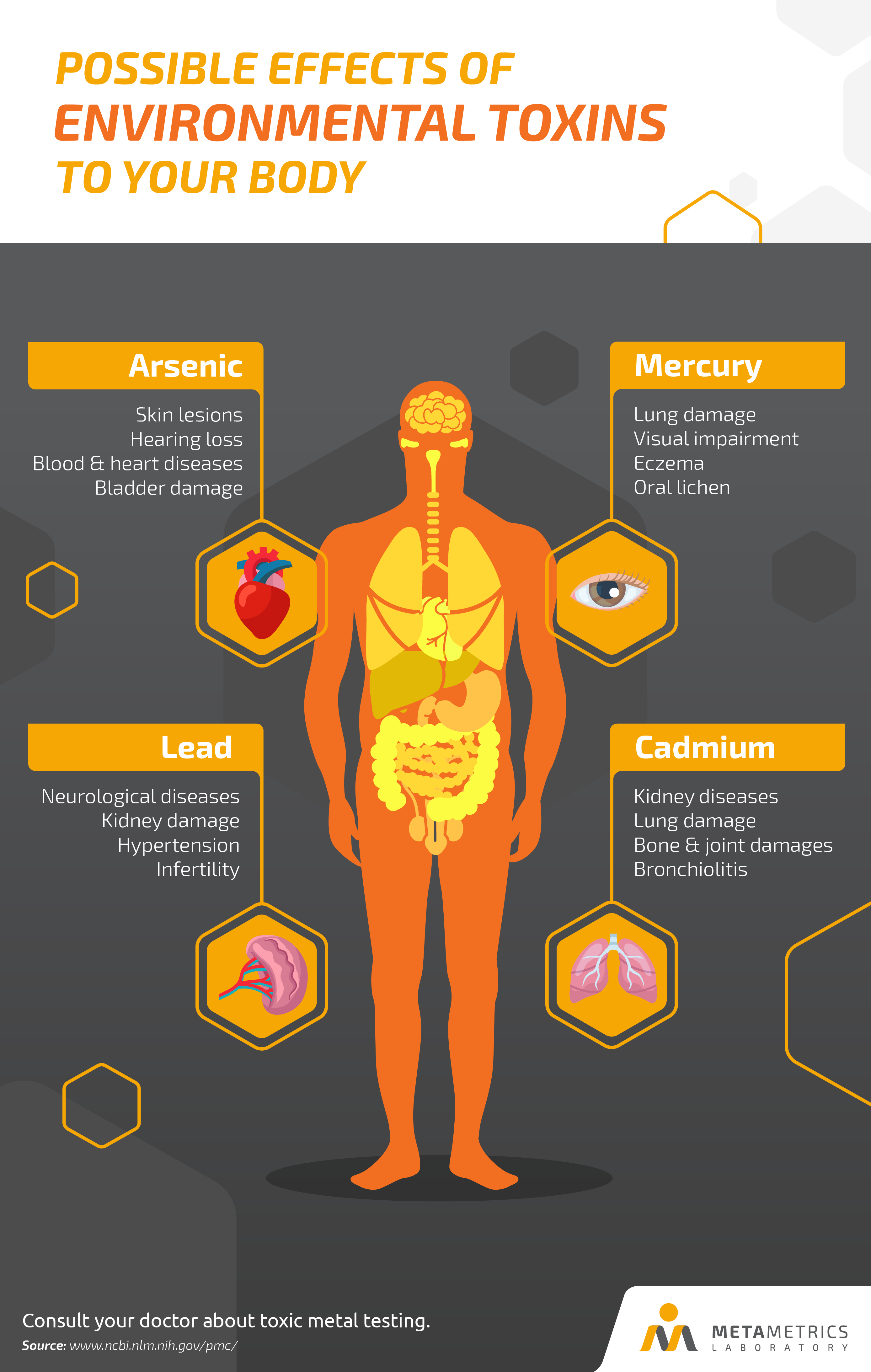

Chemical Exposure

Chemicals used in the manufacturing of mattresses and box springs can pose a significant safety hazard to workers. These chemicals can range from adhesives and flame retardants to solvents and dyes. Exposure to these chemicals can lead to skin irritation, respiratory issues, and even long-term health problems. Workers must take proper precautions when handling and working with these chemicals to minimize their exposure.

