Are you curious about how air mattresses are made? Look no further, as we take you on a comprehensive journey through the manufacturing process of this popular bedding item. From the raw materials to the finished product, we'll cover everything you need to know.1. Air Mattress Manufacturing Process: A Comprehensive Guide

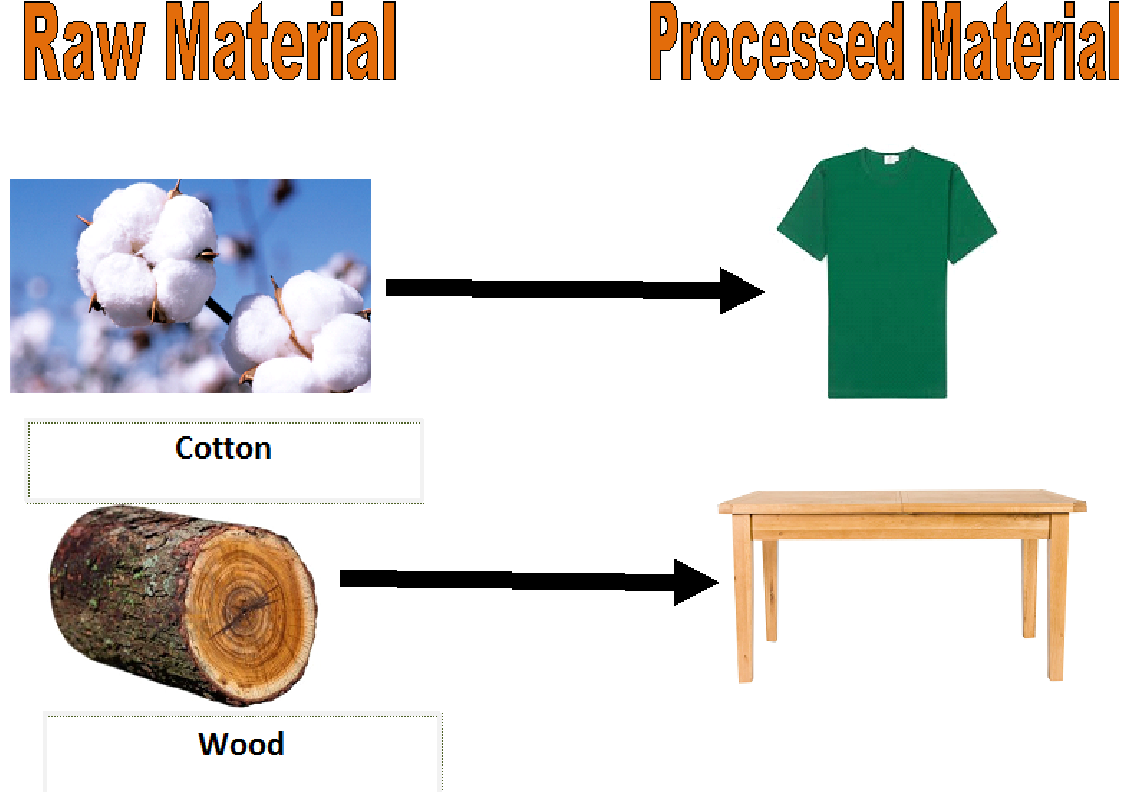

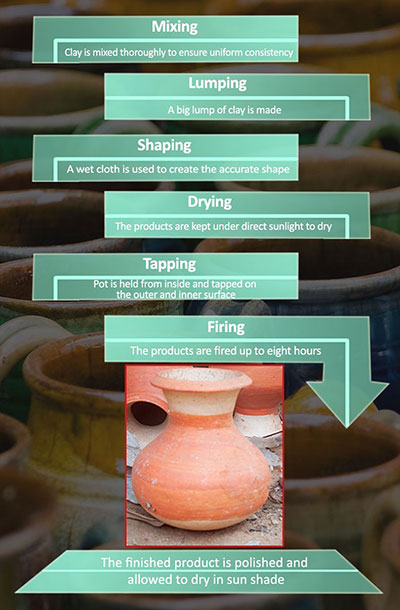

The first step in air mattress production is the selection of raw materials. Most air mattresses are made from PVC or vinyl, which are lightweight and durable materials. The materials are then cut into the desired shape and size using specialized machines. Next, the materials are joined together through a process called heat sealing, where heat is applied to bond the layers together. This creates airtight compartments within the mattress. Once the main structure of the mattress is formed, it is inflated and tested for leaks. Any defects or faults are identified and fixed at this stage. Finally, the mattress is packed and shipped to retailers for sale.2. How Air Mattresses are Made: Step-by-Step Process

