Latex Mattress Manufacturing Process

Latex mattresses have become increasingly popular in recent years due to their durability, comfort, and eco-friendliness. But have you ever wondered how these mattresses are made? In this article, we will take a closer look at the top 10 manufacturing methods of latex mattresses.

How Latex Mattresses are Made

The manufacturing process of latex mattresses involves the use of natural or synthetic latex foam, which is then combined with other materials to create a supportive and comfortable sleeping surface. Let's dive into the details of how these mattresses are made.

Latex Mattress Production Methods

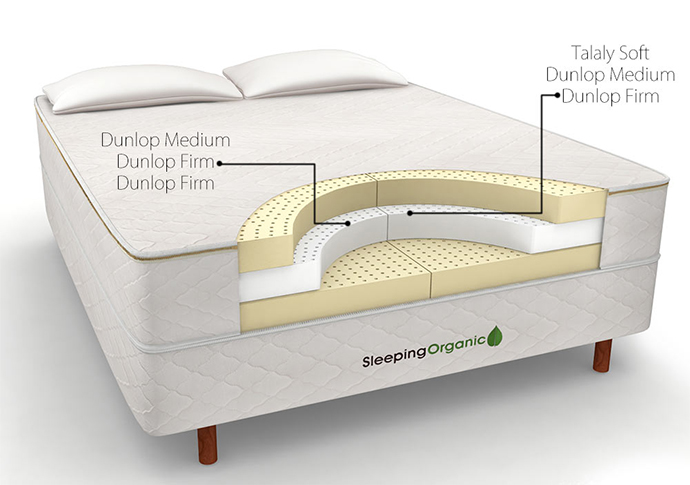

There are three main methods of producing latex mattresses: Dunlop, Talalay, and Continuous Pour. Each method has its own unique characteristics and advantages, allowing manufacturers to create a variety of latex mattress options for consumers.

Manufacturing Techniques for Latex Mattresses

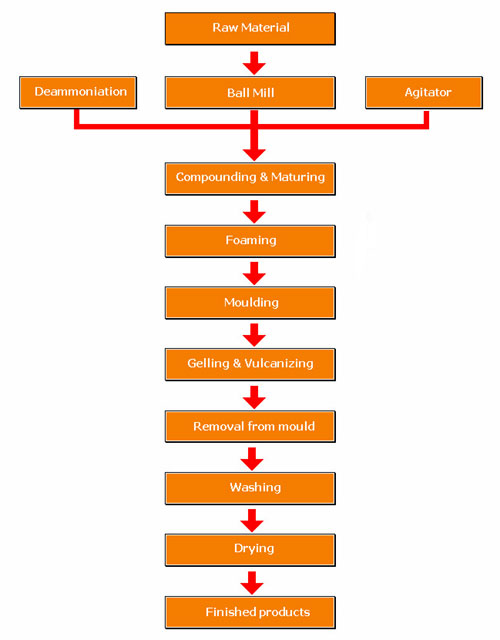

The Dunlop method is the oldest and most traditional method of producing latex foam. In this technique, liquid latex is poured into a mold, baked, and then washed to remove any impurities. This results in a denser and firmer foam, making it ideal for providing support.

