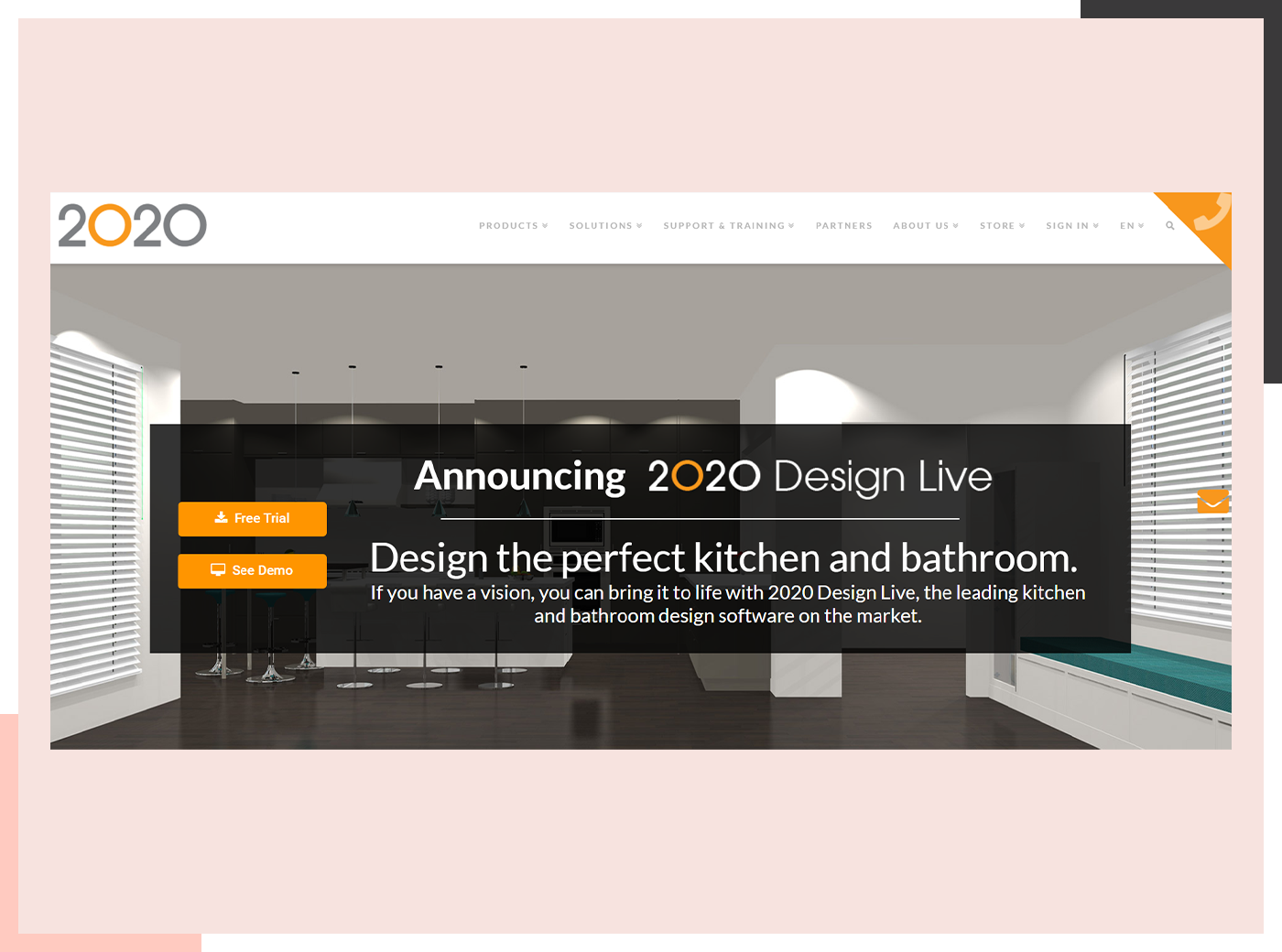

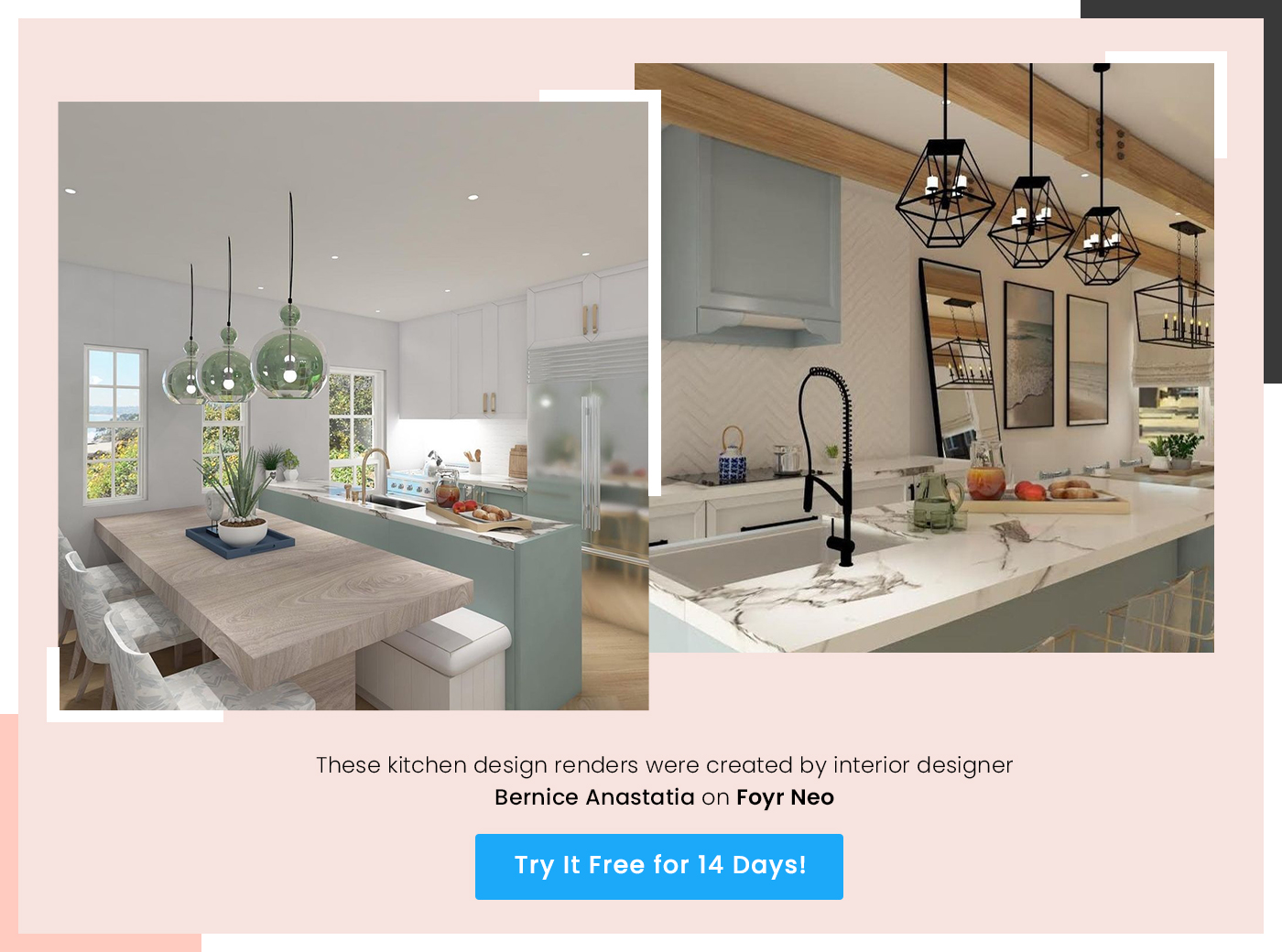

The use of technology has revolutionized the way we design and manufacture kitchens. With the help of kitchen design software, designers and manufacturers can now create highly detailed and accurate 3D models of kitchen layouts, allowing for better visualization and planning. This software also allows for easy customization and adjustments to the design, making it easier to meet the specific needs and preferences of clients.1. Kitchen Design Software

