When it comes to producing high-quality foam mattresses, having the right manufacturing machines is crucial. These machines are specifically designed to create mattresses that are comfortable, durable, and supportive. In this article, we will take a closer look at the top 10 MAIN_foam mattress manufacturing machines that are used by industry leaders to produce the best mattresses in the market. Foam Mattress Manufacturing Machines

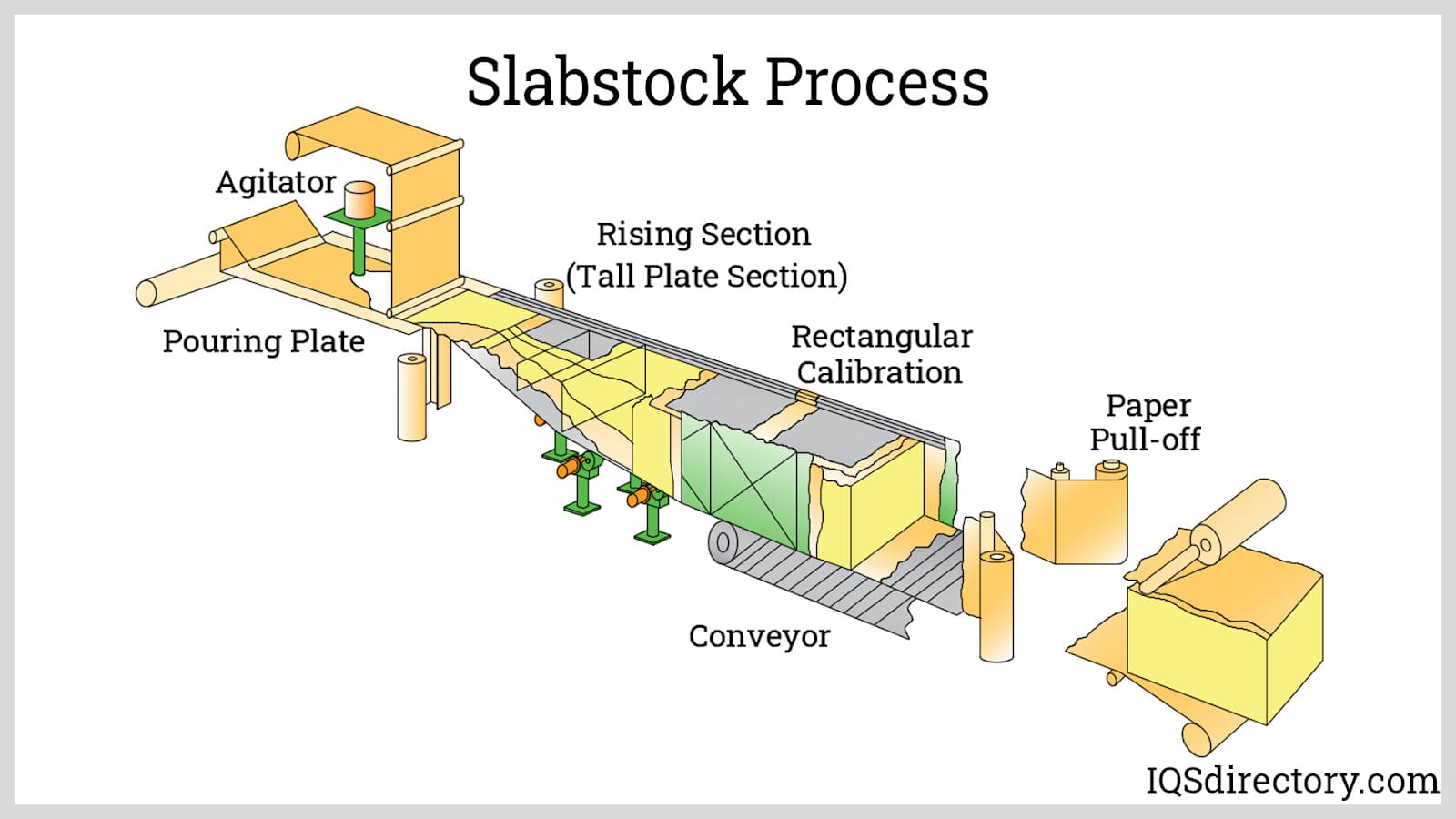

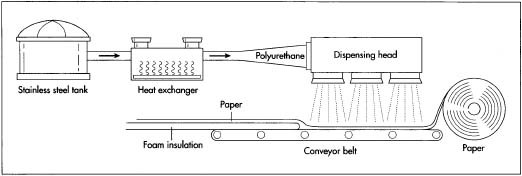

The production of foam mattresses requires specialized equipment that can handle the unique characteristics of foam materials. This equipment includes foam cutters, foam pouring machines, and foam laminating machines. Foam cutters are used to create the desired shape and size of the mattress, while foam pouring machines are used to mix and pour the foam material into the desired shape. Foam laminating machines are then used to bond different layers of foam together to create a multi-layered mattress. Foam Mattress Production Equipment

