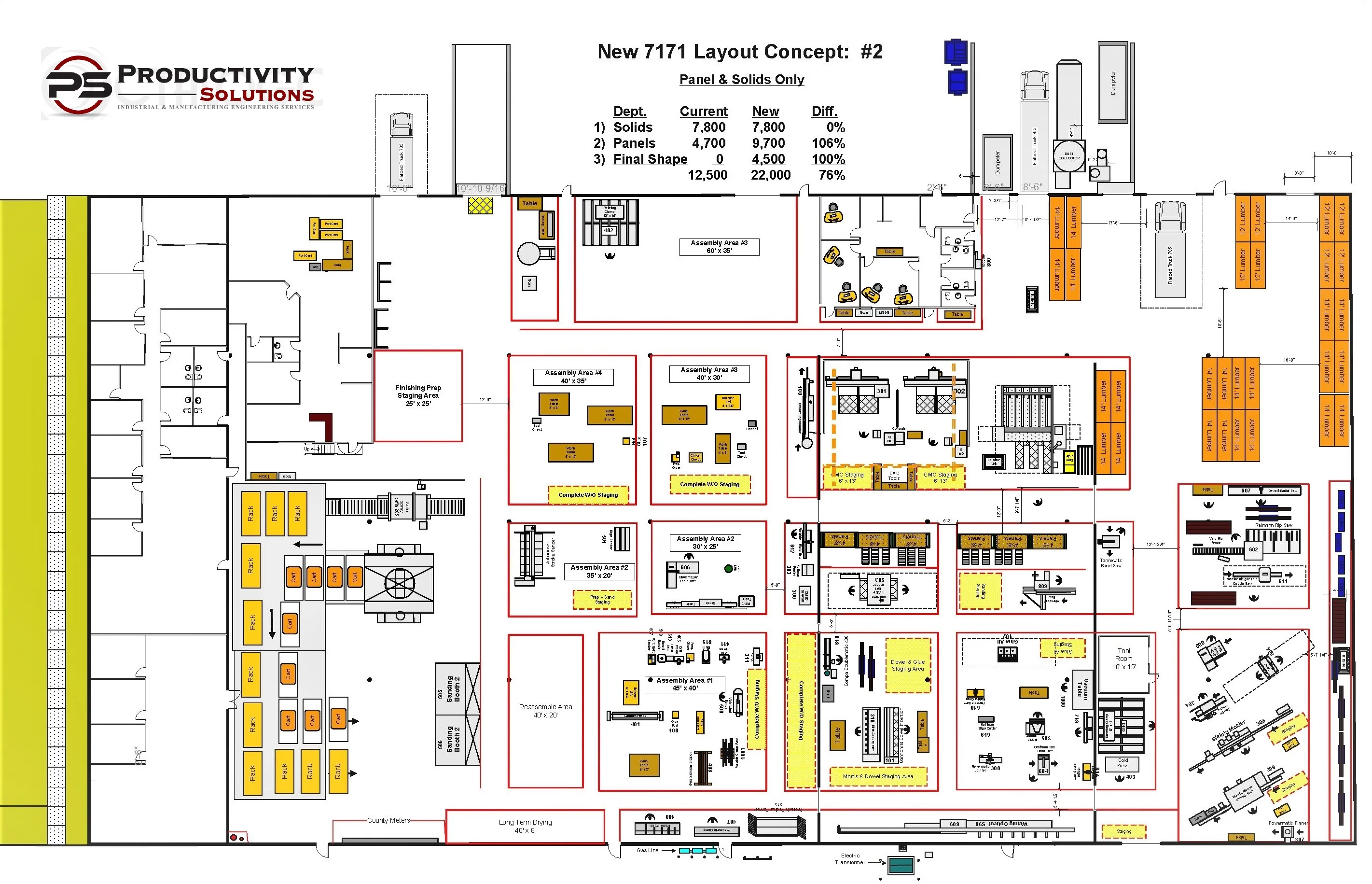

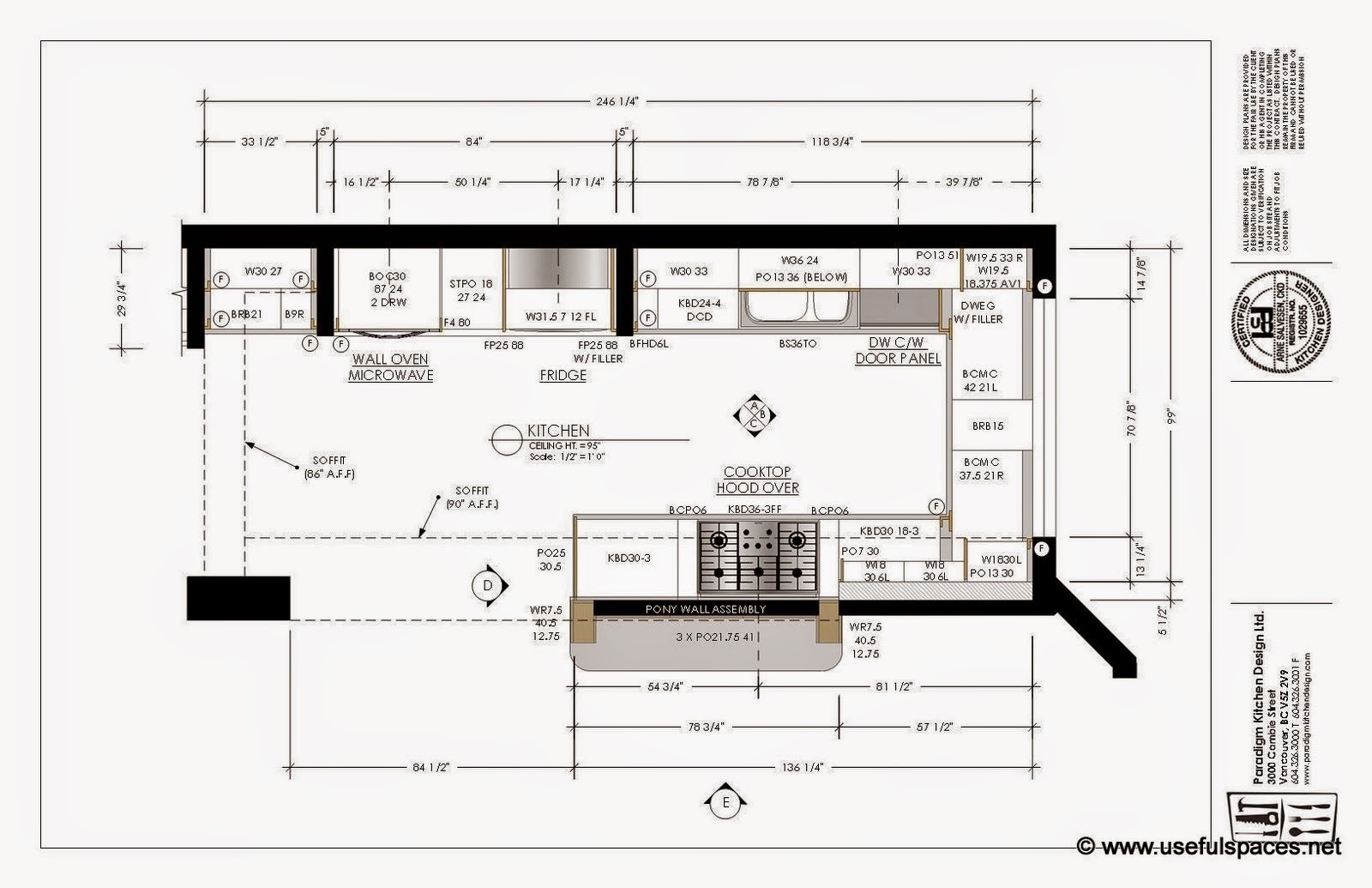

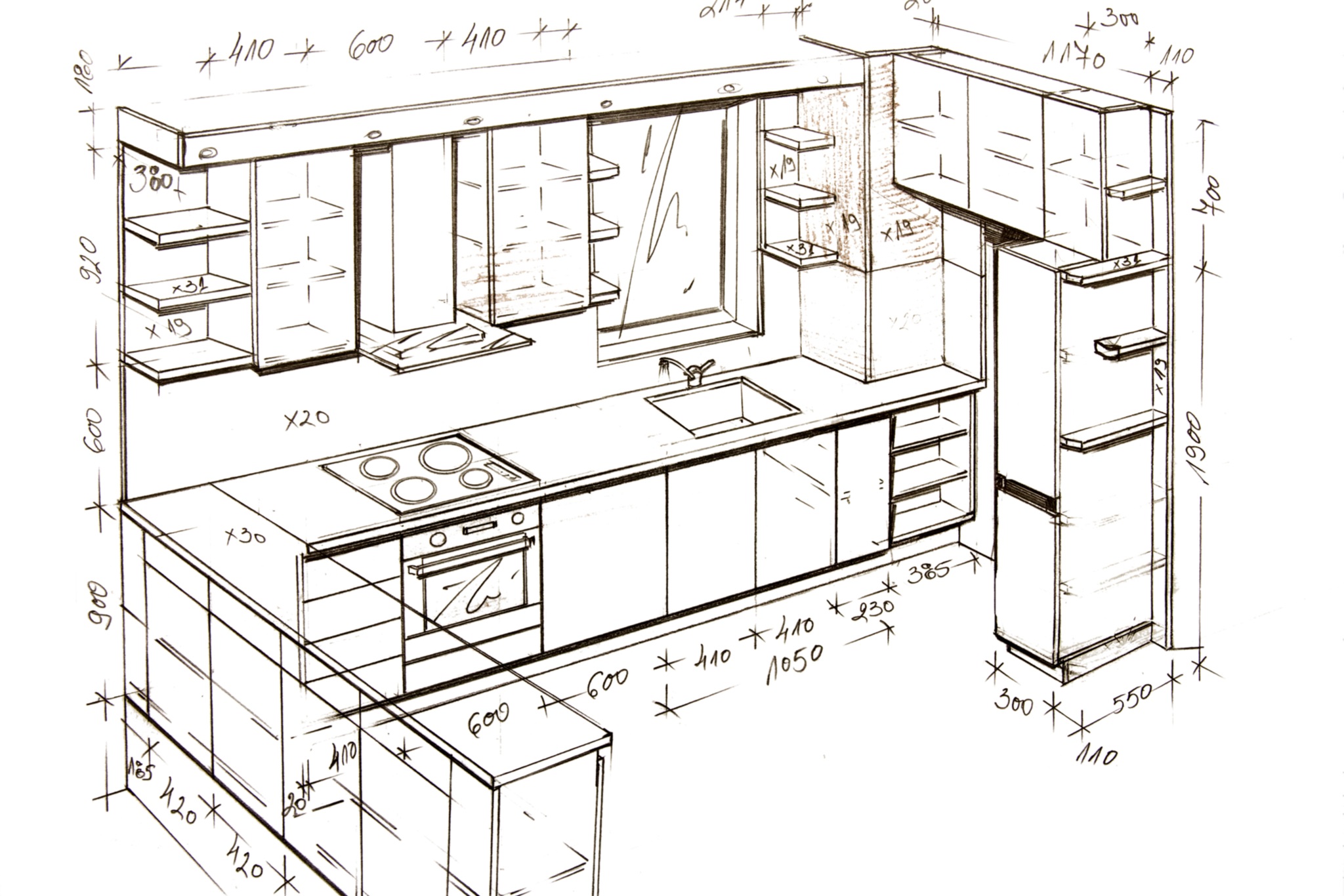

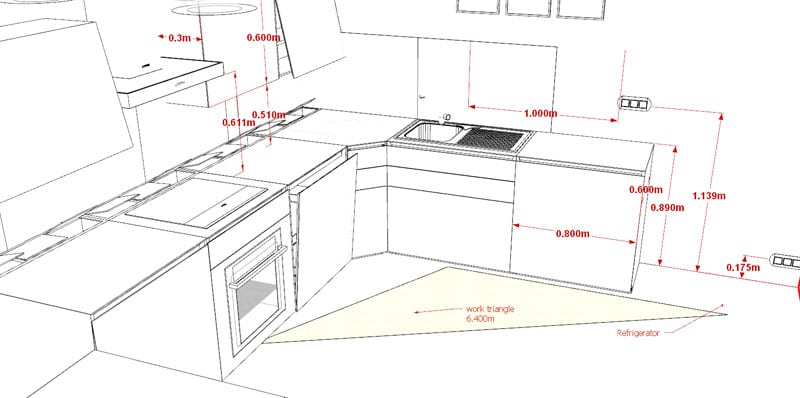

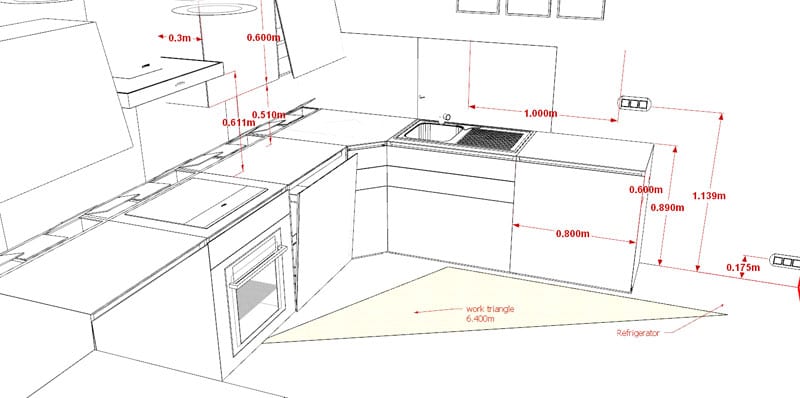

The schematic design phase is where the overall layout and flow of the production kitchen are established. It involves creating a rough sketch of the kitchen, taking into consideration factors such as available space, equipment placement, and workflow. This stage is crucial as it sets the foundation for the rest of the design process.2. Schematic Design

