Kitchen sinks have come a long way from being a simple basin for washing dishes. Today, they are a vital part of any modern kitchen, with sleek and functional designs that add to the overall aesthetic of the space. But have you ever wondered what goes into the making of these essential fixtures? It takes a combination of advanced machinery and skilled labor to produce the perfect kitchen sink. In this article, we will explore the top 10 main kitchen sink manufacturing machines that are used in the production process.The Evolution of Kitchen Sink Manufacturing: Top 10 Machines Used in the Process

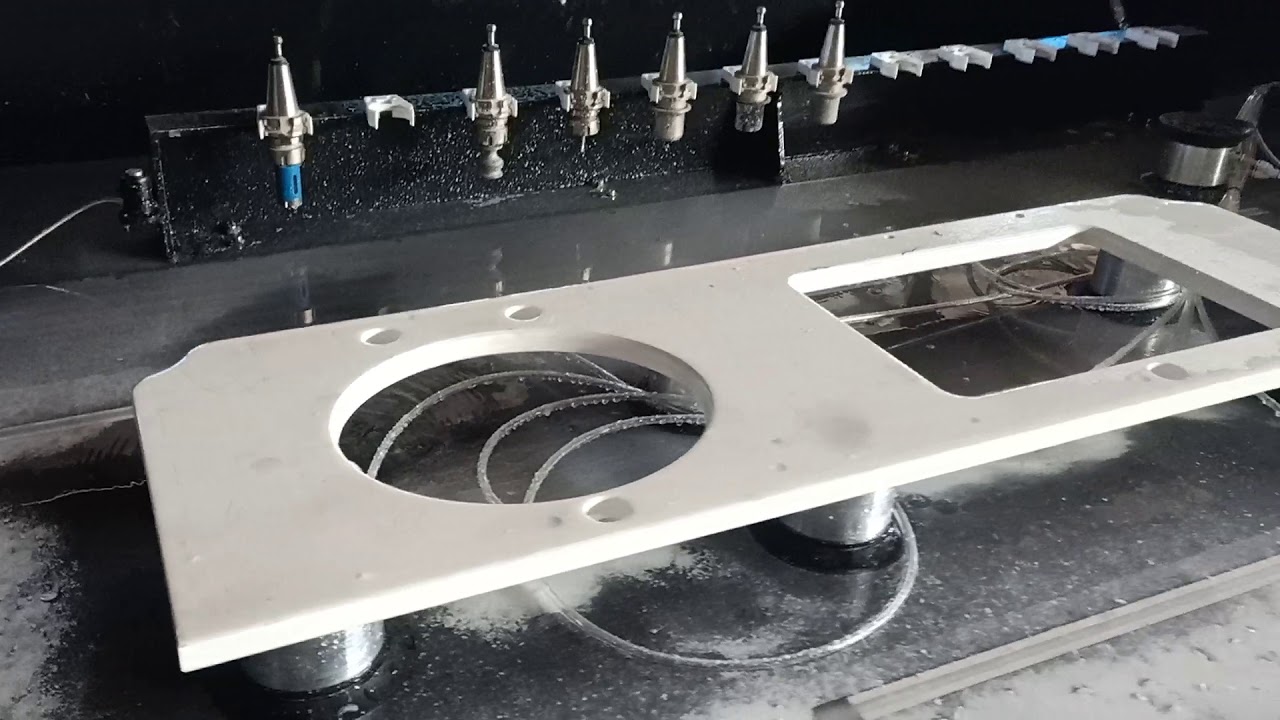

The automated kitchen sink manufacturing machine is the backbone of the production process. This machine is responsible for the shaping and cutting of the sink using advanced computer-controlled technology. It ensures precision and consistency in the size and shape of each sink, resulting in a flawless end product. The machine can be programmed to produce a variety of sink designs, making it a versatile and efficient choice for large-scale production.1. Automated Kitchen Sink Manufacturing Machine