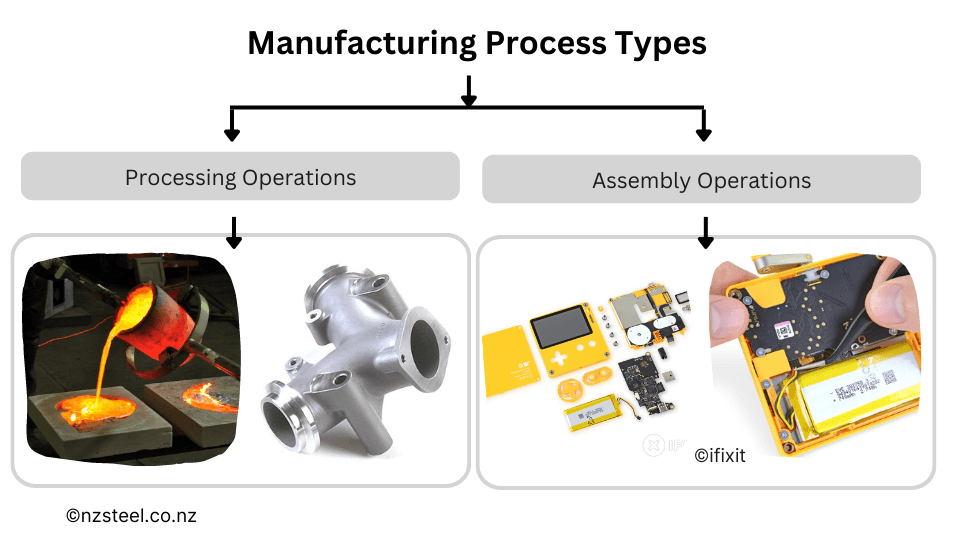

The manufacturing process of air mattresses involves a combination of manual labor and advanced machinery. Skilled workers are responsible for cutting, bonding, and testing the materials, while machines assist in the more complex tasks such as heat sealing and inflation. It is a highly precise process, as even the smallest mistake can affect the quality and durability of the final product.3. The Ins and Outs of Air Mattress Production

As mentioned earlier, the main materials used in air mattress production are PVC and vinyl. These materials are known for their elasticity, strength, and resistance to punctures. They are also lightweight, making the mattress easy to transport and set up. To enhance the comfort and support of the air mattress, foam or fabric layers may be added to the top. These layers are also cut and bonded to the main structure of the mattress. Once the mattress is fully assembled, it goes through a series of quality control tests to ensure that it meets industry standards.4. From Raw Materials to Finished Product: The Manufacturing Process of Air Mattresses

