A kitchen sink is an essential part of any kitchen, and the demand for kitchen sinks is constantly increasing. If you are looking to start a kitchen sink manufacturing plant, you are entering a lucrative market. However, starting a manufacturing plant is not an easy task, and there are many things to consider. In this comprehensive guide, we will explore everything you need to know about starting a kitchen sink manufacturing plant.1. Kitchen Sink Manufacturing Plant: A Comprehensive Guide

The first step in starting a kitchen sink manufacturing plant is to conduct thorough research. This includes understanding the market demand, identifying your target audience, and researching your competitors. You will also need to decide on the type of kitchen sinks you want to manufacture and the materials you will use. Once you have completed your research, you will need to create a business plan. This will include details about your target market, marketing strategies, production process, and financial projections. Having a well-thought-out business plan will increase your chances of success in the long run.2. How to Start a Kitchen Sink Manufacturing Plant

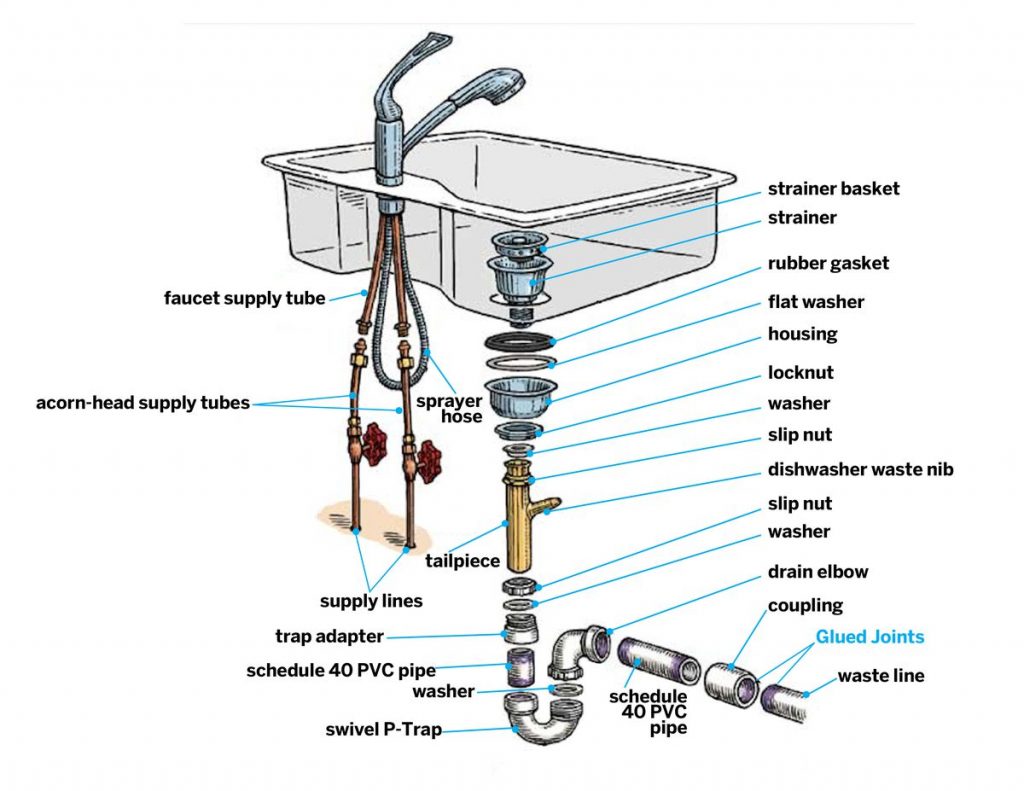

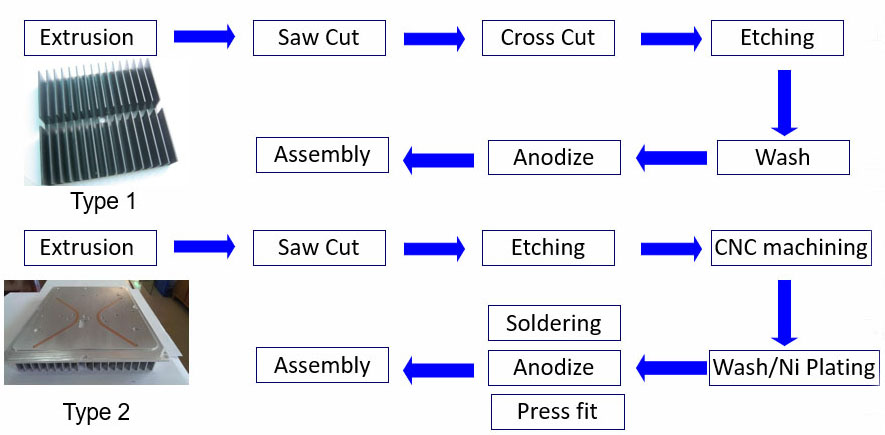

The manufacturing process of kitchen sinks involves several steps. The first step is to design the sink, which includes creating a prototype and testing it for functionality and durability. Once the design is finalized, the production process begins. The production process varies depending on the type of sink and materials used. In general, it involves cutting, shaping, welding, and finishing the sink. Quality control is essential at every stage to ensure that the sink meets industry standards.3. The Process of Manufacturing Kitchen Sinks

There are many kitchen sink manufacturers in the world, each with their own unique selling points. Some of the top manufacturers include Kohler, Blanco, Franke, and Elkay. These manufacturers are known for their high-quality sinks, innovative designs, and sustainable practices. As a new player in the market, it is essential to study these top manufacturers and learn from their success. You can also reach out to them for potential partnerships or collaborations.4. Top Kitchen Sink Manufacturers in the World

Quality control is crucial in kitchen sink manufacturing to ensure that the final product meets industry standards and customer expectations. This involves regular inspections and tests at every stage of the production process. Quality control also involves using high-quality materials and maintaining strict production standards. By prioritizing quality control, you can ensure customer satisfaction and build a strong reputation for your brand in the market.5. The Importance of Quality Control in Kitchen Sink Manufacturing