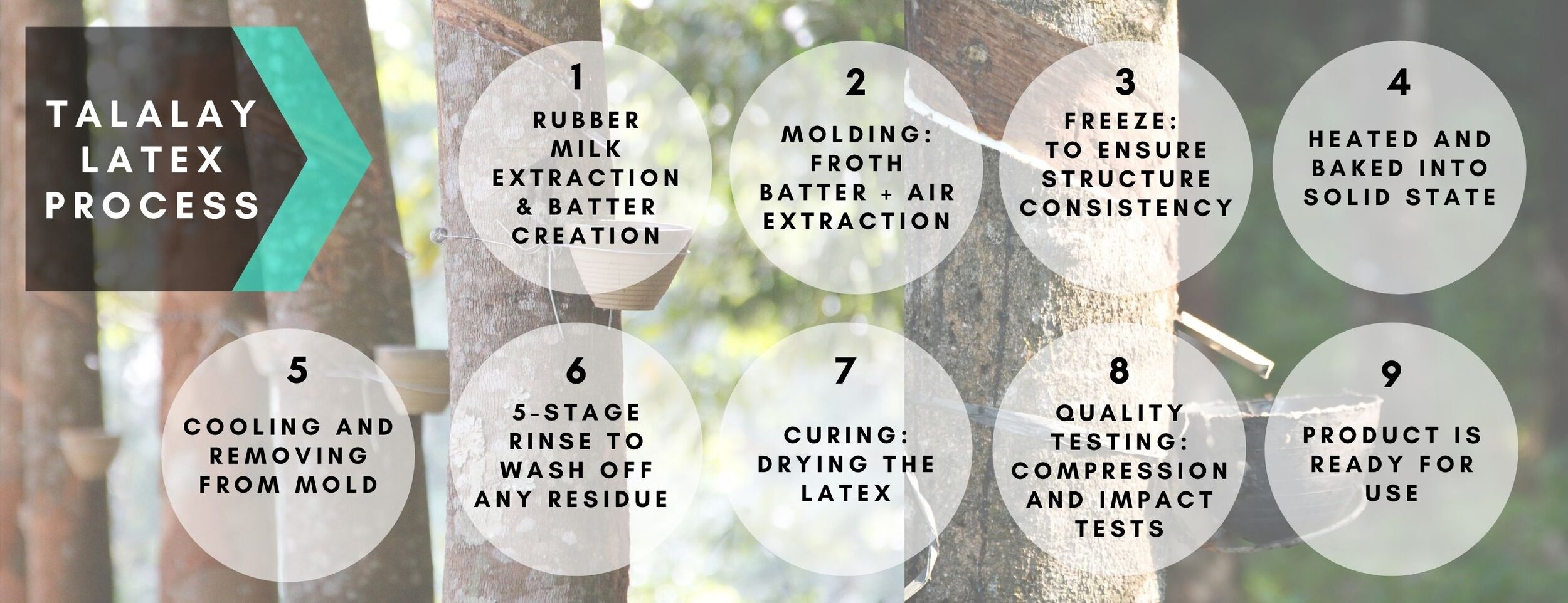

The Talalay method, on the other hand, involves a more complex process. The liquid latex is poured into a mold and then sealed before being flash-frozen. This creates a consistent cell structure throughout the foam, resulting in a softer and more uniform feel.

The Continuous Pour method, also known as the Dunlopillo method, is a combination of the Dunlop and Talalay methods. In this technique, the latex is poured into a long mold and then continuously poured into another mold, creating a long foam sheet. This allows for more flexibility in terms of customization and provides a consistent support level throughout the mattress.