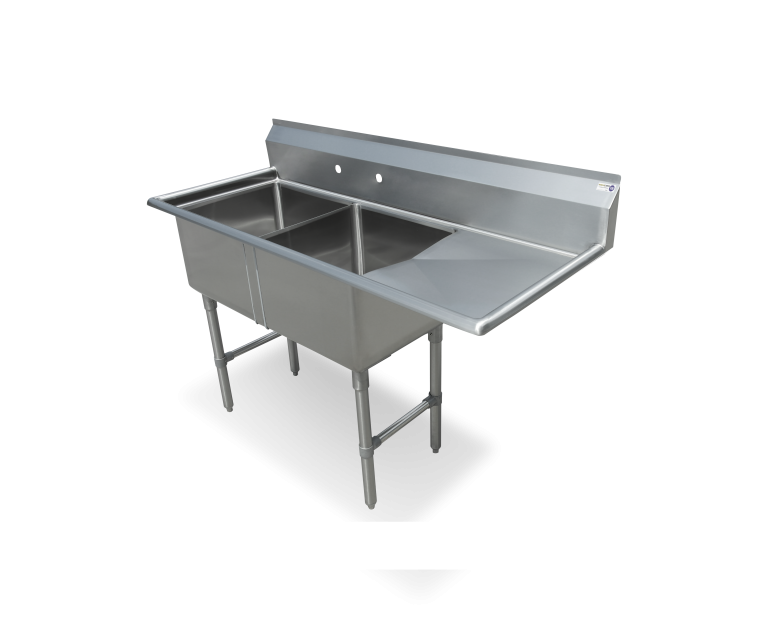

The industrial kitchen sink production line is a series of interconnected machines that work together to produce a large number of sinks in a short amount of time. It includes the automated machine, as well as other machines such as the press, welding, and polishing machines. This production line is used in high-volume manufacturing and is ideal for meeting the demands of commercial projects.2. Industrial Kitchen Sink Production Line