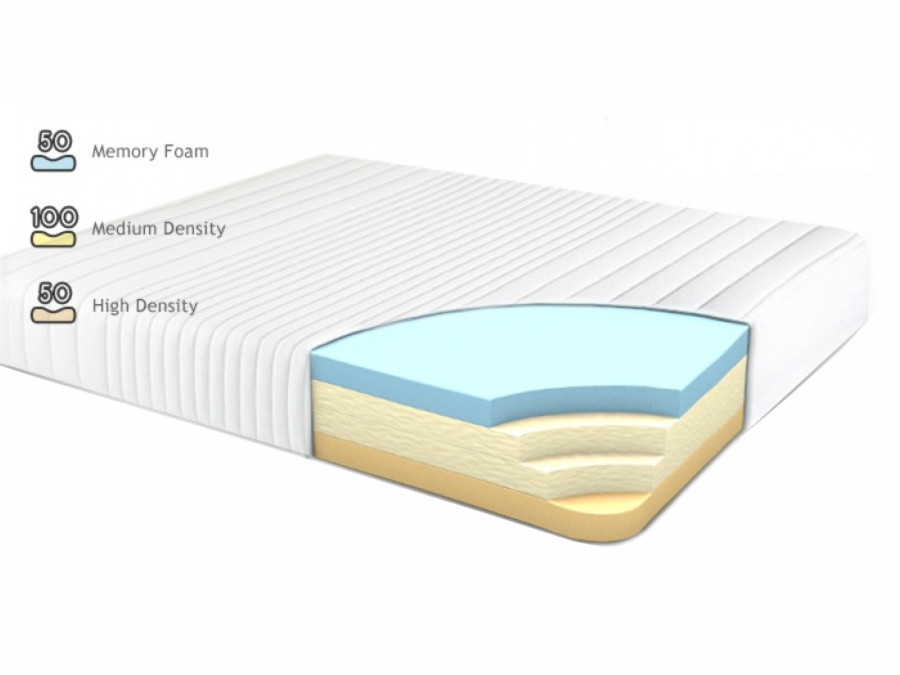

Foam mattress making machines are designed to streamline the production process and increase efficiency. These machines can handle various foam types, including memory foam, latex foam, and polyurethane foam. They also have the capability to produce different sizes and shapes of mattresses, making them versatile and adaptable to different production needs. Foam Mattress Making Machines

A foam mattress production line is a series of interconnected machines that work together to produce foam mattresses. This line typically includes a foam cutter, a foam pouring machine, a foam laminating machine, and a packaging machine. A well-designed production line can significantly increase productivity and reduce production time, allowing manufacturers to meet the high demand for foam mattresses. Foam Mattress Production Line