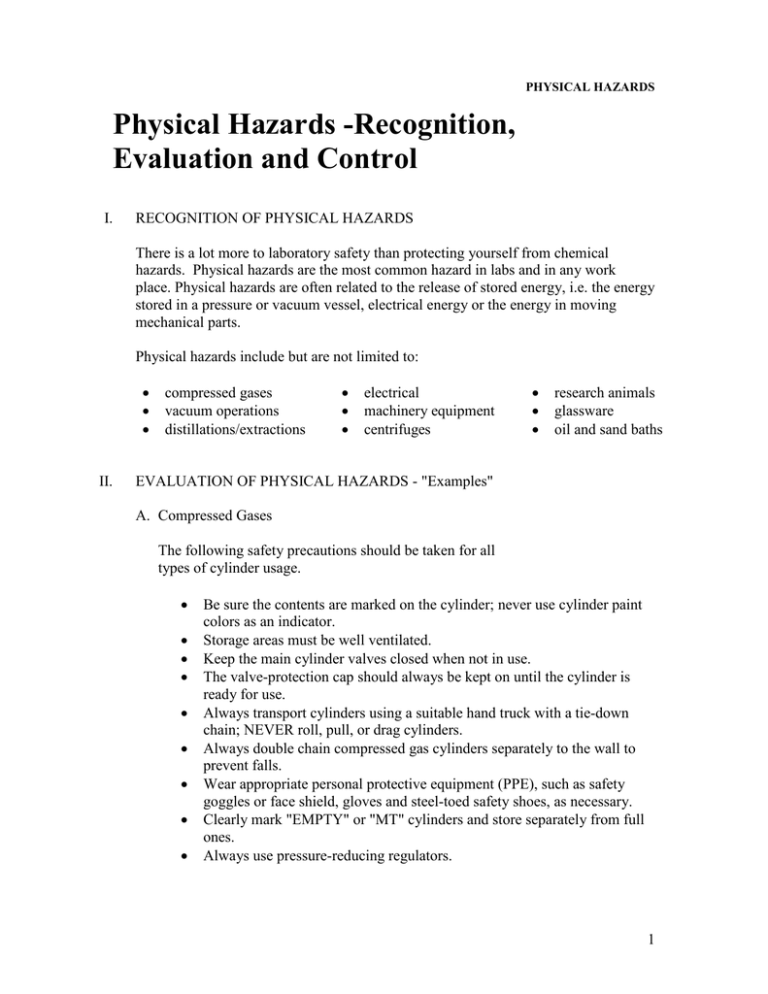

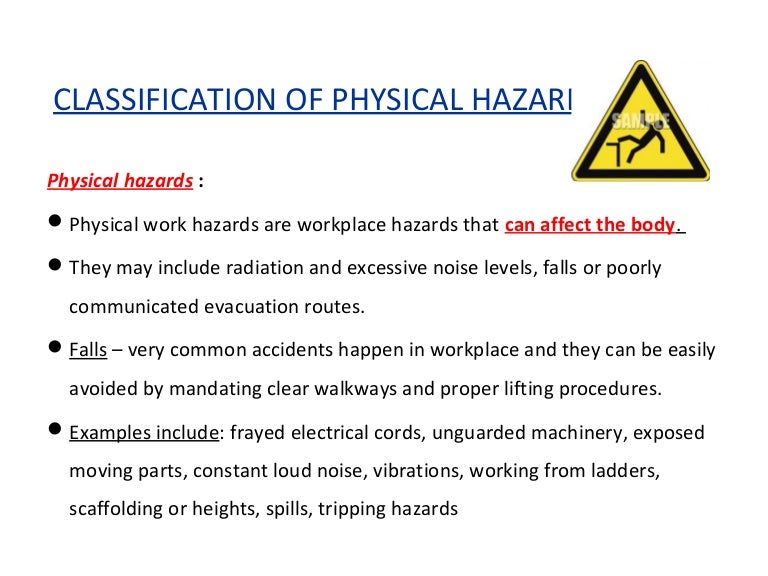

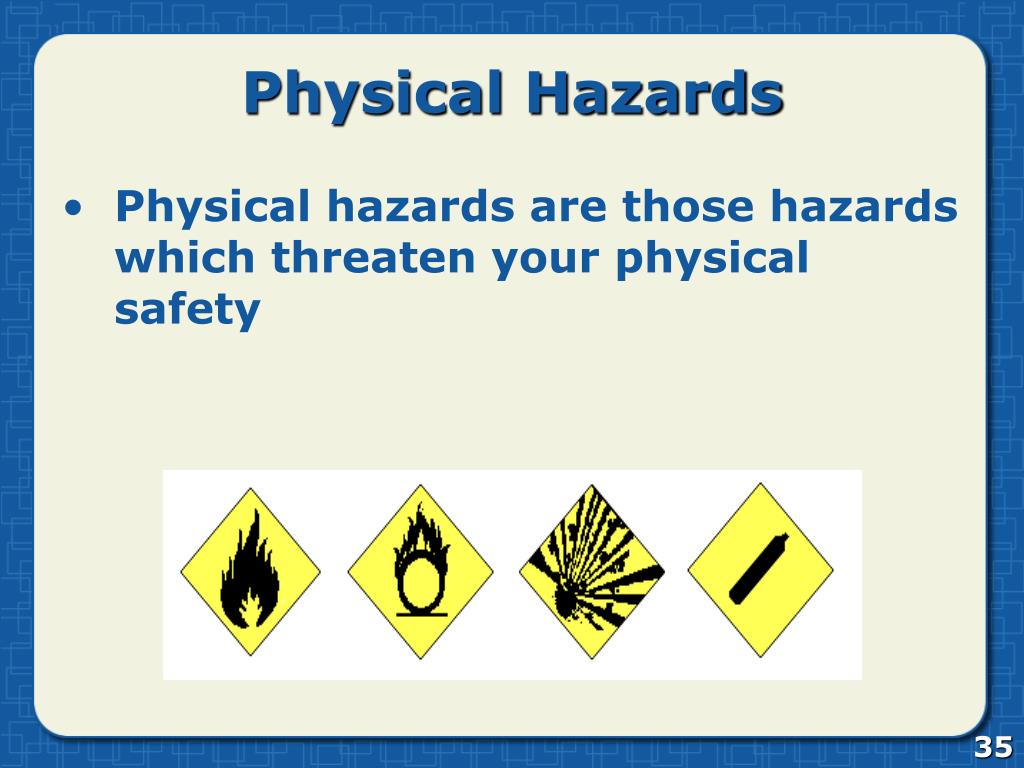

Physical Hazards

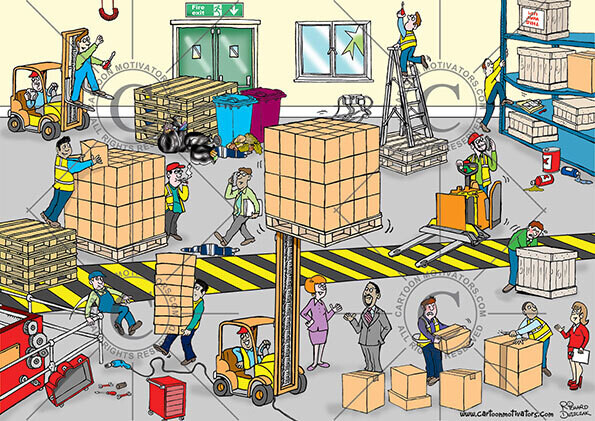

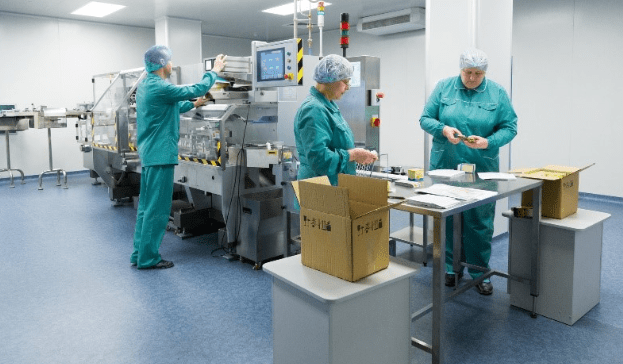

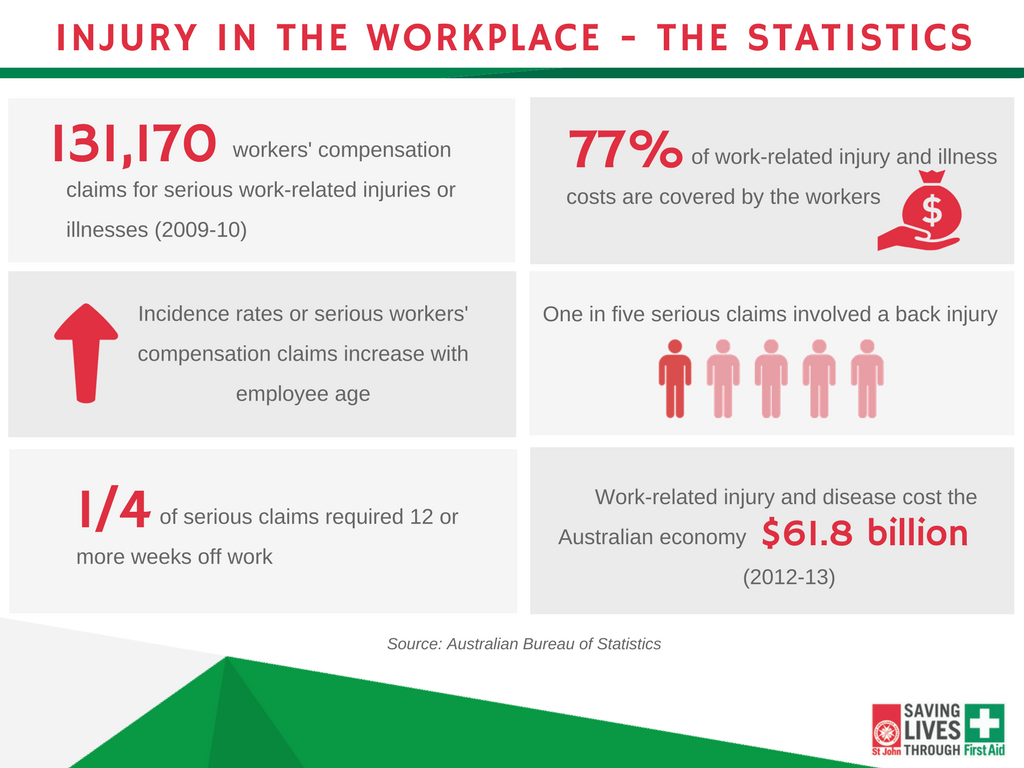

The physical hazards in a mattress and box spring manufacturing facility are numerous. Workers are constantly in close proximity to heavy machinery, which can lead to serious injuries if proper safety protocols are not followed. Moving parts, sharp edges, and other hazards can also pose a risk to workers. It is essential for workers to be properly trained on how to use and maintain equipment to avoid accidents.

