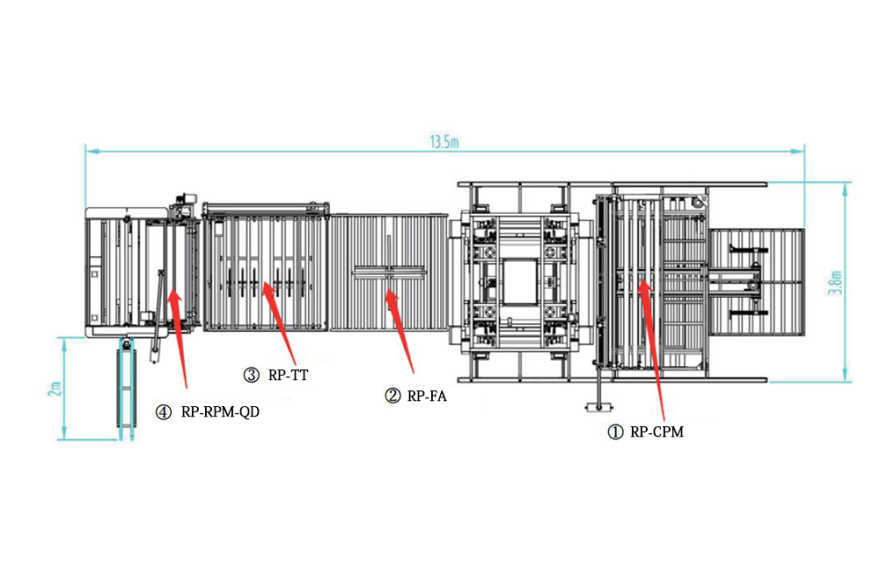

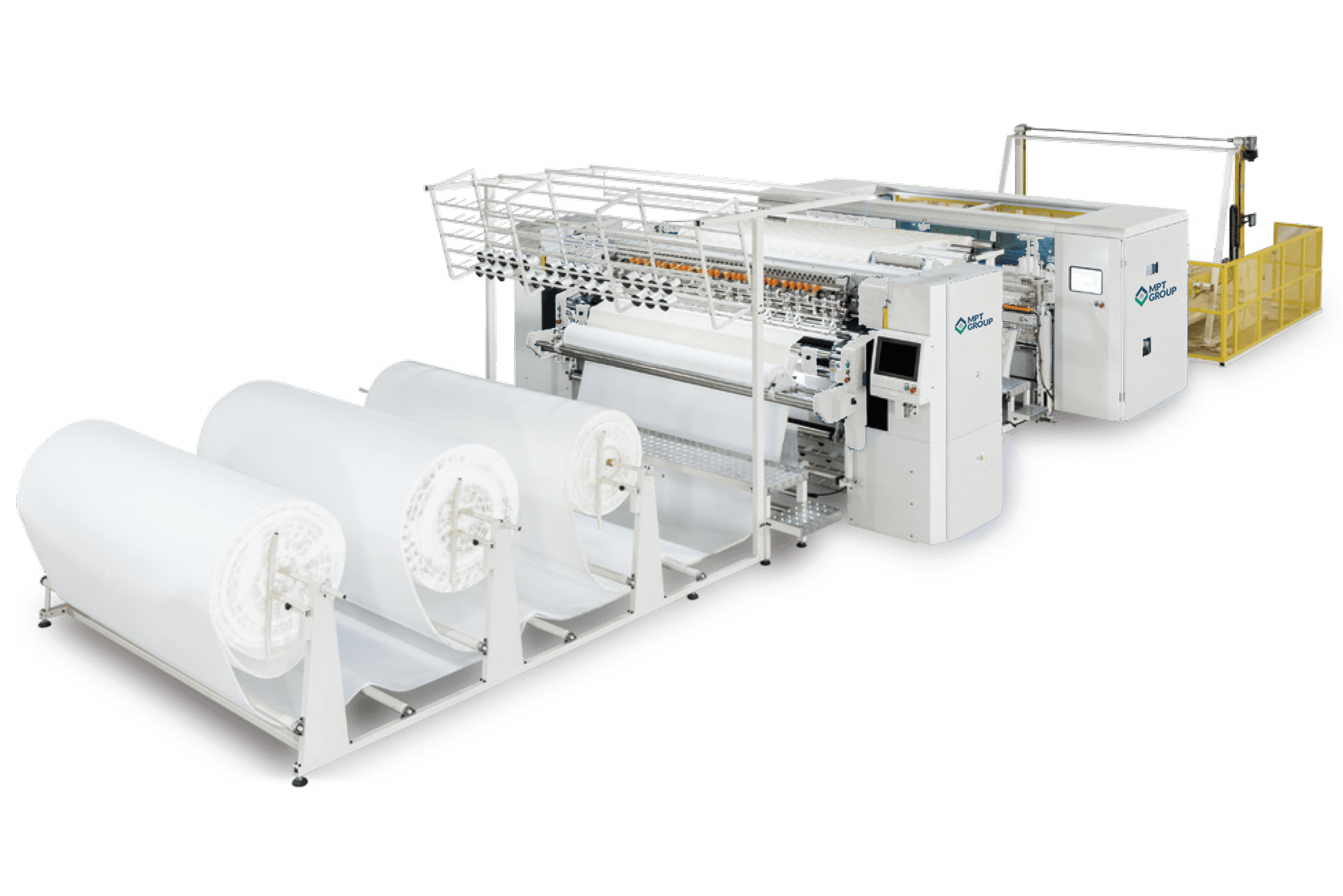

Mattresses are an essential part of our daily lives, providing us with a comfortable and restful sleep. But have you ever wondered how these mattresses are made? Well, the answer lies in the automated mattress production line. This revolutionary machine is designed to automate the entire process of mattress manufacturing, from cutting and stitching to quilting and packaging. With its advanced technology and precise movements, it ensures the production of high-quality mattresses in a fraction of the time that it would take with manual labor.1. Automated Mattress Production Line

The key to producing top-quality mattresses lies in having the right equipment. The mattress manufacturing equipment is a crucial component in the production line, as each machine has its specific function in the process. These machines are designed to produce different types of mattresses, including foam, innerspring, and hybrid mattresses. Some of the essential equipment used in the manufacturing process includes foam cutting machines, quilting machines, sewing machines, and packing machines.2. Mattress Manufacturing Equipment

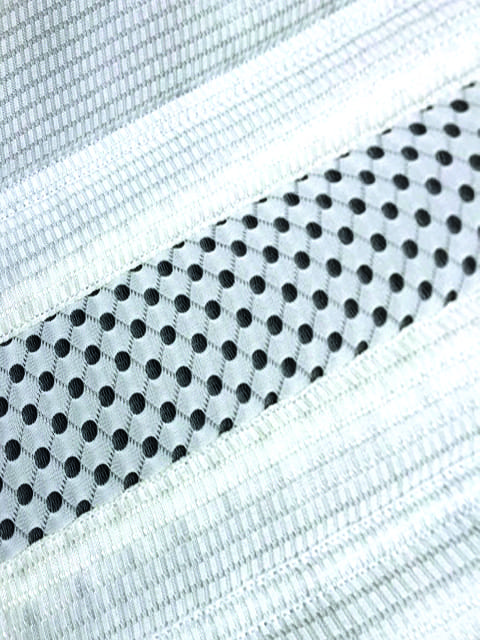

