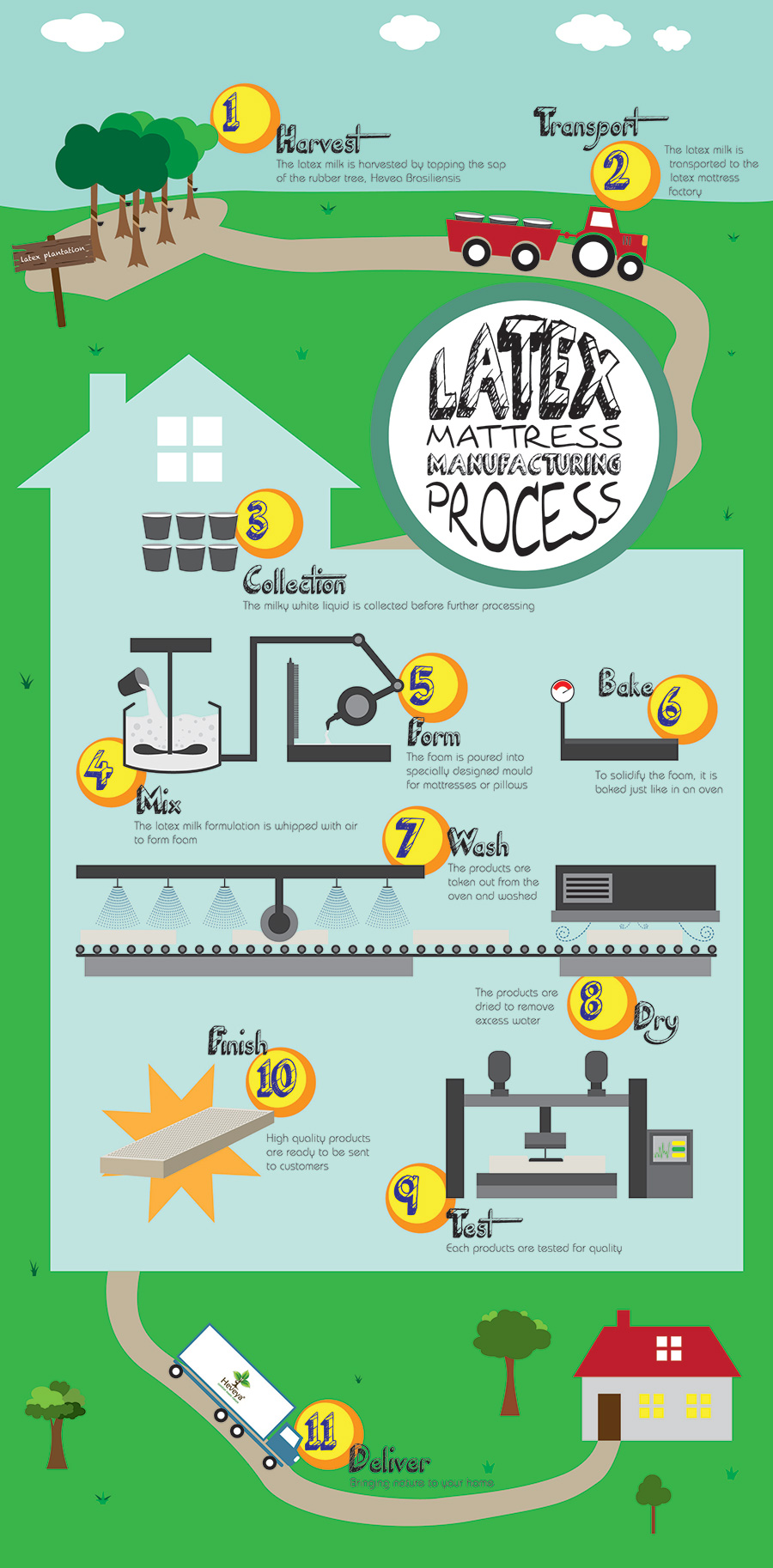

When it comes to creating a comfortable and supportive foam mattress, there are several steps involved in the production process. From selecting the right materials to ensuring quality control, each stage is crucial in creating a top-notch product that will enhance your sleep experience. Let's take a closer look at the top 10 MAIN_foam mattress production process.Foam Mattress Production Process