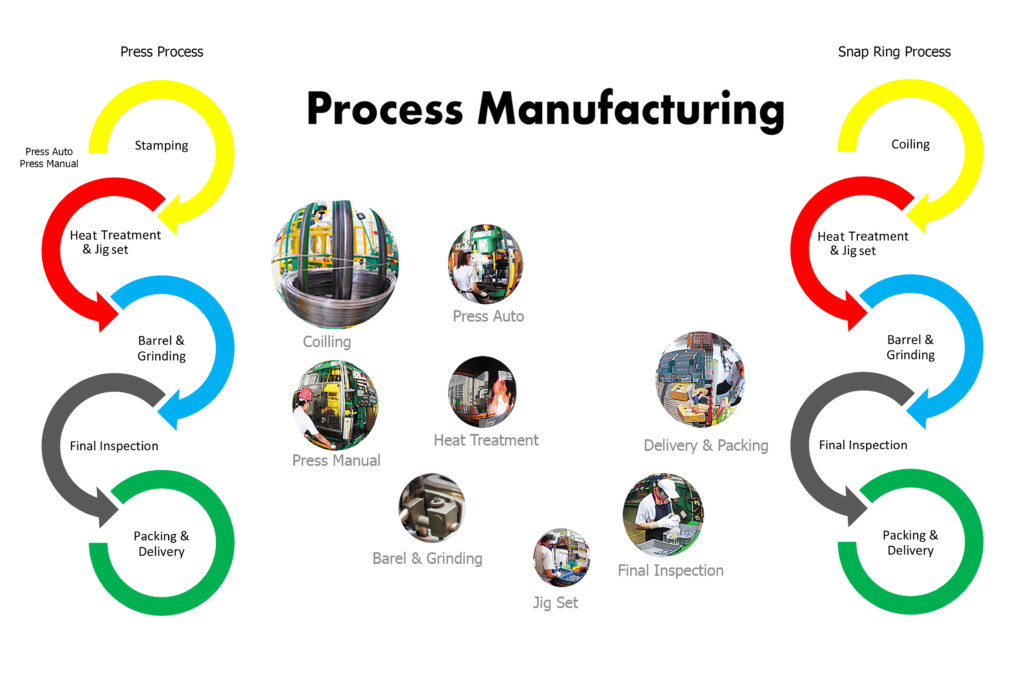

The production of kitchen cabinets has come a long way with the advancements in manufacturing technology. From traditional carpentry techniques to computer-controlled machinery, the process has become faster, more precise, and more efficient. With the use of CNC machines, cabinets can be cut, shaped, and drilled with precision, resulting in a higher quality and consistent product.2. Manufacturing Technology for Kitchen Cabinets

The kitchen design and manufacturing process has become more streamlined and integrated, thanks to technology. With the use of software and machinery, designers and manufacturers can work together seamlessly, from initial design to fabrication. This not only saves time and reduces errors but also allows for a more collaborative and efficient approach.3. Kitchen Design and Manufacturing Process

As technology continues to advance, so do the techniques used in kitchen design manufacturing. One of the latest advancements is the use of 3D printing to create prototypes and customized parts. This allows for more intricate and complex designs to be brought to life quickly and with great precision.4. Advanced Manufacturing Techniques for Kitchen Design

