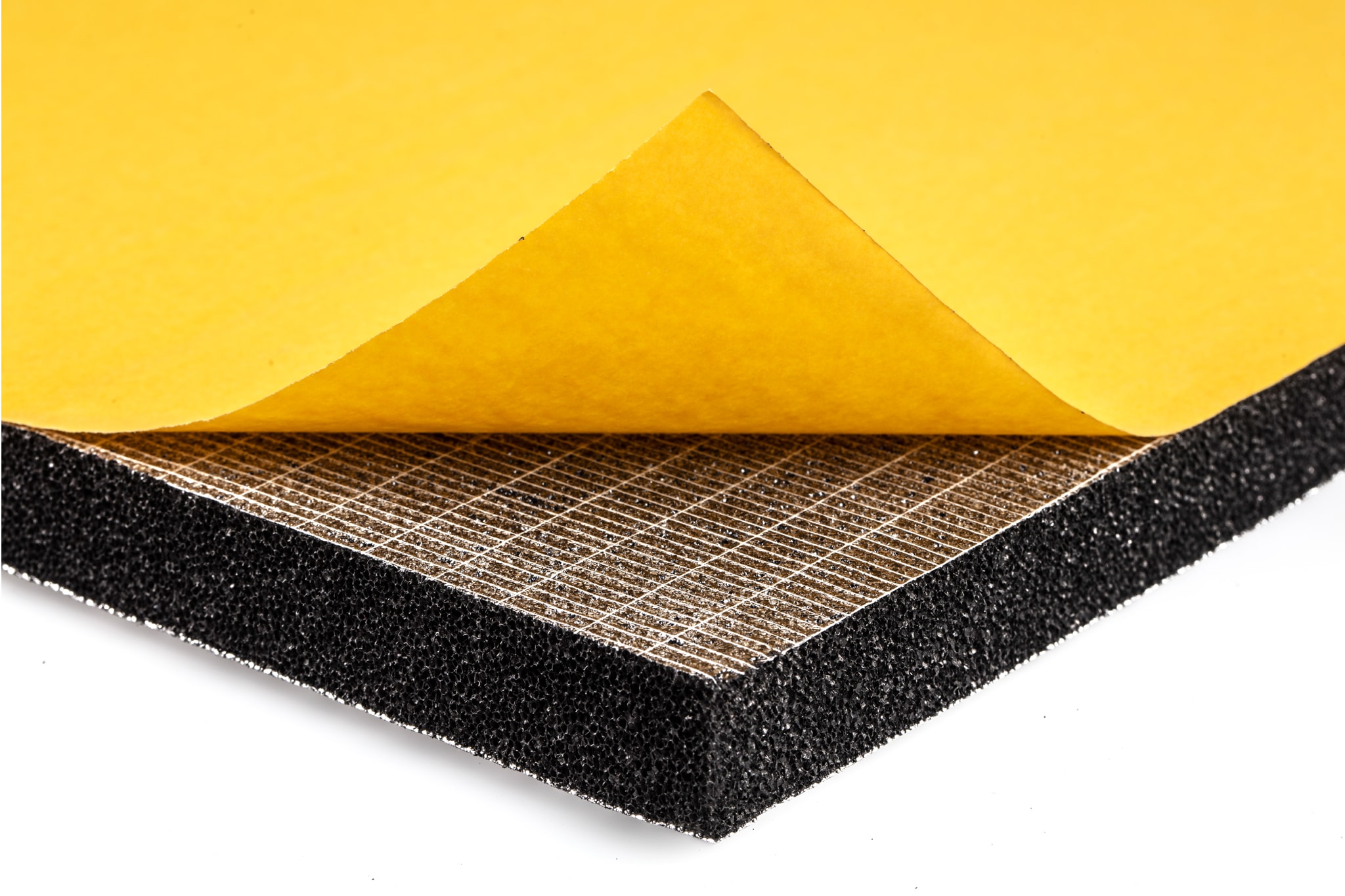

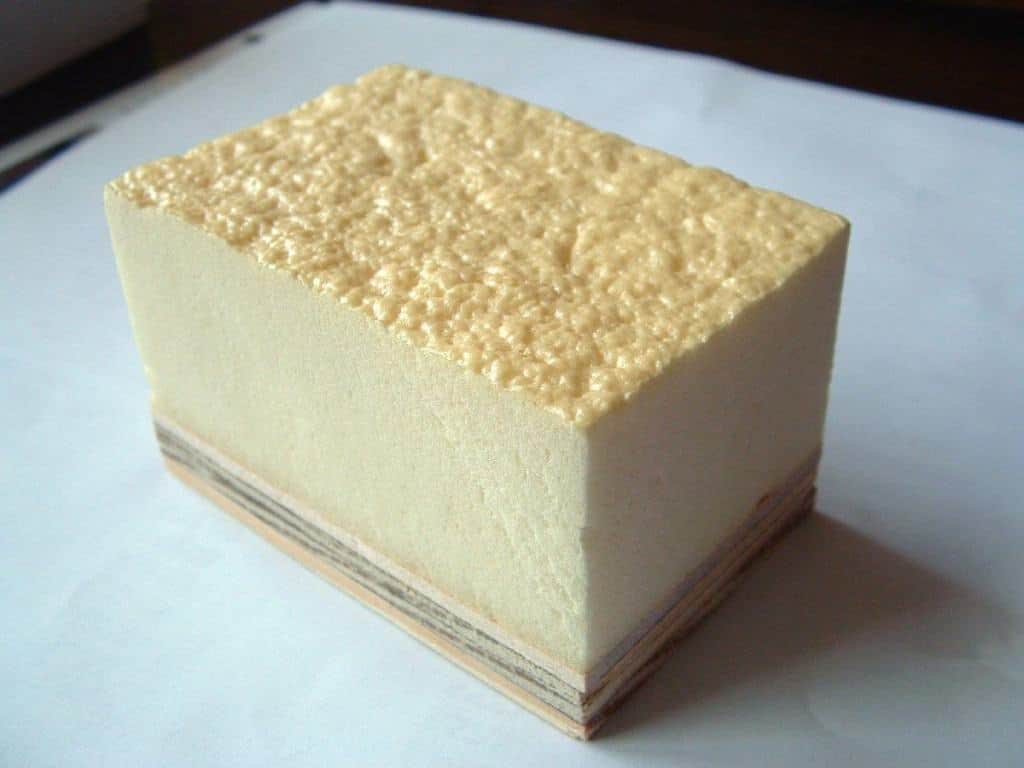

Polyurethane foam is the most commonly used material in foam mattress production. It is a type of synthetic foam that is created through a chemical reaction between polyol and diisocyanate. This foam is known for its resilience, support, and durability, making it a preferred choice for foam mattress manufacturers.1. Polyurethane Foam: The Foundation of Foam Mattresses