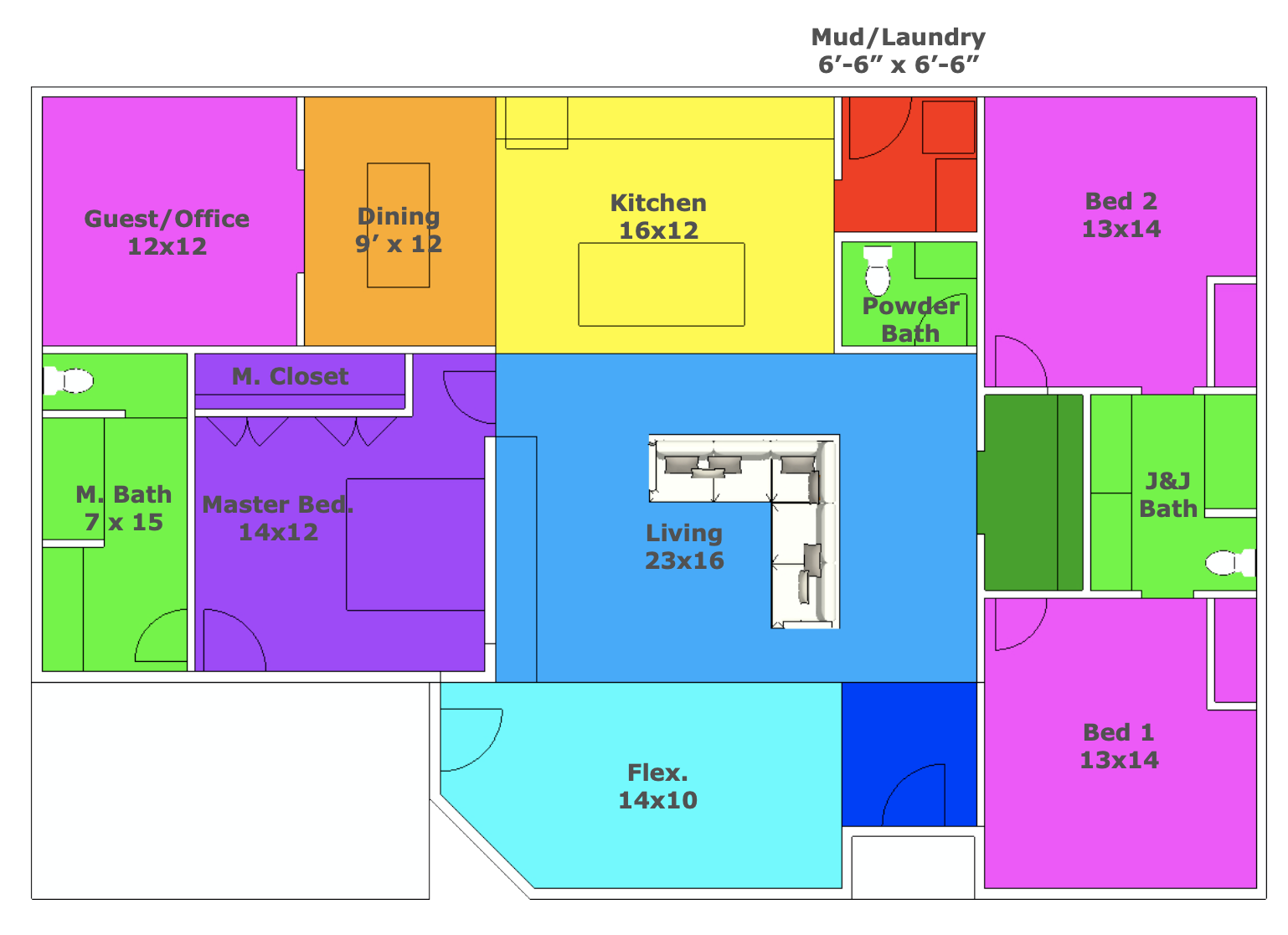

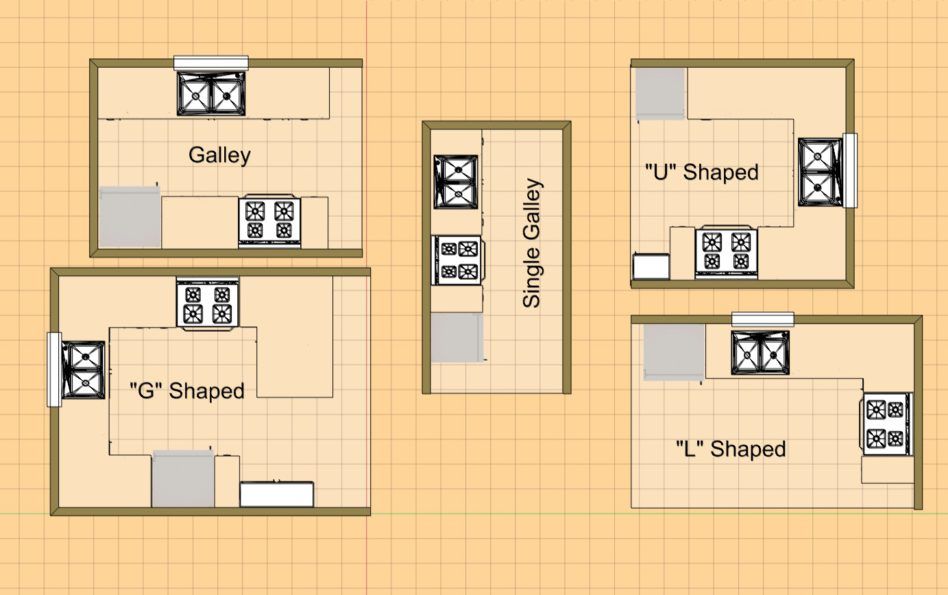

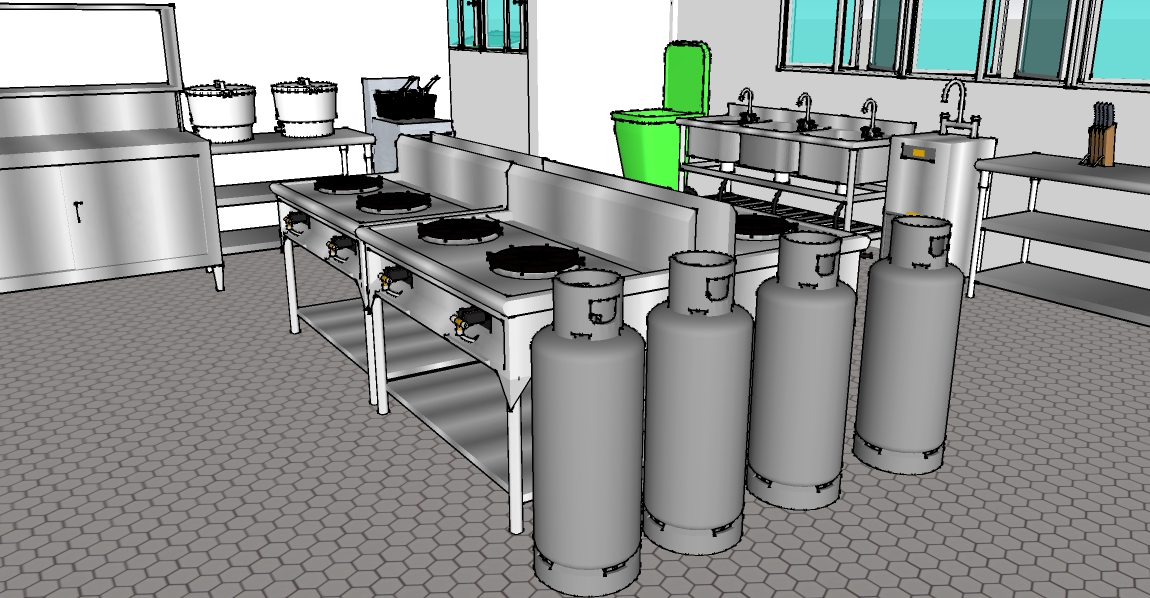

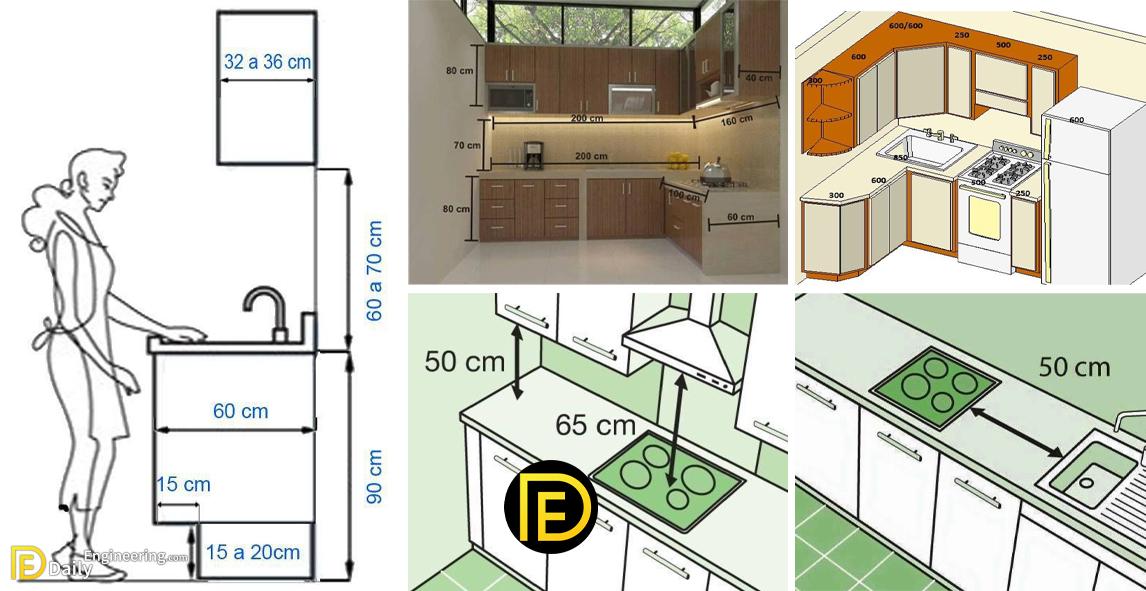

A commercial kitchen layout is different from a regular home kitchen layout. It is designed to handle a higher volume of food