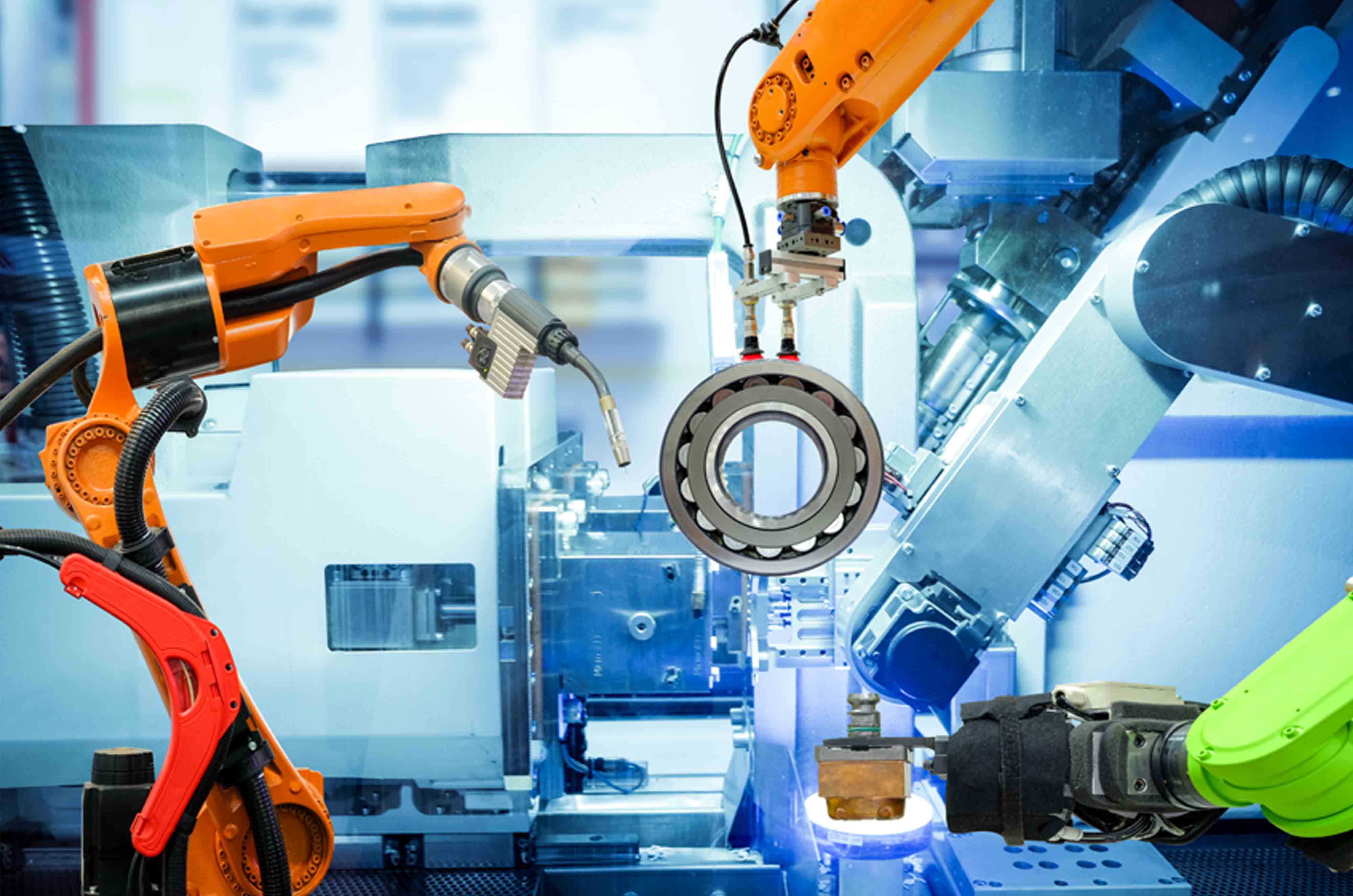

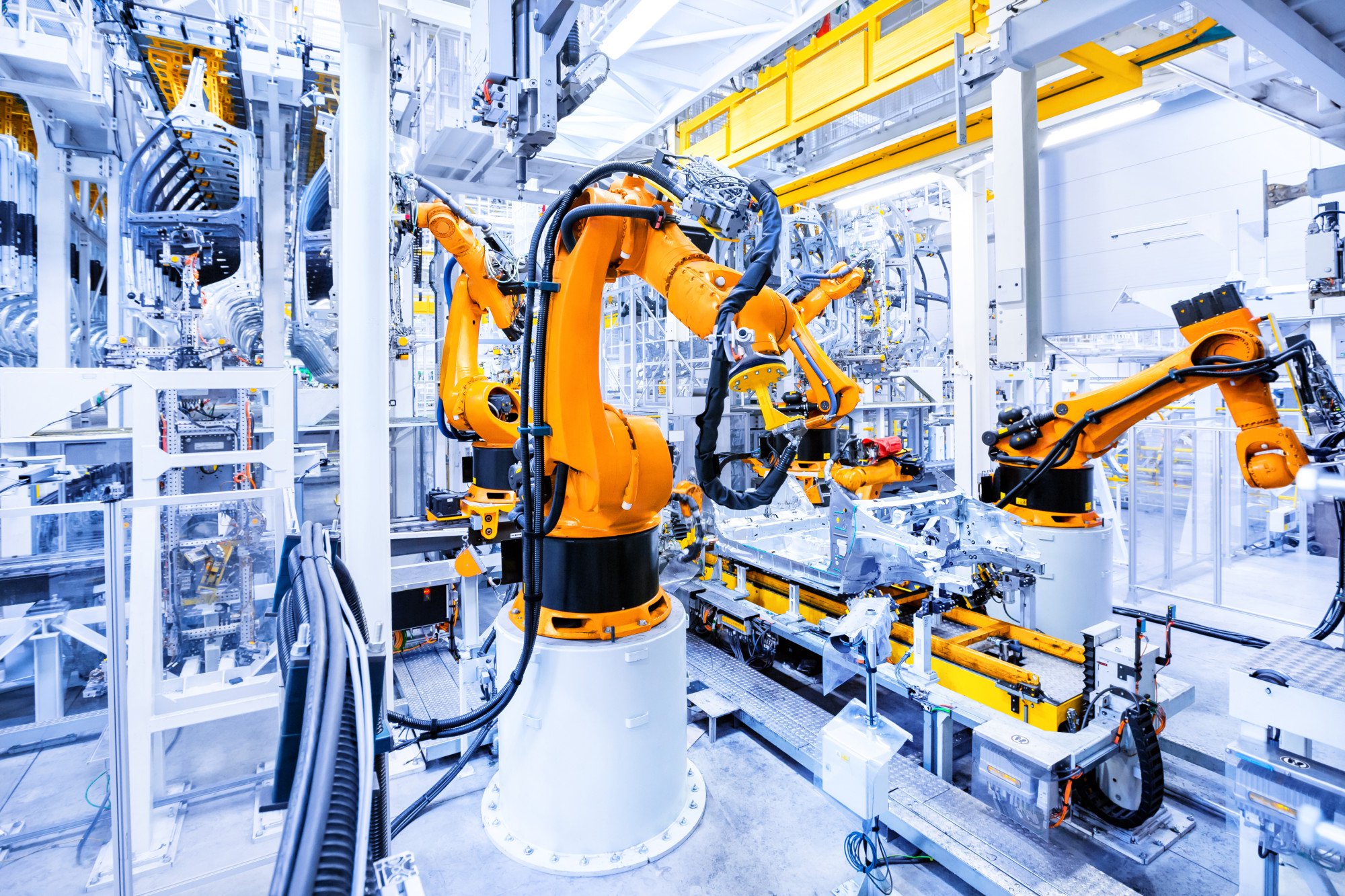

Automation is another key factor in the evolution of kitchen design and manufacturing. With the use of robots and other automated systems, tasks that were once done manually can now be completed quickly and accurately. This not only speeds up the production process but also reduces the potential for human error.5. Kitchen Design and Manufacturing Automation

The combination of design software, advanced manufacturing techniques, and automation has led to the development of innovative solutions in kitchen design manufacturing. One such solution is the use of modular construction, where components of a kitchen are prefabricated off-site and then assembled on-site. This method not only saves time and labor costs but also allows for a more sustainable approach to construction.6. Innovative Kitchen Design Manufacturing Solutions