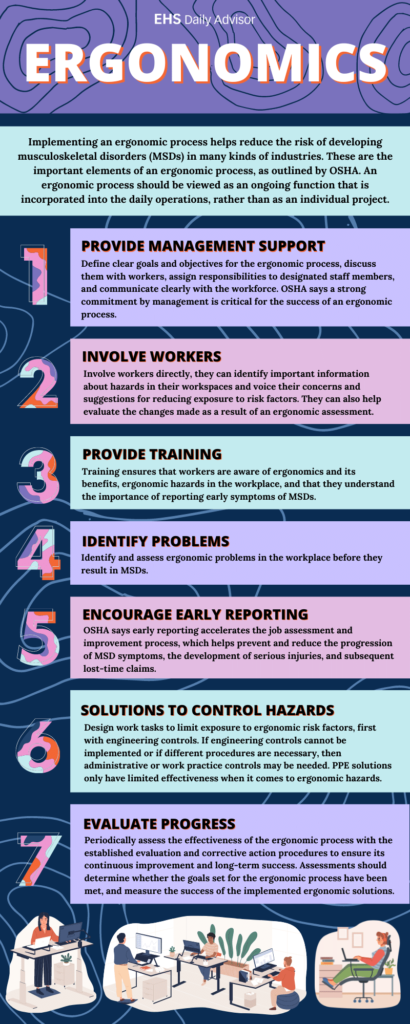

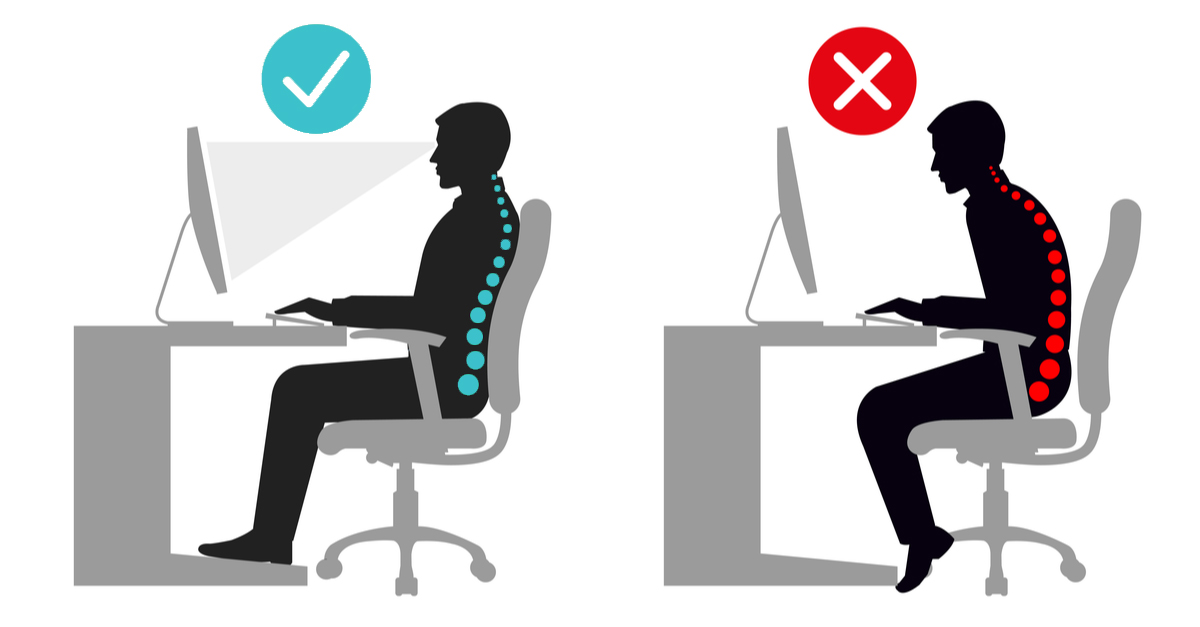

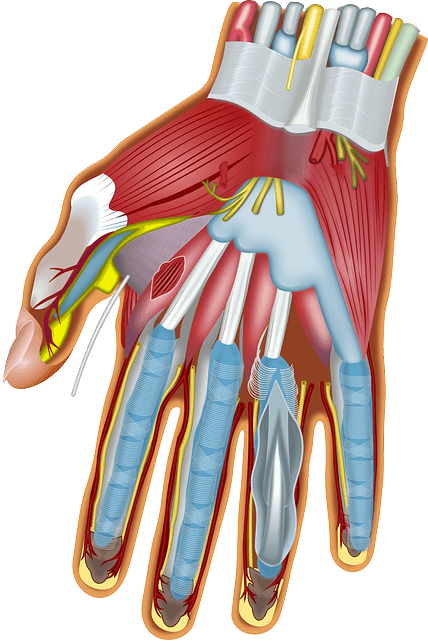

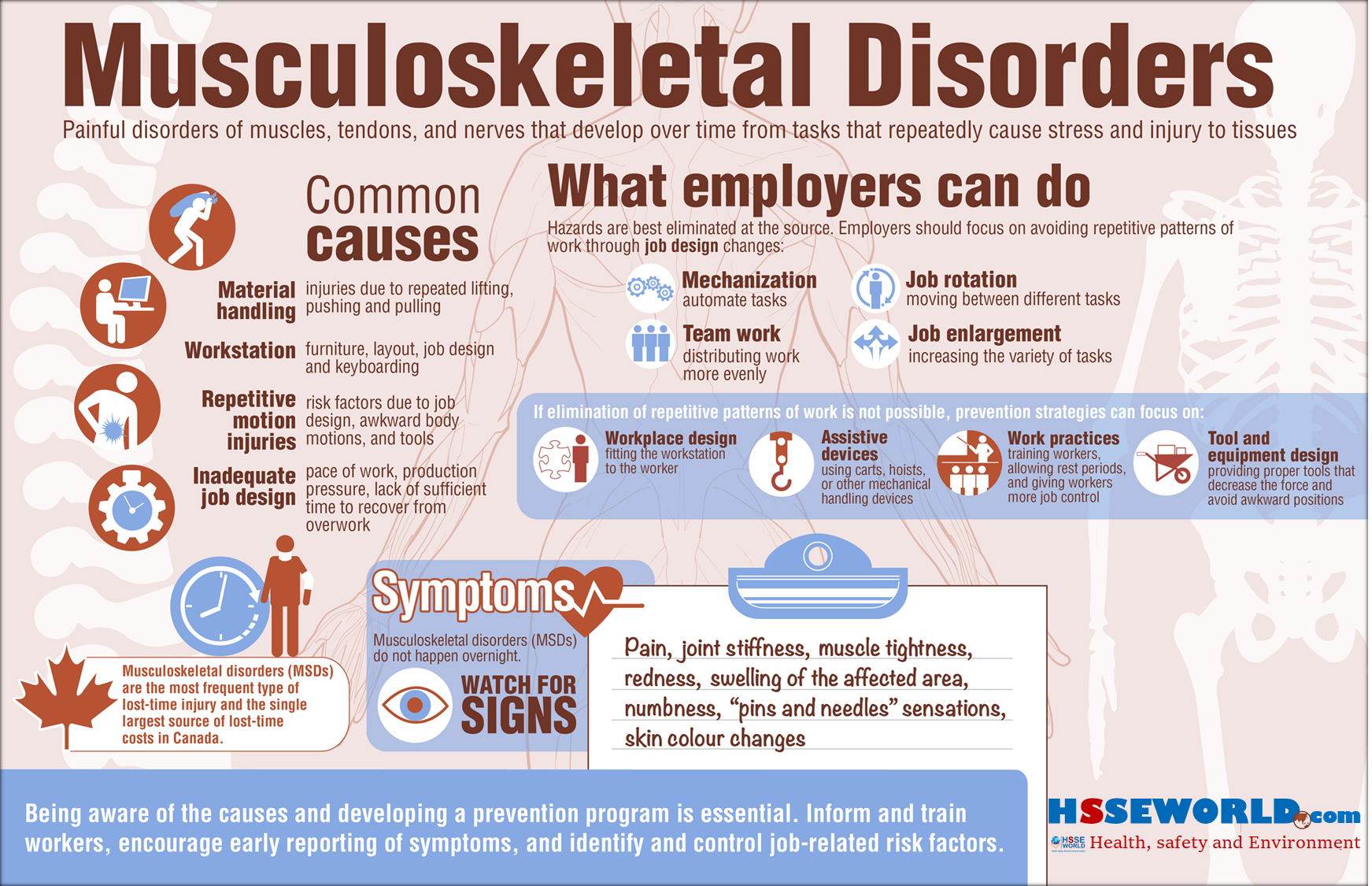

Ergonomic Risks

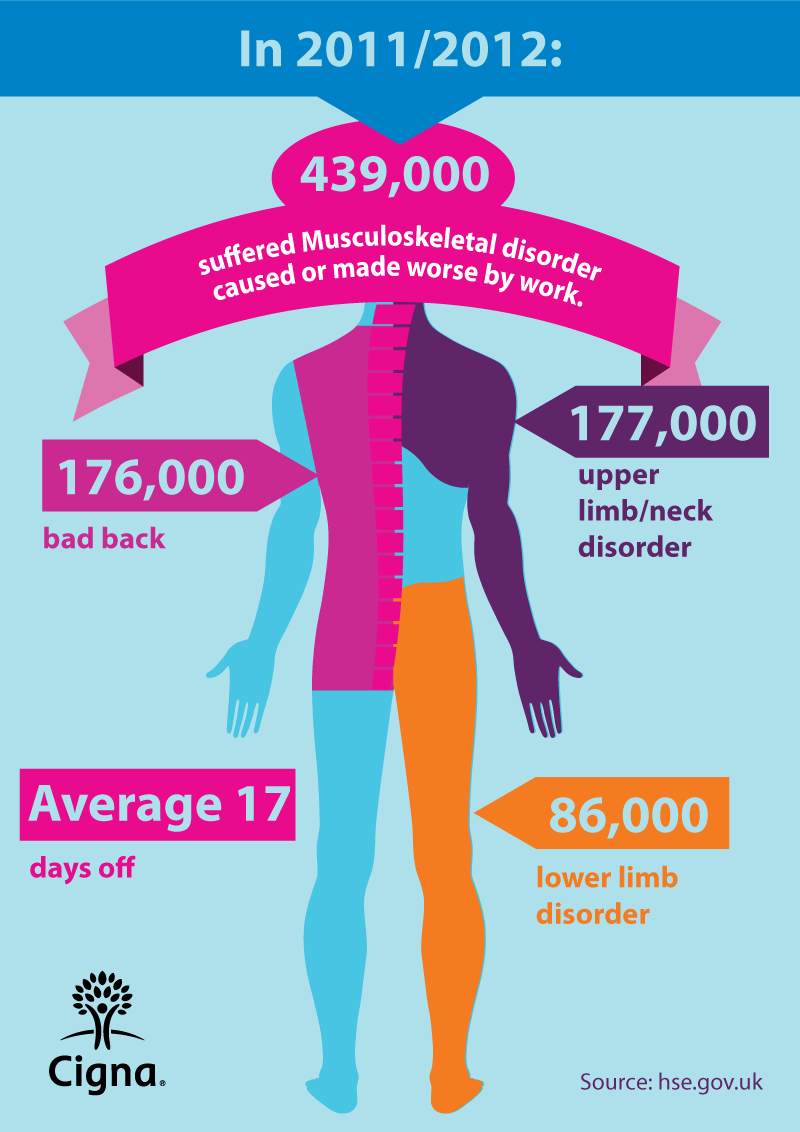

Manufacturing mattresses and box springs often requires workers to perform repetitive motions and maintain uncomfortable positions for extended periods. This can lead to musculoskeletal disorders and other ergonomic injuries. Employers should provide ergonomic training and equipment to help workers maintain proper posture and avoid injuries.

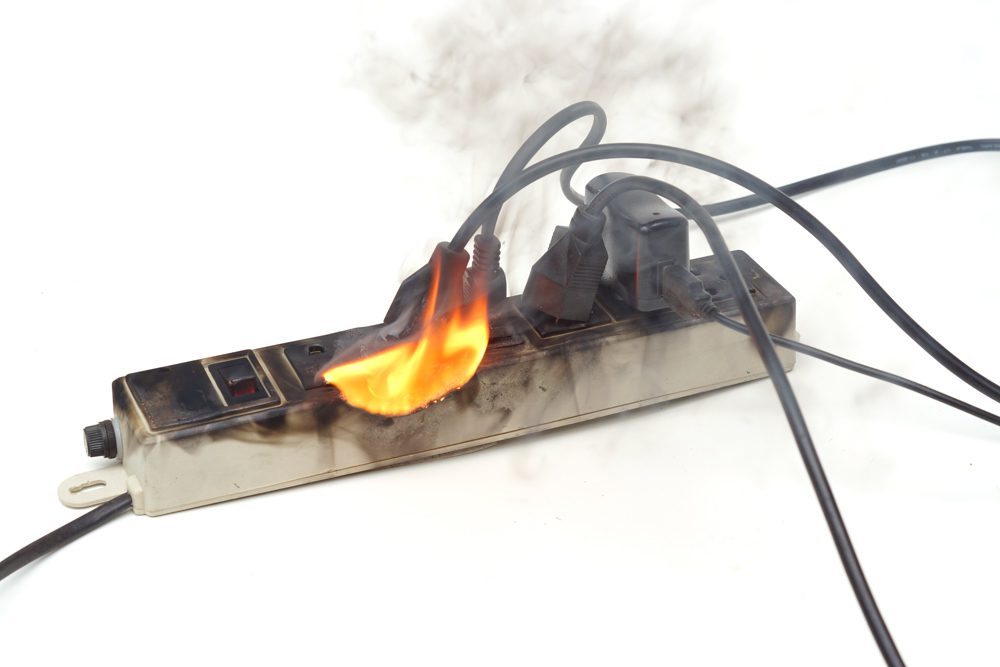

Fire Hazards

With the use of flammable materials such as adhesives and solvents, the risk of fire is high in a mattress and box spring manufacturing facility. Proper fire safety protocols must be in place, including the use of fire-resistant materials and regular maintenance of equipment. Workers should also be trained on how to respond in case of a fire emergency.

Electrical Hazards

The use of electricity in the manufacturing process also poses a safety risk. Faulty wiring or improper use of electrical equipment can lead to electrical shocks, burns, and even fire. Regular maintenance and inspections of electrical systems are necessary to ensure the safety of workers.

