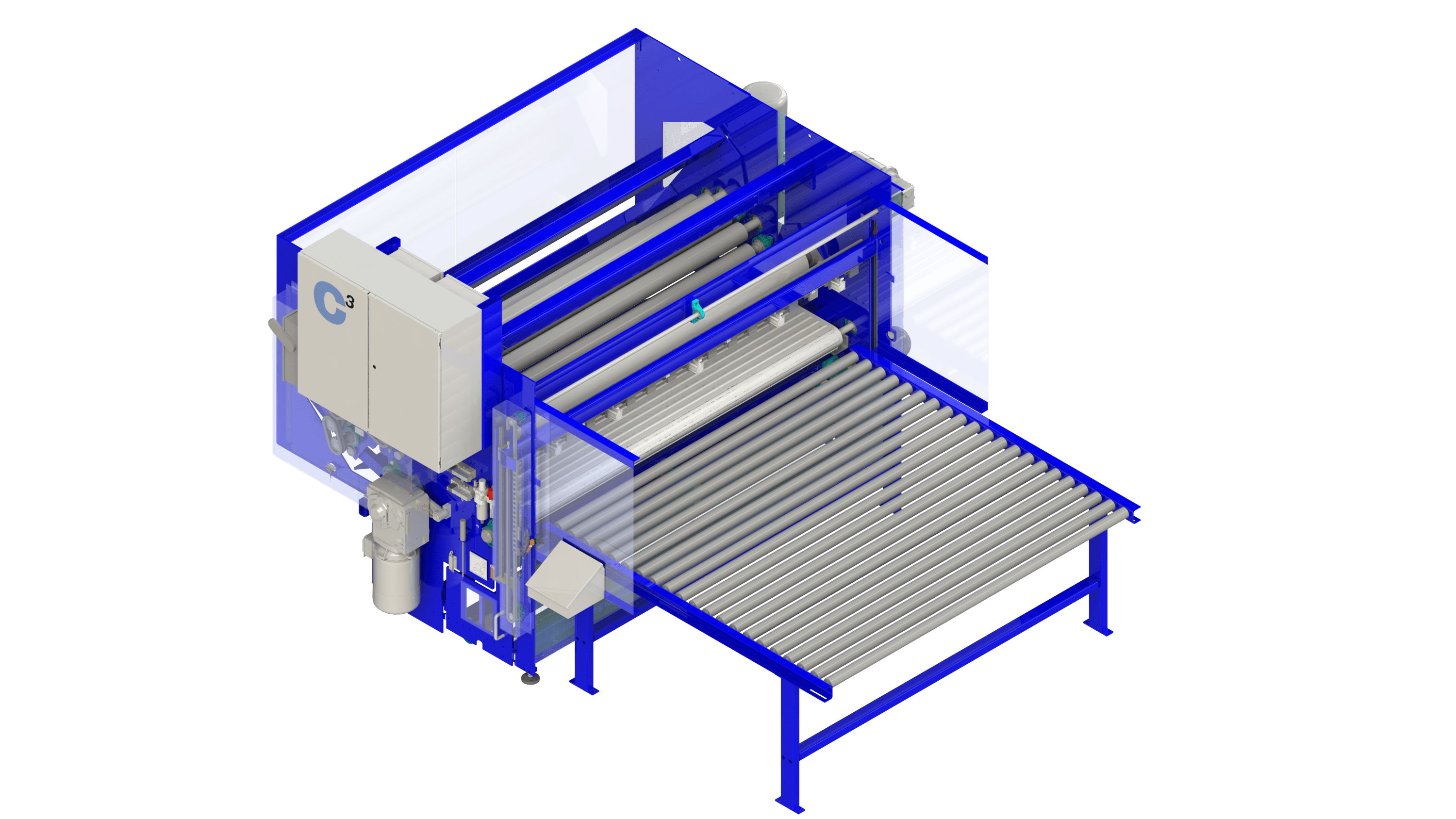

Introduction to Foam Mattress Roller Machines

Foam mattresses have become increasingly popular in recent years for their comfort and support. However, the manufacturing process of these mattresses involves a lot of pressure and compression. This is where foam mattress roller machines come in. These machines are essential for ensuring that foam mattresses are compressed and rolled into a compact and convenient size for shipping and storage.

The Importance of Foam Mattress Roller Machines

Without foam mattress roller machines, it would be nearly impossible to compress and roll foam mattresses effectively. These machines are designed to apply the perfect amount of pressure and compression to the foam, resulting in a tightly rolled and compact mattress. This is crucial for shipping and storage purposes, as it allows for more efficient use of space and lowers transportation costs.