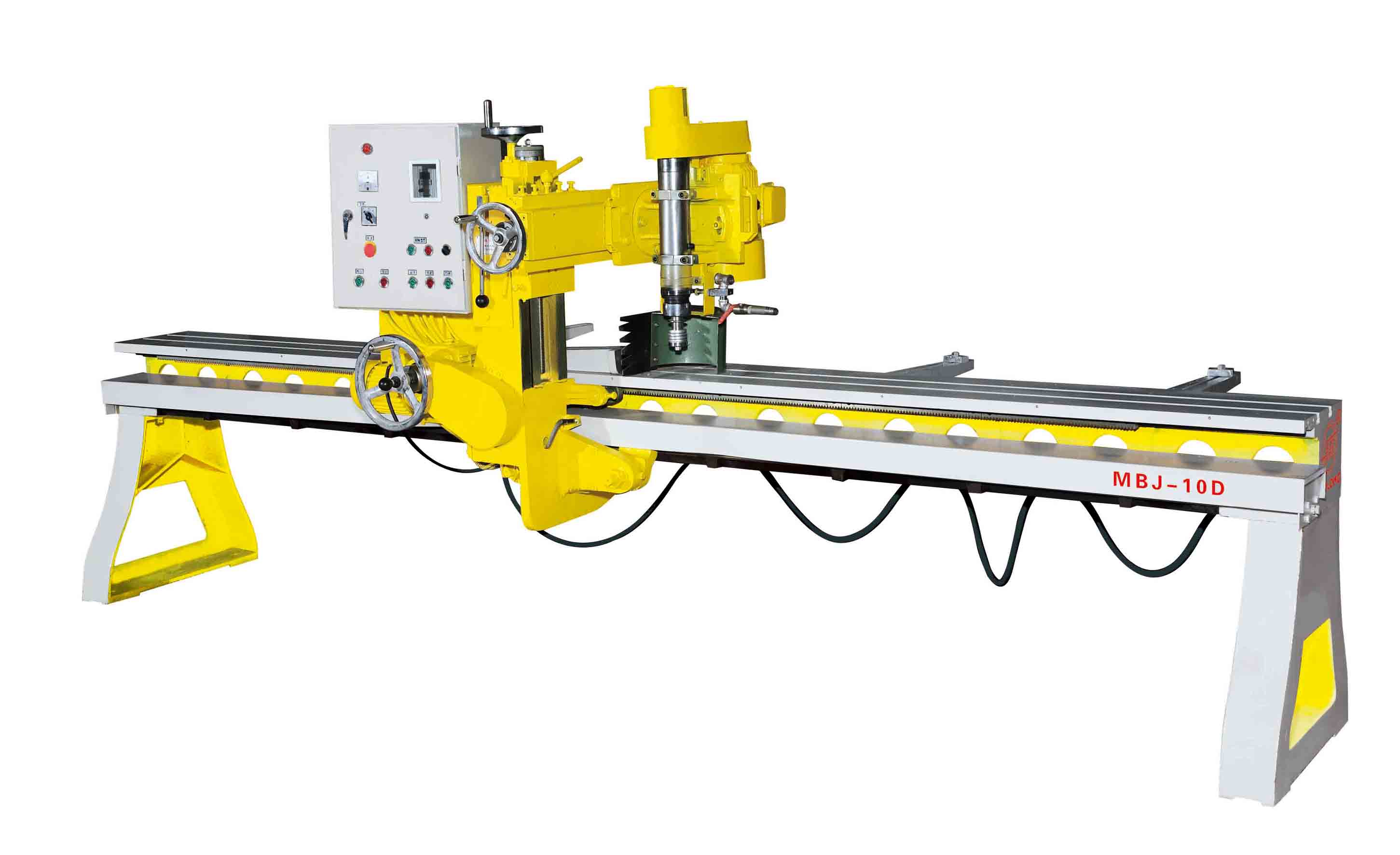

As the name suggests, the high-speed kitchen sink making machine is designed for fast and efficient production. It uses advanced technology to cut, shape, and polish the sink at a high speed, significantly reducing the production time. This machine is perfect for manufacturers who need to meet tight deadlines without compromising on quality.3. High-Speed Kitchen Sink Making Machine

Stainless steel is the most popular material used for kitchen sinks due to its durability and resistance to corrosion. The stainless steel sink manufacturing equipment is specifically designed to handle the production of these sinks. It can handle the cutting, shaping, and polishing of the stainless steel material with precision and efficiency, resulting in a high-quality end product.4. Stainless Steel Sink Manufacturing Equipment

