A popular choice for kitchen tables, a polyurethane finish offers a durable and long-lasting protective coat for your furniture. It creates a hard and glossy surface that is resistant to scratches, water, and stains. This makes it ideal for high-traffic areas like the kitchen, where spills and messes are common. The finish also brings out the natural beauty of the wood, giving it a smooth and polished look. Polyurethane finishes are available in both oil-based and water-based formulas. While the oil-based option provides a richer and deeper color, the water-based one dries faster and has a less potent smell. Whichever you choose, make sure to follow the instructions on the can carefully for the best results.1. Polyurethane finish for kitchen table

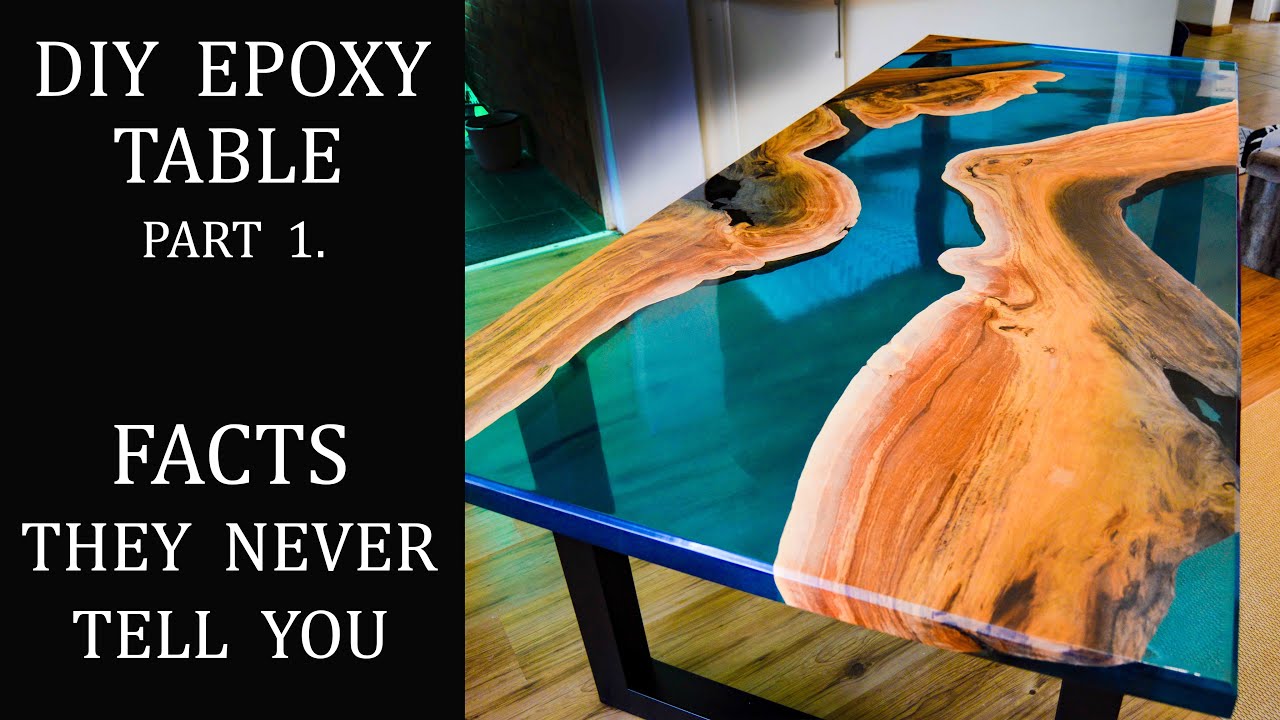

If you're looking for a high-gloss, glass-like finish for your kitchen table, epoxy resin is the way to go. This finish is created by mixing two components, resin and hardener, which chemically react to form a hard and durable surface. It is highly resistant to heat, scratches, and chemicals, making it a popular choice for kitchen tables. Epoxy resin finishes come in a variety of colors and can be customized with different additives such as glitter or pigments. It is important to note that this finish requires careful preparation and application, as any imperfections or bubbles can be difficult to fix once the resin has cured.2. Epoxy resin finish for kitchen table

Lacquer finishes have been used for centuries to give furniture a smooth, glossy, and durable coating. This finish is created by dissolving nitrocellulose in a solvent and then spraying it onto the wood. The solvent evaporates quickly, leaving behind a hard and smooth surface. Lacquer finishes are available in a wide range of colors and can be applied in multiple coats for a deeper shine. However, it is important to note that lacquer is not as resistant to heat and water as other finishes and may require maintenance over time.3. Lacquer finish for kitchen table

Similar to lacquer, varnish is a popular choice for giving furniture a shiny and protective coat. It is created by mixing resin, oil, and a solvent, and can be applied using a brush or spray. Varnish creates a hard and durable surface that is resistant to scratches and water, making it suitable for kitchen tables. One of the benefits of varnish is that it can be easily reapplied to refresh the finish or repair any damage. However, it can take longer to dry compared to other finishes, and multiple coats may be needed to achieve the desired level of shine.4. Varnish finish for kitchen table

Shellac is a natural resin extracted from the secretions of the lac bug, making it a popular choice for those looking for an eco-friendly finish. It is applied using a brush or pad and creates a hard and glossy surface that is resistant to water and alcohol. It also has the added benefit of being able to be easily repaired or refreshed with additional coats. However, shellac is not as durable as other finishes and is more susceptible to damage from heat and scratches. It is also not recommended for outdoor use or in areas with high humidity.5. Shellac finish for kitchen table