production and follows specific guidelines to ensure the efficiency and safety of the kitchen. The layout should be optimized to minimize movement and maximize productivity.3. Commercial Kitchen Layout

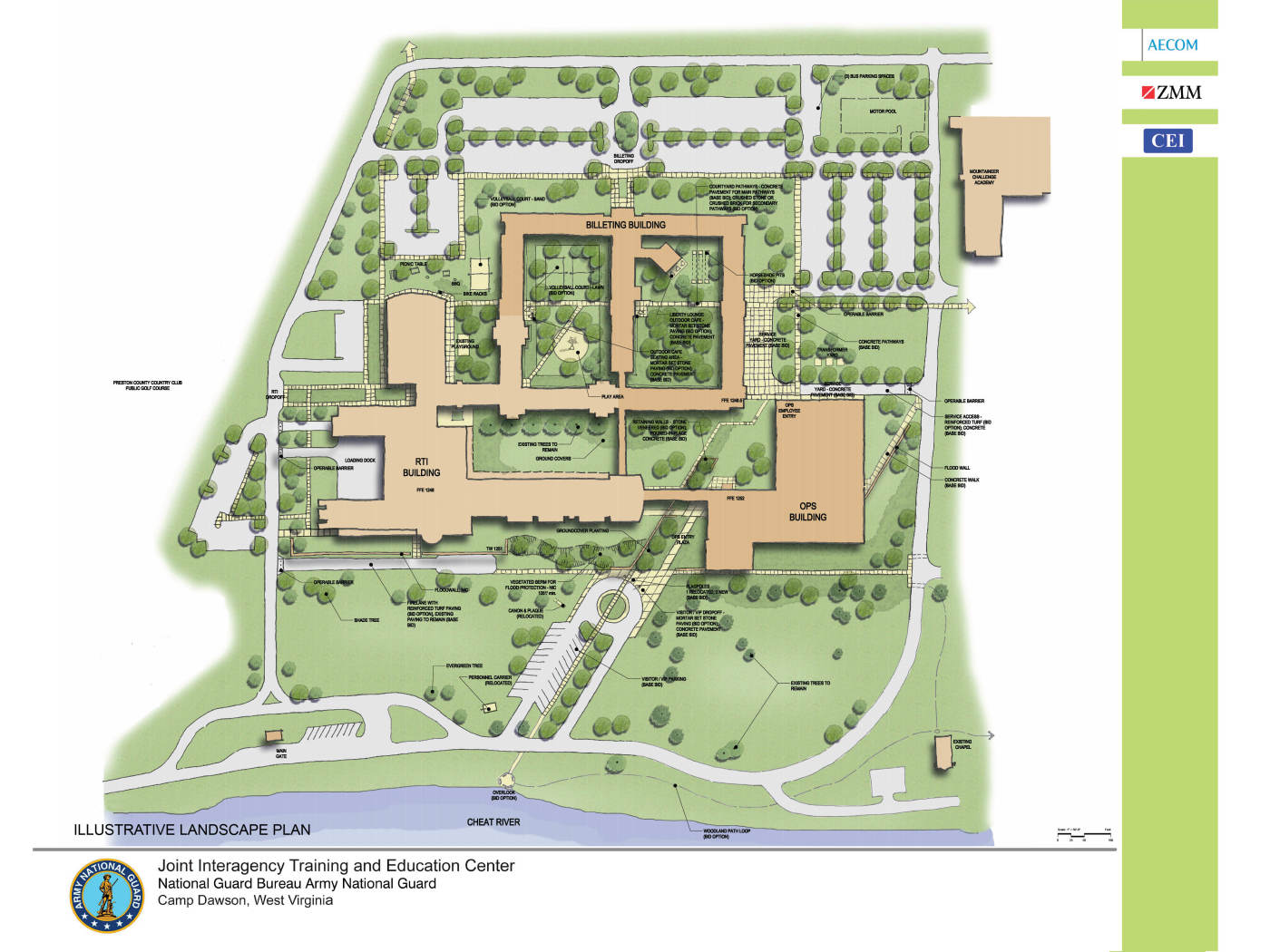

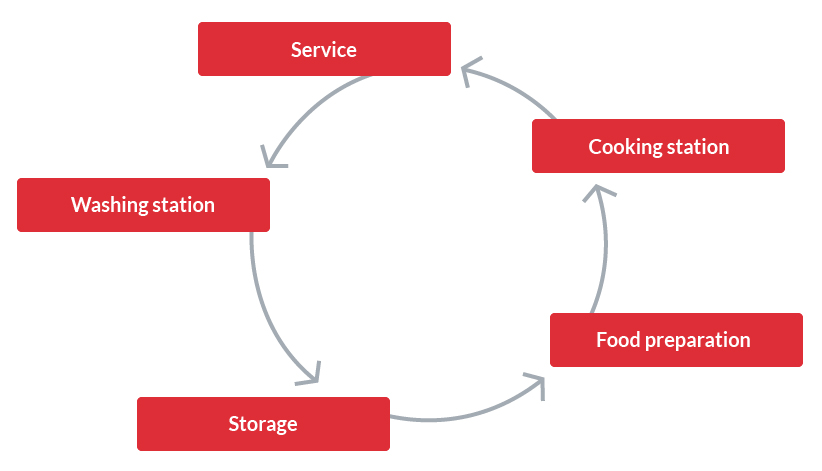

The design of a food production facility is not just limited to the kitchen area. It also includes other areas such as storage, packaging, and food handling. The entire facility needs to be designed with efficiency and safety in mind to ensure a smooth production process.4. Food Production Facility Design