The Different Types of Foam Mattress Roller Machines

There are several types of foam mattress roller machines available on the market, each with its own unique features and benefits. Some of the most common include foam mattress rolling machines, foam mattress roll machines, foam mattress compression machines, foam mattress compactors, and foam mattress compression rollers. Each of these machines serves a specific purpose in the foam mattress manufacturing process, and it's important to choose the right one for your needs.

Foam Mattress Rolling Machines

Foam mattress rolling machines are designed to compress and roll foam mattresses into a compact size for storage and transportation. These machines are typically automated and use rollers to apply pressure and compression to the foam. They are also equipped with sensors to ensure that the foam is evenly compressed, resulting in a tightly rolled mattress.

Foam Mattress Roll Machines

Similar to foam mattress rolling machines, foam mattress roll machines also use rollers to compress and roll foam mattresses. However, these machines are manually operated, making them a more affordable option for smaller businesses. They are also more compact in size, making them easier to store when not in use.

Foam Mattress Compression Machines

Foam mattress compression machines are specifically designed to compress and compact foam mattresses. These machines use hydraulic pressure to compress the foam, resulting in a tightly compressed mattress. They are ideal for businesses that produce a large volume of foam mattresses and need a more efficient and automated solution.

Foam Mattress Compactors

Foam mattress compactors are similar to foam mattress compression machines, but they are more heavy-duty and designed for larger and thicker mattresses. These machines use powerful compression to compact the foam, resulting in a smaller and more manageable size for storage and transportation.

Foam Mattress Compression Rollers

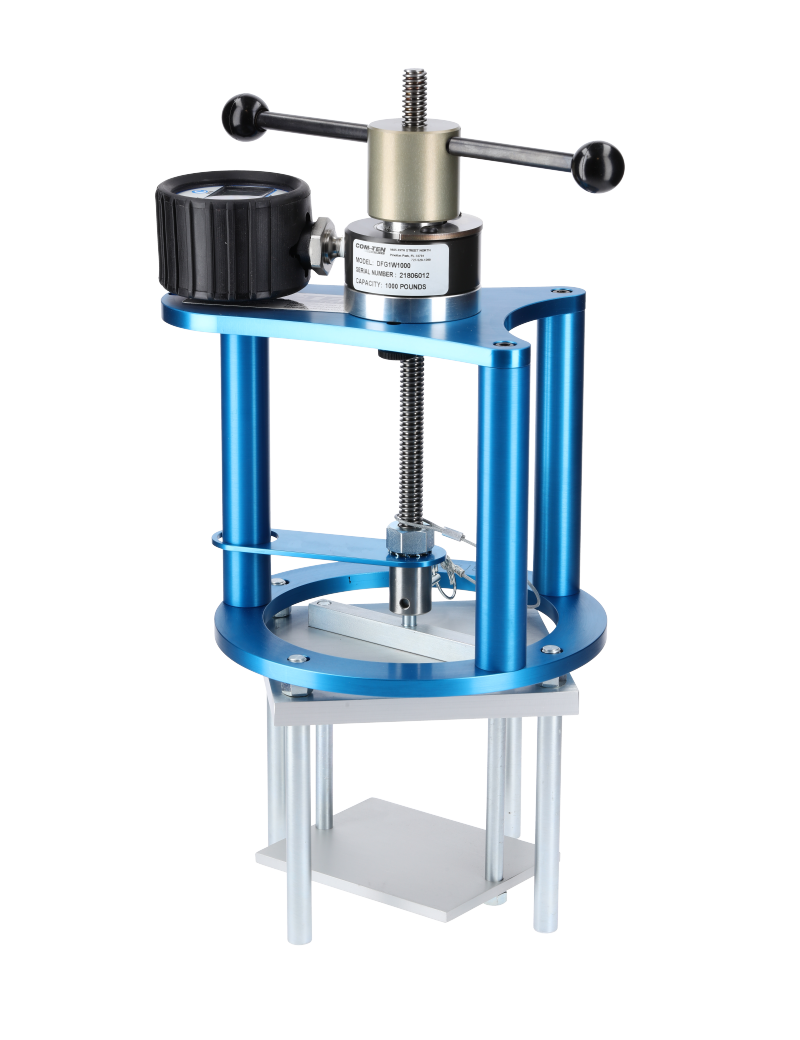

Foam mattress compression rollers are essential for ensuring that the foam is evenly compressed during the rolling process. These rollers are typically made of high-quality materials and are designed to withstand high levels of pressure. They play a crucial role in the overall efficiency and effectiveness of foam mattress rolling machines.