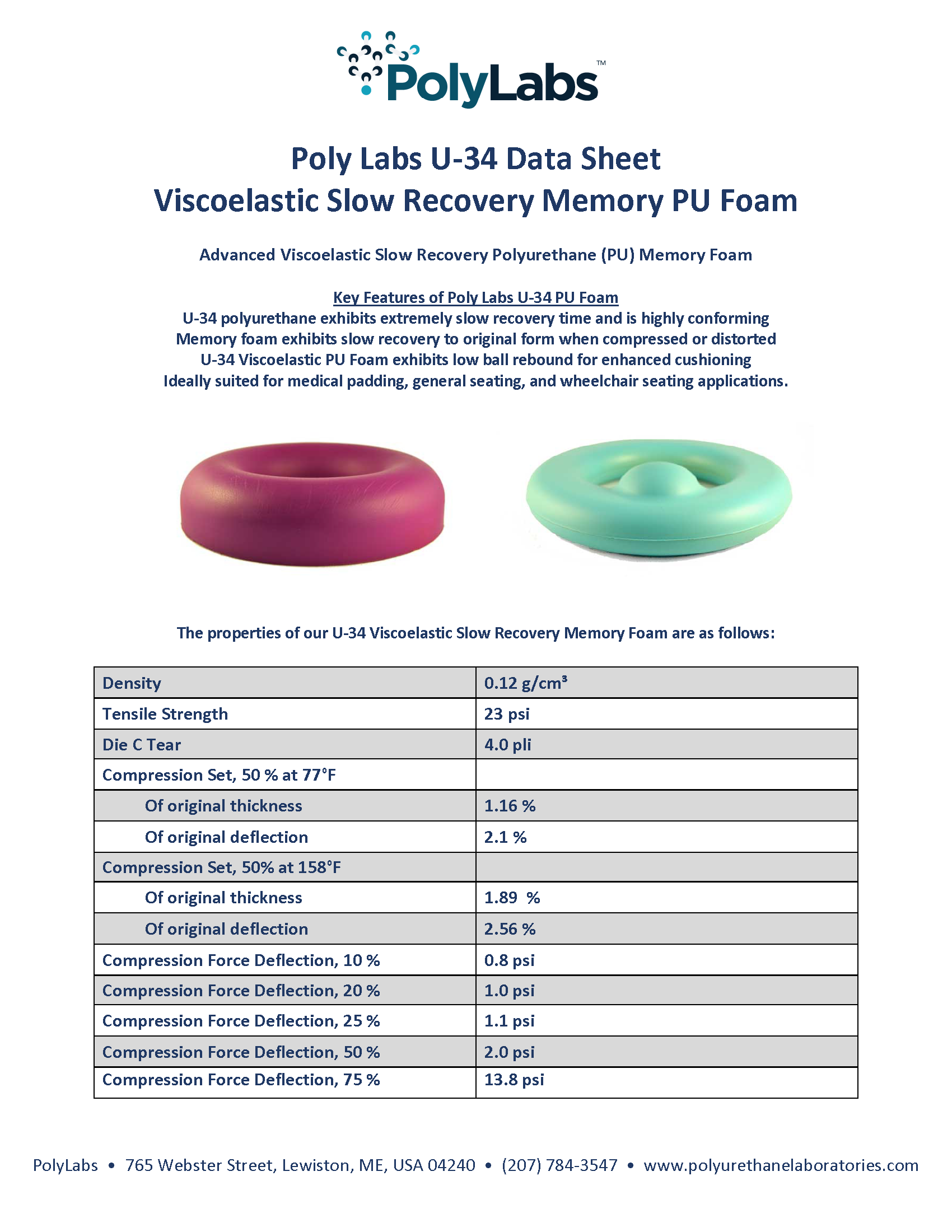

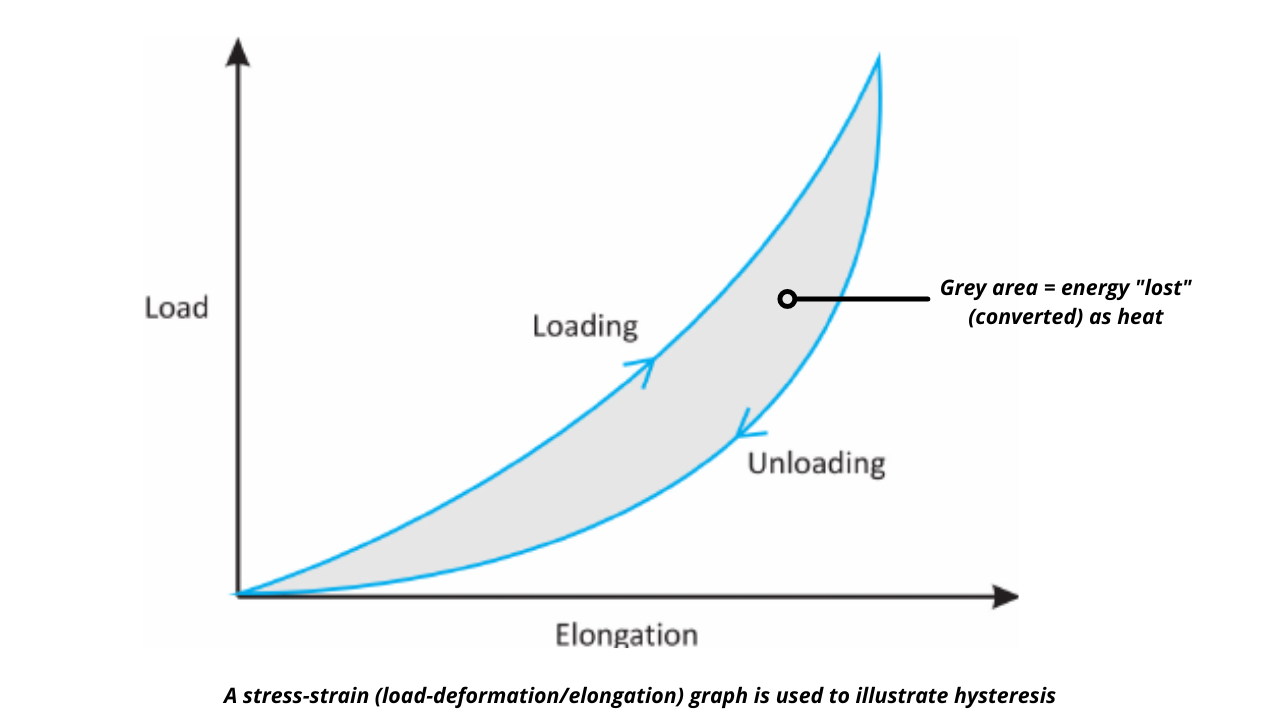

Memory foam, also known as viscoelastic foam, is a special type of polyurethane foam that has the ability to mold to the shape of your body. This unique feature makes memory foam a popular choice for foam mattress buyers, as it provides customized support and pressure relief for a more comfortable sleep.2. Memory Foam: A Contouring Comfort for a Better Sleep

Viscoelastic foam, or memory foam, is made up of polyurethane foam mixed with additional chemicals to create its unique properties. These added chemicals allow the foam to respond to heat and pressure, creating the contouring and supportive qualities that make memory foam so desirable in foam mattresses.3. Viscoelastic Foam: The Science Behind Memory Foam

Foam mattresses are made entirely of foam materials, with polyurethane foam and memory foam being the main components. This combination of materials allows foam mattresses to offer both comfort and support, making them a popular choice for those seeking a good night's sleep.4. Foam Mattresses: Comfort and Support in One Package