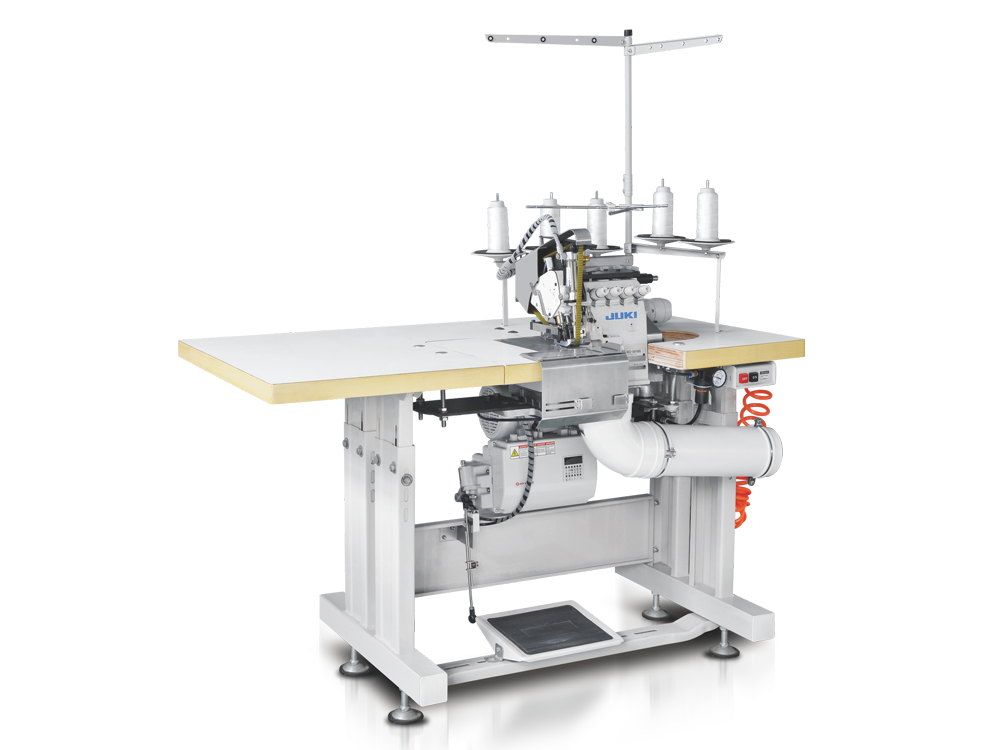

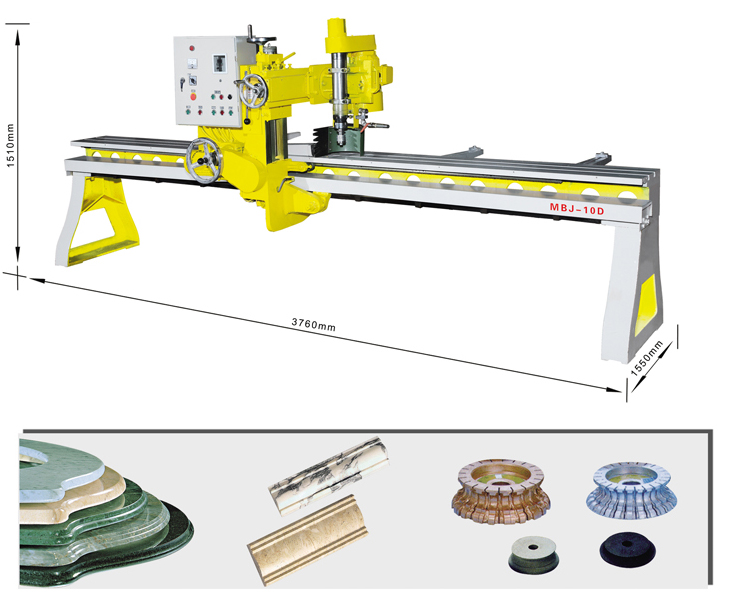

The sink forming and polishing machine is an essential part of the production process. It is responsible for forming the sink's shape and smoothing out any rough edges. This machine uses specialized tools and techniques to ensure a smooth and flawless finish on the sink's surface. It is a crucial step in the production process as it adds to the sink's overall aesthetic appeal.5. Sink Forming and Polishing Machine

