Latex mattresses have been gaining popularity in recent years due to their comfort, durability, and eco-friendliness. But have you ever wondered how these mattresses are made? In this article, we will take a closer look at the manufacturing process of latex mattresses, from the raw materials to the finished product.Latex Mattresses: The Manufacturing Process

The main raw material used in latex mattresses is, as the name suggests, latex. Latex is a natural substance derived from the sap of rubber trees. This sap is collected and processed to create the latex foam used in mattresses. The two main processes used to create latex foam are the Dunlop and Talalay processes.How Latex Mattresses are Made

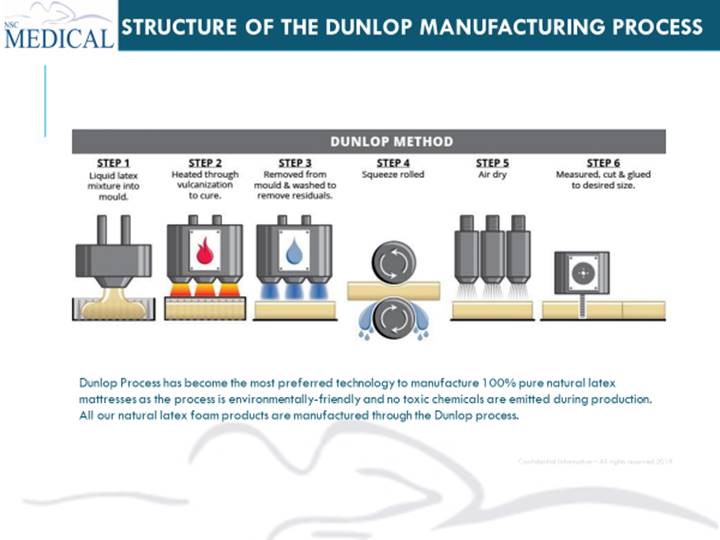

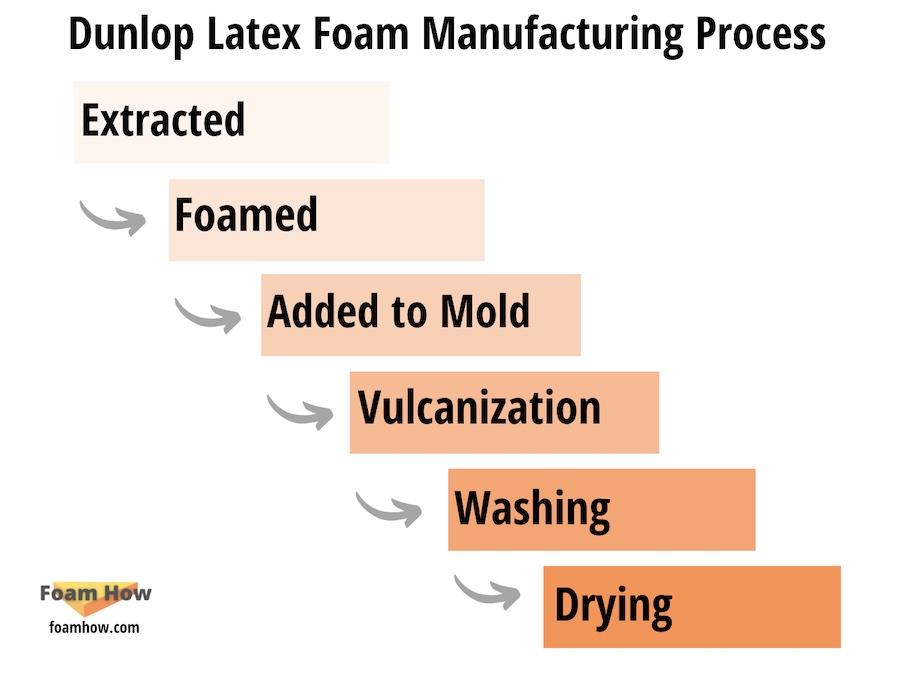

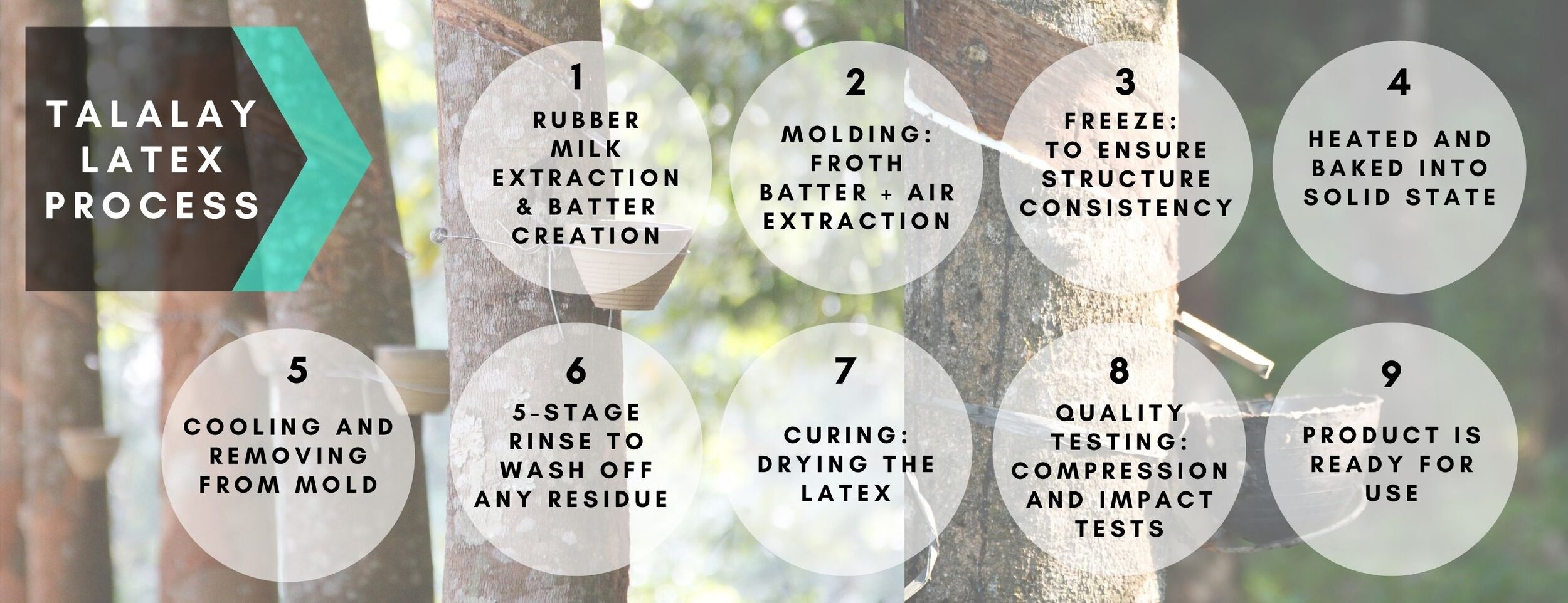

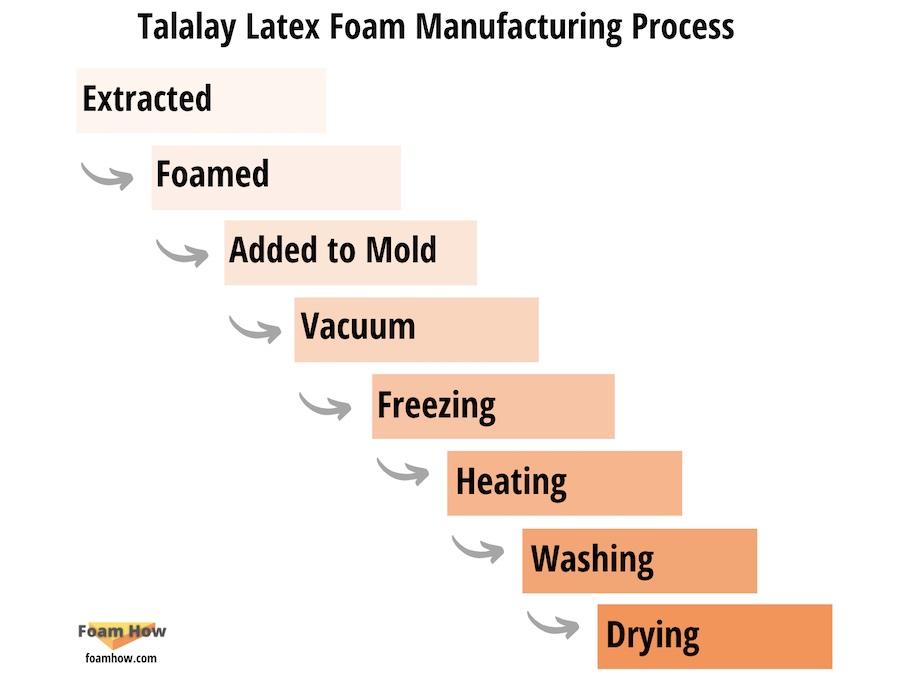

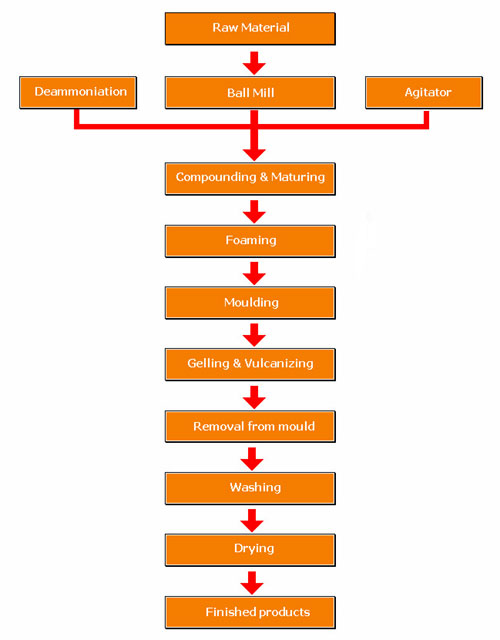

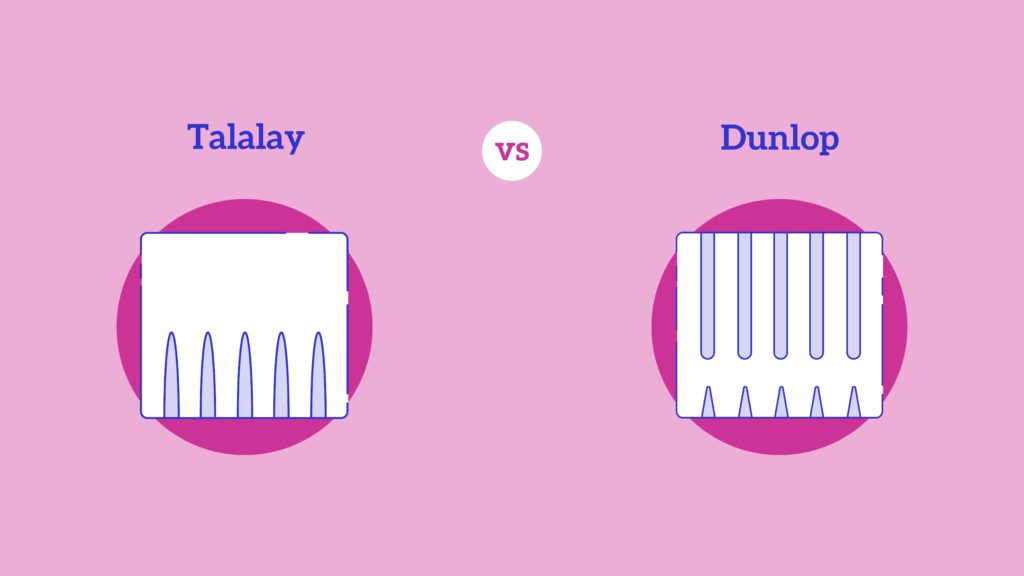

The Dunlop process is the more traditional and simpler method of creating latex foam. It involves pouring the latex sap into a mold, adding air bubbles to create a lighter and more breathable foam, and then heating the foam to solidify it. The foam is then washed and dried before being cut into the desired size and shape for the mattress. The Talalay process, on the other hand, involves a more complex and precise method of creating latex foam. The latex sap is first whipped into a frothy liquid and poured into a mold. The mold is then sealed and placed in a vacuum to remove any air bubbles. The mold is then frozen to stabilize the foam, and finally, it is heated to solidify it. The foam is then washed, dried, and cut into the desired size and shape.Step-by-Step Guide to Manufacturing Latex Mattresses