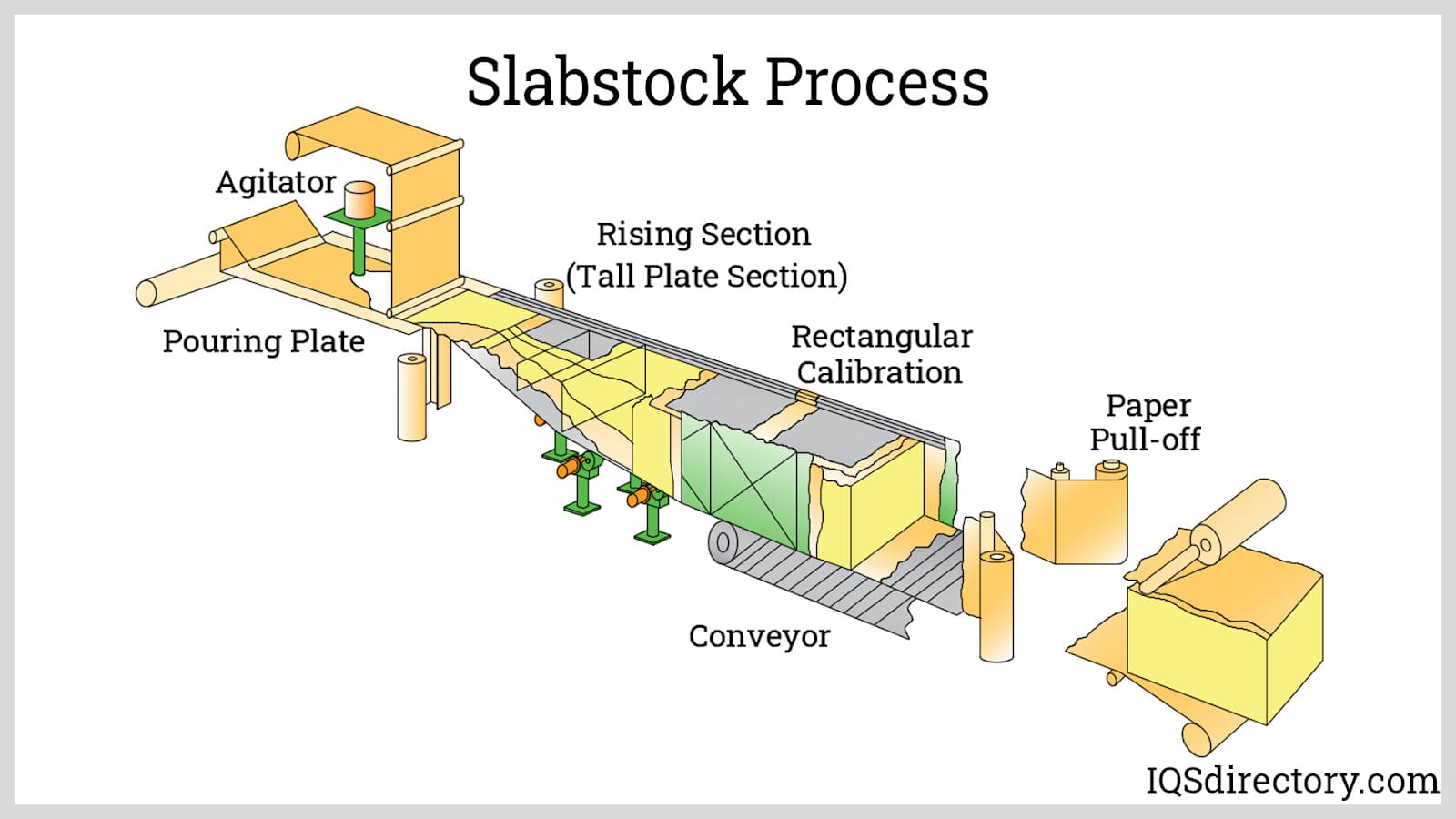

The first step in creating a foam mattress is the manufacturing process. This involves selecting the right foam materials and using specialized machinery to cut and shape them into the desired size and shape. The quality and type of foam used can greatly impact the overall comfort and support of the mattress, so this step is crucial in creating a high-quality product.Foam Mattress Manufacturing

