Japanese kitchen knives have a long history dating back to the ancient samurai warriors. The traditional design of these knives has been passed down for generations, with each knife crafted with precision and intention. The design of these knives is not only functional but also reflects the Japanese culture and values. The traditional Japanese kitchen knife design is characterized by its single-beveled edge, which is sharpened on one side only. This design allows for a sharper and more precise cut, making it ideal for delicate tasks such as slicing sashimi or preparing sushi. The blade is also thinner and lighter compared to Western knives, making it easier to maneuver and control. Another unique feature of Japanese kitchen knives is the handle. The handle is typically made from wood, which is lighter and more comfortable to hold compared to metal handles. The wood is also treated with natural oils to make it water-resistant and more durable. The handle is attached to the blade using a traditional Japanese method called "tang," where the blade extends through the handle for a stronger and more balanced grip.Traditional Japanese Kitchen Knife Design

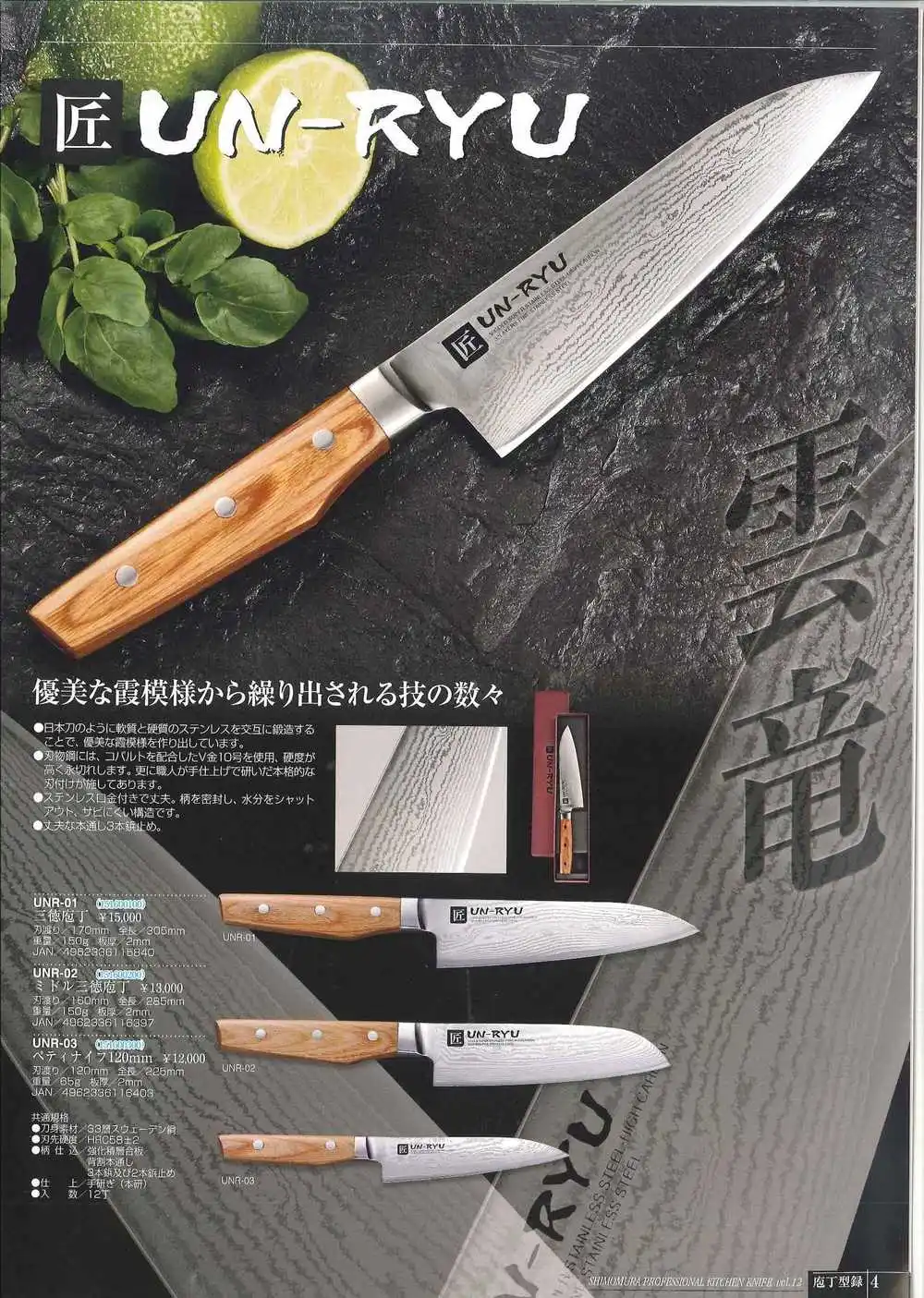

There are several styles of Japanese kitchen knives, each with its own unique purpose and design. The most popular styles include the Gyuto, Santoku, Nakiri, Deba, and Yanagiba. The Gyuto, also known as the "chef's knife," is the most versatile and commonly used Japanese kitchen knife. Its long and curved blade makes it ideal for slicing, dicing, and chopping a wide range of ingredients. The Santoku is a smaller and lighter version of the Gyuto, with a shorter and straighter blade. It is perfect for precise and delicate tasks, such as cutting herbs and vegetables. The Nakiri is a vegetable knife with a straight and thin blade, ideal for cutting and slicing vegetables and fruits. Its flat edge allows for a clean and precise cut without crushing or tearing the ingredients. The Deba is a heavy-duty knife primarily used for cutting and filleting fish. Its thick and sturdy blade can handle the tough scales and bones of fish without damaging the delicate meat. The Yanagiba, also known as the "Sashimi knife," is a long and thin knife used for slicing raw fish for sashimi and sushi. Its single-beveled edge allows for a clean and precise cut, making it a favorite among sushi chefs.Japanese Kitchen Knife Styles

The process of making a Japanese kitchen knife is a meticulous and time-consuming craft. It requires a skilled artisan to create a high-quality and functional knife. The first step in making a Japanese kitchen knife is selecting the right type of steel. The most commonly used steel is high-carbon stainless steel, which is known for its durability and sharpness. The steel is then heated to a high temperature and hammered into shape using traditional methods. Once the blade is formed, it is then sharpened and polished to achieve a razor-sharp edge. The handle is then attached using the tang method, and the knife is honed to perfection. The entire process of making a Japanese kitchen knife can take several days or even weeks, depending on the complexity of the design and the skill of the artisan.Japanese Kitchen Knife Making

