The first OSHA standard that requires employers to put a cover on table kitchen break rooms is 1910.22(a)(1). This standard states that all workplaces must be kept clean and orderly, with all aisles and passageways clear of obstructions. This includes break rooms, which are often seen as a place to relax and unwind, but can also pose safety hazards if not properly maintained.OSHA Standard 1910.22(a)(1) - General Requirements

Another important OSHA standard to consider when it comes to break room safety is 1910.22(a)(2). This standard requires all walking and working surfaces to be clean, dry, and free of hazards. This includes break room tables, which should be regularly cleaned and kept free of spills and debris that could cause slips and falls.OSHA Standard 1910.22(a)(2) - Walking-Working Surfaces

A clean and well-maintained break room is not only important for employee morale, but also for their safety. OSHA standard 1910.22(a)(3) requires employers to maintain a high level of housekeeping in all areas of the workplace, including break rooms. This means keeping floors, tables, and other surfaces free of clutter and hazards.OSHA Standard 1910.22(a)(3) - Housekeeping

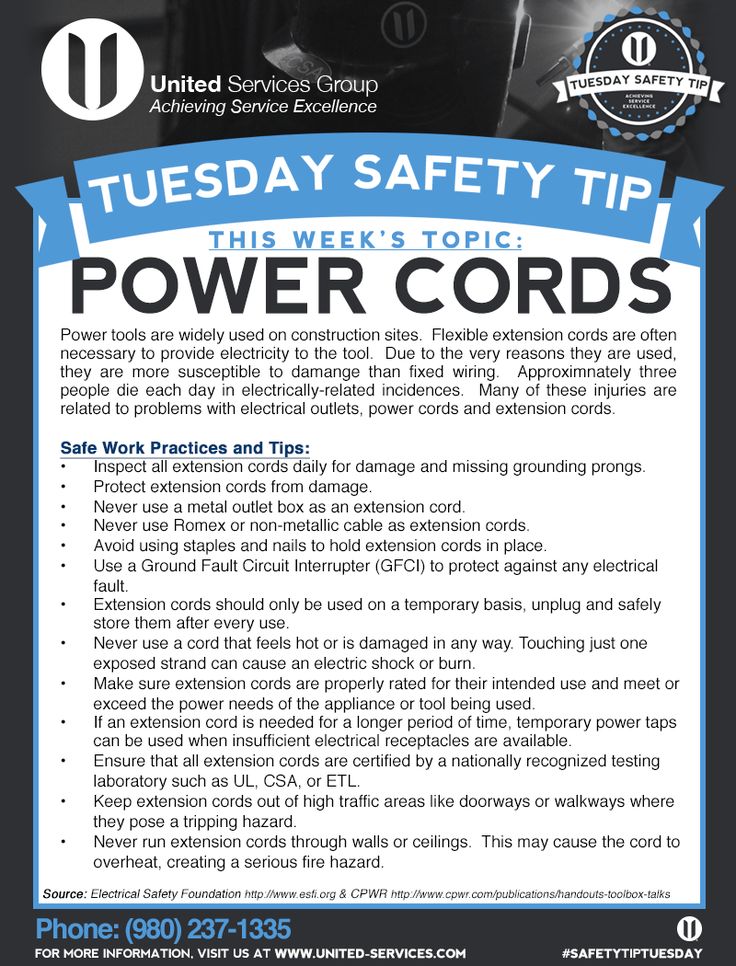

Break rooms often have a variety of equipment and appliances, such as microwaves, coffee makers, and toasters. These may have cords or other openings that could pose a tripping hazard. OSHA standard 1910.22(a)(4) requires these holes and openings to be properly covered or guarded to prevent accidents.OSHA Standard 1910.22(a)(4) - Covering Holes and Openings

In addition to covering holes and openings, OSHA standard 1910.22(a)(5) also requires employers to guard floor and wall openings and holes, such as stairwells and elevator shafts. This is especially important in break rooms where employees may be carrying hot or heavy items and could easily trip or fall into these openings if not properly guarded.OSHA Standard 1910.22(a)(5) - Guarding Floor and Wall Openings and Holes