Once the schematic design is complete, the next step is to create detailed kitchen design plans. These plans include precise measurements, equipment specifications, and workflow diagrams. They serve as a guide for contractors and kitchen designers to ensure that the final result meets the desired standards.5. Kitchen Design Plans

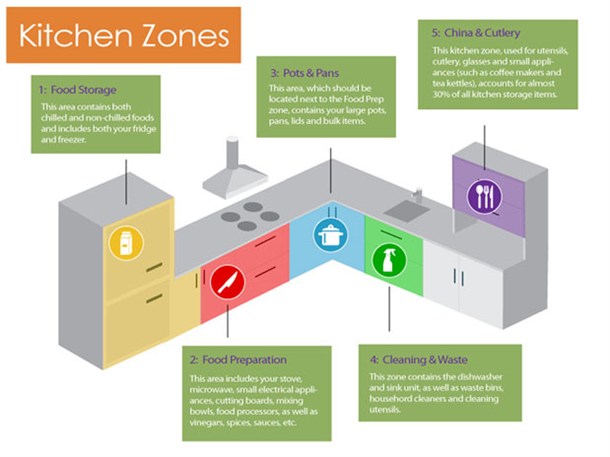

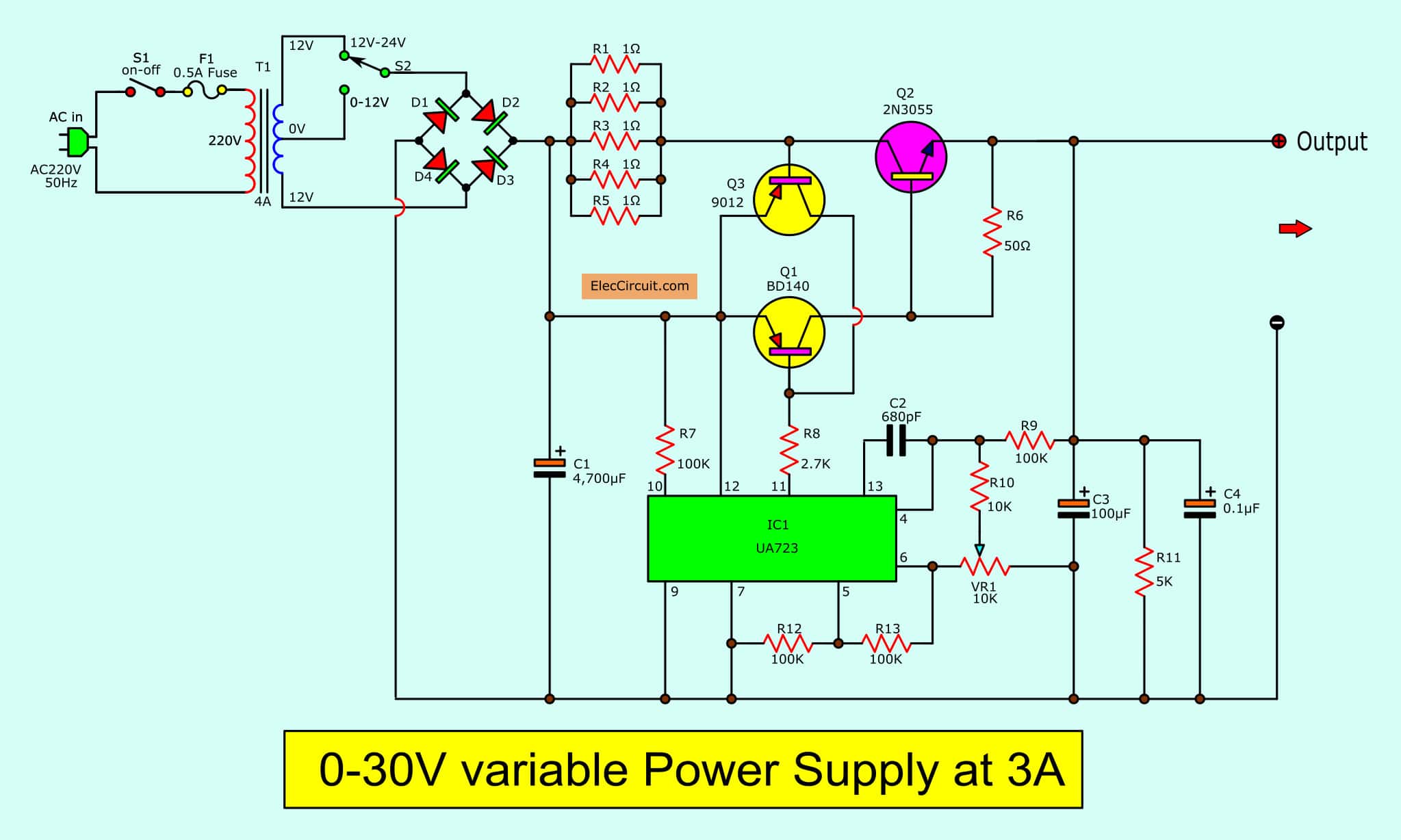