There are numerous Japanese kitchen knife brands, each with its own unique style and quality. Some of the most popular brands include Shun, Global, Miyabi, and Masamoto. Shun is known for its high-quality and handcrafted knives made using traditional Japanese techniques. Their knives are known for their sharpness and durability, making them a favorite among professional chefs. Global is known for its modern and sleek designs, with a focus on using high-quality materials and advanced technology in their knife-making process. Their knives are known for their sharpness and precision. Miyabi is a luxury brand known for its handcrafted knives made using traditional Japanese techniques. Their knives are made with the highest quality materials and are known for their exquisite design and performance. Masamoto is one of the oldest and most respected knife-making brands in Japan. Their knives are known for their traditional design and exceptional quality, making them a top choice among professional chefs.Japanese Kitchen Knife Brands

Japanese kitchen knives are made with a variety of materials, with the most commonly used being stainless steel and carbon steel. Stainless steel is a popular choice for its durability and resistance to rust and corrosion. However, it is not as sharp as carbon steel and requires more frequent sharpening. Carbon steel is known for its sharpness and ability to hold an edge for a long time. However, it is more prone to rust and corrosion, and requires more maintenance. Some Japanese kitchen knives also feature a Damascus pattern, created by layering different types of steel to create a unique and beautiful design on the blade.Japanese Kitchen Knife Materials

Sharpening a Japanese kitchen knife requires skill and precision. The traditional method of sharpening involves using a whetstone, also known as a "sharpening stone." The whetstone is soaked in water for a few minutes before use, and the blade is then placed at an angle on the stone and moved back and forth to create a sharp edge. This process requires patience and practice to achieve the desired sharpness. Some modern Japanese kitchen knives also come with a ceramic honing rod, which can be used to maintain the sharpness of the blade between sharpening sessions.Japanese Kitchen Knife Sharpening Techniques

Maintaining a Japanese kitchen knife is essential to ensure its longevity and performance. Proper maintenance involves regularly cleaning, sharpening, and storing the knife correctly. After each use, the knife should be washed and dried immediately to prevent rust and corrosion. It is also recommended to hand wash the knife and avoid using harsh chemicals or abrasive sponges. Sharpening the knife regularly is also crucial to maintain its sharpness and cutting ability. It is essential to use the proper sharpening technique and not over-sharpen the knife, as this can damage the blade. Storing the knife correctly is also essential. It is recommended to store the knife in a knife block or sheath to protect the blade and prevent accidents.Japanese Kitchen Knife Maintenance

The handle of a Japanese kitchen knife is not only functional but also adds to the overall aesthetic of the knife. The most commonly used materials for handles are wood and plastic. Wooden handles are the traditional choice, with various types of wood used, such as magnolia, ebony, and rosewood. These handles are lightweight and comfortable to hold, making them ideal for prolonged use. Plastic handles, also known as "Western-style" handles, are a more modern choice and are often used in mass-produced knives. They are durable and easy to clean but may not have the same level of comfort as wooden handles.Japanese Kitchen Knife Handles