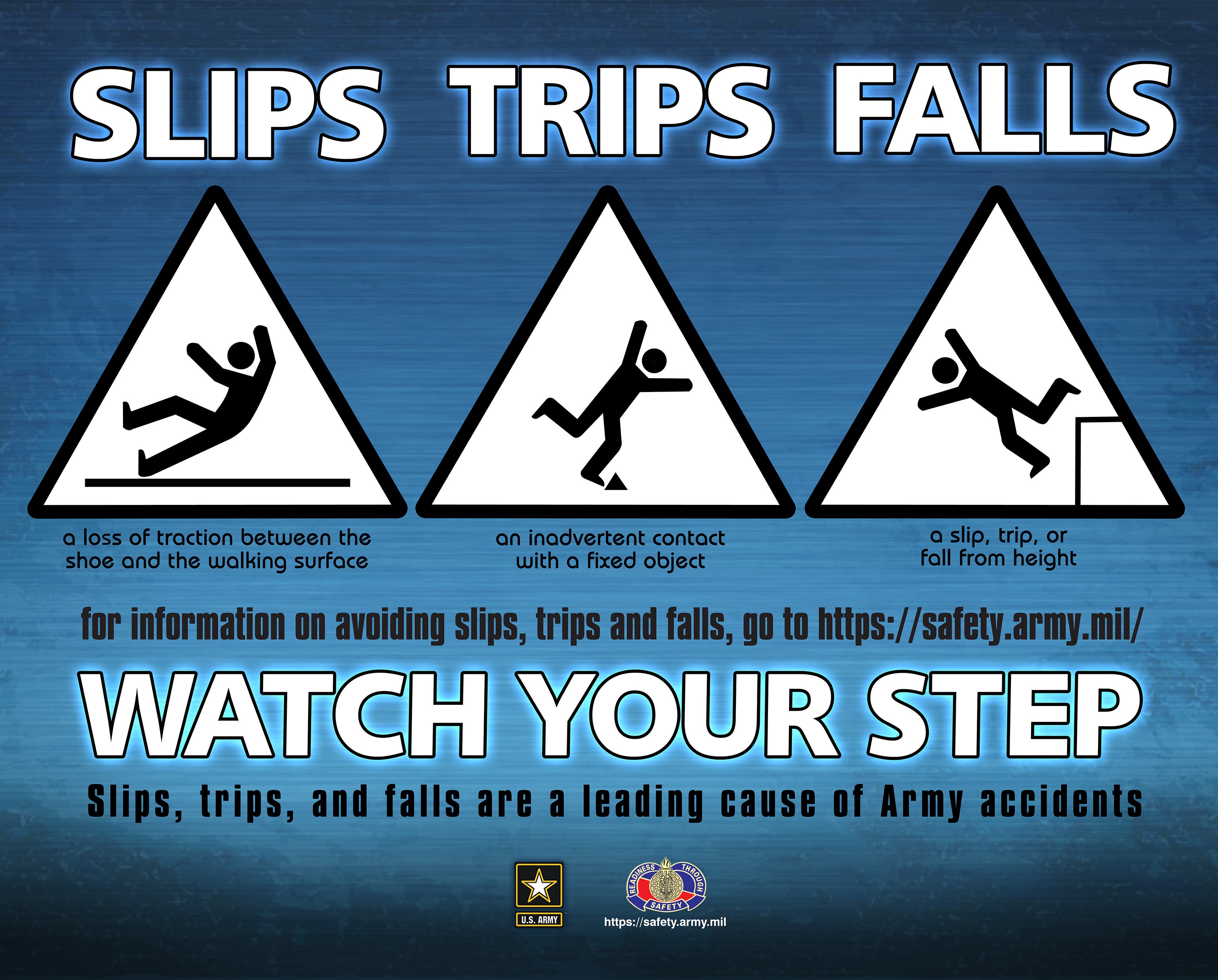

Slips, Trips, and Falls

Slips, trips, and falls are common hazards in any manufacturing facility, and mattress and box spring manufacturing is no exception. Spills, cluttered workspaces, and uneven surfaces can all contribute to accidents. Employers should implement regular housekeeping protocols and provide proper personal protective equipment to minimize the risk of slips, trips, and falls.

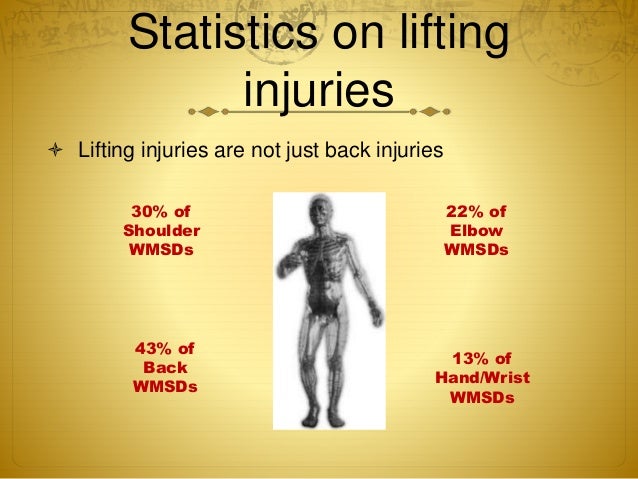

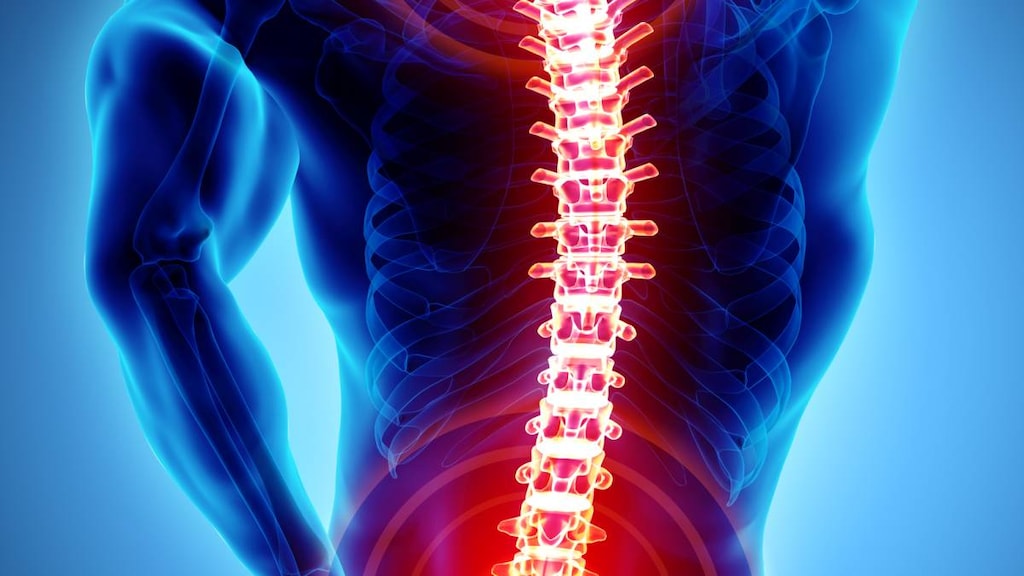

Manual Handling Injuries

Workers in the mattress and box spring manufacturing industry are often required to handle heavy materials, which can lead to manual handling injuries. These injuries can range from strains and sprains to more severe back injuries. Employers should provide proper lifting techniques and equipment to help workers safely handle heavy materials.

Respiratory Issues

The use of chemicals and exposure to dust in the manufacturing process can lead to respiratory issues for workers. This can range from minor irritation to more severe conditions such as asthma and lung damage. Employers should provide proper ventilation and personal protective equipment to minimize the risk of respiratory issues.