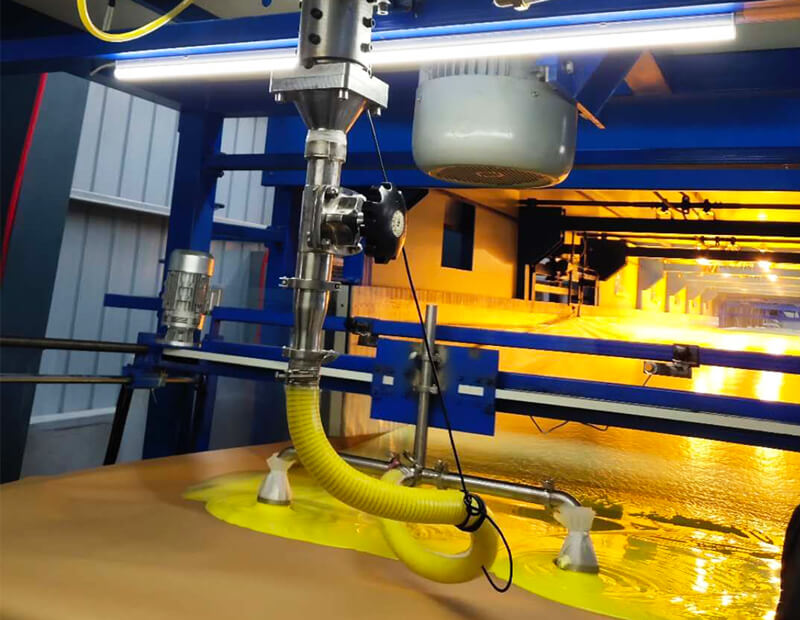

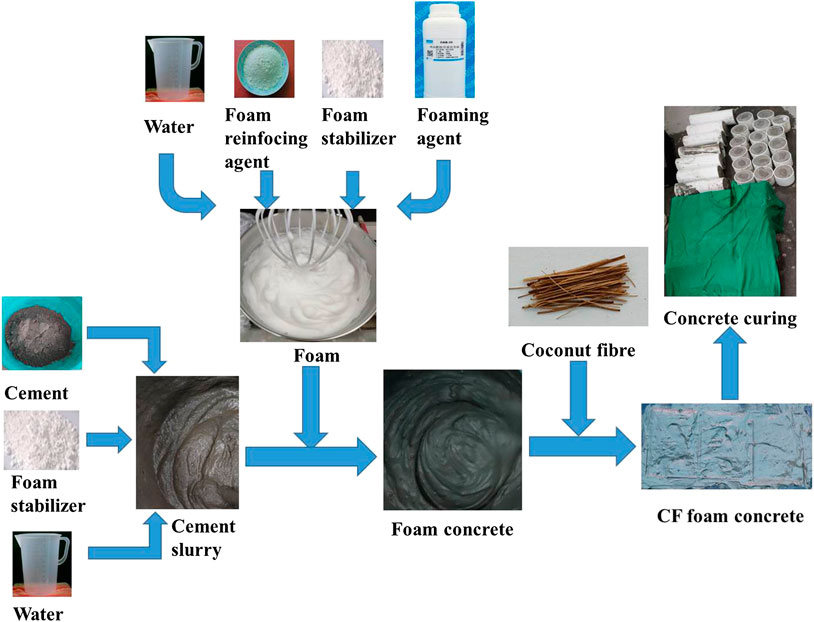

The production of foam involves a series of chemical reactions that require precise measurements and controlled conditions. The main reaction that takes place is between polyol and diisocyanate, which creates the polyurethane foam used in foam mattresses.5. Foam Production: A Complex Process of Chemical Reactions

Foam manufacturing is a process that utilizes both science and technology to produce high-quality foam materials. In addition to the chemical reactions, foam manufacturing also involves the use of specialized machinery and equipment to create foams with different densities, firmness levels, and properties.6. Foam Manufacturing: Combining Science and Technology

The chemicals used in foam production are essential for creating foams with different properties and characteristics. These chemicals can include surfactants, blowing agents, catalysts, and flame retardants, among others. Each chemical plays a specific role in the foam production process.7. Foam Chemicals: The Building Blocks of Foam Production

In addition to the main chemicals used in foam production, there are also other ingredients that are added to enhance the foam's quality and performance. These ingredients can include additives for improved airflow, fillers for added support, and stabilizers for increased durability.8. Foam Ingredients: The Key to Comfort and Durability

The foam production process involves turning a liquid mixture of chemicals into a solid foam material. This process requires carefully controlled conditions, including temperature, pressure, and humidity, to ensure the foam's proper formation and properties.9. Foam Production Process: From Liquid to Solid