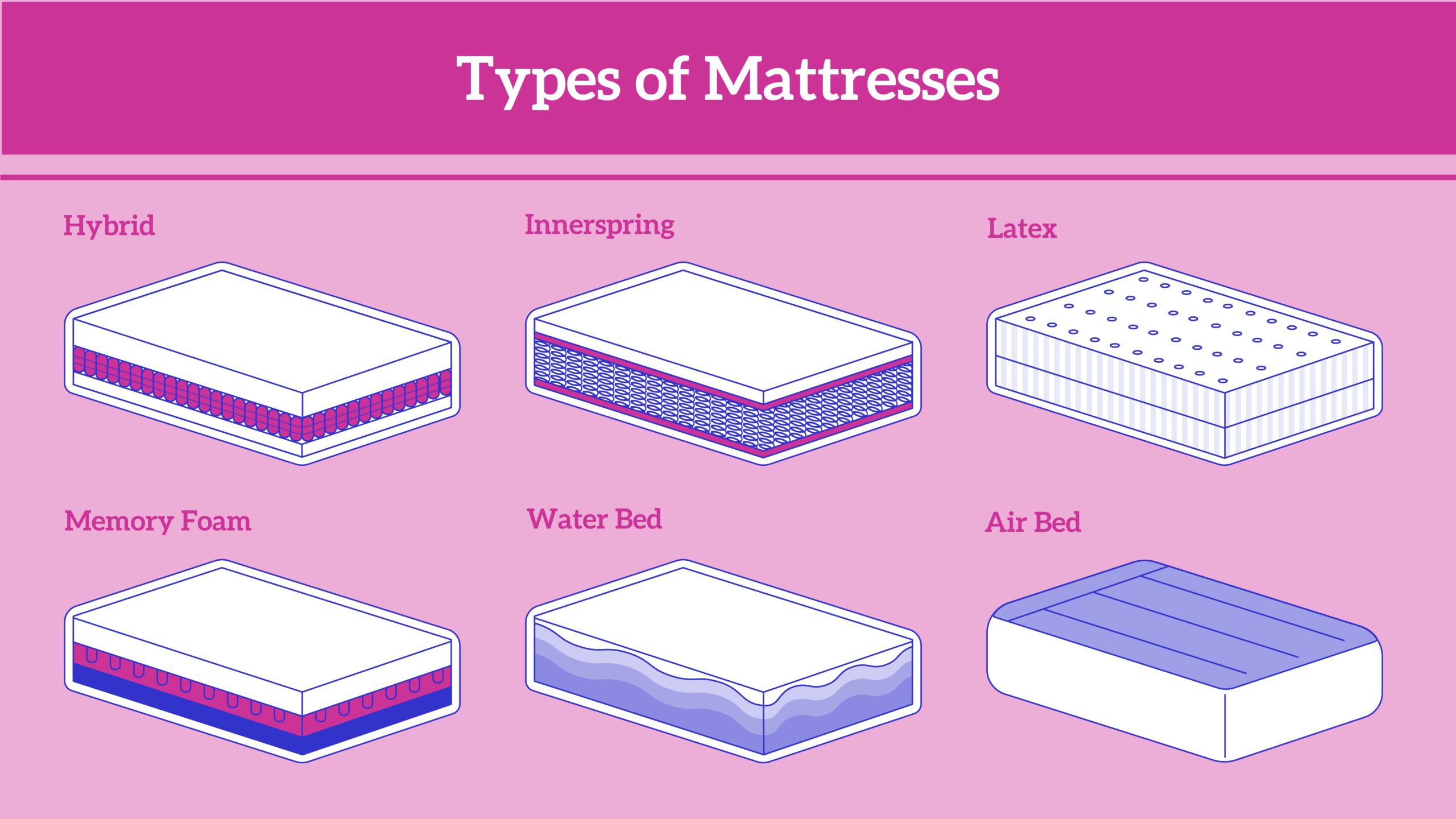

There are several types of air mattresses, each with its own unique manufacturing process. Traditional air mattresses have a single air chamber, while newer models may have multiple chambers for added support and stability. There are also hybrid air mattresses that combine the benefits of air and foam or spring mattresses. The manufacturing process for these mattresses involves more intricate steps, as different materials need to be bonded together.5. Understanding the Different Types of Air Mattresses and Their Manufacturing Processes

Technology plays a crucial role in the manufacturing of air mattresses. Advanced machines are used to cut, bond, and inflate the materials, ensuring accuracy and efficiency in the production process. Additionally, computer-aided design (CAD) software is used to design and test new models before production. This helps to identify and resolve any potential issues, resulting in a higher quality product.6. The Role of Technology in Air Mattress Manufacturing