The bedding machine is an integral part of the mattress production line, responsible for producing the outer layers of the mattress. This machine is used to stitch together layers of fabric, foam, and other materials to create the top and bottom of the mattress. It is a crucial step in the production process as it ensures the comfort and durability of the mattress. The bedding machine uses advanced technology to stitch the layers together seamlessly, providing a smooth and even surface for the mattress.3. Bedding Machine

The mattress quilting machine is responsible for adding the signature quilted pattern on the top layer of the mattress. This machine uses needles and thread to create a quilted design, providing extra padding and comfort to the mattress. The quilting machine can produce different patterns, from simple lines to intricate designs, making each mattress unique in its own way.4. Mattress Quilting Machine

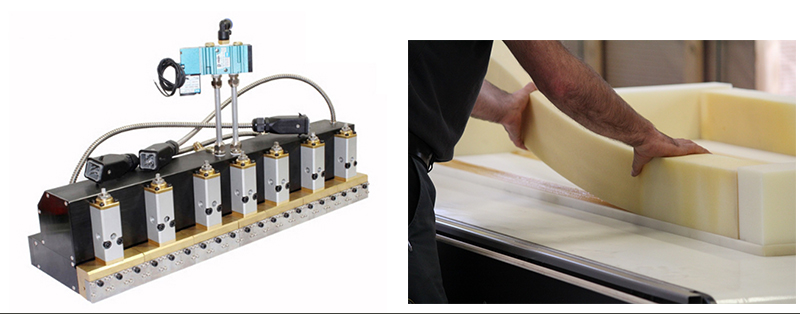

Foam is a crucial component in the manufacturing of mattresses, and the foam cutting machine ensures that the foam is cut to the right size and shape. This machine uses precise measurements and cutting tools to create foam layers that fit perfectly into the mattress. It also helps reduce waste and improve efficiency in the production process.5. Foam Cutting Machine