Latex Mattress Construction Methods

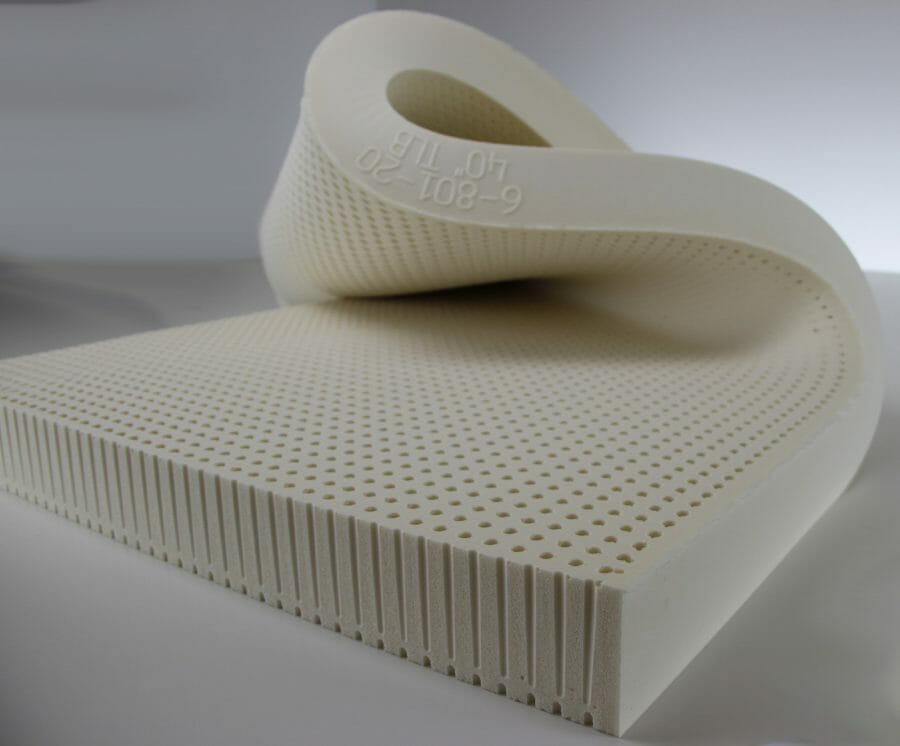

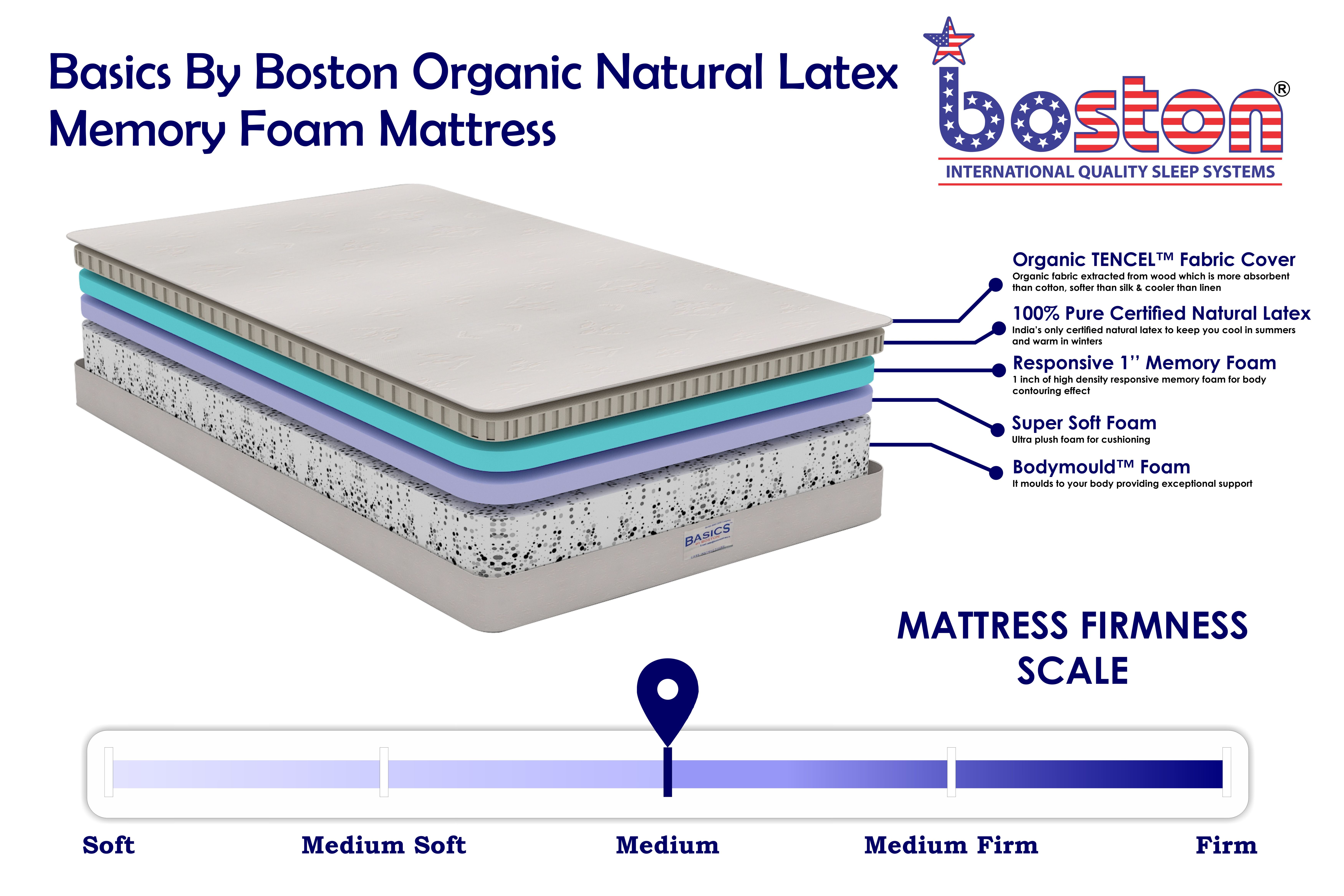

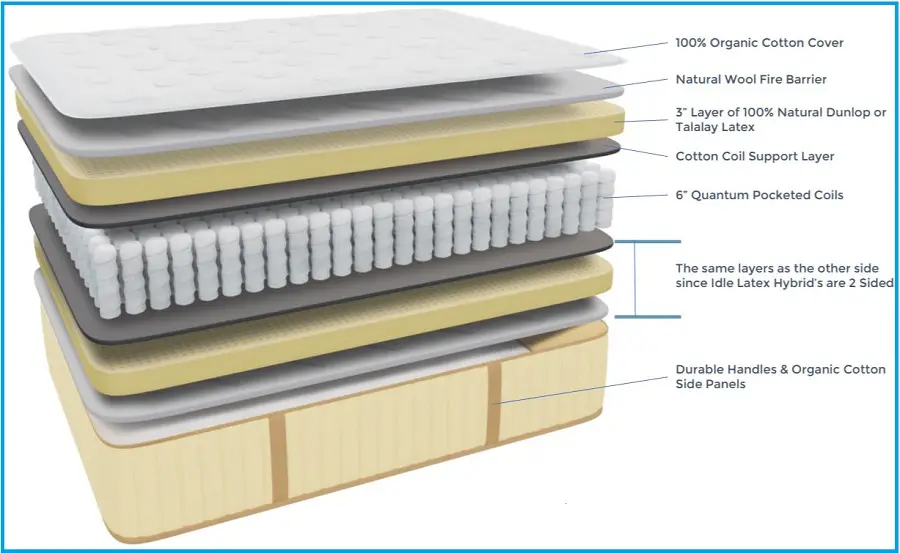

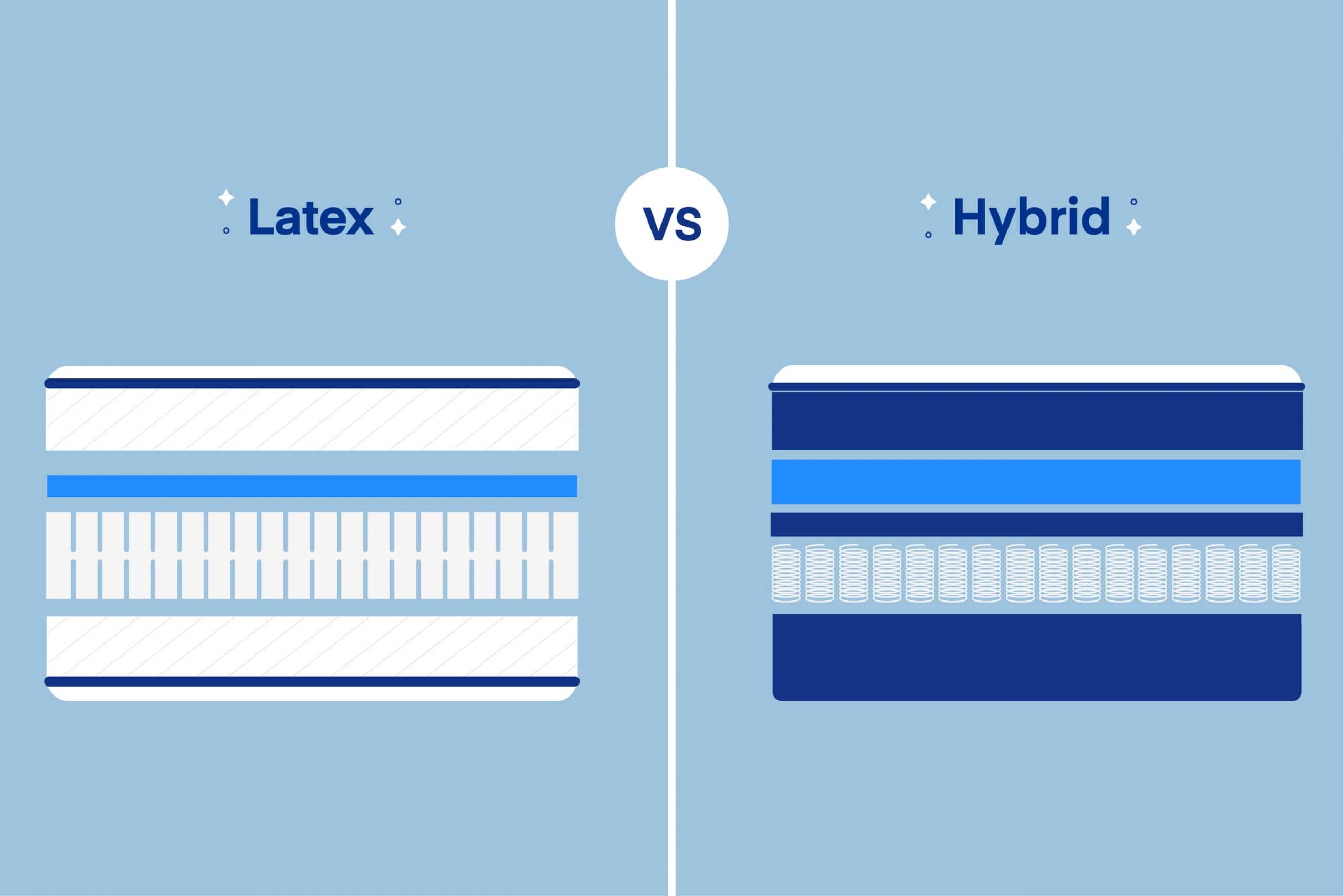

In addition to the production methods, there are also different construction methods used in the manufacturing of latex mattresses. These include layered construction, where different layers of latex foam are used to create varying levels of support, and zoned construction, where different areas of the mattress have varying levels of firmness for targeted support.

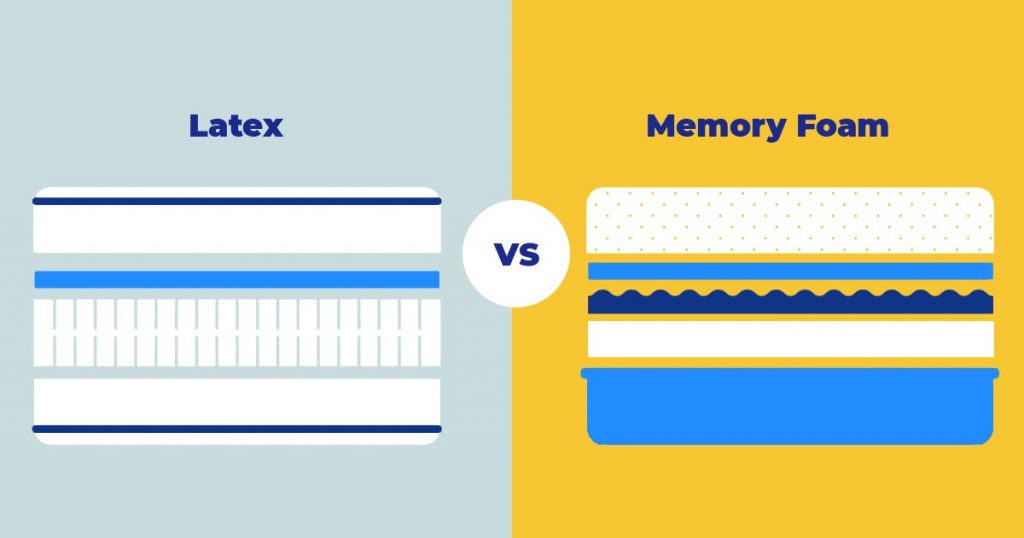

Another popular construction method is the use of a pocketed coil system, which involves placing individually wrapped coils in between layers of latex foam for added support and motion isolation. This combination of materials creates a hybrid mattress that offers the benefits of both latex and innerspring mattresses.

Latex Mattress Manufacturing Steps

The manufacturing process for latex mattresses typically involves several steps, starting with the harvesting of latex from rubber trees. The latex is then processed and poured into molds, followed by washing and drying to remove any impurities. The foam is then cut to the desired size and shape before being assembled into a mattress with other materials such as cotton, wool, or organic fabrics.

Latex Mattress Production Process

The production process for latex mattresses involves a combination of handcrafting and automated manufacturing. While many manufacturers use machines to pour and mold the latex foam, the assembly of the mattress is often done by hand. This allows for more attention to detail and customization, ensuring that each mattress meets the desired quality standards.

Methods for Making Latex Mattresses

In addition to the main methods mentioned above, there are also other techniques used for making latex mattresses. These include the use of different additives, such as graphite or copper, for added cooling or antimicrobial properties. Some manufacturers also use a vacuum seal process to compress the mattress and make it easier to ship.