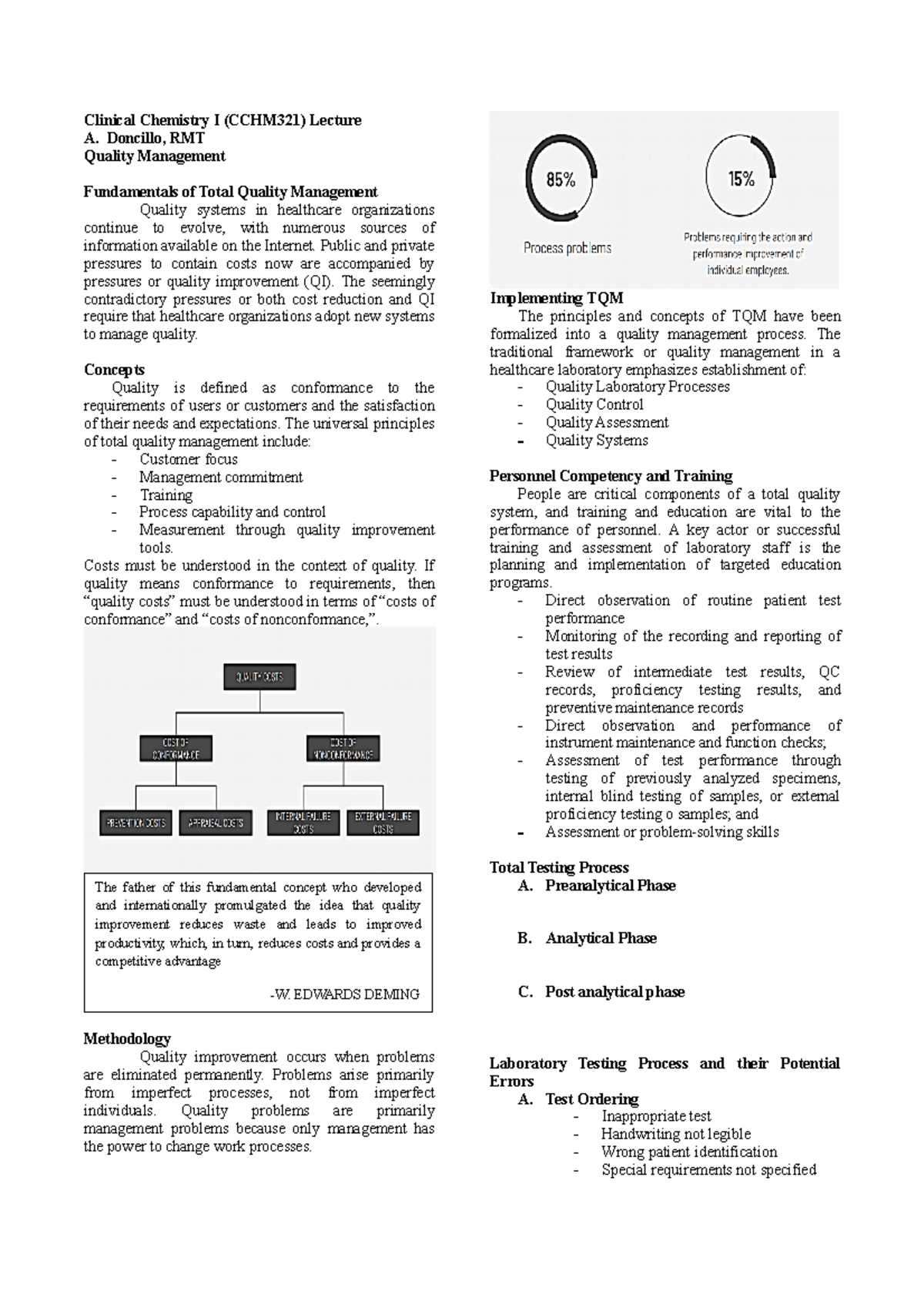

Quality control is an essential aspect of air mattress manufacturing. Each mattress goes through a series of tests to check for leaks, punctures, and other defects. This ensures that customers receive a safe and durable product that meets industry standards. Manufacturers also conduct extensive durability tests to determine the lifespan of their mattresses. This is important for customers to know, as it helps them make an informed decision when purchasing an air mattress.7. Quality Control in Air Mattress Production: Ensuring a Safe and Durable Product