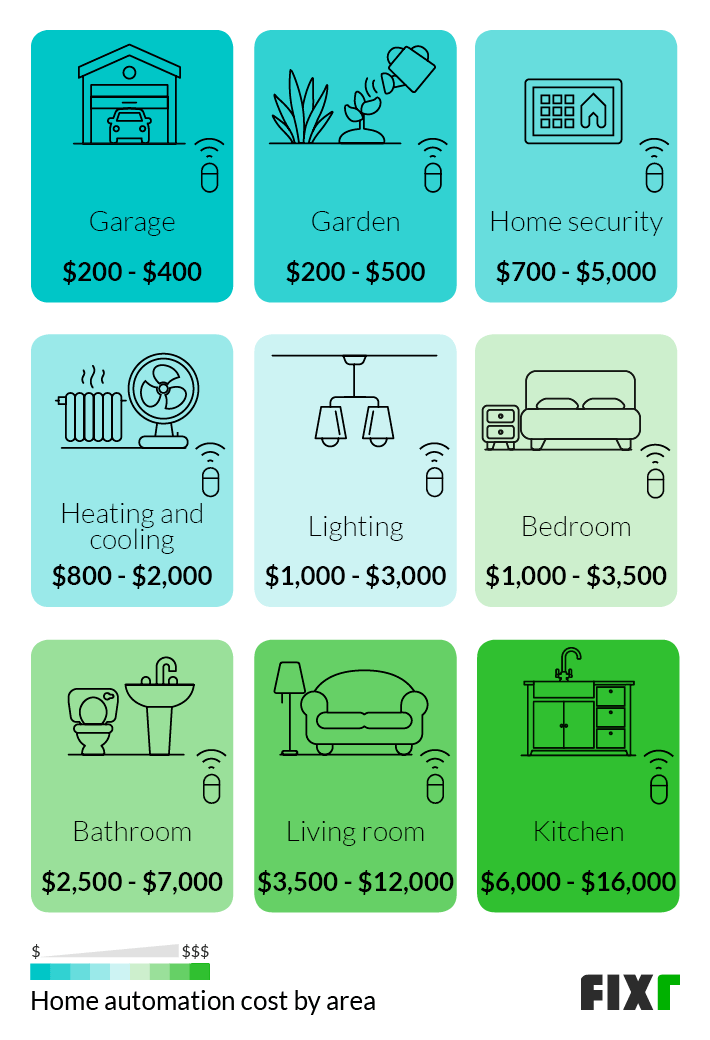

With technology constantly evolving, it's no surprise that there are numerous trends in kitchen design and manufacturing. One of the most significant trends is the integration of smart technology into kitchen appliances and fixtures. From voice-activated faucets to refrigerators with built-in touch screens, these advancements not only add convenience but also enhance the overall aesthetic of a kitchen.7. Kitchen Design and Manufacturing Trends

The use of cutting-edge technology in kitchen design manufacturing has not only improved the production process but also the end product itself. For example, laser edgebanding technology allows for a seamless and durable finish on kitchen cabinets, while thermofoil wrapping provides a cost-effective and attractive alternative to traditional wood cabinetry.8. Cutting-Edge Technology in Kitchen Design Manufacturing

With the use of advanced technology, the equipment used in kitchen design manufacturing has also evolved. From waterjet cutting machines to edgebanders, these machines are designed to handle specific tasks with precision and efficiency. Investing in quality equipment not only improves the production process but also ensures a higher quality end product.9. Kitchen Design Manufacturing Equipment

As the world becomes more environmentally conscious, sustainability has become a significant consideration in all industries, including kitchen design manufacturing. With the use of eco-friendly materials, energy-efficient equipment, and sustainable production processes, manufacturers can reduce their carbon footprint and contribute to a greener future. In conclusion, the integration of technology in kitchen design manufacturing has greatly improved the process and end product. From design software and advanced manufacturing techniques to automation and sustainable practices, technology has paved the way for more efficient, precise, and innovative kitchen design solutions.10. Sustainable Manufacturing Practices in Kitchen Design

Innovative Technology in Kitchen Design Manufacturing

Revolutionizing the Kitchen Design Industry

With the constant advancements in technology, we have seen a significant shift in the way kitchen designs are manufactured. Gone are the days of traditional handcrafted kitchens, as more and more designers are turning to technology to create innovative and efficient kitchen designs. The use of modern manufacturing techniques has not only enhanced the quality and precision of kitchen designs, but it has also made the process faster and more cost-effective.

