Interior doors are an essential element in any home or building, providing both functionality and style. To create the perfect interior door, specialized machines are used to ensure precision and quality. In this article, we will explore the top 10 interior doors machines that are revolutionizing the industry.Introduction

The CNC router is a computer-controlled cutting machine that uses a spinning tool to cut, shape, and carve materials such as wood, metal, and plastic. It is widely used in the production of interior doors as it allows for intricate designs and precise cuts, resulting in high-quality and customizable doors.The CNC Router

The edge banding machine is used to apply a thin layer of material, usually wood or plastic, to the edges of interior doors. This process not only gives the door a finished look but also protects the core material from moisture and wear. The edge banding machine ensures a seamless and durable finish, making it an essential tool in the production of interior doors.The Edge Banding Machine

Drilling machines are used to create holes and cutouts in interior doors for handles, locks, and other hardware. With the use of specialized bits and precision controls, the drilling machine ensures accurate and consistent holes, resulting in a perfect fit for the door hardware.The Drilling Machine

The sanding machine is used to smooth out the surface of interior doors, removing any imperfections or rough edges. It uses sandpaper or abrasive pads to achieve a uniform and smooth finish, resulting in a professional and polished look for the door.The Sanding Machine

Laminating machines are used in the production of interior doors to create a decorative or protective layer on the surface. This layer can be made of various materials such as wood veneer, PVC, or metal, and adds both aesthetic appeal and durability to the door.The Laminating Machine

The veneer press is used to bond thin layers of wood veneer to the surface of interior doors. This process not only enhances the appearance of the door but also adds strength and stability. The veneer press ensures a strong and long-lasting bond between the veneer and the door, resulting in a high-quality finished product.The Veneer Press