With the increasing demand for sustainable products, it is essential for kitchen sink manufacturing plants to adopt eco-friendly practices. This includes using recyclable materials, reducing waste and energy consumption, and implementing environmentally-friendly production processes. Not only does this benefit the environment, but it also appeals to eco-conscious consumers and can set your brand apart from competitors.6. Sustainable Practices in Kitchen Sink Manufacturing Plants

The kitchen sink industry is constantly evolving, and as a manufacturer, it is vital to stay updated with the latest trends and innovations. Some current trends in kitchen sink manufacturing include the use of composite materials, smart sinks with advanced features, and customization options for customers. By staying ahead of the curve and incorporating these trends into your manufacturing process, you can attract more customers and stay competitive in the market.7. The Future of Kitchen Sink Manufacturing: Trends and Innovations

The location of your manufacturing plant plays a significant role in the success of your business. It is essential to choose a location that is close to your target market, has a steady supply of skilled labor, and offers favorable tax policies and incentives for manufacturing businesses. You should also consider the cost of land, utilities, and transportation in the chosen location. Conducting thorough research and visiting potential locations can help you make an informed decision.8. Choosing the Right Location for Your Kitchen Sink Manufacturing Plant

Marketing is crucial for any business, and as a kitchen sink manufacturer, you need to reach out to potential customers and build brand awareness. Some effective marketing strategies for a manufacturing business include creating a strong online presence, attending trade shows and exhibitions, and collaborating with home renovation and design influencers. You can also offer discounts and promotions to attract customers and build a loyal customer base.9. How to Market Your Kitchen Sink Manufacturing Business

Like any business, kitchen sink manufacturing comes with its own set of challenges. These may include high production costs, maintaining quality standards, and managing inventory and supply chain. It is essential to have contingency plans in place and constantly evaluate and improve your processes to overcome these challenges. Networking with other manufacturers and seeking guidance from industry experts can also help you overcome challenges and succeed in the long run. In conclusion, starting a kitchen sink manufacturing plant is a challenging yet rewarding venture. By following these tips and continuously improving your processes, you can establish a successful and reputable brand in the market.10. Common Challenges in Kitchen Sink Manufacturing and How to Overcome Them

The Importance of High-Quality Kitchen Sinks in House Design

The Heart of the Home

A kitchen is often considered the heart of a home, and for good reason. It is where meals are prepared, memories are made, and families gather to share their days. With such an important role, it is essential to have a well-designed and functional kitchen. And at the center of every kitchen is the

kitchen sink

.