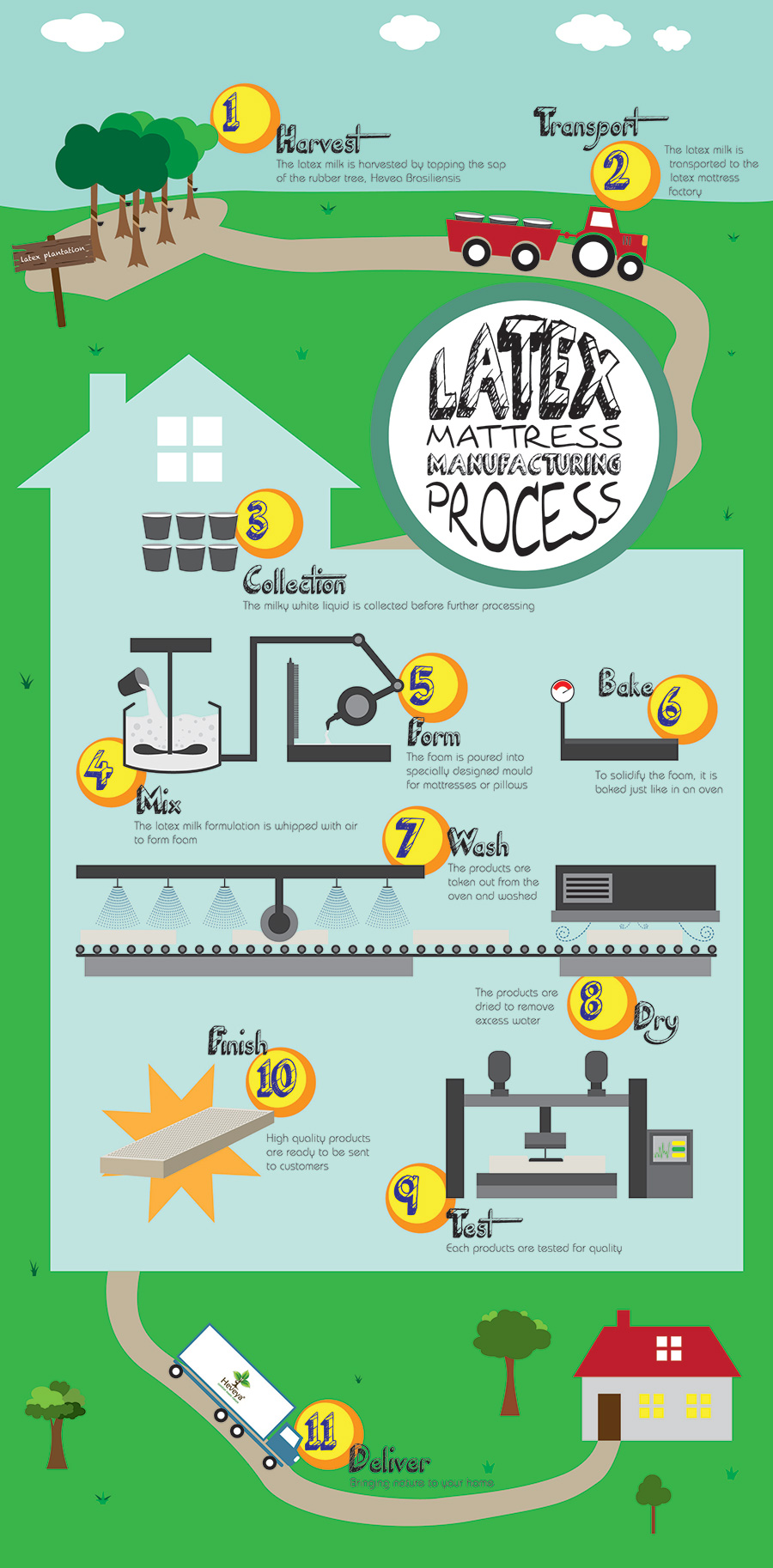

The foam manufacturing process is not only focused on creating comfortable mattresses but also on making them sustainable. Many foam manufacturers are now using eco-friendly materials and processes, such as plant-based foams and reduced chemical emissions, to produce foam mattresses that are better for both the environment and consumers.10. Foam Manufacturing Process: Creating Comfortable and Sustainable Mattresses

The Impact of Chemicals Used in Foam Mattresses on House Design

Understanding Foam Mattresses

Foam mattresses have gained popularity in recent years due to their comfort and support. They are made from a combination of polyurethane foam, memory foam, and other chemicals. These mattresses are known for their ability to conform to the body's shape, providing a comfortable and personalized sleeping experience. However, the production of foam mattresses involves the use of various chemicals, which can have both positive and negative effects on house design.