The production of air mattresses can have a significant impact on the environment. The use of PVC and vinyl, as well as the energy and resources required for production, contribute to carbon emissions and waste. However, many manufacturers are now implementing sustainable practices in their production processes. This includes using eco-friendly materials and reducing energy consumption. By choosing environmentally responsible air mattress brands, consumers can help minimize the industry's environmental impact.8. The Environmental Impact of Air Mattress Manufacturing

The air mattress industry is constantly evolving, with manufacturers always looking for ways to improve their products. Some recent innovations include self-inflating mattresses, adjustable firmness levels, and built-in pumps for easier inflation. As technology continues to advance, we can expect to see even more innovative features in air mattresses in the future.9. Innovations in Air Mattress Manufacturing: What's Next?

One of the biggest challenges in air mattress production is creating a balance between comfort and durability. As consumers demand more comfortable mattresses, manufacturers need to find ways to improve the durability of their products without compromising on comfort. Another trend in the industry is the increasing popularity of eco-friendly and sustainable products. This poses a challenge for manufacturers to find ways to reduce their environmental impact while still producing high-quality mattresses.10. The Future of Air Mattress Manufacturing: Trends and Challenges

The Importance of Quality Materials in Air Mattress Manufacturing

Ensuring Comfort and Durability for a Better Night's Sleep

When it comes to manufacturing air mattresses, one of the most crucial aspects is the quality of materials used. A high-quality air mattress not only provides comfort and support, but it also ensures durability for long-term use. This is why top manufacturers prioritize the selection of materials and have a strict quality control process in place.

Memory foam

is one of the most commonly used materials in air mattress manufacturing. This type of foam molds to the body's shape, providing personalized support and pressure relief. It also has the added benefit of being hypoallergenic, making it suitable for those with allergies or respiratory issues.

Another important material used in air mattresses is

vinyl

. This material is known for its durability and water-resistant properties, making it ideal for the top and bottom layers of the mattress. It also helps to prevent air leakage, ensuring a longer lifespan for the mattress.

Aside from the main materials,

coils and air chambers

are also crucial components in air mattress manufacturing. These provide the necessary support and structure to the mattress, allowing for proper weight distribution and preventing sagging over time.

In addition to these materials, top manufacturers also use

flocked or plush covers

to provide an extra layer of comfort for the user. These covers are soft to the touch and help to regulate temperature, ensuring a comfortable sleeping experience.

Overall, the use of high-quality materials is essential in creating a top-notch air mattress. Not only do they provide comfort and support, but they also contribute to the overall durability and lifespan of the product. So the next time you're in the market for an air mattress, be sure to pay attention to the materials used to ensure a good night's sleep for years to come.

When it comes to manufacturing air mattresses, one of the most crucial aspects is the quality of materials used. A high-quality air mattress not only provides comfort and support, but it also ensures durability for long-term use. This is why top manufacturers prioritize the selection of materials and have a strict quality control process in place.

Memory foam

is one of the most commonly used materials in air mattress manufacturing. This type of foam molds to the body's shape, providing personalized support and pressure relief. It also has the added benefit of being hypoallergenic, making it suitable for those with allergies or respiratory issues.

Another important material used in air mattresses is

vinyl

. This material is known for its durability and water-resistant properties, making it ideal for the top and bottom layers of the mattress. It also helps to prevent air leakage, ensuring a longer lifespan for the mattress.

Aside from the main materials,

coils and air chambers

are also crucial components in air mattress manufacturing. These provide the necessary support and structure to the mattress, allowing for proper weight distribution and preventing sagging over time.

In addition to these materials, top manufacturers also use

flocked or plush covers

to provide an extra layer of comfort for the user. These covers are soft to the touch and help to regulate temperature, ensuring a comfortable sleeping experience.

Overall, the use of high-quality materials is essential in creating a top-notch air mattress. Not only do they provide comfort and support, but they also contribute to the overall durability and lifespan of the product. So the next time you're in the market for an air mattress, be sure to pay attention to the materials used to ensure a good night's sleep for years to come.

:max_bytes(150000):strip_icc()/best-air-mattresses-of-2022-tout-88d25ab3b4af45f8a49255f9814d8cec.jpg)