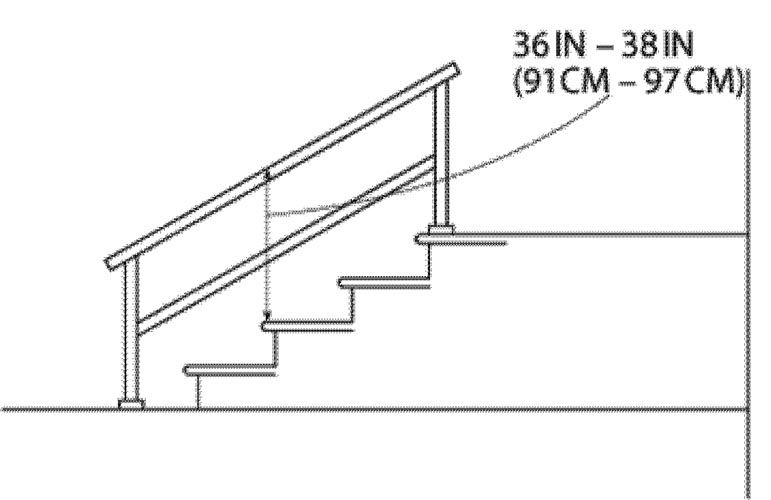

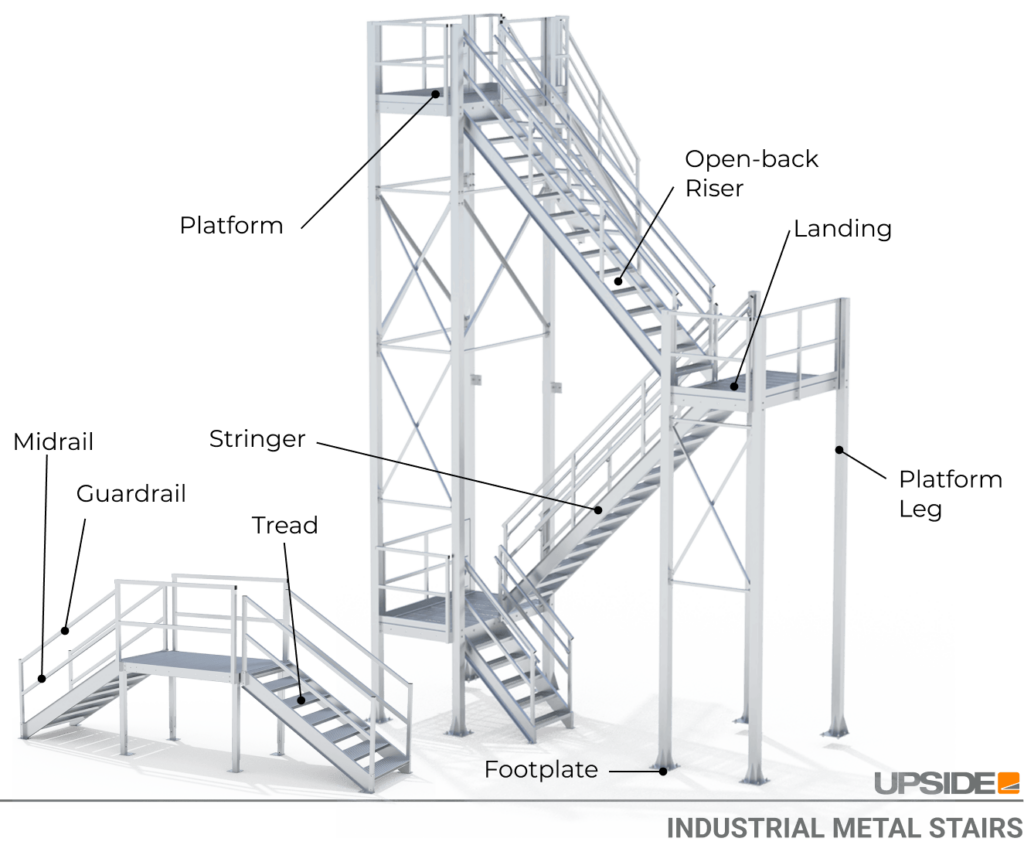

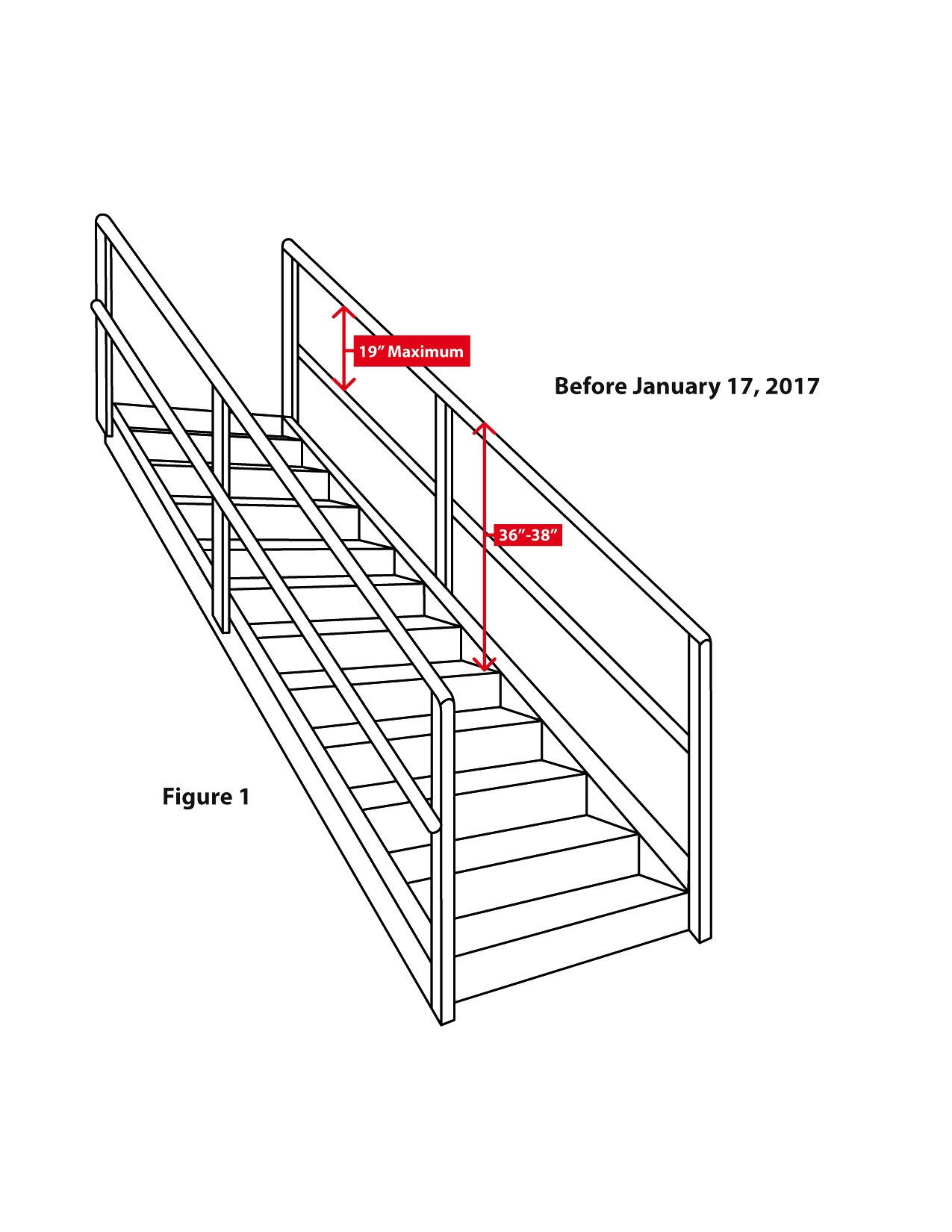

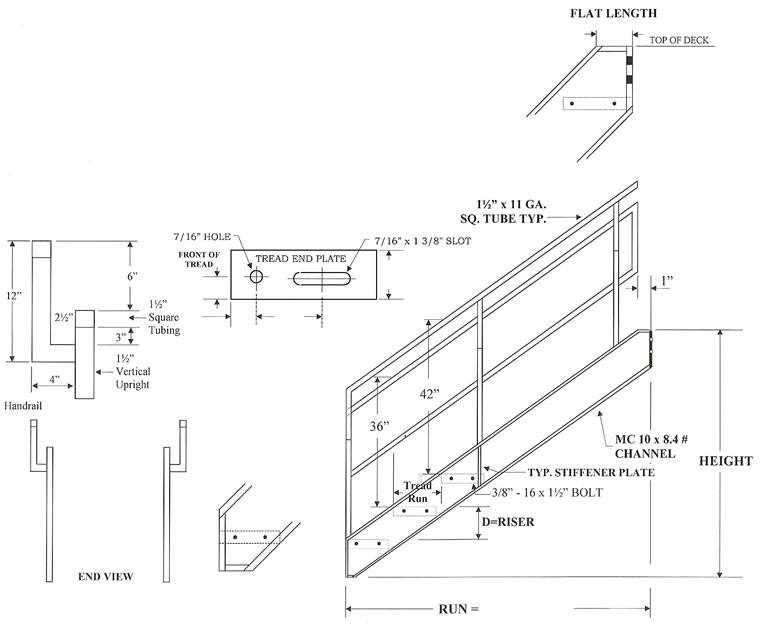

If your break room is located on a different level, it is important to ensure that all stairways have proper railings and guards. OSHA standard 1910.22(a)(6) requires all stairways with four or more risers to have handrails on at least one side and guardrails on both sides to prevent falls.OSHA Standard 1910.22(a)(6) - Stairway Railings and Guards

Break rooms may also have heavy equipment or storage shelves that could put a strain on the floor. OSHA standard 1910.22(a)(7) requires employers to ensure that the floor can support the intended load and provide additional support if necessary. This is especially important in break rooms where employees may be moving or stacking heavy items.OSHA Standard 1910.22(a)(7) - Floor Loading Protection