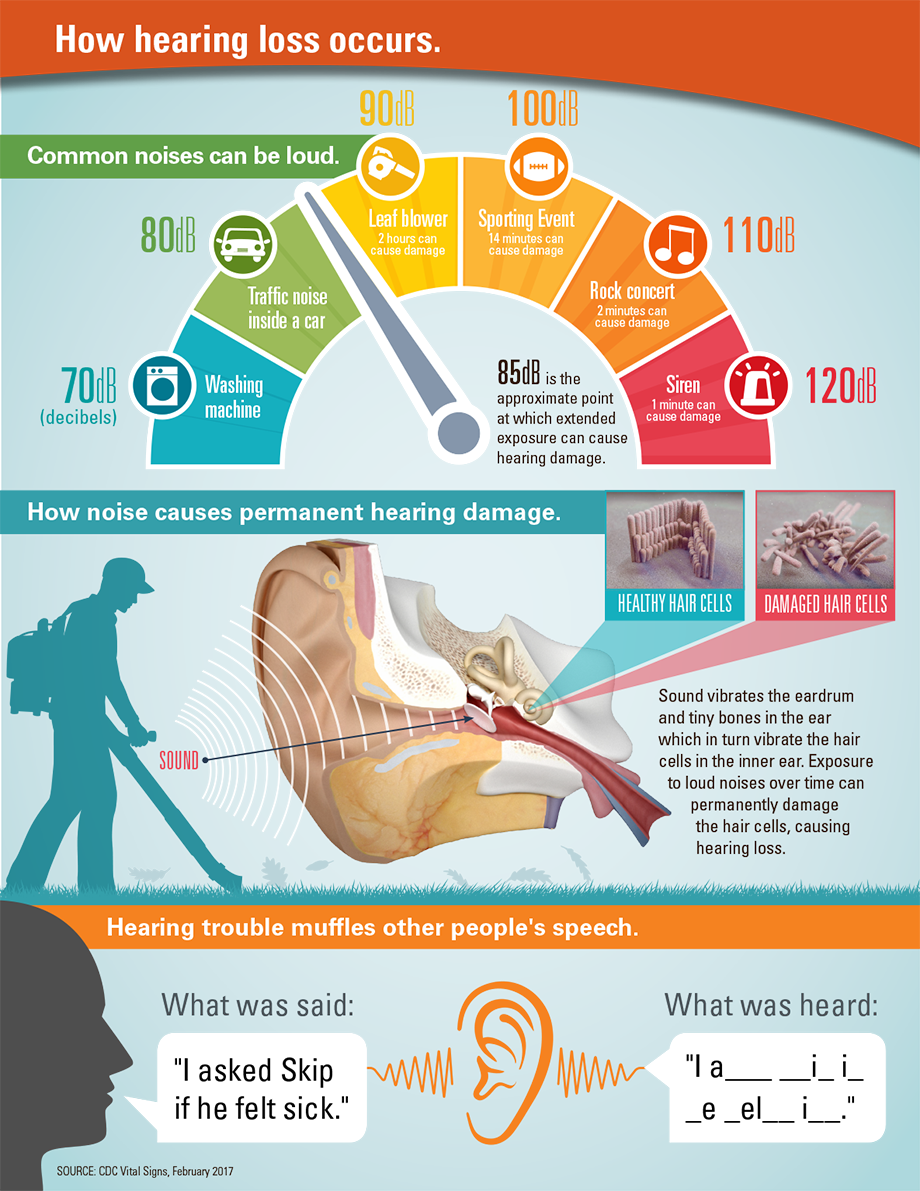

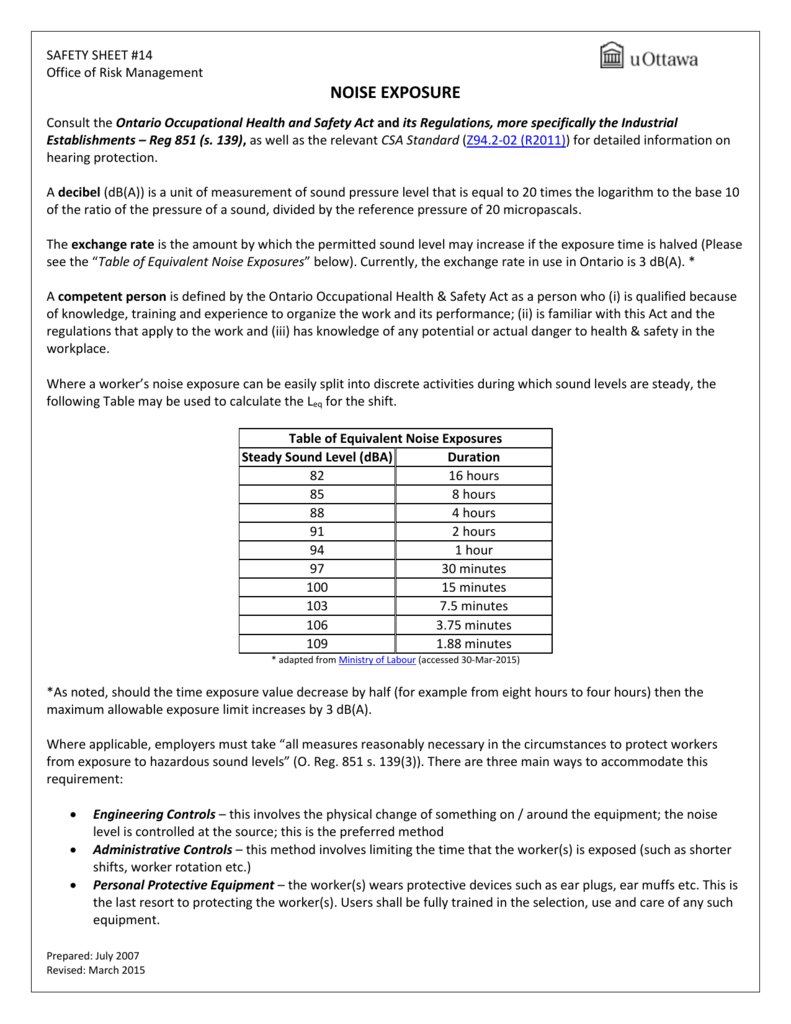

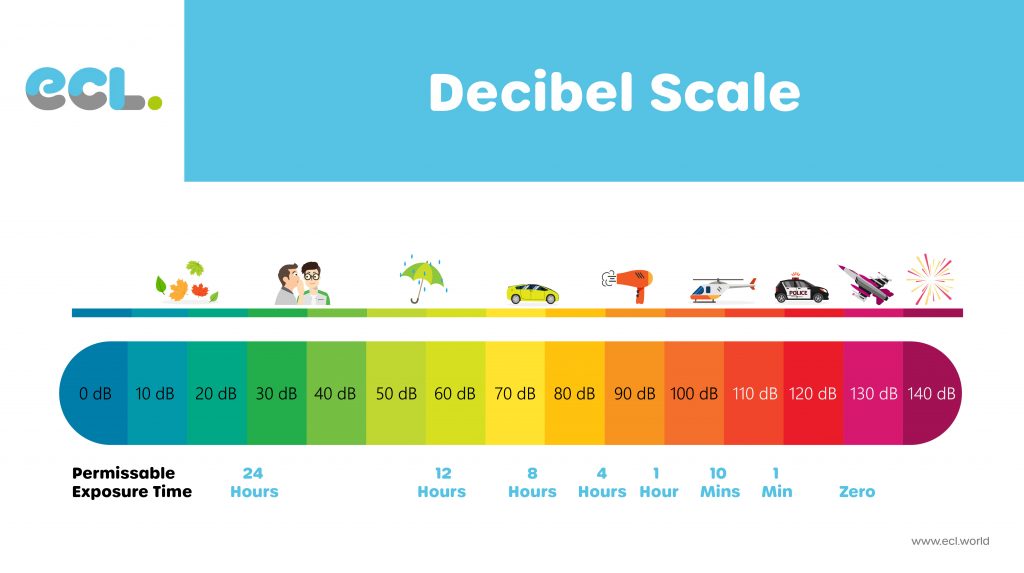

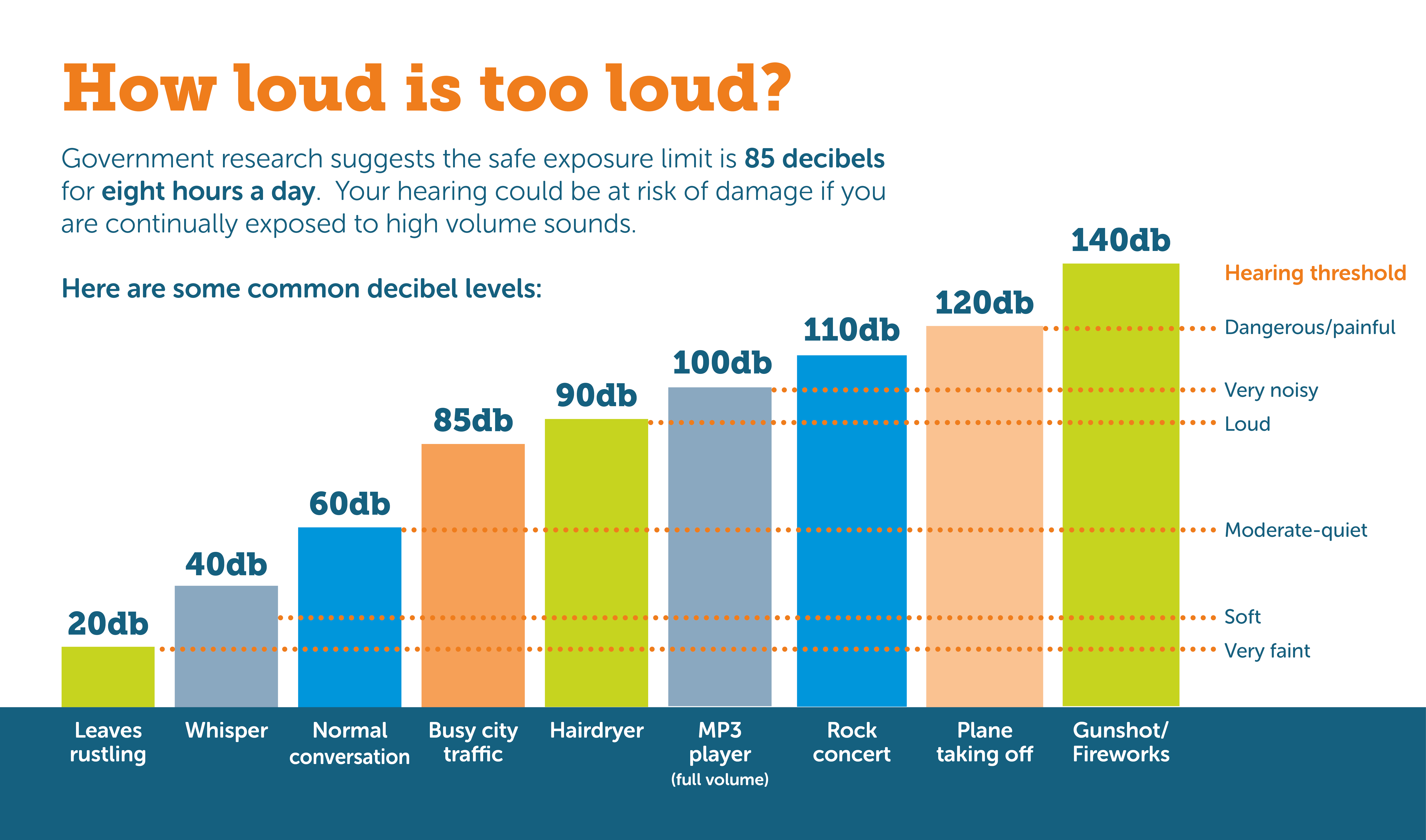

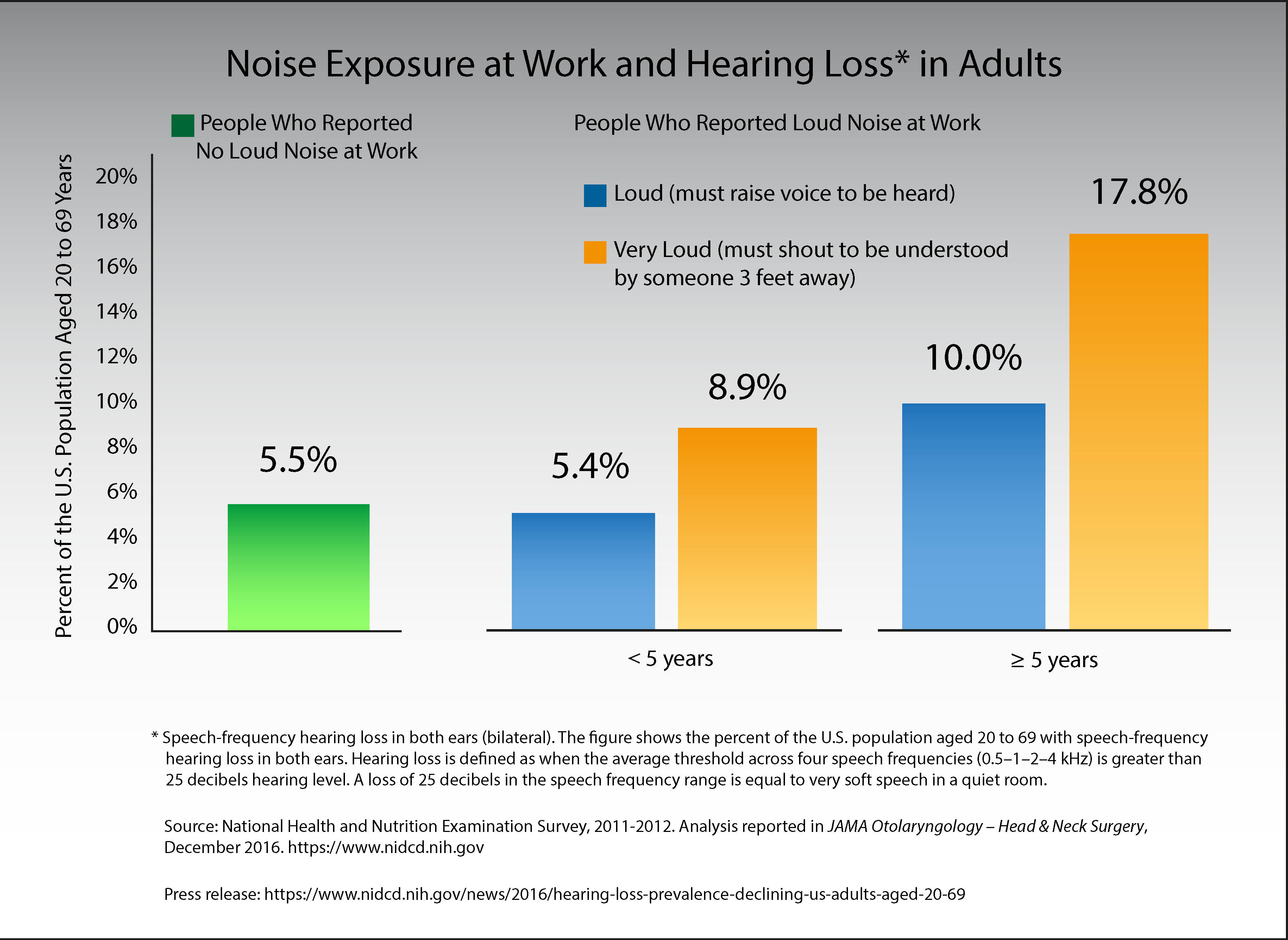

Noise Exposure

The use of heavy machinery and other equipment in a mattress and box spring manufacturing facility can lead to high levels of noise exposure for workers. Prolonged exposure to loud noise can cause hearing loss and other health problems. Employers should provide proper hearing protection and implement noise control measures to protect workers from excessive noise levels.