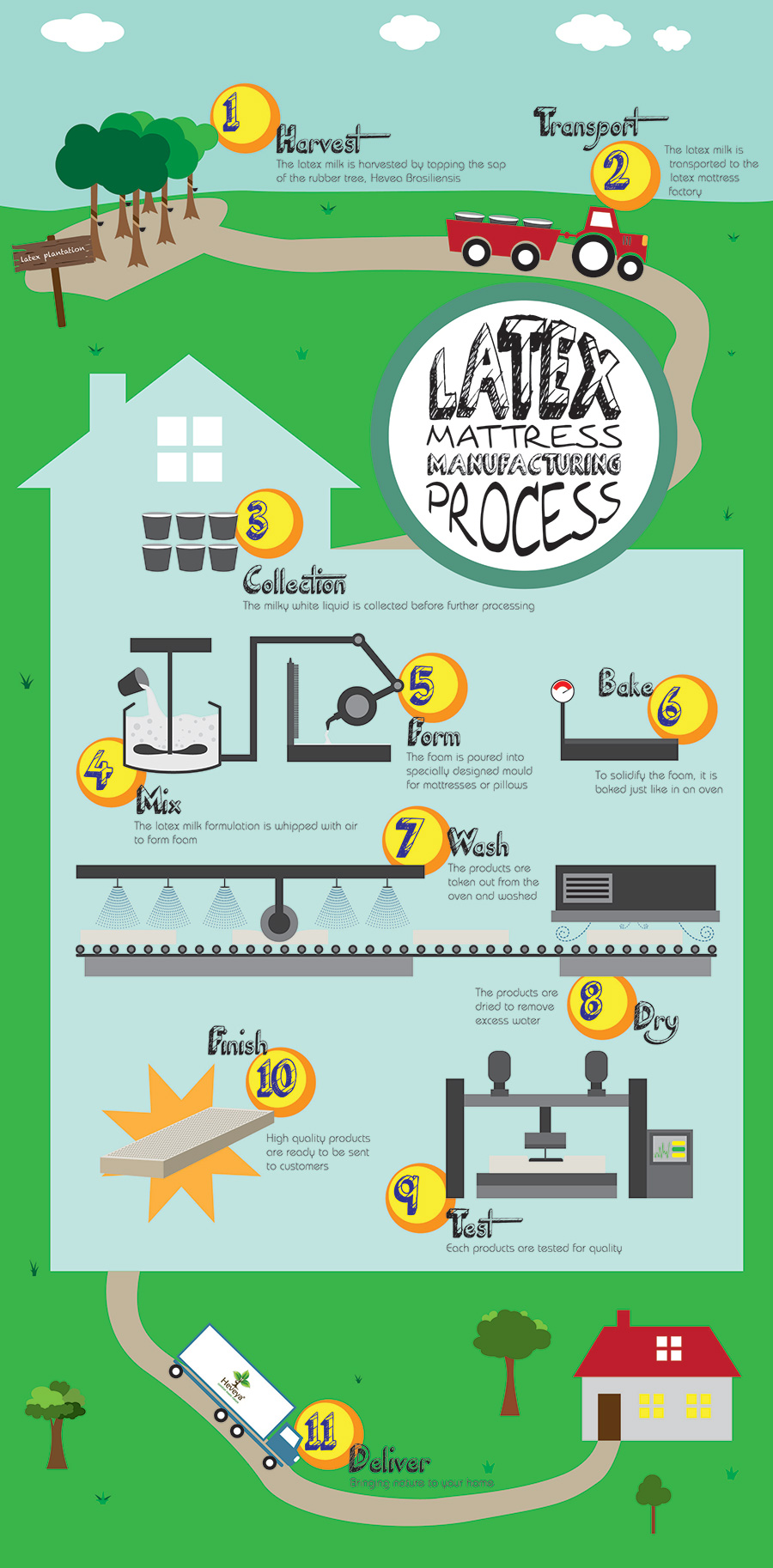

The journey of a latex mattress begins in the rubber tree plantations. These trees are tapped for their sap, which is then collected in buckets. The sap is then transported to a latex processing plant, where it undergoes the Dunlop or Talalay process to create the latex foam. The foam is then sent to a mattress factory, where it is assembled with other materials to create the final product.Latex Mattress Production: From Tree to Bed

The main component of latex foam is rubber, which is known for its elasticity and resilience. This makes latex foam an ideal material for mattresses as it can provide both support and comfort. The Dunlop and Talalay processes also add air bubbles to the foam, making it lighter and more breathable. This allows for better air circulation and temperature regulation, leading to a more comfortable sleep experience.The Science Behind Latex Mattress Manufacturing