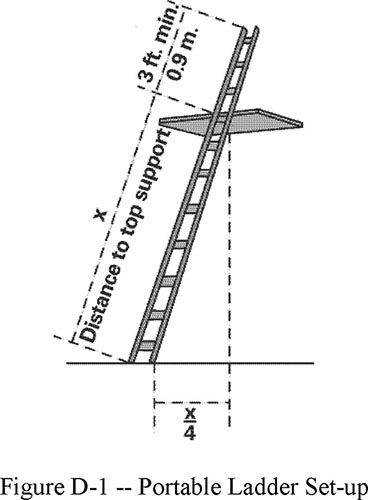

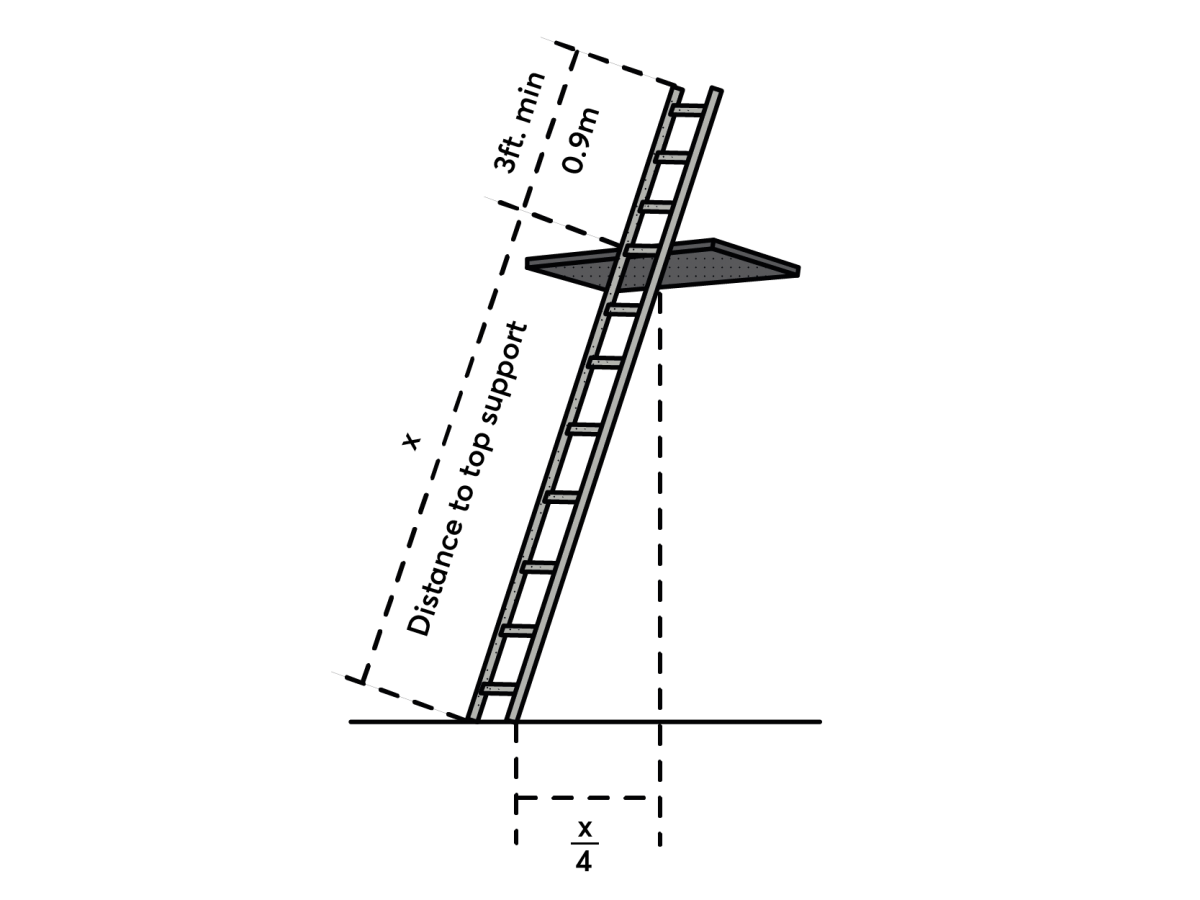

Portable ladders are often used in break rooms to reach high shelves or cabinets. OSHA standard 1910.22(a)(8) requires employers to ensure that all portable ladders are in good condition and properly used. This includes ensuring that the ladder is the correct height and angle, and that it is placed on a stable surface to prevent tipping.OSHA Standard 1910.22(a)(8) - Portable Ladders