A kitchen is often considered the heart of a home, and for good reason. It is where meals are prepared, memories are made, and families gather to share their days. With such an important role, it is essential to have a well-designed and functional kitchen. And at the center of every kitchen is the

kitchen sink

.

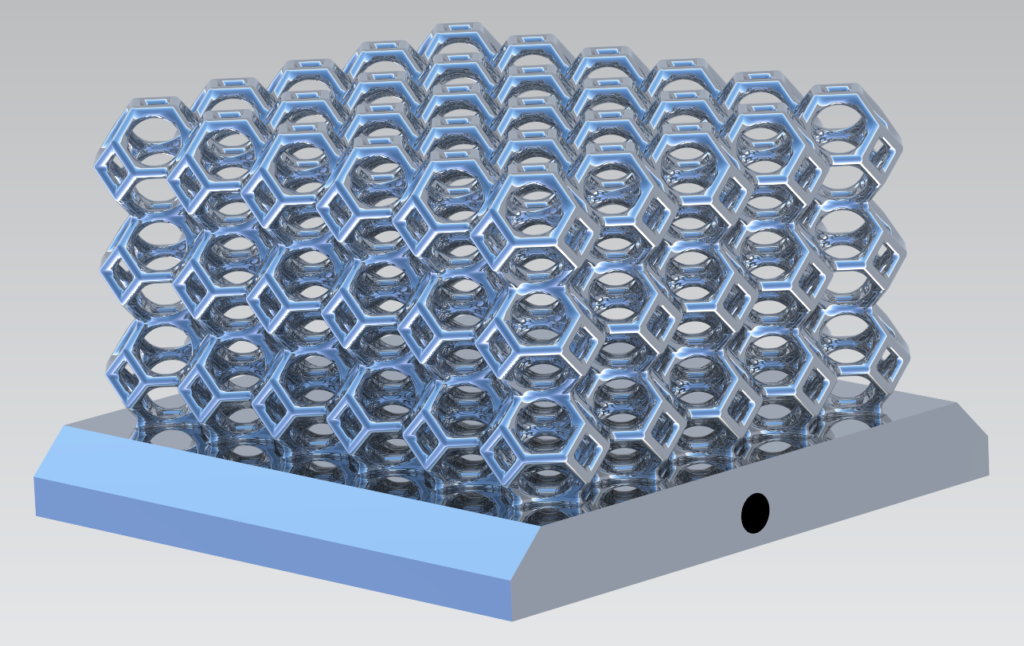

The Manufacturing Process

At a

kitchen sink manufacturing plant

, skilled craftsmen use a combination of technology and traditional techniques to produce high-quality kitchen sinks. Each sink is carefully crafted with precision and attention to detail. The process begins with the selection of materials, such as stainless steel or porcelain, which are then molded and shaped into the desired design. The sinks are then polished to a smooth finish, making them not only aesthetically pleasing but also easy to clean and maintain.

At a

kitchen sink manufacturing plant

, skilled craftsmen use a combination of technology and traditional techniques to produce high-quality kitchen sinks. Each sink is carefully crafted with precision and attention to detail. The process begins with the selection of materials, such as stainless steel or porcelain, which are then molded and shaped into the desired design. The sinks are then polished to a smooth finish, making them not only aesthetically pleasing but also easy to clean and maintain.