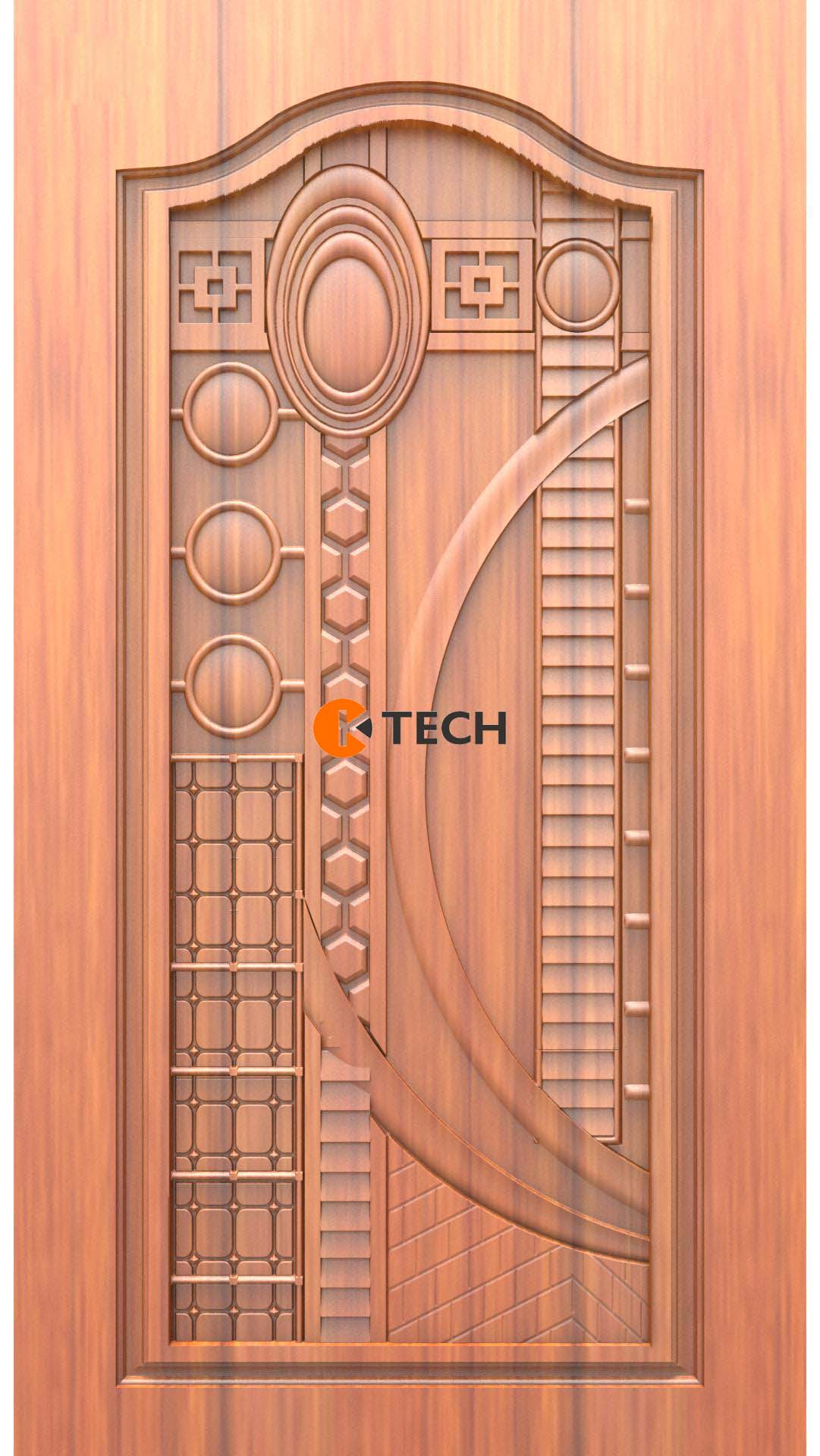

The embossing machine is used to create raised or indented designs on the surface of interior doors. It can add texture and depth to the door, making it a focal point in any room. The embossing machine allows for endless design possibilities, making it a popular choice for interior door manufacturers.The Embossing Machine

Molding machines are used to create decorative moldings and trims that are often seen on interior doors. These machines come in various sizes and can produce intricate designs, adding a touch of elegance and sophistication to the door.The Molding Machine

The panel saw is a specialized machine used to cut large panels of wood or other materials into smaller, more manageable pieces. It is a crucial tool in the production of interior doors, as it allows for accurate and efficient cutting of panels to the required size.The Panel Saw

The Benefits of Using Interior Doors Machines for Your House Design

When it comes to designing your home, every detail matters. From the color of the walls to the furniture, every aspect of your house should reflect your personal style and taste. One important element that is often overlooked is the interior doors . These are not just functional pieces that provide privacy and separation between rooms, they also play a significant role in the overall aesthetic of your home.

If you are looking to elevate the design of your home, consider using interior doors machines to create custom doors that will add a unique and stylish touch to your space. These machines use state-of-the-art technology to create high-quality doors that are not only visually appealing but also durable and long-lasting.

Efficiency and Precision

One of the main benefits of using interior doors machines is the efficiency and precision they offer. These machines are designed to produce doors with consistent sizing and accurate cuts, ensuring a perfect fit every time. This eliminates the need for manual labor and reduces the margin of error, resulting in a smooth and streamlined production process.

Additionally, interior doors machines are equipped with advanced features that allow for intricate designs and details to be incorporated into the doors. This level of precision and customization cannot be achieved through traditional methods, making these machines a game-changer in the world of door design.

Unlimited Design Options

Another advantage of using interior doors machines is the endless design possibilities they offer. With traditional methods, you are limited to a few standard door designs and sizes. However, with these machines, you have the freedom to create doors in any shape, size, and style you desire.

Whether you want a sleek and modern door or a more intricate and traditional design, interior doors machines can bring your vision to life. You can also choose from a wide range of materials, including wood, glass, and metal, to create a truly unique and personalized door for your home.

Cost-Effective Solution

Investing in interior doors machines may seem like a significant expense, but in the long run, it can actually save you money. With the ability to produce custom doors, you can avoid the high costs of ordering from specialized door manufacturers.

Moreover, the precision and efficiency of these machines result in minimal waste and fewer errors, reducing production costs. This allows you to produce high-quality doors at a lower cost, making it a cost-effective solution for your house design needs.

In conclusion, interior doors machines offer numerous benefits for your house design. From efficiency and precision to unlimited design options and cost-effectiveness, these machines are a valuable addition to any home design project. So why settle for standard doors when you can have custom, high-quality doors that truly reflect your personal style and elevate the look of your home?