Once the mattress is complete, it needs to be packed and prepared for shipping. The mattress packing machine is responsible for compressing and rolling the mattress into a compact size for easier transportation. This machine uses a combination of heat and pressure to compress the mattress, making it easier to handle and ship to different locations.6. Mattress Packing Machine

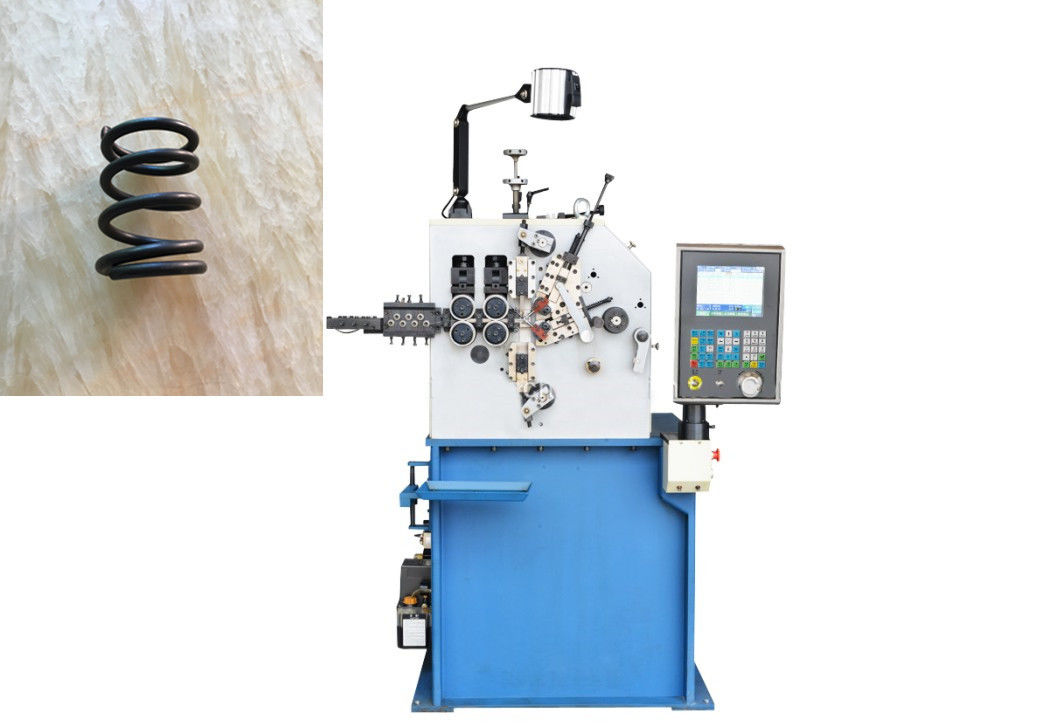

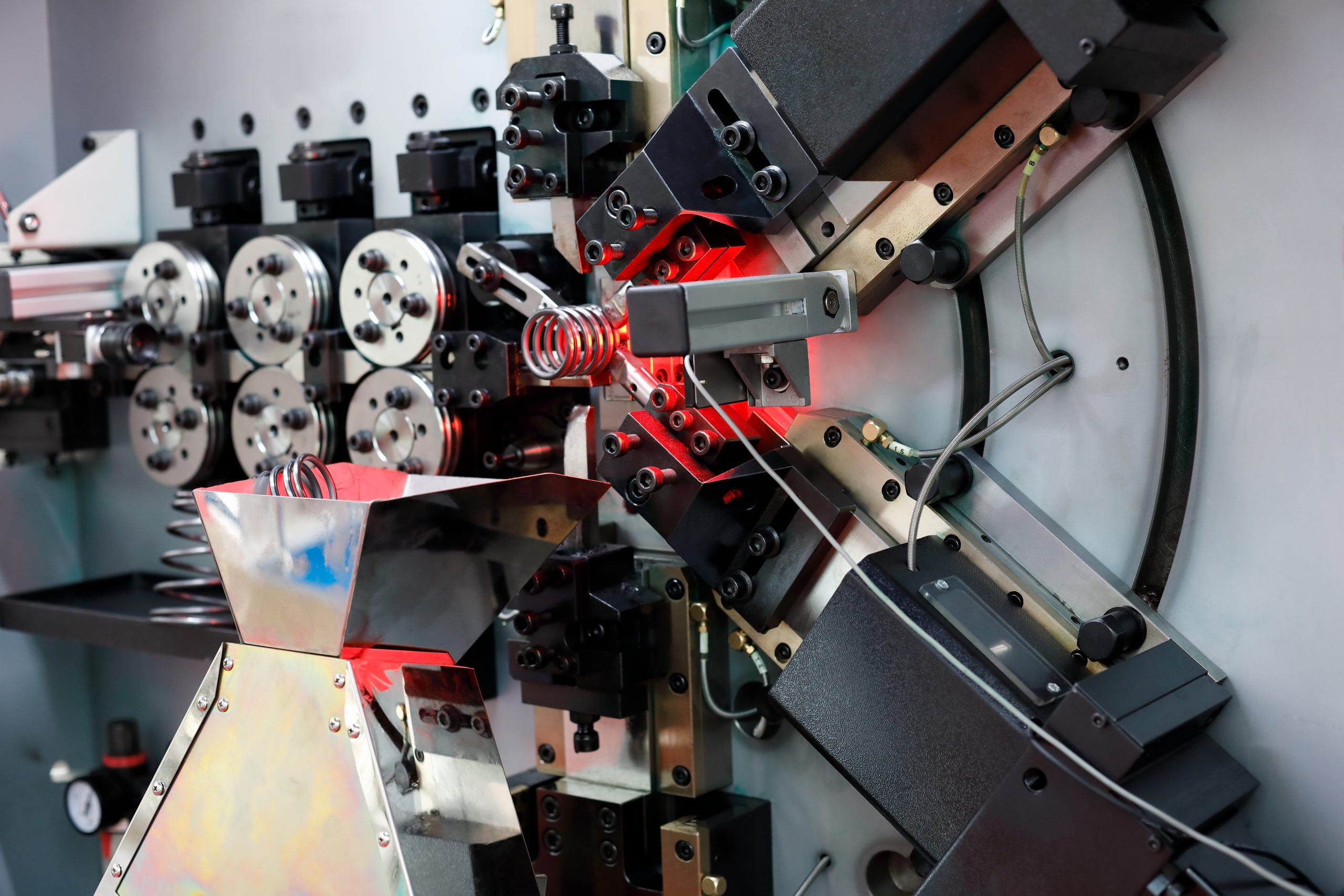

Innerspring mattresses are made with coils that provide support and comfort. The spring coiling machine is used to produce these coils with precision and accuracy. This machine uses high-quality steel wire to create coils of different sizes and shapes, depending on the type of mattress being produced. The coils are then connected and inserted into the mattress to provide the necessary support.7. Spring Coiling Machine