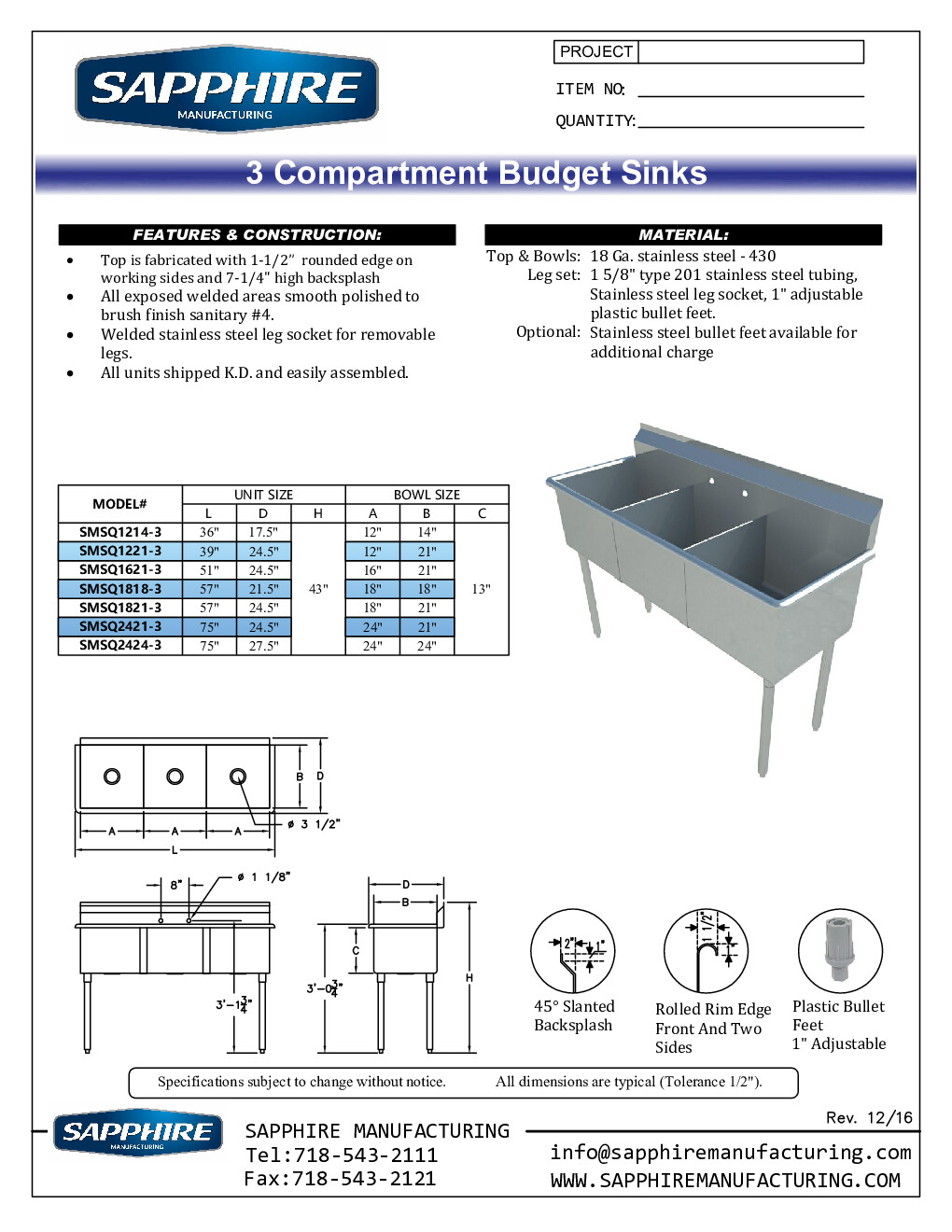

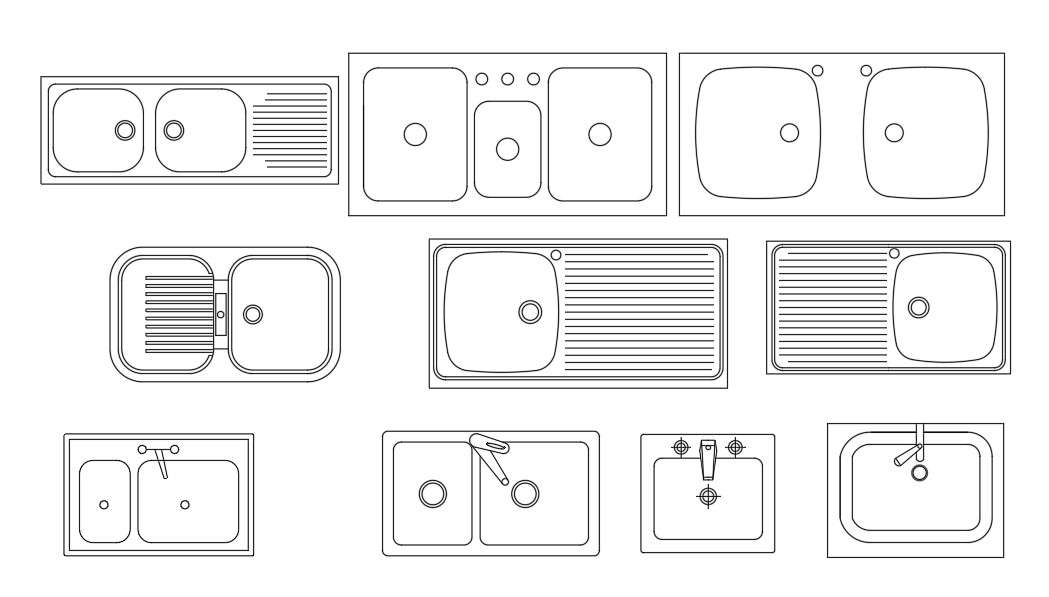

Design Options to Suit Every Home

One of the advantages of a

kitchen sink manufacturing plant

is the wide range of design options available. From traditional farmhouse sinks to sleek and modern designs, there is a sink to suit every style and preference. These sinks can also come in various sizes and configurations, making it possible to find the perfect fit for any kitchen layout.

One of the advantages of a

kitchen sink manufacturing plant

is the wide range of design options available. From traditional farmhouse sinks to sleek and modern designs, there is a sink to suit every style and preference. These sinks can also come in various sizes and configurations, making it possible to find the perfect fit for any kitchen layout.

Durable and Long-Lasting

Investing in a high-quality kitchen sink from a reputable manufacturing plant means investing in a durable and long-lasting product. These sinks are built to withstand the everyday wear and tear of a busy kitchen. They are resistant to scratches, stains, and heat, making them a practical choice for any household.

Investing in a high-quality kitchen sink from a reputable manufacturing plant means investing in a durable and long-lasting product. These sinks are built to withstand the everyday wear and tear of a busy kitchen. They are resistant to scratches, stains, and heat, making them a practical choice for any household.

The Final Touch