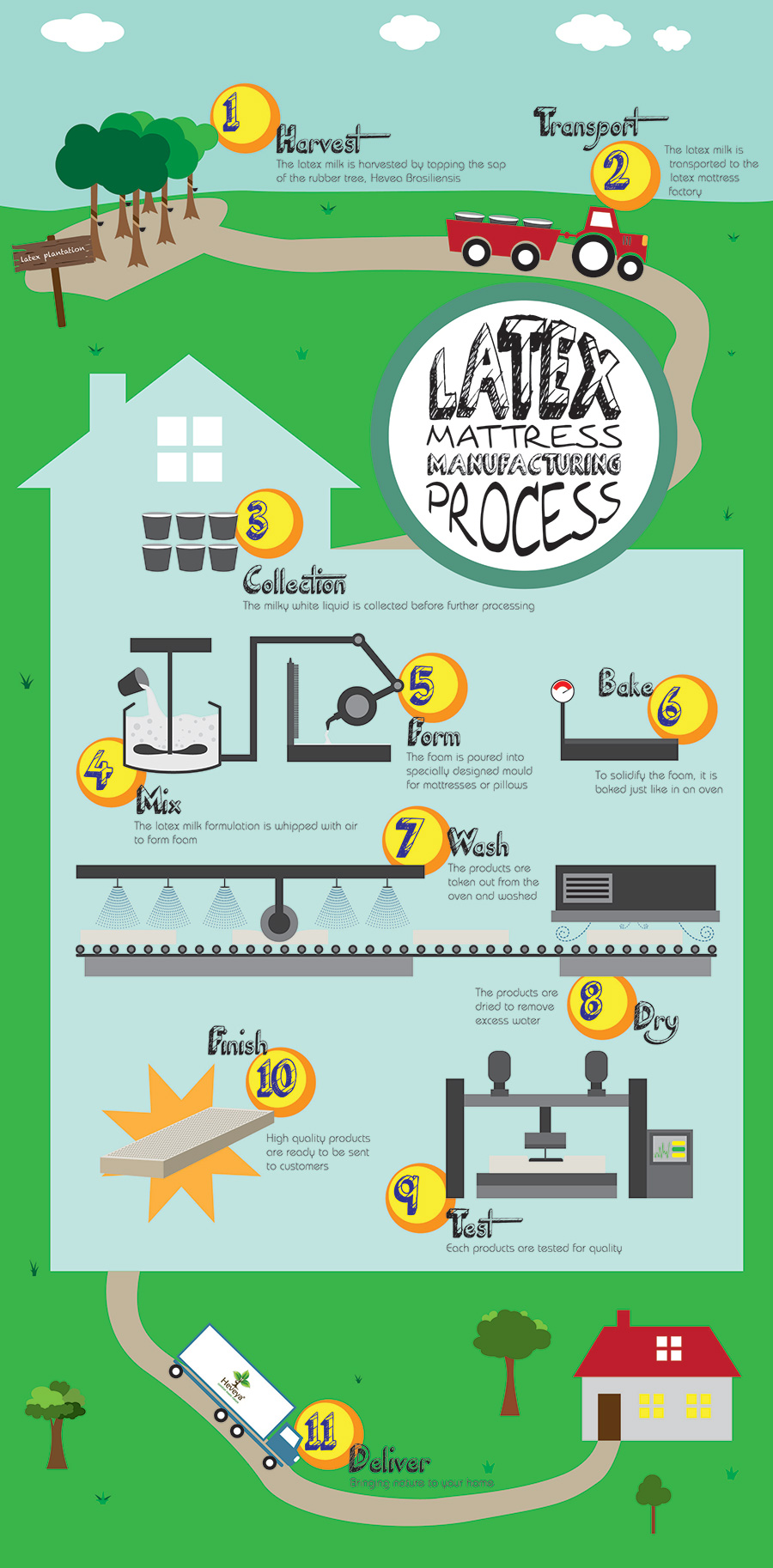

The foam mattress manufacturing process involves several steps, including mixing and pouring the foam material, cutting and shaping the foam, and laminating multiple layers together. This process requires precise machinery and skilled operators to ensure the quality and consistency of the final product. The use of advanced foam mattress manufacturing machines makes this process more efficient and accurate. Foam Mattress Manufacturing Process