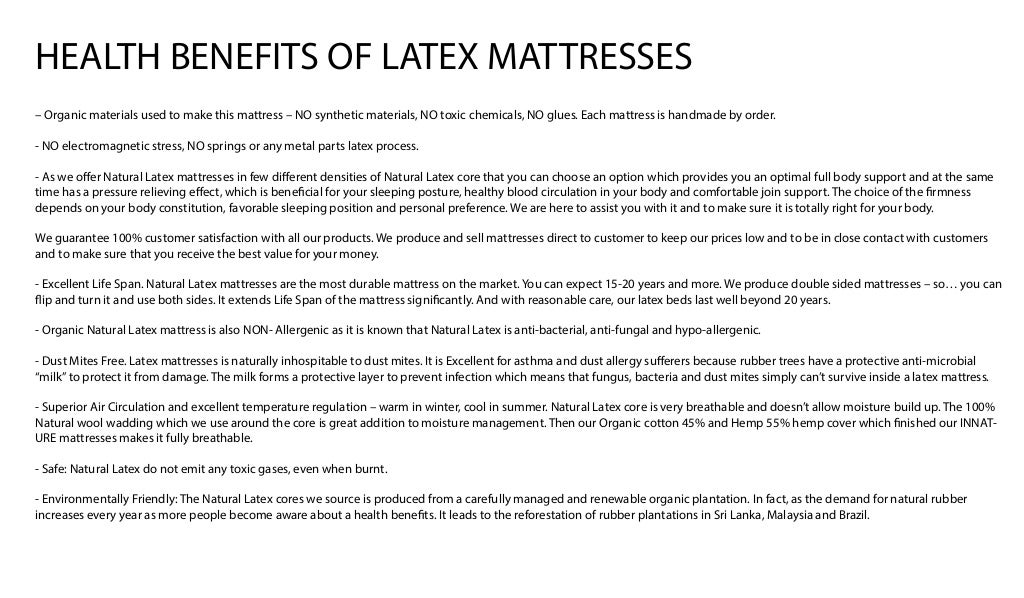

One of the main advantages of latex mattresses is that they are made from natural, renewable materials. Rubber trees are grown in sustainable plantations, and the tapping process does not harm the trees. Additionally, the Dunlop and Talalay processes do not involve the use of any harmful chemicals, making the production of latex mattresses environmentally-friendly.Latex Mattress Manufacturing: A Sustainable Process