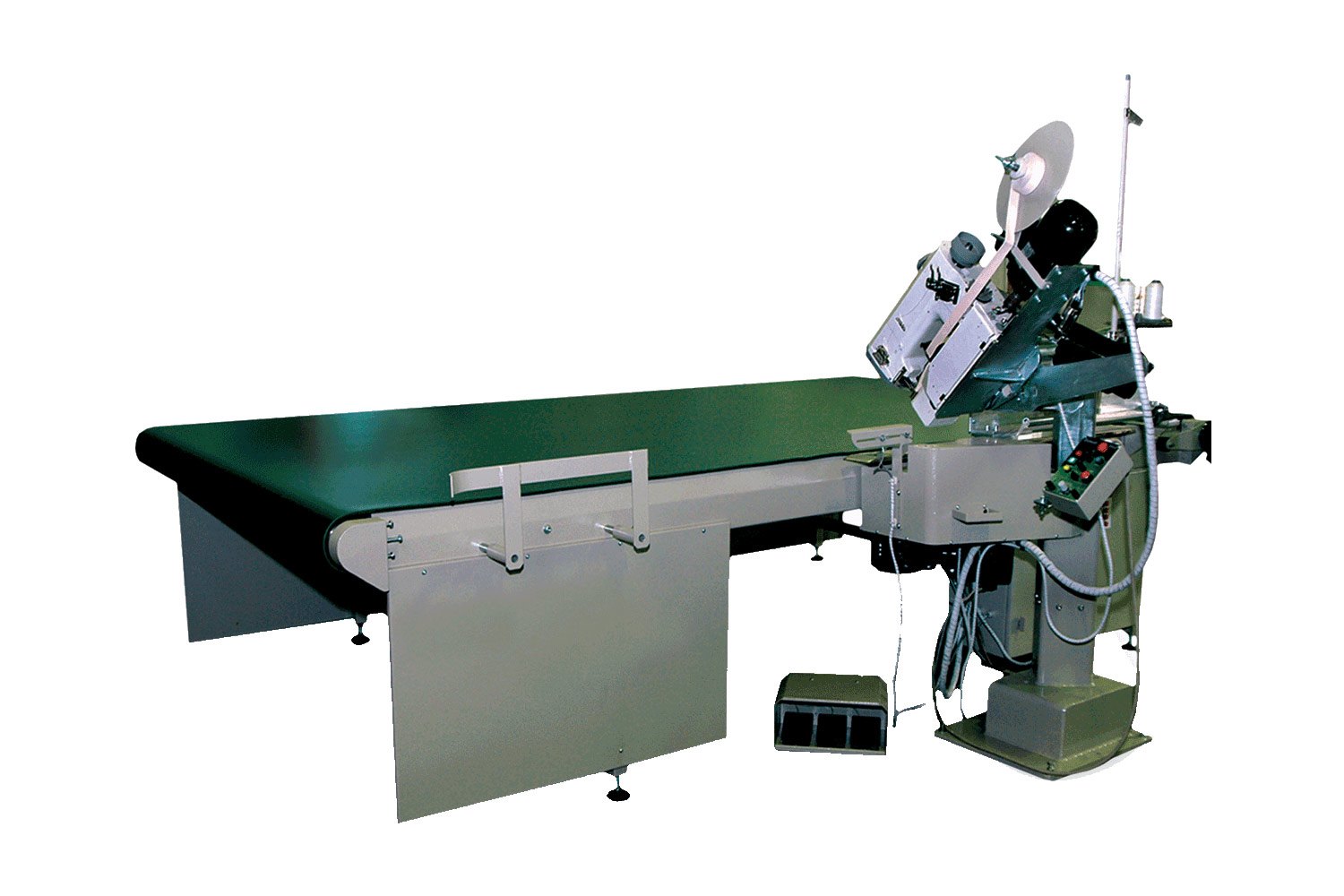

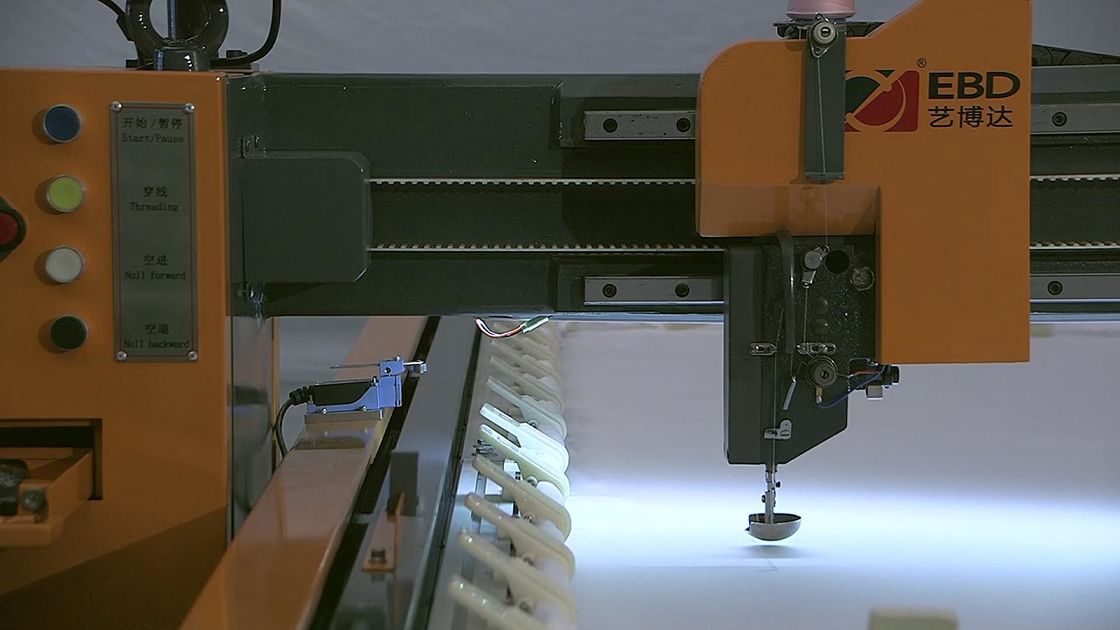

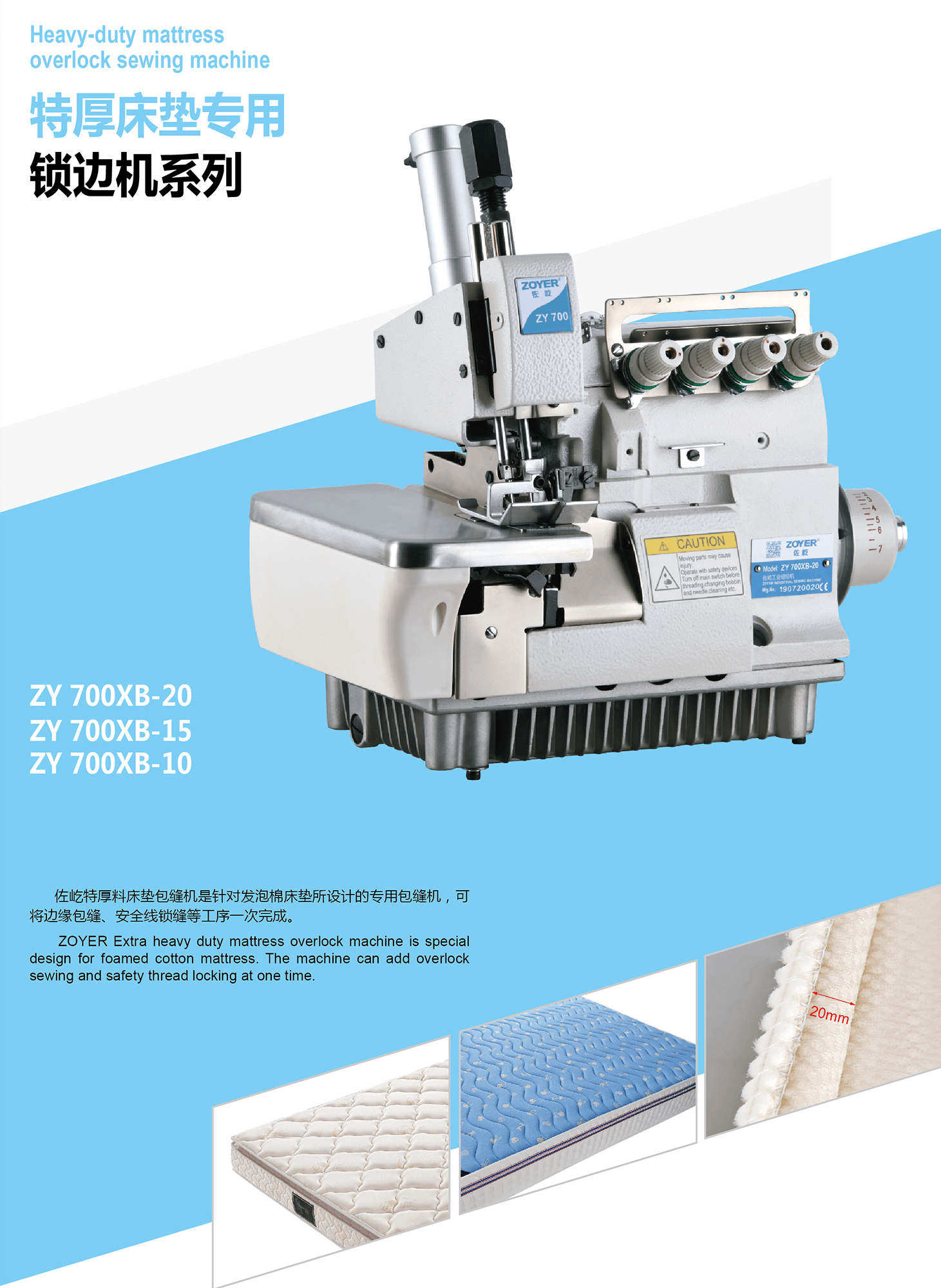

The mattress sewing machine is responsible for stitching together the layers of the mattress to create a sturdy and durable product. It uses advanced technology and precise movements to ensure that the stitches are even and strong, providing longevity to the mattress. This machine is essential in the production process as it ensures the layers of the mattress are held together securely.8. Mattress Sewing Machine

Another crucial step in the production process is the final packing of the mattress. The mattress roll packing machine is used to compress the mattress into a roll and then seal it with plastic for protection. This machine ensures that the mattress is tightly packed and ready for shipping to different locations.9. Mattress Roll Packing Machine

The last step in the production process is the application of glue to the mattress. The mattress gluing machine is used to apply adhesive to the layers of the mattress to keep them firmly in place. This machine uses advanced technology to apply the glue evenly and precisely, ensuring that the mattress is strong and durable. With the help of these top 10 mattress making machines, manufacturers can produce high-quality mattresses efficiently and effectively. These machines not only improve the production process but also ensure the comfort and durability of the final product. Investing in these machines is a smart choice for any mattress manufacturer, as it leads to increased productivity and customer satisfaction.10. Mattress Gluing Machine