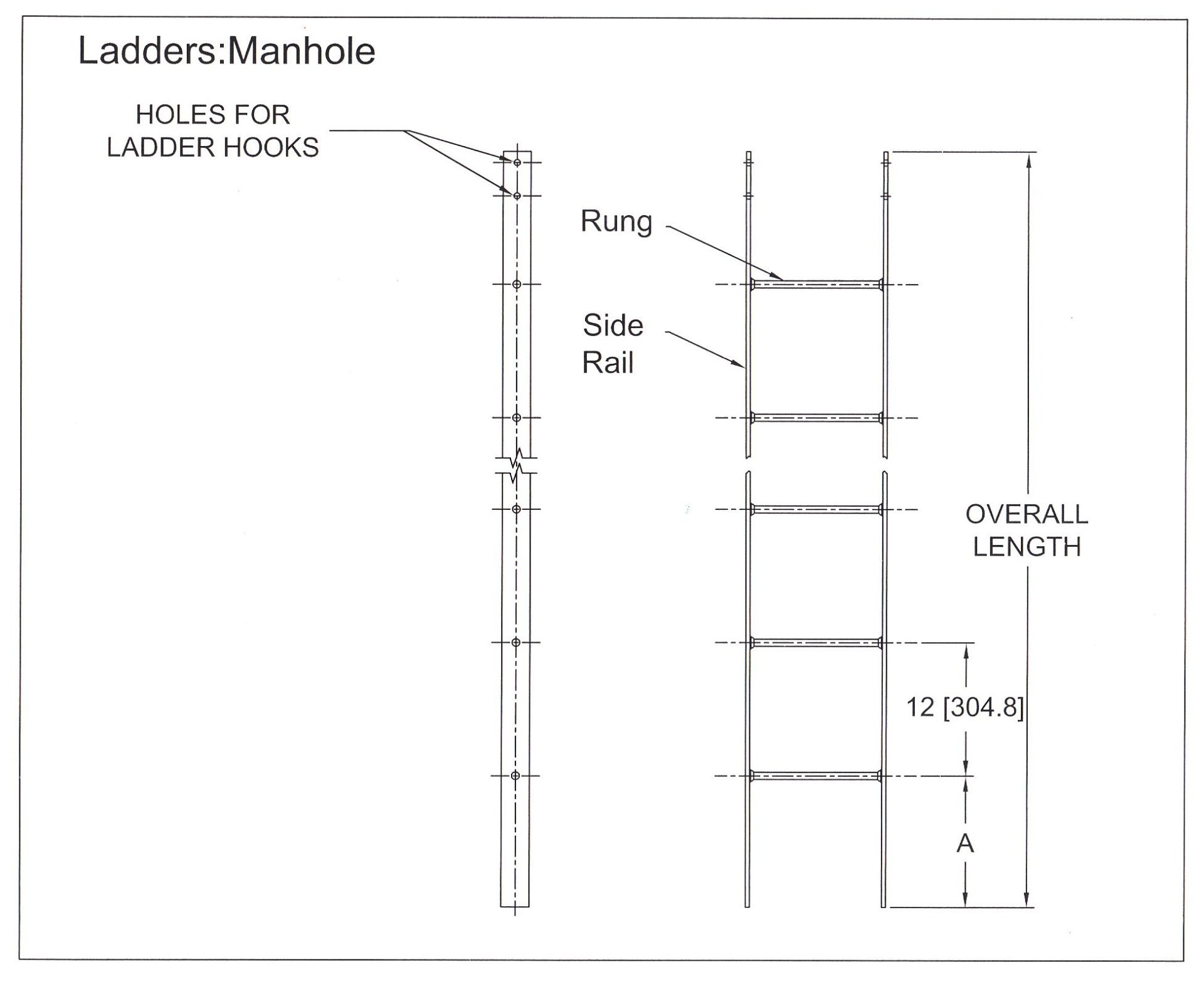

In some break rooms, there may be fixed ladders leading to storage areas or other elevated spaces. OSHA standard 1910.22(a)(9) requires these ladders to be properly designed, installed, and maintained to ensure the safety of employees who may need to use them.OSHA Standard 1910.22(a)(9) - Fixed Ladders

Some break rooms may have loading docks or other areas where dockboards or dock plates are used to bridge the gap between the dock and the truck bed. OSHA standard 1910.22(a)(10) requires these boards to be properly secured and in good condition to prevent accidents and injuries. By following these 10 OSHA standards, employers can ensure the safety of their employees in break rooms and throughout the workplace. Putting a cover on break room tables is just one step in creating a safe and hazard-free environment for employees to enjoy.OSHA Standard 1910.22(a)(10) - Dockboards (Dock Plates)

Why OSHA Standards Require a Cover on Kitchen Break Room Tables

Ensuring Workplace Safety with Proper Table Coverings

The Occupational Safety and Health Administration (OSHA) is responsible for setting and enforcing workplace safety standards to protect the health and well-being of employees. One of these standards requires that all kitchen break room tables have a cover in place at all times. This seemingly simple precaution has significant benefits for both employees and employers, highlighting the importance of proper house design in creating a safe and productive work environment.