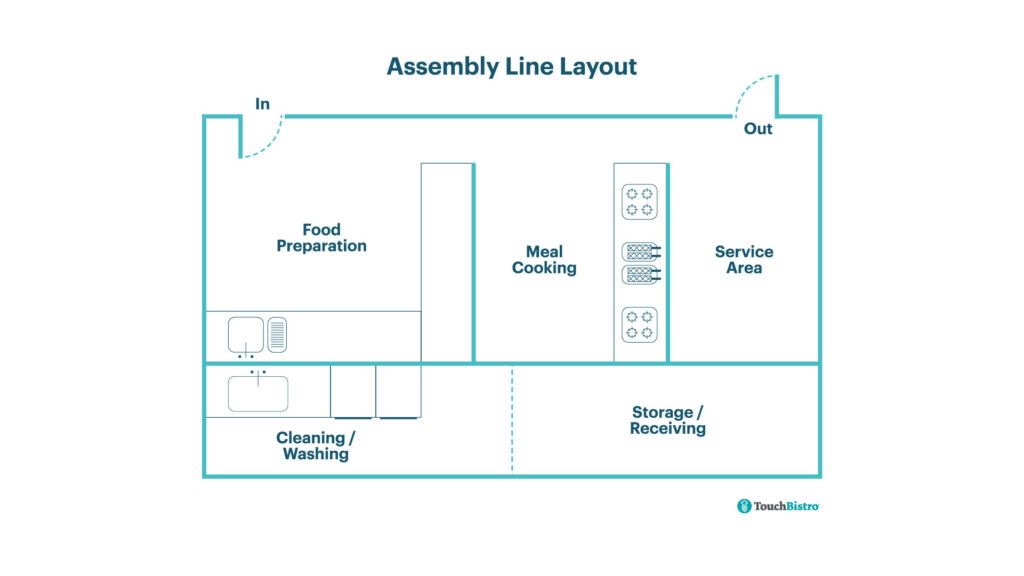

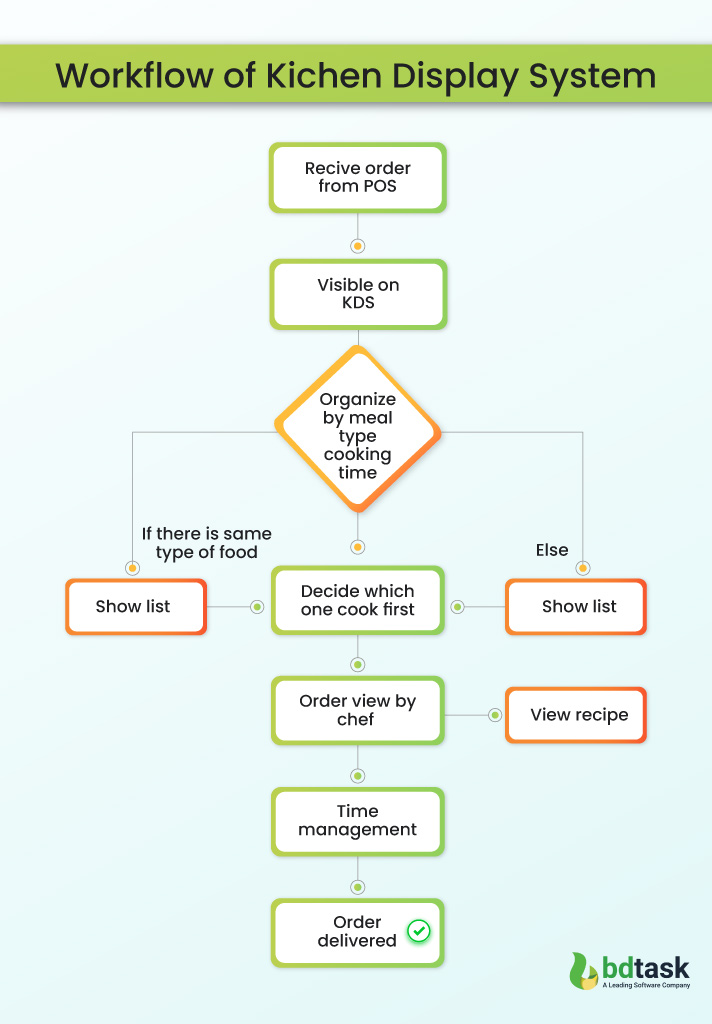

The workflow in a production kitchen is crucial for efficiency and productivity. The design should take into consideration the various steps involved in the production process and ensure that there is a logical flow between them. This includes the placement of equipment, workstations, and storage areas.6. Kitchen Workflow Design