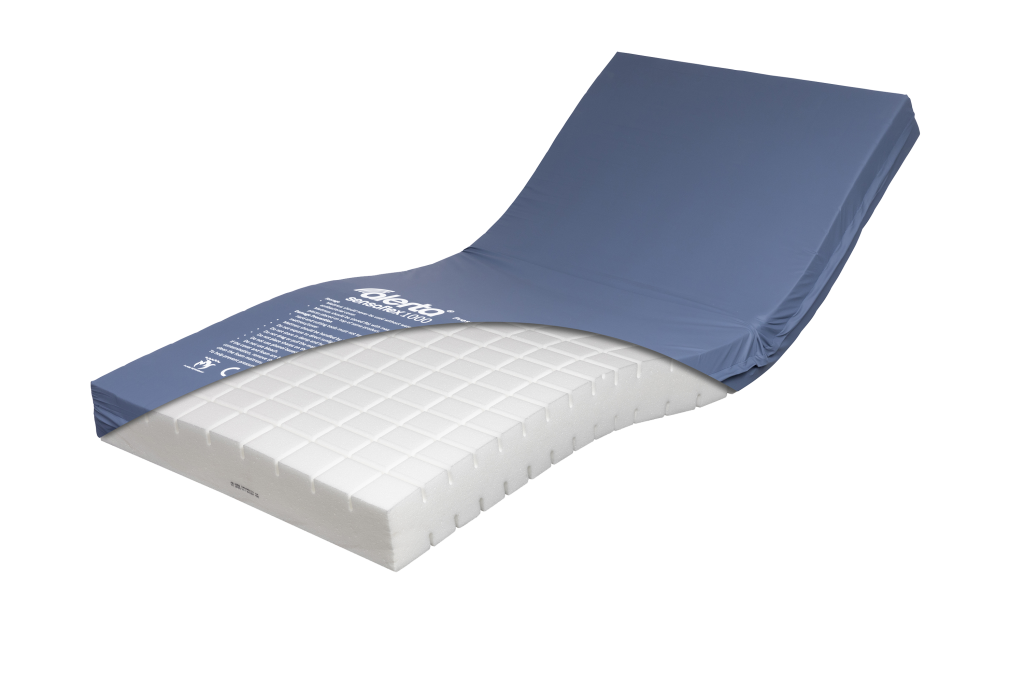

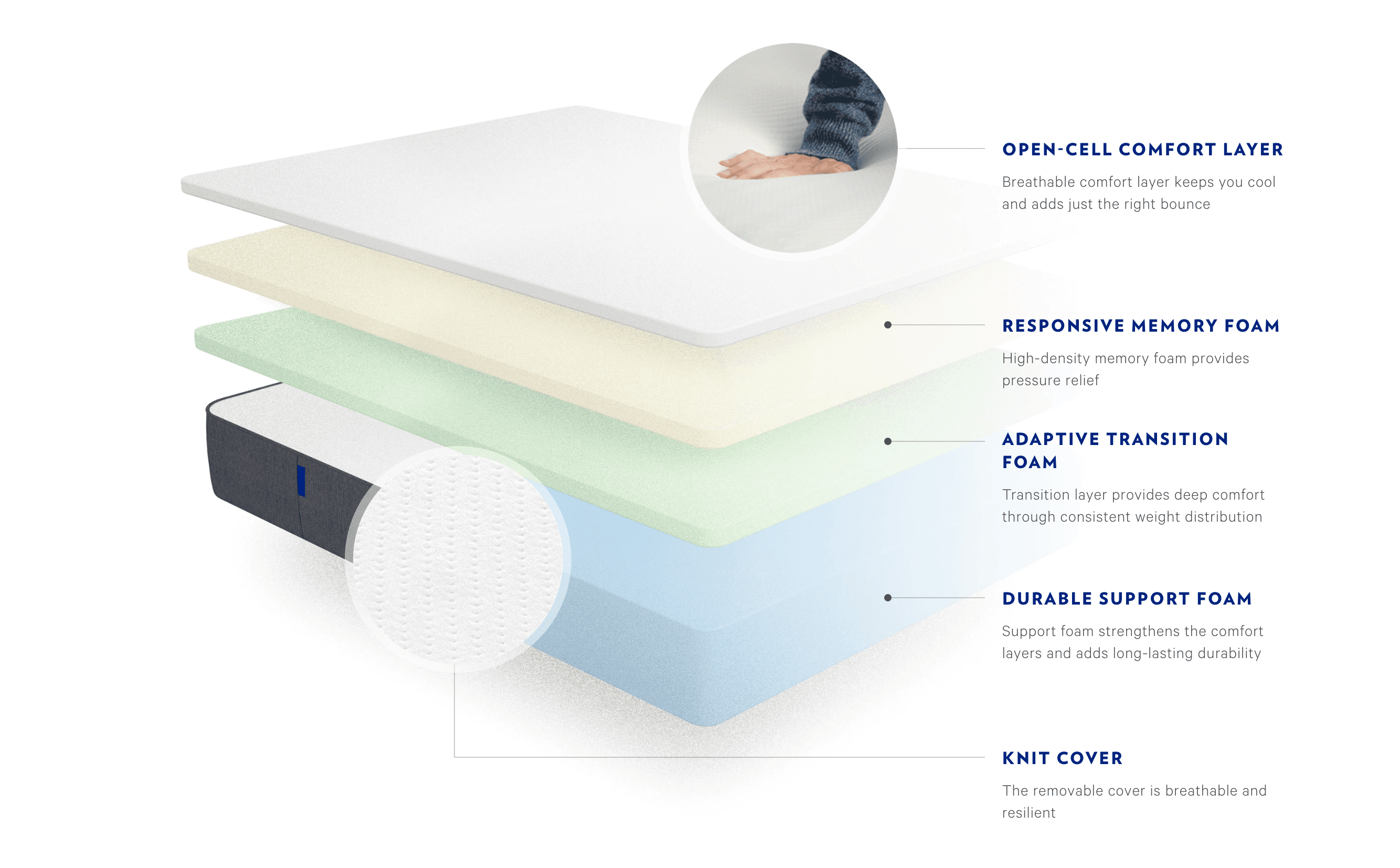

Once the foam materials have been manufactured, the next step is to assemble them into a mattress. This involves layering different types of foam, such as memory foam and support foam, to create the desired level of comfort and support. The layers are then glued together to ensure they stay in place and provide a stable base for the mattress.Foam Mattress Assembly

Before the foam materials can be assembled, they need to be cut to the correct size and shape. This is done using specialized machinery that ensures precise and accurate cutting for a perfect fit. The cutting process is crucial in creating a comfortable and supportive mattress that fits standard bed sizes.Foam Mattress Cutting

As mentioned earlier, the foam layers are glued together during the assembly process. This step is essential in creating a cohesive and stable mattress that will provide consistent support and comfort. The type of glue used is also important, as it should be strong enough to hold the layers together but also safe for use in a bedding product.Foam Mattress Gluing

Once the mattress is assembled and the layers are glued together, it is time for packaging. This involves wrapping the mattress in a protective cover to ensure it stays clean and dust-free during transportation and storage. The packaging also includes labeling and instructions for the consumer, making it easy to set up the mattress once it arrives.Foam Mattress Packaging

Quality control is an essential step in the foam mattress production process. This involves thorough testing of the materials and finished product to ensure it meets high standards of comfort, support, and durability. Any flaws or defects are identified and corrected to ensure the final product is of the highest quality.Foam Mattress Quality Control

The materials used in a foam mattress can greatly impact its overall quality. The most common materials include memory foam, latex foam, and support foam, each with their own unique properties and benefits. The right combination of materials can create a mattress that offers both comfort and support for a restful night's sleep.Foam Mattress Materials

The design of a foam mattress is another crucial aspect of the production process. This includes not only the shape and size of the mattress but also the placement and combination of different foam layers. A well-designed mattress will provide the right balance of comfort and support, resulting in a better sleep experience for the consumer.Foam Mattress Design