The Evolution of Bed Mattress Making Machines

Innovative Technology for Comfort and Quality

The bed mattress is an essential element of any bedroom, providing comfort and support for a good night's sleep. However, the process of making a mattress has come a long way from hand-stitching and stuffing straw or feathers. With the advancement of technology, the introduction of bed mattress making machines has revolutionized the industry, providing a more efficient and precise way of creating high-quality mattresses. These machines have not only improved the production process but also enhanced the overall sleeping experience for consumers.

The bed mattress is an essential element of any bedroom, providing comfort and support for a good night's sleep. However, the process of making a mattress has come a long way from hand-stitching and stuffing straw or feathers. With the advancement of technology, the introduction of bed mattress making machines has revolutionized the industry, providing a more efficient and precise way of creating high-quality mattresses. These machines have not only improved the production process but also enhanced the overall sleeping experience for consumers.

The Benefits of Bed Mattress Making Machines

The use of bed mattress making machines has significantly increased the productivity of mattress manufacturers. These machines are equipped with advanced technology that allows for faster and more accurate production, resulting in a higher output of mattresses in a shorter amount of time. This has not only reduced the manufacturing costs but also enabled manufacturers to meet the growing demand for mattresses in the market.

Moreover, these machines have also improved the quality of mattresses. The precise cutting and stitching capabilities of these machines ensure that the mattress is made to the exact specifications, resulting in a consistent and uniform product. This eliminates the human error and variations that were common in the traditional hand-crafted method, resulting in a more durable and comfortable mattress for consumers.

The use of bed mattress making machines has significantly increased the productivity of mattress manufacturers. These machines are equipped with advanced technology that allows for faster and more accurate production, resulting in a higher output of mattresses in a shorter amount of time. This has not only reduced the manufacturing costs but also enabled manufacturers to meet the growing demand for mattresses in the market.

Moreover, these machines have also improved the quality of mattresses. The precise cutting and stitching capabilities of these machines ensure that the mattress is made to the exact specifications, resulting in a consistent and uniform product. This eliminates the human error and variations that were common in the traditional hand-crafted method, resulting in a more durable and comfortable mattress for consumers.

The Impact on House Design

The evolution of bed mattress making machines has not only impacted the mattress industry but also had an influence on house design. With the production of more comfortable and durable mattresses, consumers are now looking for bed frames and furniture that can accommodate these larger and heavier mattresses. This has led to the development of modern and sleek bed designs that can support these mattresses, adding a touch of elegance to any bedroom.