With the constant advancements in technology, we have seen a significant shift in the way kitchen designs are manufactured. Gone are the days of traditional handcrafted kitchens, as more and more designers are turning to technology to create innovative and efficient kitchen designs. The use of modern manufacturing techniques has not only enhanced the quality and precision of kitchen designs, but it has also made the process faster and more cost-effective.

The Role of CNC Machines

One of the key technologies that have revolutionized kitchen design manufacturing is the use of Computer Numerical Control (CNC) machines. These machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) to precisely cut and shape materials, such as wood, metal, and plastic, according to the exact specifications of the design. This technology has eliminated the need for manual labor, reducing the risk of human error and increasing the speed and accuracy of the manufacturing process.

CNC machines

have also opened up a world of possibilities in terms of design. With their ability to create intricate and complex designs, designers can now push the boundaries of traditional kitchen design and create unique and personalized spaces. This has given rise to a new era of

customized kitchen designs

, where homeowners can have a say in every aspect of their kitchen, from the materials used to the smallest details of the design.

One of the key technologies that have revolutionized kitchen design manufacturing is the use of Computer Numerical Control (CNC) machines. These machines use computer-aided design (CAD) and computer-aided manufacturing (CAM) to precisely cut and shape materials, such as wood, metal, and plastic, according to the exact specifications of the design. This technology has eliminated the need for manual labor, reducing the risk of human error and increasing the speed and accuracy of the manufacturing process.

CNC machines

have also opened up a world of possibilities in terms of design. With their ability to create intricate and complex designs, designers can now push the boundaries of traditional kitchen design and create unique and personalized spaces. This has given rise to a new era of

customized kitchen designs

, where homeowners can have a say in every aspect of their kitchen, from the materials used to the smallest details of the design.

3D Printing in Kitchen Design

Another technology that has had a significant impact on kitchen design manufacturing is 3D printing. This process involves creating a physical object from a digital model by laying down layer upon layer of material. While 3D printing is still in its early stages in the kitchen design industry, it has the potential to revolutionize the way kitchen components are made. With the ability to create complex and intricate shapes, 3D printing allows for more creative and unique designs, unlike anything seen before in the industry.

3D printing

also offers a more sustainable approach to manufacturing as it reduces material waste and energy consumption. This aligns with the growing trend towards environmentally friendly and sustainable designs in the housing industry.

Another technology that has had a significant impact on kitchen design manufacturing is 3D printing. This process involves creating a physical object from a digital model by laying down layer upon layer of material. While 3D printing is still in its early stages in the kitchen design industry, it has the potential to revolutionize the way kitchen components are made. With the ability to create complex and intricate shapes, 3D printing allows for more creative and unique designs, unlike anything seen before in the industry.

3D printing

also offers a more sustainable approach to manufacturing as it reduces material waste and energy consumption. This aligns with the growing trend towards environmentally friendly and sustainable designs in the housing industry.

The Future of Kitchen Design Manufacturing

As technology continues to advance, we can expect to see even more innovative and efficient ways of manufacturing kitchen designs. From

virtual reality

design software to

artificial intelligence

in manufacturing processes, the possibilities are endless. These technologies will not only enhance the quality and efficiency of kitchen design manufacturing but also provide a more personalized and sustainable approach to creating the heart of every home.

As technology continues to advance, we can expect to see even more innovative and efficient ways of manufacturing kitchen designs. From

virtual reality

design software to

artificial intelligence

in manufacturing processes, the possibilities are endless. These technologies will not only enhance the quality and efficiency of kitchen design manufacturing but also provide a more personalized and sustainable approach to creating the heart of every home.

/https:%2F%2Fspecials-images.forbesimg.com%2Fimageserve%2F5fb52784bd56b9f72a755b1a%2F0x0.jpg)

/exciting-small-kitchen-ideas-1821197-hero-d00f516e2fbb4dcabb076ee9685e877a.jpg)