Before a foam mattress is released to the market, it undergoes rigorous testing to ensure it meets industry standards for comfort, support, and durability. This involves simulated use and stress testing to ensure the mattress can withstand regular use without losing its shape or support. Only after passing these tests will a foam mattress be deemed ready for sale.Foam Mattress Testing

The Benefits of Using Foam Mattresses in House Design

Enhanced Comfort and Support

Foam mattresses have gained popularity in recent years due to the enhanced comfort and support they provide. Unlike traditional spring mattresses, foam mattresses are made with a layer of memory foam, which conforms to the shape of your body. This allows for even weight distribution, reducing pressure points and promoting better sleep. The foam also provides support for your spine, keeping it properly aligned throughout the night. This results in a more comfortable and restful sleep, making it an ideal choice for house design.

Foam mattresses have gained popularity in recent years due to the enhanced comfort and support they provide. Unlike traditional spring mattresses, foam mattresses are made with a layer of memory foam, which conforms to the shape of your body. This allows for even weight distribution, reducing pressure points and promoting better sleep. The foam also provides support for your spine, keeping it properly aligned throughout the night. This results in a more comfortable and restful sleep, making it an ideal choice for house design.

Durable and Long-Lasting

One of the main advantages of using a foam mattress in house design is its durability. Foam mattresses are made with high-quality materials that are designed to last for many years. They are resistant to wear and tear, making them a great investment for your home. Unlike traditional mattresses, foam mattresses do not sag or lose their shape over time, ensuring that you get a comfortable and supportive sleep for years to come.

One of the main advantages of using a foam mattress in house design is its durability. Foam mattresses are made with high-quality materials that are designed to last for many years. They are resistant to wear and tear, making them a great investment for your home. Unlike traditional mattresses, foam mattresses do not sag or lose their shape over time, ensuring that you get a comfortable and supportive sleep for years to come.

Hypoallergenic Properties

Another benefit of foam mattresses is their hypoallergenic properties. Traditional mattresses can be a breeding ground for dust mites, which can trigger allergies and asthma. Foam mattresses, on the other hand, are made with materials that are resistant to dust mites and other allergens. This makes them a great choice for those who suffer from allergies or have respiratory issues. Furthermore, foam mattresses are also resistant to mold and mildew, making them a healthier and safer option for house design.

Another benefit of foam mattresses is their hypoallergenic properties. Traditional mattresses can be a breeding ground for dust mites, which can trigger allergies and asthma. Foam mattresses, on the other hand, are made with materials that are resistant to dust mites and other allergens. This makes them a great choice for those who suffer from allergies or have respiratory issues. Furthermore, foam mattresses are also resistant to mold and mildew, making them a healthier and safer option for house design.

Customizable Options

Foam mattresses come in a variety of options, allowing you to choose the best one for your specific needs. There are different types of foam, such as memory foam, latex foam, and polyurethane foam, each with its own unique properties. Additionally, foam mattresses come in different levels of firmness, from soft to extra firm, allowing you to find the perfect fit for your comfort preferences. This customizability makes foam mattresses a versatile choice for any house design.

Foam mattresses come in a variety of options, allowing you to choose the best one for your specific needs. There are different types of foam, such as memory foam, latex foam, and polyurethane foam, each with its own unique properties. Additionally, foam mattresses come in different levels of firmness, from soft to extra firm, allowing you to find the perfect fit for your comfort preferences. This customizability makes foam mattresses a versatile choice for any house design.

Conclusion

In conclusion, foam mattresses are a great addition to any house design due to their enhanced comfort, durability, hypoallergenic properties, and customizable options. They provide a comfortable and supportive sleep, ensuring that you wake up feeling well-rested and ready to take on the day. With their numerous benefits, it's no wonder that foam mattresses have become a popular choice for house design. Consider incorporating a foam mattress into your home to experience the many advantages it has to offer.

In conclusion, foam mattresses are a great addition to any house design due to their enhanced comfort, durability, hypoallergenic properties, and customizable options. They provide a comfortable and supportive sleep, ensuring that you wake up feeling well-rested and ready to take on the day. With their numerous benefits, it's no wonder that foam mattresses have become a popular choice for house design. Consider incorporating a foam mattress into your home to experience the many advantages it has to offer.