Latex Mattress Manufacturing Equipment

To produce high-quality latex mattresses, manufacturers use specialized equipment such as vulcanizers, which heat and cure the latex foam. They also use precision cutting machines to ensure accuracy and consistency in the size and shape of the foam. Some manufacturers also have their own testing equipment to ensure the durability and quality of their mattresses.

Latex Mattress Production Line

The production line for latex mattresses involves various stages, from raw materials to the final product. This includes harvesting and processing the latex, pouring and molding the foam, assembling and sewing the mattress, and finally packaging and shipping the product. Each step is crucial in creating a high-quality latex mattress that meets the needs and preferences of consumers.

In conclusion, the manufacturing process of latex mattresses involves a combination of different methods, techniques, and equipment to create a comfortable and supportive sleeping surface. Whether you prefer a firmer or softer feel, there is a latex mattress option for you. So next time you lay down on your latex mattress, you can appreciate the intricate process that went into creating your perfect sleeping companion.

The Benefits of the Manufacturing Method of Latex Mattresses

Quality and Durability

When it comes to choosing a mattress, quality and durability are key factors to consider. This is where the manufacturing method of latex mattresses shines.

Latex mattresses are known for their long-lasting durability and superior quality.

This is because latex is naturally resistant to wear and tear, making it a smart investment for those looking for a long-term mattress solution. The manufacturing process of latex mattresses involves using high-quality materials and advanced technology to ensure that each mattress is built to last.

When it comes to choosing a mattress, quality and durability are key factors to consider. This is where the manufacturing method of latex mattresses shines.

Latex mattresses are known for their long-lasting durability and superior quality.

This is because latex is naturally resistant to wear and tear, making it a smart investment for those looking for a long-term mattress solution. The manufacturing process of latex mattresses involves using high-quality materials and advanced technology to ensure that each mattress is built to last.

Comfort and Support

One of the main reasons why latex mattresses have gained popularity in recent years is because of their unparalleled comfort and support.

The manufacturing method of latex mattresses allows for customized firmness levels and support zones.

This means that each mattress can be tailored to fit the individual needs and preferences of the sleeper. Latex mattresses are also known for their ability to contour to the body, providing optimal pressure relief and spinal alignment. This results in a comfortable and restful sleep, making latex mattresses a top choice for those struggling with back pain or other sleep-related issues.

One of the main reasons why latex mattresses have gained popularity in recent years is because of their unparalleled comfort and support.

The manufacturing method of latex mattresses allows for customized firmness levels and support zones.

This means that each mattress can be tailored to fit the individual needs and preferences of the sleeper. Latex mattresses are also known for their ability to contour to the body, providing optimal pressure relief and spinal alignment. This results in a comfortable and restful sleep, making latex mattresses a top choice for those struggling with back pain or other sleep-related issues.

Environmentally Friendly

In today's world, more and more people are becoming conscious of their environmental impact and are looking for ways to reduce their carbon footprint.

The manufacturing method of latex mattresses is a more eco-friendly option compared to other mattress materials.

Latex is a renewable and biodegradable material that is sourced from the sap of rubber trees. This means that latex mattresses are not only good for your health but also for the environment. Additionally, the production process of latex mattresses uses fewer chemicals and emissions, making it a greener choice for your home.

In conclusion, the manufacturing method of latex mattresses offers a wide range of benefits that make it a top choice for those in the market for a new mattress. Its quality, comfort, support, and eco-friendly nature make it a smart investment for your sleep and overall well-being. Consider upgrading to a latex mattress and experience the difference for yourself.

In today's world, more and more people are becoming conscious of their environmental impact and are looking for ways to reduce their carbon footprint.

The manufacturing method of latex mattresses is a more eco-friendly option compared to other mattress materials.

Latex is a renewable and biodegradable material that is sourced from the sap of rubber trees. This means that latex mattresses are not only good for your health but also for the environment. Additionally, the production process of latex mattresses uses fewer chemicals and emissions, making it a greener choice for your home.

In conclusion, the manufacturing method of latex mattresses offers a wide range of benefits that make it a top choice for those in the market for a new mattress. Its quality, comfort, support, and eco-friendly nature make it a smart investment for your sleep and overall well-being. Consider upgrading to a latex mattress and experience the difference for yourself.