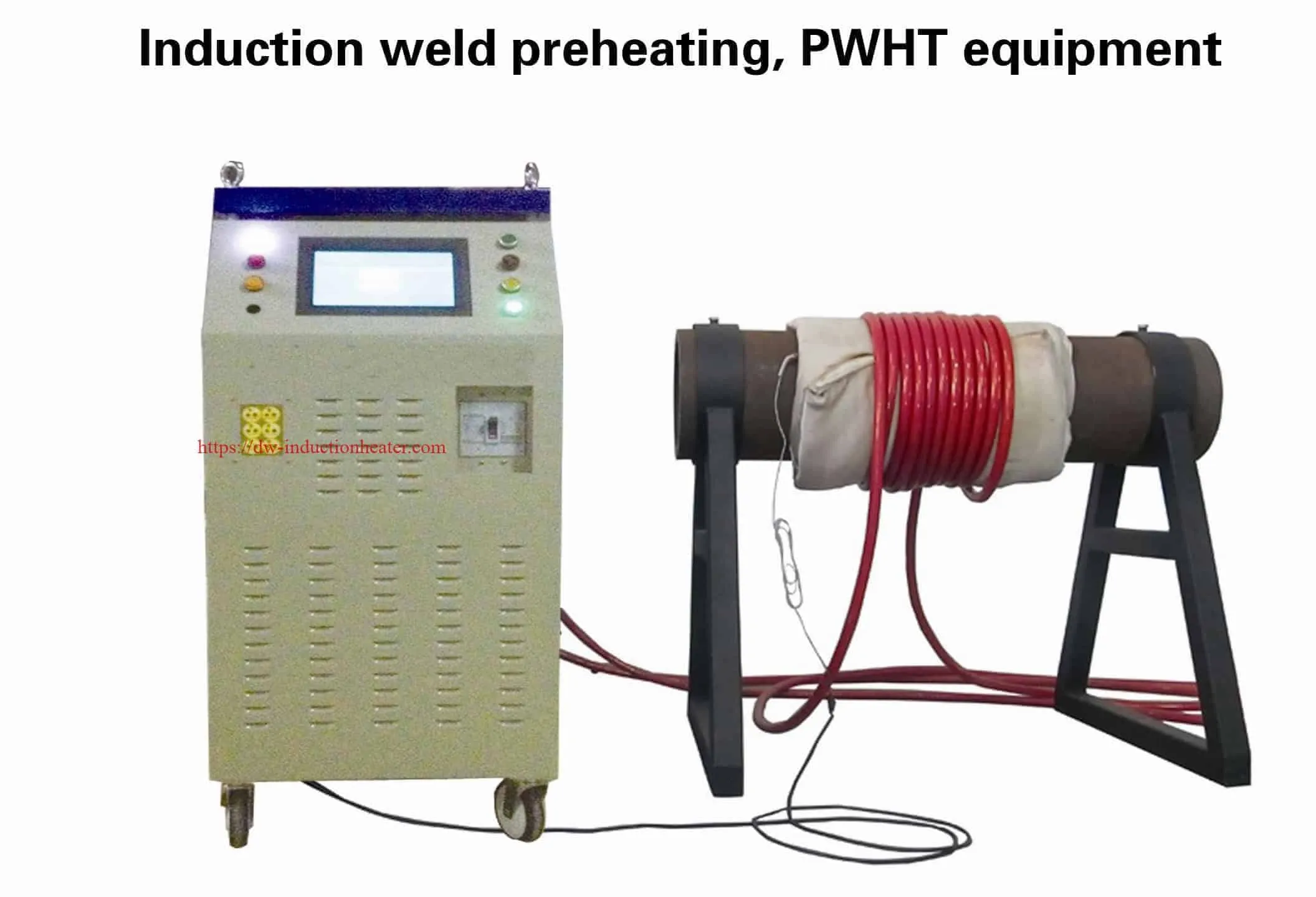

In the production of sinks, the pressing and welding machine is used to join different parts of the sink together. This machine uses high pressure and heat to fuse the sink's components, resulting in a seamless and sturdy sink. It is a crucial step in the production process as it ensures the sink's structural integrity and longevity.6. Sink Pressing and Welding Machine

The multi-station kitchen sink production machine is a versatile and efficient choice for manufacturers who produce a variety of sink designs. This machine has multiple stations that can be used for cutting, shaping, and polishing different types of sinks simultaneously. It is a time-saving and cost-effective option for manufacturers who need to produce different sink designs in large quantities.7. Multi-Station Kitchen Sink Production Machine

The CNC (Computer Numerical Control) kitchen sink cutting and bending machine is a highly advanced piece of equipment. It uses computer-controlled technology to precisely cut and bend the sink's material to the desired shape and size. This machine is ideal for producing complex sink designs that require precision and accuracy.8. CNC Kitchen Sink Cutting and Bending Machine

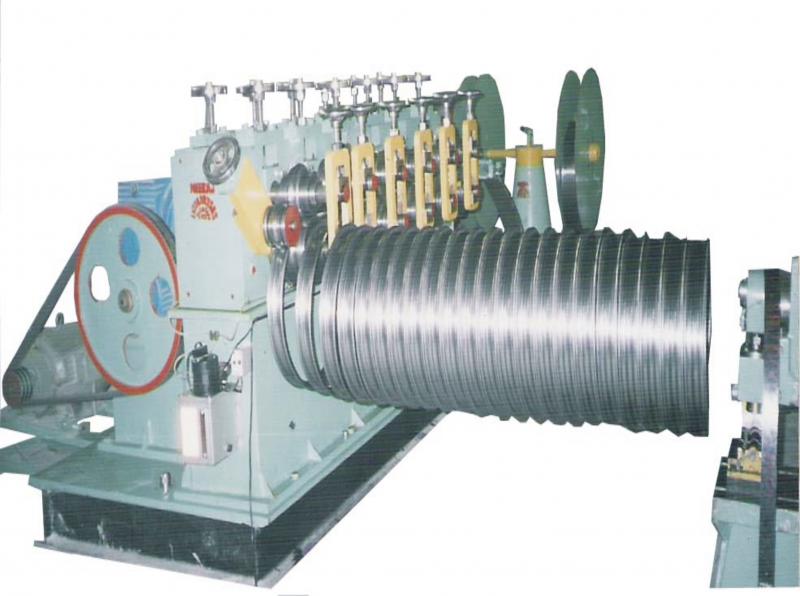

The sink rim rolling and flanging machine is used to create the rim of the sink, which is the top edge that sits on the countertop. This machine uses specialized tools to roll and bend the sink's material to form a smooth and sturdy rim. It is an essential step in the production process as it adds to the sink's overall strength and stability.9. Sink Rim Rolling and Flanging Machine

The Evolution of Kitchen Sink Manufacturing Machines

The Importance of Kitchen Sinks in House Design

When it comes to house design, the kitchen is often considered the heart of the home. It is where meals are prepared, memories are made, and families gather. And at the center of every kitchen is the kitchen sink. This essential fixture serves as a functional and aesthetic focal point in any kitchen design.