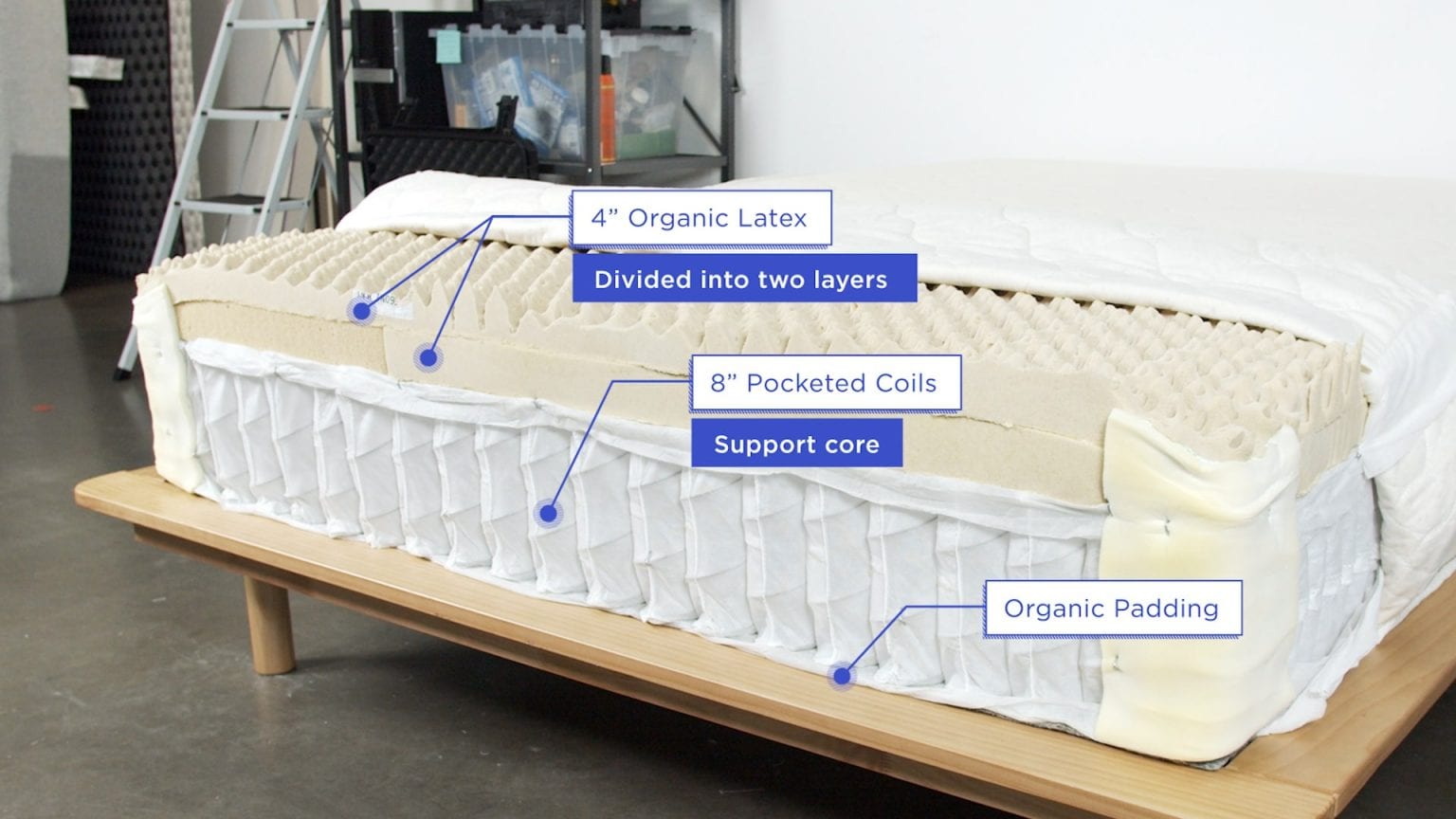

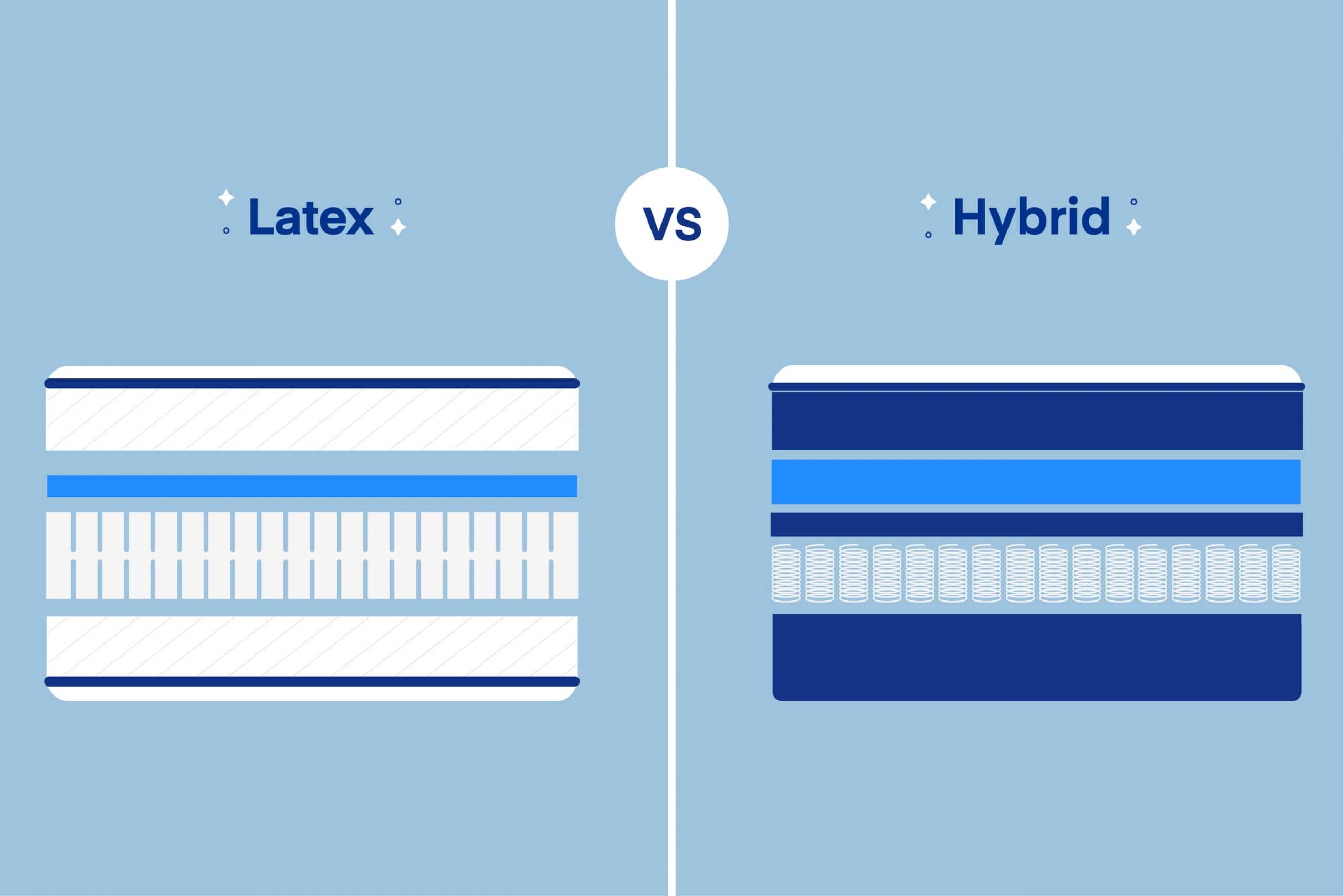

A latex mattress factory is a complex and well-organized facility. The raw materials are carefully sourced and tested for quality before being used in production. The latex foam is then cut, shaped, and layered with other materials such as organic cotton, wool, or bamboo to create the mattress. The finished product is then thoroughly inspected for any defects before being packaged and shipped out.Inside a Latex Mattress Factory

The manufacturing of latex mattresses follows strict quality control measures to ensure that the final product meets industry standards. The latex foam must pass various tests for density, firmness, and durability. The other materials used in the mattress, such as the cover and support layers, also undergo rigorous testing to ensure they meet quality standards.Latex Mattress Production: Quality Control and Standards

While both the Dunlop and Talalay processes produce high-quality latex foam, there are some key differences between the two. Latex mattresses made with the Dunlop process tend to be firmer and more supportive, making them a better choice for those who prefer a firmer mattress. They are also more affordable than Talalay latex mattresses.The Benefits of Choosing a Latex Mattress Made with the Dunlop Process

The Talalay process produces a softer and more luxurious latex foam, making it a popular choice for those who prefer a softer mattress. It also has a more consistent cell structure, making it more durable than Dunlop latex foam. However, Talalay latex mattresses tend to be more expensive due to the complex and precise manufacturing process.Understanding the Talalay Latex Mattress Manufacturing Process

The Importance of Choosing a Quality Latex Mattress for Your Home

Why Should You Consider a Latex Mattress?