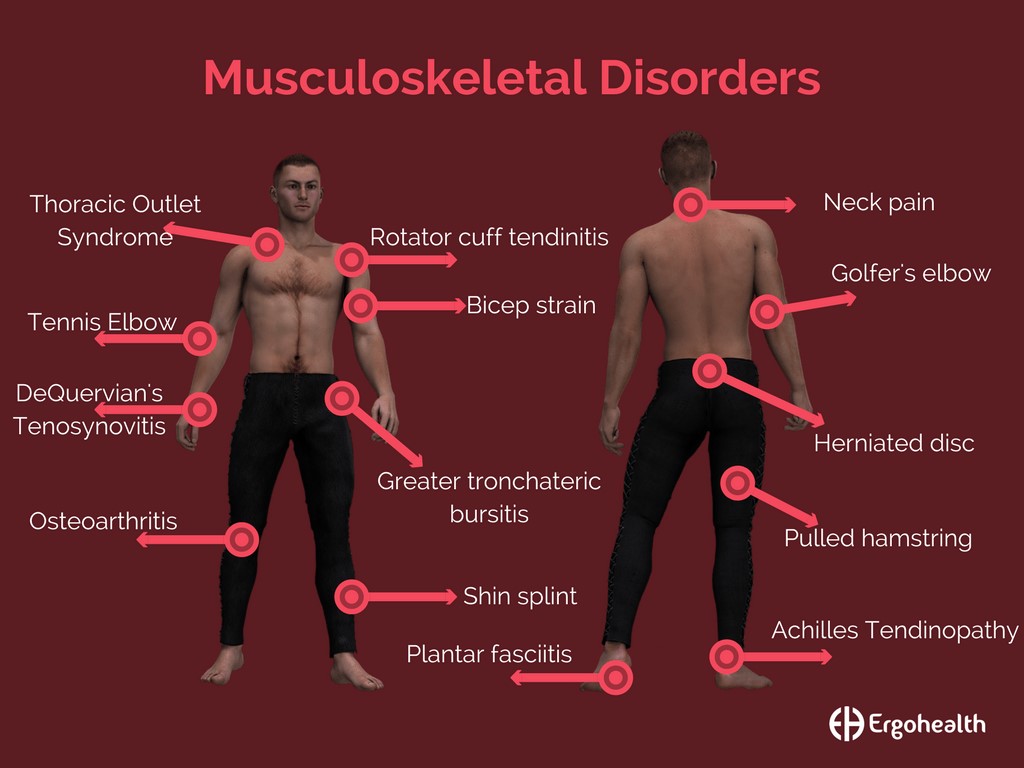

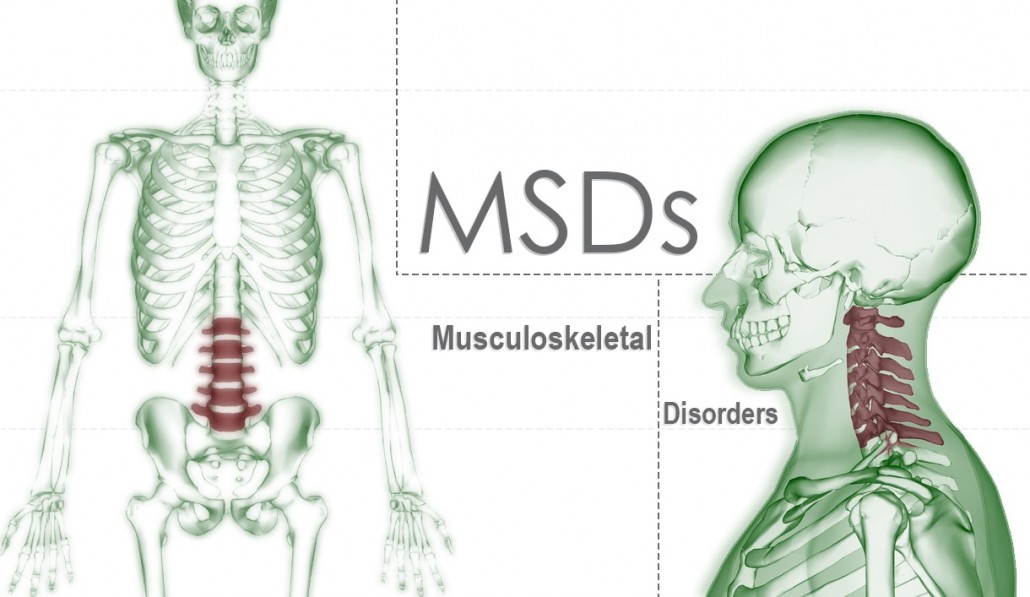

Musculoskeletal Disorders

The repetitive nature of the work in mattress and box spring manufacturing can lead to musculoskeletal disorders such as carpal tunnel syndrome and tendonitis. Proper ergonomic training and equipment, as well as regular breaks and rotation of tasks, can help prevent these types of injuries.

In conclusion, the manufacturing of mattresses and box springs comes with its own unique set of safety hazards. Employers must prioritize the safety and well-being of their workers by implementing proper training, protocols, and equipment to minimize these risks. By doing so, they can create a safer and more productive work environment for everyone involved.

The Importance of Safety in Manufacturing Mattresses and Box Springs

Introduction

When it comes to designing a safe and comfortable home, one of the most important elements to consider is the quality of your mattresses and box springs. These essential pieces of furniture are where we spend a third of our lives, and it is crucial to ensure that they are not only comfortable but also safe for use. However, many people are not aware of the potential safety hazards that come with manufacturing these household items. In this article, we will discuss the various safety hazards associated with manufacturing mattresses and box springs and how to mitigate them.

When it comes to designing a safe and comfortable home, one of the most important elements to consider is the quality of your mattresses and box springs. These essential pieces of furniture are where we spend a third of our lives, and it is crucial to ensure that they are not only comfortable but also safe for use. However, many people are not aware of the potential safety hazards that come with manufacturing these household items. In this article, we will discuss the various safety hazards associated with manufacturing mattresses and box springs and how to mitigate them.

Flammability

One of the primary safety concerns when it comes to manufacturing mattresses and box springs is their flammability. These items are typically made from materials such as foam, cotton, and polyester, which are highly flammable. In the event of a fire, these materials can quickly catch fire and spread, putting the occupants of a home at risk. To combat this, manufacturers are required to use

flame-retardant chemicals

in their products, which can be harmful to both humans and the environment. These chemicals have been linked to various health issues, including respiratory problems and even cancer. As a result, it is essential to do your research and opt for mattresses and box springs that use

safer, more eco-friendly materials

in their production.

One of the primary safety concerns when it comes to manufacturing mattresses and box springs is their flammability. These items are typically made from materials such as foam, cotton, and polyester, which are highly flammable. In the event of a fire, these materials can quickly catch fire and spread, putting the occupants of a home at risk. To combat this, manufacturers are required to use

flame-retardant chemicals

in their products, which can be harmful to both humans and the environment. These chemicals have been linked to various health issues, including respiratory problems and even cancer. As a result, it is essential to do your research and opt for mattresses and box springs that use

safer, more eco-friendly materials

in their production.

Off-gassing

Another safety hazard of manufacturing mattresses and box springs is the process of off-gassing. This refers to the release of volatile organic compounds (VOCs) from the materials used in these products. These chemicals can be harmful to human health, causing headaches, dizziness, and even respiratory problems. To reduce the risk of off-gassing, it is crucial to

choose mattresses and box springs that are CertiPUR-US certified

. This certification ensures that the products have been tested and are free from harmful chemicals, making them safer for use in your home.

Another safety hazard of manufacturing mattresses and box springs is the process of off-gassing. This refers to the release of volatile organic compounds (VOCs) from the materials used in these products. These chemicals can be harmful to human health, causing headaches, dizziness, and even respiratory problems. To reduce the risk of off-gassing, it is crucial to

choose mattresses and box springs that are CertiPUR-US certified

. This certification ensures that the products have been tested and are free from harmful chemicals, making them safer for use in your home.

Structural Integrity

In addition to the potential health hazards, there are also safety concerns regarding the structural integrity of mattresses and box springs. Poorly made products can have weak or faulty frames, causing them to collapse or break, resulting in injuries. To ensure the safety and durability of your mattresses and box springs, it is crucial to

purchase them from reputable manufacturers

who use high-quality materials and have proper quality control measures in place.

In addition to the potential health hazards, there are also safety concerns regarding the structural integrity of mattresses and box springs. Poorly made products can have weak or faulty frames, causing them to collapse or break, resulting in injuries. To ensure the safety and durability of your mattresses and box springs, it is crucial to

purchase them from reputable manufacturers

who use high-quality materials and have proper quality control measures in place.

Conclusion

In conclusion, when it comes to designing a safe and comfortable home, it is essential to pay attention to the quality and safety of your mattresses and box springs. Flammability, off-gassing, and structural integrity are just a few of the potential hazards associated with manufacturing these household items. By being aware of these risks and making informed decisions when purchasing these products, you can ensure the safety and well-being of yourself and your family. Remember to do your research and opt for safer, more eco-friendly options to create a safe and healthy home environment.

In conclusion, when it comes to designing a safe and comfortable home, it is essential to pay attention to the quality and safety of your mattresses and box springs. Flammability, off-gassing, and structural integrity are just a few of the potential hazards associated with manufacturing these household items. By being aware of these risks and making informed decisions when purchasing these products, you can ensure the safety and well-being of yourself and your family. Remember to do your research and opt for safer, more eco-friendly options to create a safe and healthy home environment.

/GettyImages-1053029940-9bffdb28ff5147048b02c65a91c48436.jpg)