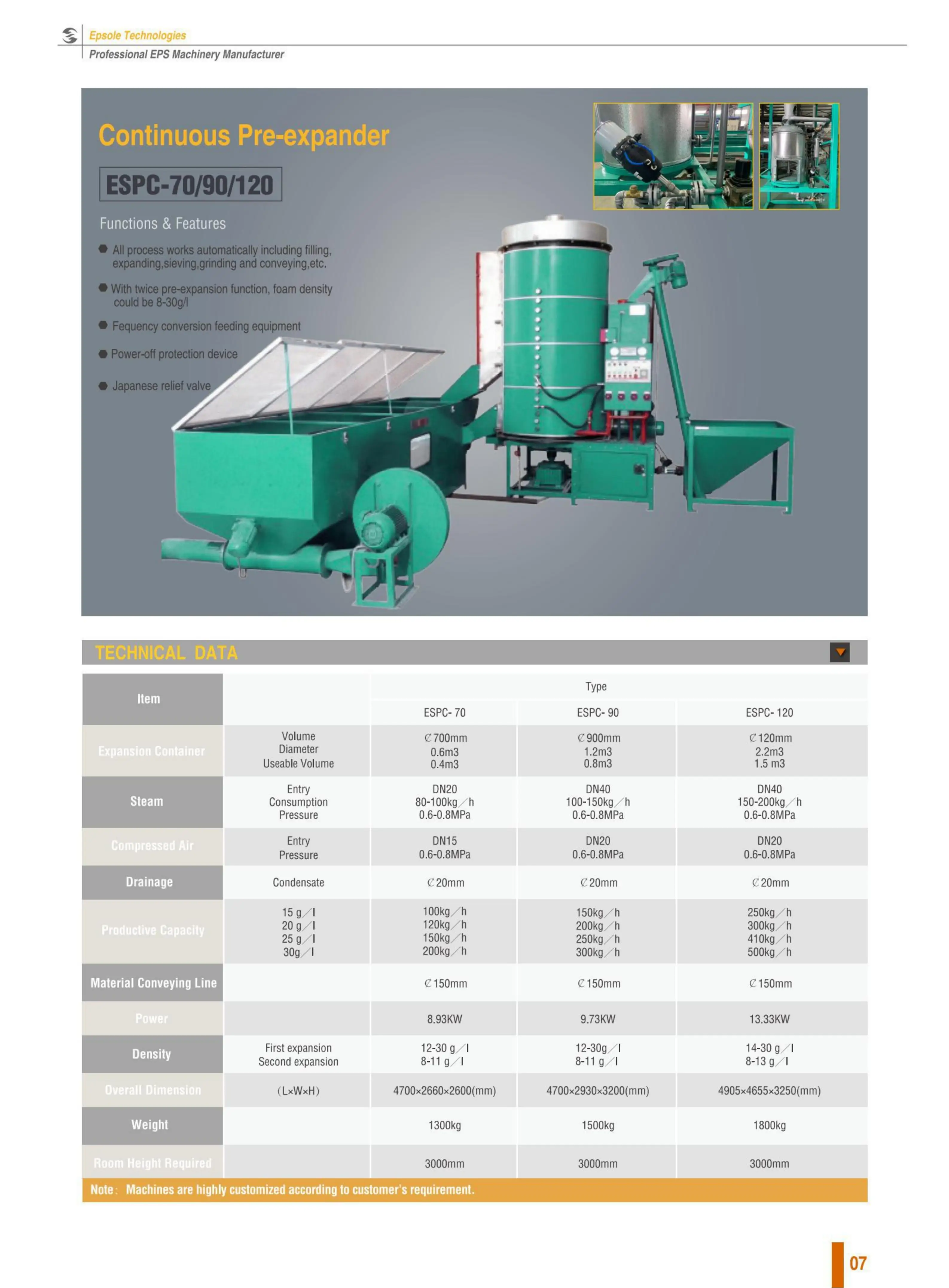

Foam mattress production machinery includes a range of equipment, from automated machines to manual tools. Automated machines, such as CNC foam cutters and robotic foam pourers, are used for larger production volumes, while manual tools, such as hand-held foam cutters, are more suitable for smaller operations. The type of production machinery used will depend on the production needs and budget of the manufacturer. Foam Mattress Production Machinery

Manufacturing foam mattresses requires specialized equipment that can handle the unique properties of foam materials. This equipment includes foam curing ovens, foam shredders, and foam compressors. Foam curing ovens are used to dry and cure the foam material, while foam shredders are used to recycle foam waste. Foam compressors are essential for compressing foam mattresses for shipping and storage. Foam Mattress Manufacturing Equipment

There are various types of foam mattress production machines available in the market, each with its own specific functions and features. Some machines are designed to produce specific types of foam mattresses, such as memory foam or latex foam, while others are more versatile and can produce different types of foam mattresses. It is essential to choose the right production machine that meets the specific needs of the manufacturer. Foam Mattress Production Machines

The use of foam mattress manufacturing systems allows for a more streamlined and efficient production process. These systems typically include a combination of automated machines and manual tools, as well as a software program that controls and monitors the production process. With the help of these systems, manufacturers can produce high-quality foam mattresses with minimal human error and maximum productivity. Foam Mattress Manufacturing Systems