Foam Mattress Rolling Press

Foam mattress rolling presses are another type of machine used in the foam mattress manufacturing process. These machines use a combination of pressure and heat to compress and roll the foam. They are ideal for businesses that produce a large volume of foam mattresses and need a more efficient and automated solution.

Foam Mattress Compression Press

Similar to foam mattress rolling presses, foam mattress compression presses also use a combination of pressure and heat to compress and compact foam mattresses. These machines are designed to handle thicker and heavier mattresses, making them ideal for businesses that produce a variety of mattress sizes.

The Benefits of Using a Foam Mattress Roller Machine for House Design

Efficiency and Precision in Design

When it comes to designing a house, precision and efficiency are key factors. Every detail matters and can greatly impact the overall look and feel of the space. That's where a

foam mattress roller machine

comes in handy. This innovative technology allows for precise and accurate rolling of foam mattresses, ensuring that every inch is evenly compressed. This level of precision is crucial in creating a solid foundation for your house design. It ensures that your furniture, flooring, and other design elements will fit seamlessly and provide a cohesive look.

When it comes to designing a house, precision and efficiency are key factors. Every detail matters and can greatly impact the overall look and feel of the space. That's where a

foam mattress roller machine

comes in handy. This innovative technology allows for precise and accurate rolling of foam mattresses, ensuring that every inch is evenly compressed. This level of precision is crucial in creating a solid foundation for your house design. It ensures that your furniture, flooring, and other design elements will fit seamlessly and provide a cohesive look.

Time and Cost Savings

In the world of house design, time is money. The longer it takes to complete a project, the more money you are spending on labor and materials. With a

foam mattress roller machine

, you can save both time and cost. The machine is designed to work quickly and efficiently, reducing the time it takes to compress foam mattresses. This means you can complete your house design projects faster, allowing you to take on more projects and increase your profits. Additionally, by using a foam mattress roller machine, you can reduce waste and save money on materials, making it a cost-effective solution for your house design needs.

In the world of house design, time is money. The longer it takes to complete a project, the more money you are spending on labor and materials. With a

foam mattress roller machine

, you can save both time and cost. The machine is designed to work quickly and efficiently, reducing the time it takes to compress foam mattresses. This means you can complete your house design projects faster, allowing you to take on more projects and increase your profits. Additionally, by using a foam mattress roller machine, you can reduce waste and save money on materials, making it a cost-effective solution for your house design needs.

Improved Comfort and Durability

A key aspect of house design is creating a comfortable and durable living space. When it comes to furniture and mattresses, a

foam mattress roller machine

can greatly enhance these qualities. By evenly compressing foam mattresses, the machine helps to eliminate any lumps or uneven spots, creating a more comfortable and supportive surface for sleeping and sitting. Additionally, the compressed foam is more durable and less likely to sag or lose its shape over time, ensuring that your house design will stand the test of time.

A key aspect of house design is creating a comfortable and durable living space. When it comes to furniture and mattresses, a

foam mattress roller machine

can greatly enhance these qualities. By evenly compressing foam mattresses, the machine helps to eliminate any lumps or uneven spots, creating a more comfortable and supportive surface for sleeping and sitting. Additionally, the compressed foam is more durable and less likely to sag or lose its shape over time, ensuring that your house design will stand the test of time.

Conclusion

In conclusion, a

foam mattress roller machine

is a valuable tool for any house design project. Its precision, time and cost savings, and improved comfort and durability make it an essential piece of equipment for creating the perfect living space. With its ability to compress foam mattresses efficiently and accurately, you can achieve a flawless foundation for your house design, making it a must-have for any professional designer or homeowner. Invest in a foam mattress roller machine and take your house design to the next level.

In conclusion, a

foam mattress roller machine

is a valuable tool for any house design project. Its precision, time and cost savings, and improved comfort and durability make it an essential piece of equipment for creating the perfect living space. With its ability to compress foam mattresses efficiently and accurately, you can achieve a flawless foundation for your house design, making it a must-have for any professional designer or homeowner. Invest in a foam mattress roller machine and take your house design to the next level.

2011/masonair(1).jpg)

:max_bytes(150000):strip_icc()/modern-farmhouse-kitchen-ideas-4147983-hero-6e296df23de941f58ad4e874fefbc2a3.jpg)