Preventing Contamination and Illness

The kitchen break room is often a hub for employees to gather and take their breaks, making it a high-traffic area in the workplace. With this high traffic comes an increased risk of contamination and the spread of illness-causing bacteria. A cover on the table helps to prevent food and drinks from coming into direct contact with the surface, reducing the likelihood of cross-contamination. This is especially important in shared break rooms where multiple individuals may use the same table throughout the day.

Promoting Cleanliness and Hygiene

In addition to preventing contamination, a table cover also promotes cleanliness and hygiene in the break room. Without a cover, spills and crumbs can easily accumulate on the table surface, creating a breeding ground for germs and bacteria. A cover can be easily wiped down and sanitized after each use, ensuring a clean and sanitary surface for employees to eat and relax.

Protecting the Table Surface

Furthermore, having a cover on the table can help protect the surface from scratches, stains, and other damage. This not only maintains the appearance of the break room but also prolongs the lifespan of the table, saving the company money in the long run. It also reduces the need for frequent cleaning and maintenance, allowing employees to focus on their work rather than worrying about the condition of the table.

Compliance with OSHA Standards

By following OSHA's standard of having a cover on break room tables, employers are not only ensuring the safety and well-being of their employees but also complying with regulations. Failure to comply with OSHA standards can result in fines and penalties, as well as potential legal issues. Having a cover on the table is a simple and effective way to meet this requirement and maintain a safe workplace.

In conclusion, OSHA's standard of having a cover on kitchen break room tables serves as a crucial measure in promoting workplace safety and cleanliness. It not only prevents contamination and illness but also protects the table surface and ensures compliance with regulations. Employers should prioritize proper house design, including the use of table covers, to create a safe and healthy work environment for their employees.

The Occupational Safety and Health Administration (OSHA) is responsible for setting and enforcing workplace safety standards to protect the health and well-being of employees. One of these standards requires that all kitchen break room tables have a cover in place at all times. This seemingly simple precaution has significant benefits for both employees and employers, highlighting the importance of proper house design in creating a safe and productive work environment.

Preventing Contamination and Illness

The kitchen break room is often a hub for employees to gather and take their breaks, making it a high-traffic area in the workplace. With this high traffic comes an increased risk of contamination and the spread of illness-causing bacteria. A cover on the table helps to prevent food and drinks from coming into direct contact with the surface, reducing the likelihood of cross-contamination. This is especially important in shared break rooms where multiple individuals may use the same table throughout the day.

Promoting Cleanliness and Hygiene

In addition to preventing contamination, a table cover also promotes cleanliness and hygiene in the break room. Without a cover, spills and crumbs can easily accumulate on the table surface, creating a breeding ground for germs and bacteria. A cover can be easily wiped down and sanitized after each use, ensuring a clean and sanitary surface for employees to eat and relax.

Protecting the Table Surface

Furthermore, having a cover on the table can help protect the surface from scratches, stains, and other damage. This not only maintains the appearance of the break room but also prolongs the lifespan of the table, saving the company money in the long run. It also reduces the need for frequent cleaning and maintenance, allowing employees to focus on their work rather than worrying about the condition of the table.

Compliance with OSHA Standards

By following OSHA's standard of having a cover on break room tables, employers are not only ensuring the safety and well-being of their employees but also complying with regulations. Failure to comply with OSHA standards can result in fines and penalties, as well as potential legal issues. Having a cover on the table is a simple and effective way to meet this requirement and maintain a safe workplace.

In conclusion, OSHA's standard of having a cover on kitchen break room tables serves as a crucial measure in promoting workplace safety and cleanliness. It not only prevents contamination and illness but also protects the table surface and ensures compliance with regulations. Employers should prioritize proper house design, including the use of table covers, to create a safe and healthy work environment for their employees.