Technology plays a significant role in the production of foam mattresses. With the advancement of technology, manufacturers can now produce foam mattresses with enhanced comfort and support. For example, gel-infused memory foam mattresses have become increasingly popular due to their cooling properties, and this is made possible through the use of advanced production technology. It is crucial for manufacturers to stay updated with the latest production technology to stay ahead in the market. Foam Mattress Production Technology

The Advantages of Using Foam Mattress Manufacturing Machines in House Design

Efficiency and Precision in Production

When it comes to house design, every detail counts. That's why using foam mattress manufacturing machines can greatly benefit designers and homeowners alike. These machines are specifically designed to produce high-quality foam mattresses with utmost efficiency and precision. With advanced technology and automated processes, these machines can produce consistent and uniform foam mattresses, ensuring that every piece meets the same high standards. This not only saves time and labor costs, but also guarantees a flawless end product.

When it comes to house design, every detail counts. That's why using foam mattress manufacturing machines can greatly benefit designers and homeowners alike. These machines are specifically designed to produce high-quality foam mattresses with utmost efficiency and precision. With advanced technology and automated processes, these machines can produce consistent and uniform foam mattresses, ensuring that every piece meets the same high standards. This not only saves time and labor costs, but also guarantees a flawless end product.

Customization and Versatility

One of the biggest challenges in house design is finding the right mattress that fits the unique needs and preferences of each homeowner. Foam mattress manufacturing machines offer a wide range of customization options, from size and thickness to density and firmness. This allows designers to create mattresses that cater to specific sleeping habits and health conditions. It also allows for versatile use in different areas of the house, such as guest rooms, children's rooms, and even outdoor spaces.

One of the biggest challenges in house design is finding the right mattress that fits the unique needs and preferences of each homeowner. Foam mattress manufacturing machines offer a wide range of customization options, from size and thickness to density and firmness. This allows designers to create mattresses that cater to specific sleeping habits and health conditions. It also allows for versatile use in different areas of the house, such as guest rooms, children's rooms, and even outdoor spaces.

Eco-Friendly and Sustainable

In today's world, sustainability is a key consideration in any industry. Foam mattress manufacturing machines use eco-friendly materials and processes, making them a more environmentally responsible choice. Most machines use water-based adhesives and recyclable materials, reducing the carbon footprint of the production process. This not only benefits the planet, but also appeals to environmentally conscious consumers.

In today's world, sustainability is a key consideration in any industry. Foam mattress manufacturing machines use eco-friendly materials and processes, making them a more environmentally responsible choice. Most machines use water-based adhesives and recyclable materials, reducing the carbon footprint of the production process. This not only benefits the planet, but also appeals to environmentally conscious consumers.

Innovative Technology for Comfort

Gone are the days of uncomfortable and lumpy mattresses. Foam mattress manufacturing machines use innovative technology to create mattresses that provide optimal comfort and support. With the ability to produce different layers and densities of foam, these machines can create mattresses that contour to the body and alleviate pressure points. This results in a better night's sleep and improved overall health and well-being.

Gone are the days of uncomfortable and lumpy mattresses. Foam mattress manufacturing machines use innovative technology to create mattresses that provide optimal comfort and support. With the ability to produce different layers and densities of foam, these machines can create mattresses that contour to the body and alleviate pressure points. This results in a better night's sleep and improved overall health and well-being.

The Future of House Design

As the demand for high-quality and customizable mattresses continues to rise, foam mattress manufacturing machines are becoming an essential tool in house design. With their efficiency, customization options, eco-friendliness, and comfort, these machines are revolutionizing the way we think about mattresses and their role in creating a comfortable and stylish home. Incorporating foam mattress manufacturing machines into house design not only enhances the overall aesthetic, but also ensures a better night's sleep for homeowners.

As the demand for high-quality and customizable mattresses continues to rise, foam mattress manufacturing machines are becoming an essential tool in house design. With their efficiency, customization options, eco-friendliness, and comfort, these machines are revolutionizing the way we think about mattresses and their role in creating a comfortable and stylish home. Incorporating foam mattress manufacturing machines into house design not only enhances the overall aesthetic, but also ensures a better night's sleep for homeowners.