A well-designed kitchen sink not only adds functionality but also adds to the overall aesthetic of a kitchen. It is the final touch that ties the room together. With a variety of designs, materials, and finishes to choose from, a kitchen sink can be a statement piece or seamlessly blend in with the rest of the kitchen design.

In conclusion, a

kitchen sink manufacturing plant

plays a crucial role in the design and functionality of a kitchen. With their attention to detail, high-quality materials, and a wide range of design options, they produce sinks that are not only practical but also add to the overall appeal of a kitchen. So, when it comes to designing your dream kitchen, investing in a high-quality kitchen sink is a must.

A well-designed kitchen sink not only adds functionality but also adds to the overall aesthetic of a kitchen. It is the final touch that ties the room together. With a variety of designs, materials, and finishes to choose from, a kitchen sink can be a statement piece or seamlessly blend in with the rest of the kitchen design.

In conclusion, a

kitchen sink manufacturing plant

plays a crucial role in the design and functionality of a kitchen. With their attention to detail, high-quality materials, and a wide range of design options, they produce sinks that are not only practical but also add to the overall appeal of a kitchen. So, when it comes to designing your dream kitchen, investing in a high-quality kitchen sink is a must.

:max_bytes(150000):strip_icc()/Basic-kitchen-sink-types-1821207_color_rev-0b539306b9ef4236a136624ad2a89a4c.jpg)