Foam mattresses have gained popularity in recent years due to their comfort and support. They are made from a combination of polyurethane foam, memory foam, and other chemicals. These mattresses are known for their ability to conform to the body's shape, providing a comfortable and personalized sleeping experience. However, the production of foam mattresses involves the use of various chemicals, which can have both positive and negative effects on house design.

The Negative Effects of Chemicals

Chemicals used in the production of foam mattresses

can release harmful gases such as volatile organic compounds (VOCs), which can cause respiratory problems, allergies, and skin irritation. These gases can linger in the air for a long time, affecting the indoor air quality of a house and potentially causing health issues for its occupants. Additionally, some of these chemicals are known to be carcinogenic, which can have long-term effects on the health of individuals.

Chemicals used in the production of foam mattresses

can release harmful gases such as volatile organic compounds (VOCs), which can cause respiratory problems, allergies, and skin irritation. These gases can linger in the air for a long time, affecting the indoor air quality of a house and potentially causing health issues for its occupants. Additionally, some of these chemicals are known to be carcinogenic, which can have long-term effects on the health of individuals.

The Positive Effects of Chemicals

Despite the negative effects, the use of chemicals in foam mattresses also has some positive impacts on house design. These chemicals help to make the mattresses fire-resistant, reducing the risk of fire hazards in homes. They also contribute to the durability and longevity of foam mattresses, making them a long-term investment for a house. Furthermore, the use of chemicals in foam mattresses allows for customization, as manufacturers can adjust the level of firmness and support to cater to individual needs.

Despite the negative effects, the use of chemicals in foam mattresses also has some positive impacts on house design. These chemicals help to make the mattresses fire-resistant, reducing the risk of fire hazards in homes. They also contribute to the durability and longevity of foam mattresses, making them a long-term investment for a house. Furthermore, the use of chemicals in foam mattresses allows for customization, as manufacturers can adjust the level of firmness and support to cater to individual needs.