When it comes to designing your home, one of the most important aspects to consider is the type of mattress you choose for your bedroom. A good night's sleep is crucial for both physical and mental well-being, and a quality mattress is a key factor in achieving this. With the various options available in the market, it can be overwhelming to decide which mattress is best for you. However,

latex mattresses

stand out as a popular choice due to their unique manufacturing process and the numerous benefits they offer.

When it comes to designing your home, one of the most important aspects to consider is the type of mattress you choose for your bedroom. A good night's sleep is crucial for both physical and mental well-being, and a quality mattress is a key factor in achieving this. With the various options available in the market, it can be overwhelming to decide which mattress is best for you. However,

latex mattresses

stand out as a popular choice due to their unique manufacturing process and the numerous benefits they offer.

The Manufacturing Process of Latex Mattresses

Latex mattresses are made from the sap of rubber trees, which is collected and processed to create a natural foam material. This process involves tapping the trees to extract the milky white sap, which is then whipped into a frothy foam. The foam is then poured into molds and baked to create the desired shape and size of the mattress. This natural process results in a durable, eco-friendly, and hypoallergenic mattress that is suitable for individuals with allergies or respiratory issues.

Latex mattresses are made from the sap of rubber trees, which is collected and processed to create a natural foam material. This process involves tapping the trees to extract the milky white sap, which is then whipped into a frothy foam. The foam is then poured into molds and baked to create the desired shape and size of the mattress. This natural process results in a durable, eco-friendly, and hypoallergenic mattress that is suitable for individuals with allergies or respiratory issues.