Japanese kitchen knives come in various blade shapes, each designed for a specific purpose and type of cutting technique. The most common blade shapes include the Gyuto, Santoku, Deba, and Yanagiba, which were mentioned earlier. Other popular blade shapes include the Usuba, which is a vegetable knife with a straight and thin blade, and the Kiritsuke, which is a multi-purpose knife with a long and straight blade.Japanese Kitchen Knife Blade Shapes

The cutting techniques used with Japanese kitchen knives are just as important as the design and materials of the knife itself. The most commonly used techniques include the push cut, where the blade is pushed forward in a slicing motion, and the pull cut, where the blade is pulled backward in a slicing motion. These techniques require a precise and controlled movement to achieve a clean and precise cut. Other techniques include the chop cut, where the blade is brought down in a chopping motion, and the rocking cut, where the blade is moved back and forth in a rocking motion. These techniques are commonly used for larger and tougher ingredients.Japanese Kitchen Knife Cutting Techniques

The History of Japanese Kitchen Knife Design

From Samurai Swords to Culinary Tools

Japanese kitchen knives are known for their exceptional quality, precision, and craftsmanship. But what many may not know is that the design of these knives has a rich history deeply rooted in Japanese culture. The origins of Japanese kitchen knife design can be traced back to the samurai swords used by warriors in feudal Japan.

Samurai swords were not only weapons, but also symbols of honor and status in Japanese society.

The process of creating these swords, known as "katana," involved a specialized method of forging and shaping the blade, resulting in a strong and sharp edge. This same technique and attention to detail would later be applied to the production of Japanese kitchen knives.

With the decline of the samurai class in the late 1800s, swordsmiths shifted their focus to creating knives for everyday use.

The demand for high-quality kitchen knives grew as Japanese cuisine gained popularity around the world.

This led to the development of various types of Japanese kitchen knives, each with a specific purpose and design.

One of the most popular types of Japanese kitchen knives is the

gyuto

, which translates to "cow sword." This knife is a chef's best friend, with its long and versatile blade that can be used for various cutting techniques. Another well-known type is the

santoku

, which means "three virtues" and is known for its ability to slice, dice, and mince with ease.

But it's not just the shape and functionality of Japanese kitchen knives that sets them apart.

The materials used and the traditional forging process also play a significant role in their design.

Japanese knives are typically made from high-carbon steel, which allows for a sharper and more durable edge. The forging process involves heating and hammering the steel multiple times to create a strong and precise blade.

In recent years,

modern technology and design have also influenced the evolution of Japanese kitchen knives.

While traditional methods are still used, there has been an increase in the use of machinery and newer materials to enhance the performance and aesthetics of these knives.

In conclusion, the design of Japanese kitchen knives is a perfect blend of tradition, culture, and innovation.

Each knife is a work of art, crafted with precision and attention to detail, making it not only a useful tool in the kitchen but also a symbol of Japanese craftsmanship.

Whether you are a professional chef or a home cook, a Japanese kitchen knife is a must-have in any kitchen.

Japanese kitchen knives are known for their exceptional quality, precision, and craftsmanship. But what many may not know is that the design of these knives has a rich history deeply rooted in Japanese culture. The origins of Japanese kitchen knife design can be traced back to the samurai swords used by warriors in feudal Japan.

Samurai swords were not only weapons, but also symbols of honor and status in Japanese society.

The process of creating these swords, known as "katana," involved a specialized method of forging and shaping the blade, resulting in a strong and sharp edge. This same technique and attention to detail would later be applied to the production of Japanese kitchen knives.

With the decline of the samurai class in the late 1800s, swordsmiths shifted their focus to creating knives for everyday use.

The demand for high-quality kitchen knives grew as Japanese cuisine gained popularity around the world.

This led to the development of various types of Japanese kitchen knives, each with a specific purpose and design.

One of the most popular types of Japanese kitchen knives is the

gyuto

, which translates to "cow sword." This knife is a chef's best friend, with its long and versatile blade that can be used for various cutting techniques. Another well-known type is the

santoku

, which means "three virtues" and is known for its ability to slice, dice, and mince with ease.

But it's not just the shape and functionality of Japanese kitchen knives that sets them apart.

The materials used and the traditional forging process also play a significant role in their design.

Japanese knives are typically made from high-carbon steel, which allows for a sharper and more durable edge. The forging process involves heating and hammering the steel multiple times to create a strong and precise blade.

In recent years,

modern technology and design have also influenced the evolution of Japanese kitchen knives.

While traditional methods are still used, there has been an increase in the use of machinery and newer materials to enhance the performance and aesthetics of these knives.

In conclusion, the design of Japanese kitchen knives is a perfect blend of tradition, culture, and innovation.

Each knife is a work of art, crafted with precision and attention to detail, making it not only a useful tool in the kitchen but also a symbol of Japanese craftsmanship.

Whether you are a professional chef or a home cook, a Japanese kitchen knife is a must-have in any kitchen.