Over the years, kitchen sinks have evolved from simple basins to highly functional and stylish fixtures. And with the rise of technology, the process of manufacturing kitchen sinks has also undergone a significant transformation, giving birth to the kitchen sink manufacturing machine.

When it comes to house design, the kitchen is often considered the heart of the home. It is where meals are prepared, memories are made, and families gather. And at the center of every kitchen is the kitchen sink. This essential fixture serves as a functional and aesthetic focal point in any kitchen design.

Over the years, kitchen sinks have evolved from simple basins to highly functional and stylish fixtures. And with the rise of technology, the process of manufacturing kitchen sinks has also undergone a significant transformation, giving birth to the kitchen sink manufacturing machine.

What is a Kitchen Sink Manufacturing Machine?

A kitchen sink manufacturing machine is a specialized piece of equipment used to produce kitchen sinks. It is a complex and sophisticated machine that can create a variety of sink designs, shapes, and sizes. With the help of this machine, kitchen sink manufacturers can produce high-quality, durable, and visually appealing sinks at a faster and more efficient rate.

A kitchen sink manufacturing machine is a specialized piece of equipment used to produce kitchen sinks. It is a complex and sophisticated machine that can create a variety of sink designs, shapes, and sizes. With the help of this machine, kitchen sink manufacturers can produce high-quality, durable, and visually appealing sinks at a faster and more efficient rate.

The Benefits of Using a Kitchen Sink Manufacturing Machine

The use of kitchen sink manufacturing machines has revolutionized the way kitchen sinks are produced. Here are some of the benefits of this advanced technology:

- Faster Production:

With traditional methods, it can take days or even weeks to produce a single sink. With a kitchen sink manufacturing machine, multiple sinks can be produced in a matter of hours.

- Consistency and Precision:

These machines are equipped with advanced technology that ensures precision and consistency in the production process. This results in high-quality and uniform sinks that meet strict industry standards.

- Cost-Efficiency:

By streamlining the production process and reducing manual labor, kitchen sink manufacturing machines can significantly cut down on production costs. This allows manufacturers to offer more competitive prices to consumers.

The use of kitchen sink manufacturing machines has revolutionized the way kitchen sinks are produced. Here are some of the benefits of this advanced technology:

- Faster Production:

With traditional methods, it can take days or even weeks to produce a single sink. With a kitchen sink manufacturing machine, multiple sinks can be produced in a matter of hours.

- Consistency and Precision:

These machines are equipped with advanced technology that ensures precision and consistency in the production process. This results in high-quality and uniform sinks that meet strict industry standards.

- Cost-Efficiency:

By streamlining the production process and reducing manual labor, kitchen sink manufacturing machines can significantly cut down on production costs. This allows manufacturers to offer more competitive prices to consumers.

The Future of Kitchen Sink Manufacturing

As technology continues to advance, the future of kitchen sink manufacturing looks promising. With the use of 3D printing and other innovative techniques, we can expect to see even more versatile and customizable kitchen sink designs in the market.

In conclusion, the kitchen sink manufacturing machine has played a crucial role in the evolution of kitchen sinks and house design. It has made the production process faster, more efficient, and more cost-effective, ultimately providing consumers with a wider range of high-quality and visually appealing sink options. With constant advancements and improvements in this technology, we can expect to see even more innovative and functional kitchen sinks in the future.

As technology continues to advance, the future of kitchen sink manufacturing looks promising. With the use of 3D printing and other innovative techniques, we can expect to see even more versatile and customizable kitchen sink designs in the market.

In conclusion, the kitchen sink manufacturing machine has played a crucial role in the evolution of kitchen sinks and house design. It has made the production process faster, more efficient, and more cost-effective, ultimately providing consumers with a wider range of high-quality and visually appealing sink options. With constant advancements and improvements in this technology, we can expect to see even more innovative and functional kitchen sinks in the future.