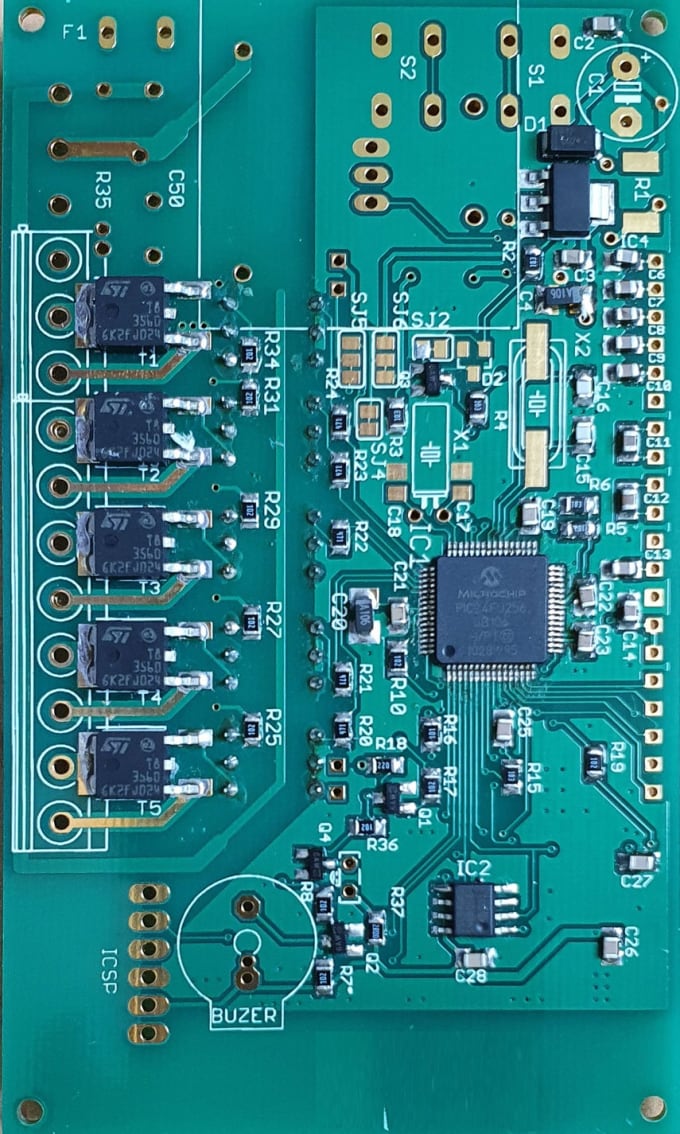

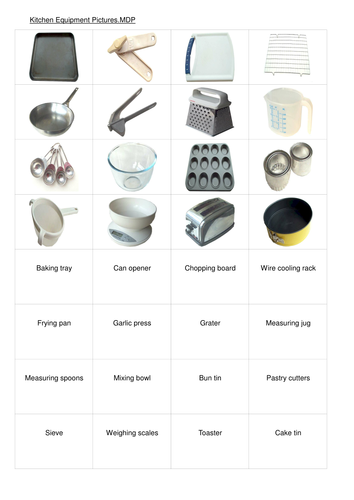

The equipment layout is a crucial aspect of production kitchen design. It involves strategically placing equipment to optimize workflow and minimize movement. The arrangement should also consider factors such as ventilation, safety, and accessibility to ensure a smooth production process.7. Kitchen Equipment Layout

In addition to the production kitchen, foodservice areas such as dining rooms and service counters also need to be designed efficiently. These areas should be designed to support the production process and provide a comfortable and appealing space for customers to enjoy their meals.8. Foodservice Design

There are various guidelines and standards that need to be followed when designing a production kitchen. These guidelines cover areas such as equipment sizing, ventilation, fire safety, and hygiene. It is essential to adhere to these guidelines to ensure a safe and effective kitchen design.9. Kitchen Design Guidelines

In addition to guidelines, there are also standards set by organizations such as the National Kitchen and Bath Association (NKBA) and the Food and Drug Administration (FDA). These standards cover everything from equipment specifications to food handling and are crucial to follow to ensure a safe and compliant production kitchen.10. Kitchen Design Standards

Schematic Design of Production Kitchen

Efficiency and Functionality

When it comes to designing a production kitchen, the main focus should always be on efficiency and functionality. A production kitchen is a space where food is prepared in large quantities, so it's important to have a well thought out and organized design to ensure smooth operations.

Space utilization

is a key factor in the schematic design of a production kitchen. It's important to make the most out of the available space to accommodate all the necessary equipment and work stations. This includes

proper placement

of appliances, work tables, and storage areas to optimize the workflow and minimize any potential bottlenecks.

When it comes to designing a production kitchen, the main focus should always be on efficiency and functionality. A production kitchen is a space where food is prepared in large quantities, so it's important to have a well thought out and organized design to ensure smooth operations.

Space utilization

is a key factor in the schematic design of a production kitchen. It's important to make the most out of the available space to accommodate all the necessary equipment and work stations. This includes

proper placement

of appliances, work tables, and storage areas to optimize the workflow and minimize any potential bottlenecks.

Workflow and Traffic Flow

Workflow

and

traffic flow

are crucial considerations in the design of a production kitchen. The layout should be designed to minimize the distance between different work stations and appliances, ensuring a smooth flow of work. This also includes having designated areas for each step in the cooking process, from prep work to cooking and plating.

Proper ventilation

is also a key factor in the schematic design of a production kitchen. With the use of various cooking equipment and appliances, it's important to have a ventilation system that can effectively remove heat, steam, and odors from the kitchen to maintain a comfortable and safe working environment.

Workflow

and

traffic flow

are crucial considerations in the design of a production kitchen. The layout should be designed to minimize the distance between different work stations and appliances, ensuring a smooth flow of work. This also includes having designated areas for each step in the cooking process, from prep work to cooking and plating.

Proper ventilation

is also a key factor in the schematic design of a production kitchen. With the use of various cooking equipment and appliances, it's important to have a ventilation system that can effectively remove heat, steam, and odors from the kitchen to maintain a comfortable and safe working environment.

Flexibility and Adaptability

In the fast-paced world of food production, the ability to adapt and be flexible is crucial. This is why the design of a production kitchen should also consider

future expansion

and

adaptability

. As the business grows, the kitchen should be able to accommodate new equipment and work stations without major renovations. This can be achieved by leaving room for future additions and ensuring a flexible layout.

In conclusion, the schematic design of a production kitchen should prioritize efficiency, functionality, workflow, and adaptability. By considering these factors, a well-designed production kitchen can greatly contribute to the success and smooth operations of a food production business.

In the fast-paced world of food production, the ability to adapt and be flexible is crucial. This is why the design of a production kitchen should also consider

future expansion

and

adaptability

. As the business grows, the kitchen should be able to accommodate new equipment and work stations without major renovations. This can be achieved by leaving room for future additions and ensuring a flexible layout.

In conclusion, the schematic design of a production kitchen should prioritize efficiency, functionality, workflow, and adaptability. By considering these factors, a well-designed production kitchen can greatly contribute to the success and smooth operations of a food production business.

:max_bytes(150000):strip_icc()/commercial-kitchen-equipment-checklist-2888867-v7-5ba4fe764cedfd0050db4afa.png)

:max_bytes(150000):strip_icc()/Modernkitchen-GettyImages-1124517056-c5fecb44794f4b47a685fc976c201296.jpg)