Tung oil is a natural finishing product made from the pressed seeds of the tung tree. It is known for its ability to enhance the natural beauty of wood, giving it a warm and rich color. Tung oil penetrates deep into the wood, creating a durable and water-resistant finish. This finish is easy to apply and can be reapplied over time for maintenance. However, it does take longer to dry compared to other finishes and may require multiple coats for a desired level of shine.6. Tung oil finish for kitchen table

Water-based finishes are a popular choice for those looking for a low-odor and environmentally friendly option. These finishes are created by mixing resin and water, and can be applied using a brush or spray. They dry quickly and create a clear and durable surface that is resistant to scratches, chemicals, and heat. Water-based finishes are available in a variety of sheens, from matte to high-gloss, and can be easily cleaned up with soap and water. However, they may not bring out the natural warmth and beauty of wood as much as other finishes.7. Water-based finish for kitchen table

Oil-based finishes, such as linseed or tung oil, are known for their ability to enhance the natural grain and color of wood. These finishes penetrate deep into the wood, creating a durable and water-resistant surface. They also give the wood a warm and rich color and can be easily reapplied for maintenance over time. However, oil-based finishes can take longer to dry compared to other finishes and may require multiple coats for the desired level of shine. They also have a strong odor and may require proper ventilation during application.8. Oil-based finish for kitchen table

Conversion varnish finishes are a popular choice for commercial and high-traffic areas due to their durability and resistance to chemicals, water, and heat. They are created by mixing two components, a resin and a catalyst, and require careful application techniques. Conversion varnish finishes provide a high-gloss and hard surface that is easy to clean and maintain. However, they can be challenging to apply and may require professional help for the best results.9. Conversion varnish finish for kitchen table

Wax finishes are a traditional and easy-to-apply option for giving your kitchen table a smooth and protective coat. They are created by combining a solvent, such as mineral spirits, with natural waxes, such as beeswax or carnauba wax. This creates a soft and smooth surface that is resistant to water and stains. Wax finishes are available in a variety of colors and can be buffed to achieve a desired level of shine. However, they may require regular maintenance and reapplication to keep the surface protected and looking its best.10. Wax finish for kitchen table

The Importance of a Hard Finish for Your Kitchen Table

Maintaining a Beautiful and Functional Kitchen

One of the most important elements in any kitchen design is the kitchen table. It is not only a place for meals, but also a central gathering spot for family and friends. This is why it is crucial to choose a kitchen table with a

hard finish

that can withstand the wear and tear of daily use. A

hard finish

not only adds to the aesthetic appeal of your kitchen, but also makes it more durable and functional.

One of the most important elements in any kitchen design is the kitchen table. It is not only a place for meals, but also a central gathering spot for family and friends. This is why it is crucial to choose a kitchen table with a

hard finish

that can withstand the wear and tear of daily use. A

hard finish

not only adds to the aesthetic appeal of your kitchen, but also makes it more durable and functional.

Protecting Against Scratches and Stains

A kitchen table with a

hard finish

is essential in protecting against scratches and stains. The kitchen is a high-traffic area and the table is constantly exposed to spills, hot dishes, and sharp utensils. A

hard finish

acts as a barrier, preventing these damages from penetrating the surface of the table and leaving permanent marks. This not only keeps your kitchen looking beautiful, but also saves you the hassle and expense of constantly having to refinish or replace your table.

A kitchen table with a

hard finish

is essential in protecting against scratches and stains. The kitchen is a high-traffic area and the table is constantly exposed to spills, hot dishes, and sharp utensils. A

hard finish

acts as a barrier, preventing these damages from penetrating the surface of the table and leaving permanent marks. This not only keeps your kitchen looking beautiful, but also saves you the hassle and expense of constantly having to refinish or replace your table.

Easy Maintenance

Not only does a

hard finish

protect against scratches and stains, but it also makes for easy maintenance. With a simple wipe down, spills and stains can be easily removed without any damage to the table. This is especially important in a kitchen, where spills and messes are inevitable. A

hard finish

also makes cleaning up after meals a breeze, allowing you to spend more time enjoying your kitchen and less time cleaning it.

Not only does a

hard finish

protect against scratches and stains, but it also makes for easy maintenance. With a simple wipe down, spills and stains can be easily removed without any damage to the table. This is especially important in a kitchen, where spills and messes are inevitable. A

hard finish

also makes cleaning up after meals a breeze, allowing you to spend more time enjoying your kitchen and less time cleaning it.

Added Durability

A kitchen table with a

hard finish

is designed to withstand the daily wear and tear of a busy kitchen. It is able to resist scratches, dents, and heat, making it a durable and long-lasting investment. This is especially important for families with children, who tend to be rough on furniture. A

hard finish

ensures that your kitchen table will not only look beautiful, but also remain functional for years to come.

A kitchen table with a

hard finish

is designed to withstand the daily wear and tear of a busy kitchen. It is able to resist scratches, dents, and heat, making it a durable and long-lasting investment. This is especially important for families with children, who tend to be rough on furniture. A

hard finish

ensures that your kitchen table will not only look beautiful, but also remain functional for years to come.

/cdn.vox-cdn.com/uploads/chorus_image/image/65890720/tung_oil.0.jpg)