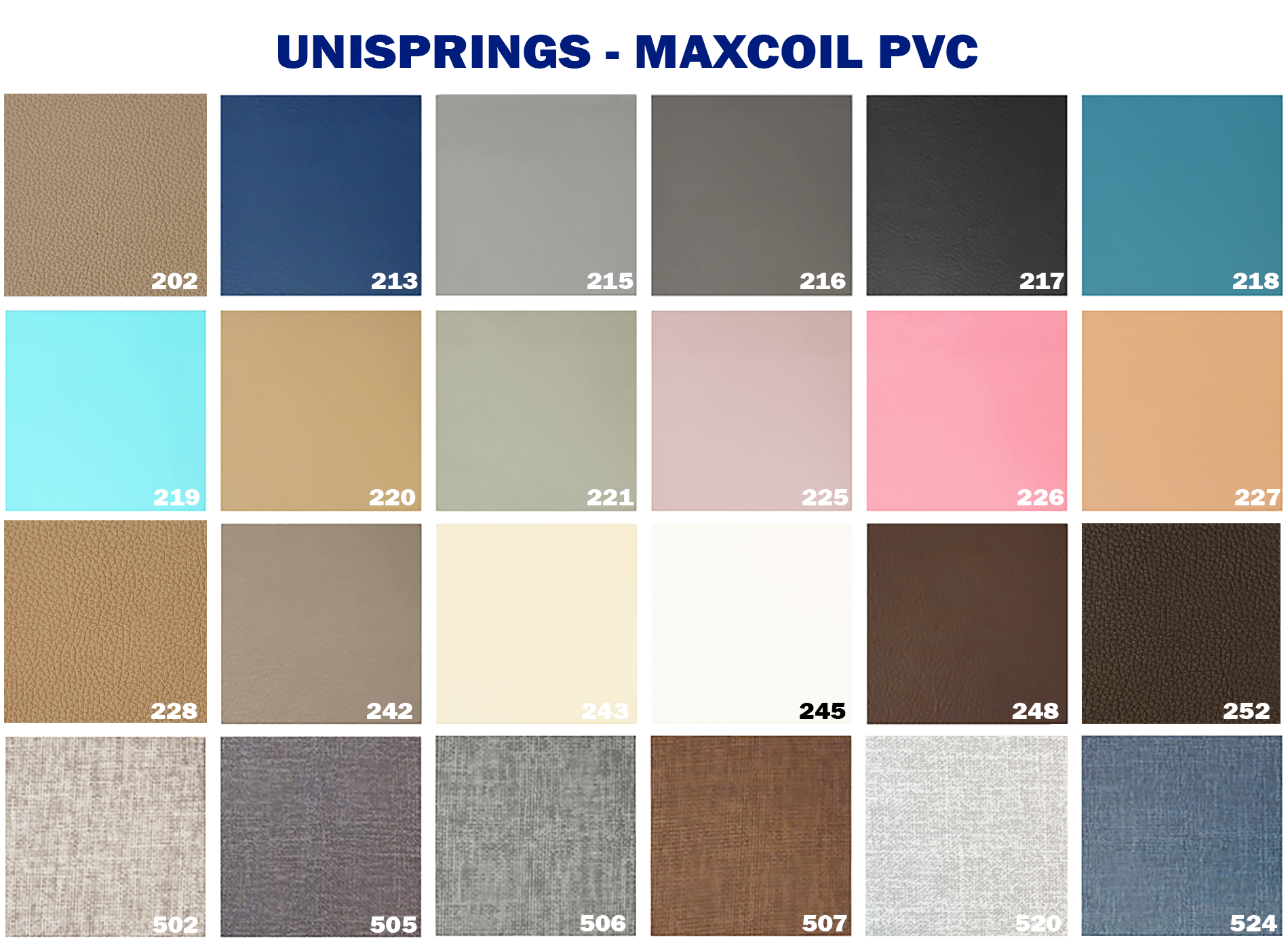

In addition, the use of advanced technology in bed mattress making machines has allowed for the creation of different types of mattresses to cater to various needs and preferences. From memory foam to hybrid mattresses, these machines have made it possible to produce a wide range of options, giving consumers the opportunity to choose the perfect mattress for their specific needs and preferences.

The evolution of bed mattress making machines has not only impacted the mattress industry but also had an influence on house design. With the production of more comfortable and durable mattresses, consumers are now looking for bed frames and furniture that can accommodate these larger and heavier mattresses. This has led to the development of modern and sleek bed designs that can support these mattresses, adding a touch of elegance to any bedroom.

In addition, the use of advanced technology in bed mattress making machines has allowed for the creation of different types of mattresses to cater to various needs and preferences. From memory foam to hybrid mattresses, these machines have made it possible to produce a wide range of options, giving consumers the opportunity to choose the perfect mattress for their specific needs and preferences.

The Future of Bed Mattress Making Machines

As technology continues to advance, we can expect even more innovative bed mattress making machines to enter the market. These machines will not only improve the efficiency and quality of mattress production but also offer more customizable options for consumers. With the rising demand for comfortable and high-quality mattresses, the future of bed mattress making machines looks bright, and the possibilities are endless.

In conclusion, the introduction of bed mattress making machines has transformed the mattress industry, providing a more efficient and precise way of creating high-quality mattresses. From increased productivity to improved quality, these machines have had a significant impact on house design and the overall sleeping experience for consumers. As technology continues to evolve, we can only expect further advancements in the world of bed mattress making machines.

As technology continues to advance, we can expect even more innovative bed mattress making machines to enter the market. These machines will not only improve the efficiency and quality of mattress production but also offer more customizable options for consumers. With the rising demand for comfortable and high-quality mattresses, the future of bed mattress making machines looks bright, and the possibilities are endless.

In conclusion, the introduction of bed mattress making machines has transformed the mattress industry, providing a more efficient and precise way of creating high-quality mattresses. From increased productivity to improved quality, these machines have had a significant impact on house design and the overall sleeping experience for consumers. As technology continues to evolve, we can only expect further advancements in the world of bed mattress making machines.

:max_bytes(150000):strip_icc()/lavender7-59d56980b501e800116fa0b1.jpg)

:max_bytes(150000):strip_icc()/gray-kitchen-cabinet-ideas-22-cathie-hong-interiors-scandinavian-c08d577bdaf54eb7a7715b0bacfec108.jpeg)