The Benefits of Choosing a Latex Mattress

Latex mattresses

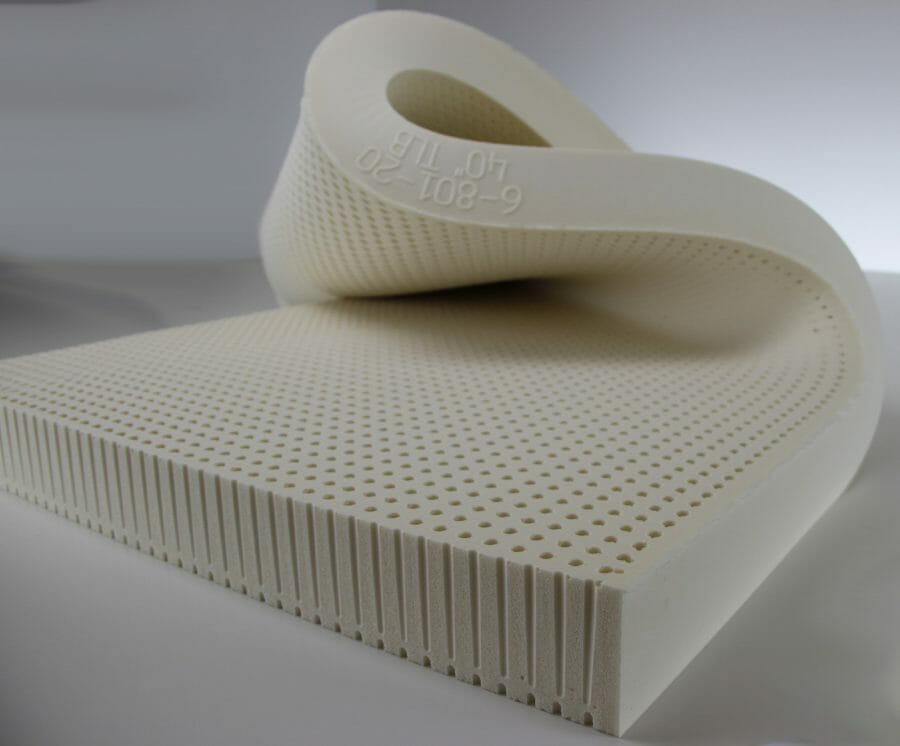

are known for their exceptional comfort and support. The natural foam material conforms to the body's shape, providing pressure relief and promoting proper spinal alignment. This makes them an ideal choice for individuals with back pain or joint issues. Moreover, the open-cell structure of latex foam allows for better air circulation, keeping the mattress cool and comfortable throughout the night.

In addition, latex mattresses are highly durable and can last up to 20 years, making them a great long-term investment for your home. They are also resistant to dust mites, mold, and mildew, making them a healthier option for those with allergies. Furthermore, the natural materials used in the manufacturing process make latex mattresses environmentally friendly and biodegradable, reducing their impact on the environment.

Latex mattresses

are known for their exceptional comfort and support. The natural foam material conforms to the body's shape, providing pressure relief and promoting proper spinal alignment. This makes them an ideal choice for individuals with back pain or joint issues. Moreover, the open-cell structure of latex foam allows for better air circulation, keeping the mattress cool and comfortable throughout the night.

In addition, latex mattresses are highly durable and can last up to 20 years, making them a great long-term investment for your home. They are also resistant to dust mites, mold, and mildew, making them a healthier option for those with allergies. Furthermore, the natural materials used in the manufacturing process make latex mattresses environmentally friendly and biodegradable, reducing their impact on the environment.

Final Thoughts

Investing in a quality latex mattress is a wise decision for your home. Its unique manufacturing process, along with its numerous benefits, makes it a top choice for those looking for a comfortable, supportive, and eco-friendly mattress. So, if you want to improve the quality of your sleep and overall well-being, consider choosing a

latex mattress

for your bedroom.

Investing in a quality latex mattress is a wise decision for your home. Its unique manufacturing process, along with its numerous benefits, makes it a top choice for those looking for a comfortable, supportive, and eco-friendly mattress. So, if you want to improve the quality of your sleep and overall well-being, consider choosing a

latex mattress

for your bedroom.