Alternative Options

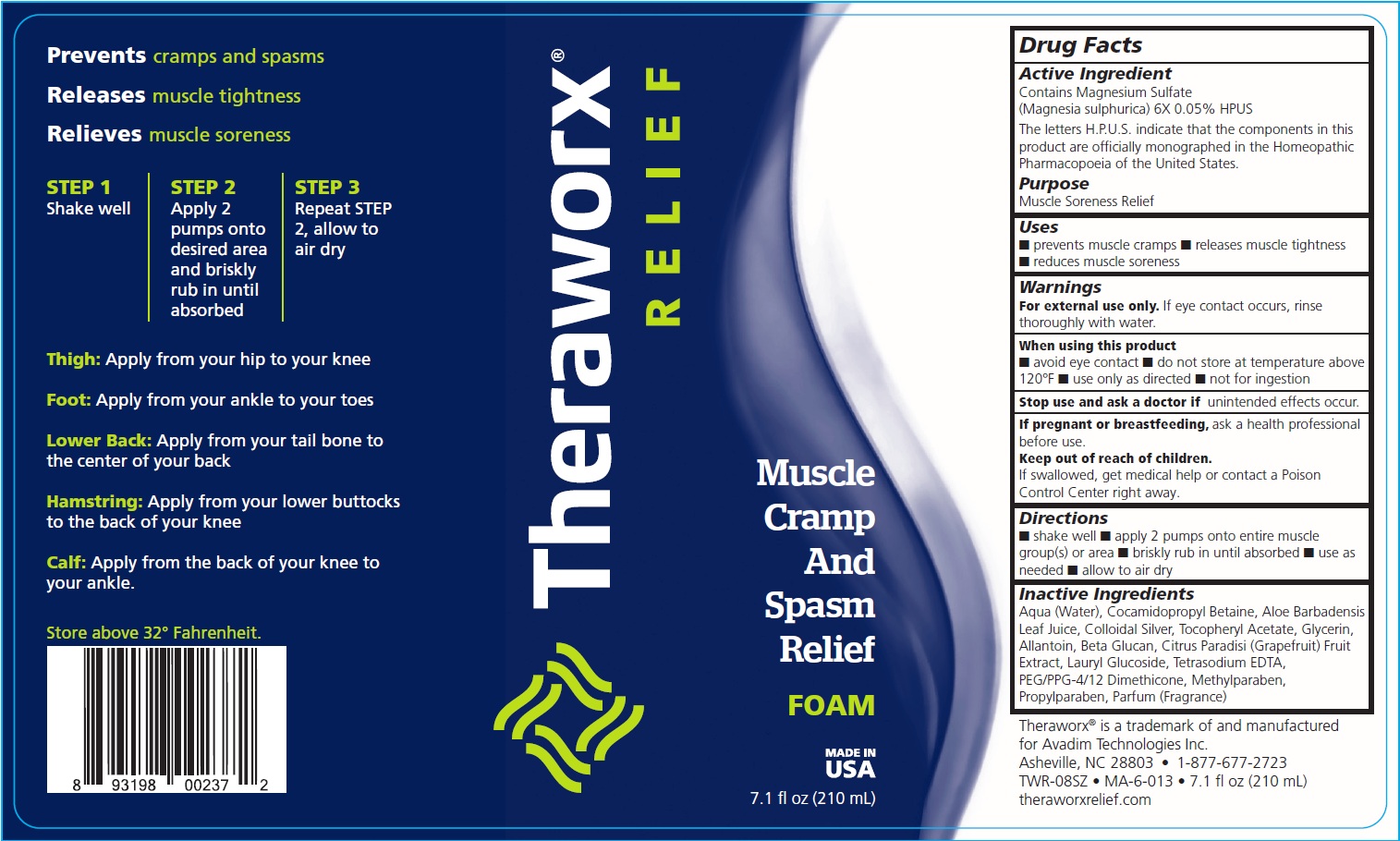

For those concerned about the negative effects of chemicals, there are alternative options available.

Natural and organic mattresses

made from materials such as latex and cotton are becoming more popular, providing a healthier and eco-friendly alternative to foam mattresses. These mattresses use natural materials that do not emit harmful gases and are biodegradable, making them a more sustainable choice for house design.

For those concerned about the negative effects of chemicals, there are alternative options available.

Natural and organic mattresses

made from materials such as latex and cotton are becoming more popular, providing a healthier and eco-friendly alternative to foam mattresses. These mattresses use natural materials that do not emit harmful gases and are biodegradable, making them a more sustainable choice for house design.

Incorporating Foam Mattresses into House Design

While the use of chemicals in foam mattresses may raise concerns, it is still possible to incorporate them into house design in a safe and responsible way. Proper ventilation and air filtration systems can help reduce the concentration of harmful gases in the air. Additionally, choosing foam mattresses made with CertiPUR-US certified foam can ensure that the materials used are safe and free of harmful chemicals.

While the use of chemicals in foam mattresses may raise concerns, it is still possible to incorporate them into house design in a safe and responsible way. Proper ventilation and air filtration systems can help reduce the concentration of harmful gases in the air. Additionally, choosing foam mattresses made with CertiPUR-US certified foam can ensure that the materials used are safe and free of harmful chemicals.

In Conclusion

Foam mattresses are a popular choice for their comfort and support, but the chemicals used in their production can have both positive and negative effects on house design. It is essential to consider the potential impacts and make informed choices when selecting a mattress for your home. By understanding the effects of chemicals in foam mattresses and exploring alternative options, you can create a healthier and more sustainable environment for your house design.

Foam mattresses are a popular choice for their comfort and support, but the chemicals used in their production can have both positive and negative effects on house design. It is essential to consider the potential impacts and make informed choices when selecting a mattress for your home. By understanding the effects of chemicals in foam mattresses and exploring alternative options, you can create a healthier and more sustainable environment for your house design.